STABILUS ACE TUBUS TR-L Service manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

Table of contents Page

General instructions................................. 2

Safety information ................................... 2

Intended use........................................... 2

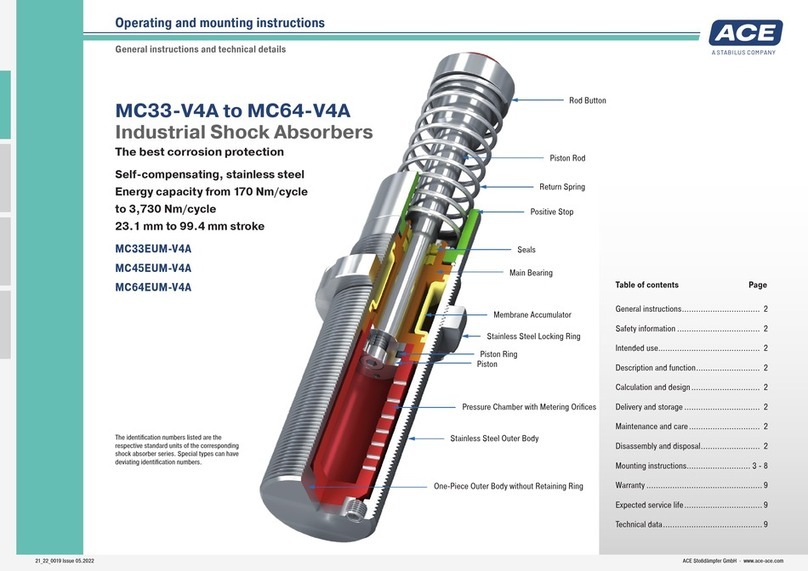

Description and function........................... 2

Calculation and design ............................. 2

Delivery and storage ................................ 2

Maintenance and care.............................. 2

Disassembly and disposal......................... 2

Mounting instructions................................ 3

Warranty ................................................. 4

Expected service life ................................. 4

Technical data.......................................... 4

TR-L

TUBUS TR-L

Profile Dampers

Powerhouse in long body length

Radial damping, long version

Energy capacity 7.2 Nm/cycle to 10,780 Nm/cycle

Maximum stroke 17 mm to 108 mm

The identification numbers listed are the

respective standard units of the corresponding

damper series. Special types can have deviating

identification numbers.

General instructions and technical details

Operating and mounting instructions

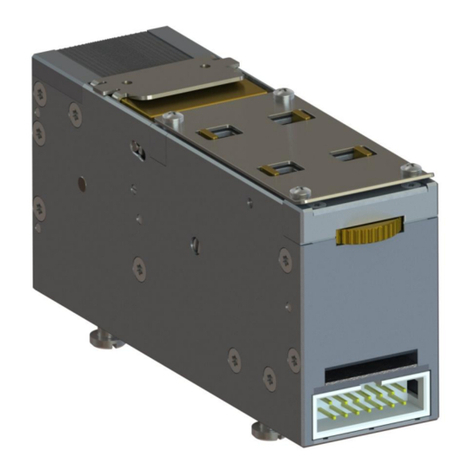

Profile Body

Mounting Screw

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

2

General instructions

This manual is for the disruption-free use of the product

types listed on page 1; its compliance is a prerequisite

for the fulfilment of any warranty claims.

Therefore, make sure to read this manual before use.

Please always maintain the specified limits from the per-

formance table (technical data). Take into account the

predominant environmental conditions and restrictions.

Note the regulations of the trade association, TÜV or

corresponding national, international and European reg-

ulations. Installation and commissioning only according

to mounting instructions.

Intended use

ACE profile dampers are an alternative product to the hydraulic

end position damper. They are used wherever moving masses

do not have to be accurately stopped and the energy does not

have to be completely absorbed. The reversible profile dampers

are intended for emergency stop and continuous uses. The

TUBUS profile dampers of the TR-L range are designed for force

absorption in an radial direction.

WARNING

If TUBUS profile dampers are used where a failure of the

product could lead to personal injuries and/or material

damage, additional safety elements must be implemented.

Free-moving masses can lead to injuries by crushing

during installation of the profile damper. Secure moving

masses against inadvertent starting with suitable safety

precautions before installing the profile damper.

Safety information

Description and function

The TR-L profile dampers of the ACE TUBUS series are

maintenance-free, ready-to-install damping elements made

from a co-polyester elastomer. The radial loading enables very

long and soft braking with a progressive energy absorption at

the end of stroke. The tube dampers were developed especially

for applications with low end forces. The energy absorption is

between 26 % and 41 %.

A structural change in the production process of these damping

elements creates a defined preloading, whereby the TUBUS

converts the occurring force into heat through friction.

One part of the occurring energy is therefore absorbed, whilst the

other part is released again by the return of the body to its original

position.

Calculation and design

In order to ensure an optimum, fault-free and durable function of

the TUBUS Profile Dampers they must be correctly dimensioned

and designed. The following parameters must be known and used

in the calculation:

- Moving mass [kg]

- Impact velocity of the mass into the profile damper(s) [m/s]

- Additionally acting propelling force, propelling power or propel-

ling torque [N, kW, Nm]

- Number of profile dampers acting in parallel [n]

- Number of strokes or cycles per hour [1/h]

The dampers must be dimensioned in such a way that the

maximum energy capacity per stroke is not exceeded during

continuous duty or for emergency stop applications. The specified

performance data and dimensions for the profile damper type

used can be found in the performance table. The correct size

of the profile dampers for emergency stop applications can be

determined with the ACE online calculation programme at www.

ace-ace.com. The calculations are based on dynamic loads.

Where necessary we will also happily send you the respective

dynamic and static characteristic curves. You can also send us

the completed online form by email for checking.

Or make use of our free calculation service by phoning: +49

(0)2173 9226 20

Delivery and storage

The profile damper can become damaged when opening the

packaging. Do not use cutting tools if possible.

- After delivery please check the profile dampers for any damage.

- Profile dampers can generally be stored in any position.

Maintenance and care

Profile dampers are made from one part and therefore do not need

any special maintenance. Profile dampers that are not regularly

operated (e.g. emergency stop devices) are checked at least

once per year as part of the normal safety check of the plant. The

surface is to be checked for cracks and deformations and the

mounting elements checked that they are properly secured. For

profile dampers that are regularly operated, these checks should

take place at intervals of no more than three months.

What should be noted after a damper impact?

Profile dampers that are not regularly operated are to be checked

after a damper impact.

Disassembly and disposal

The profile damper is 100 % recyclable and can be discarded in

household waste.

Profile Dampers TR-L (radial damping, long version)

Manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

3

Installation instructions

Before installation and use check whether the identification

number on the damper or on the packaging matches the

respective designation on the delivery note. Profile dampers are

maintenance-free and ready to install.

Operating temperature range: -40 °C to +90 °C

Temperature effect: The W3values given in the performance

table are valid for room temperature in the environment. At higher

temperatures the energy capacity per stroke is reduced.

Mounting: in any position, however, always in such a way that

the impact surface of the profile damper is evenly loaded. A side

load angle between profile damper and occurring mass is to be

avoided as transverse forces can lead to tearing off or permanent

deformation of the damper.

The outer diameter of the damper increases upon impact. Note

the max. compressed diameter (d1) listed in the table. The moving

mass should have at least the same diameter so that the entire

impact surface is loaded.

Mounting information: To mount the damper we recommend

the use of original ACE mounting screws. The listed maximum

torque is to be observed. Please also check the thread length (LM)

along with all further dimensions listed in the table.

Permissible torque of mounting screw:

M5: 3 Nm

M8: 20 Nm

M16: 40 Nm (DIN912)

M16: 120 Nm (collar bolt)

Note: For seawater applications please use stainless steel bolts

– these are not included.

Packaging disposal

Please dispose of the transportation packaging in an environ-

mentally-friendly manner. Recycling packaging materials saves

raw materials and reduces waste. The packaging materials do not

contain any prohibited materials.

WARNING

A failure of the product can lead to personal injuries and/or

material damage. Use additional safety elements.

During installation/disassembly of the profile dampers,

moving masses can lead to injuries due to inadvertent

starting. Secure moving masses against inadvertent

moving.

The profile dampers may be unsuitable for use and

have an insufficient damping effect. Before installation

check the correct size of the dampers using the field

data, performance table (page 4) and calculations. The

energy capacity per stroke during continuous duty and for

emergency stop applications may not be exceeded (see

performance table).

The profile damper can tear off upon impact. Always lay out

the connection structure in such a way that the maximum

occurring forces can be absorbed with sufficient safety.

The maximum reacting forces Q listed in the calculations

may deviate from the actually occurring reacting forces, as

these are based on theoretical values.

The profile dampers may be unsuitable for use as a

rebound effect can occur. Note that the moving mass is

not accurately braked and the energy is not completely

absorbed. A limited application range is therefore to be

observed for the following drive types: toothed belt drive,

threaded spindle drive, drive with gears. The maximum

return forces listed in the calculations may deviate from

the actually occurring return forces, as these are based on

theoretical values.

Exceeding or falling below the maximum or minimum

temperature can lead to the destruction of the damper

material and the profile damper could lose its function.

Maintain the operating temperature range of -40 °C to

+90 °C.

Fluids or aggressive media in the surrounding area can

attack or destroy the material of the profile damper and

cause it to fail. Insulate the "external materials" in the area

around the profile damper. Note the chemical resistance

list.

Impact velocity that is too high can lead to damage to

the profile damper and failure. Note the maximum impact

velocity of 5 m/s.

The profile dampers for emergency stop may be unsuitable

for continued use after one impact. Profile dampers

that are not regularly operated (e.g. for emergency stop

devices) are to be checked after a damper impact.

Damage to the surface by other external influences

can lead to an insufficient damping and to a premature

failure of the profile damper. We recommend regularly

checking the surface for cracks and deformations as well

as checking the mounting elements are properly secured.

Check emergency stop devices at least once per year and,

in the case of continuous duty, at intervals of a maximum

of three months.

Please mount the dampers in such a way that there is

sufficient room for the max. compressed external diameter.

The moving mass should have at least the same diameter

so that it does not buckle or crack.

(middle hole only TR-L-5/6/7)

E

B

C

LM

Max.

Stroke

M

D

A

TR-L

(middle hole only TR-L-5/6/7)

E

B

C

LM

Max.

Stroke

M

D

A

Mounting instructions and mounting accessories

Profile Dampers TR-L (radial damping, long version)

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

4

Warranty

Fundamentally, all modifications to the product by third parties

lead to exclusion from the warranty.

Obvious defects must be reported to the vendor in writing immedi-

ately after delivery, no later than one week, but in any case before

processing or installation, otherwise the assertion of a warranty

claim is excluded. A timely dispatch is sufficient to keep the term.

The vendor is to be given an opportunity to check on site. If the

complaint is justified the vendor offers warranty by repair or re-

placement at its own discretion. If the rectification fails, the buyer

may choose to demand reduction of payment or cancellation of

the contract. If there is only a minor lack of conformity, particularly

with only minor defects, the buyer nevertheless has a right of

withdrawal.

If, after failed rectification, the buyer chooses to cancel the

contract due to a defect of title or material defect, they are not

entitled to additionally claim for damages.

If, after failed fulfilment, the buyer chooses compensation, the

goods remain with the buyer, if this is reasonable. The compen-

sation is limited to the difference between the purchase price and

the value of the defective item. This does not apply if the vendor

maliciously causes the breach of contract.

The quality of the goods is only considered as agreed upon with

the product description of the vendor. Public statements, claims

or advertising of the manufacturer do not represent an additional

contractual specification of quality of the goods.

If the buyer receives defective mounting instructions, the buyer

is only obligated to deliver defect-free mounting instructions and

only if the defect to the mounting instructions prevents proper

mounting.

The warranty period is two years and begins upon completion.

Exchange and return of custom products are fundamentally

excluded. The factory conditions of the manufacturing factory

apply to parts not manufactured and processed by the vendor,

which can be viewed by the orderer at the vendor at any time.

Construction and installation parts are delivered according to the

present standard of engineering.

Service life

In general TUBUS profile dampers are machine elements that

are subject to wear. The wear is largely dependent upon the

respective application and its operating parameters.

When used under optimum conditions and maintaining the

parameters specified in the performance table, a service life of up

to 1 million load changes is to be expected.

Technical data

Energy capacity: 7.2 Nm/cycle to 10,780 Nm/cycle

Energy absorption: 26 % to 41 %

Dynamic force range: 1,312 N to 217,700 N

Operating temperature range: -40 °C to +90 °C

Construction size: 29 mm to 188 mm

Mounting: in any position

Material hardness rating: Shore 55D

Material: Profile body: Co-polyester elastomer

Mounting screws:

Special socket head screws with internal hex socket, zinc-plated

44Smn28 material (SAE 1144 machining steel):

M5x8, M5x11, M8x20

Socket head screw with internal hex socket, zinc-plated steel

according to ISO 4762 - 8.8:

M16x60 (with washer according to DIN 7349, zinc-plated steel)

For seawater applications please use stainless steel bolts – these

are not included.

Environment: Resistant to microbes, seawater or chemical

attack. Excellent UV and ozone resistance. Material does not

absorb water or swell.

Impact velocity range: Max. 5 m/s

Torque max.:

M5: 3 Nm

M8: 20 Nm

M16: 40 Nm (DIN912)

M16: 120 Nm (collar bolt)

Application field: Offshore industry, Agricultural machinery,

Impact panels, Conveyor systems, Stacking units, Shipbuilding,

Shovels or articulated joints for construction machinery, Transport

roads, Loading and lifting equipment

Note: Suitable for emergency stop applications and for

continuous use. For applications with preloading and increased

temperatures please consult ACE.

Safety instructions: Mounting screw should additionally be

secured with Loctite.

On request: Special strokes, -characteristics, -spring rates,

-sizes and -materials.

Performance data and dimensions

TYPES

1W3

Nm/cycle

Emergency

stop

W3

Nm/cycle

Stroke max.

mm

A

mm

B

mm

C

mm

D

mm

E

mm

LM

mm

M Weight

kg

TR29-17L 7.2 10.9 17 25 80 29 38 40 5 M5 0.044

TR43-25L 14.0 32.7 25 37 80 43 58 40 5 M5 0.072

TR63-43L 21.9 32.0 43 55 80 63 87 40 5 M5 0.106

TR66-40L-1 102.0 143.0 40 59 152 66 87 102 8 M8 0.284

TR66-40L-2 204.0 286.0 40 59 305 66 87 254 8 M8 0.580

TR66-40L-3 306.0 428.0 40 59 457 66 87 406 8 M8 0.830

TR66-40L-4 408.0 571.0 40 59 610 66 87 559 8 M8 1.130

TR66-40L-5 510.0 714.0 40 59 762 66 87 711 8 M8 1.330

TR76-45L-1 145.0 203.0 45 68 152 76 100 102 8 M8 0.380

TR76-45L-2 290.0 406.0 45 68 305 76 100 254 8 M8 0.696

TR76-45L-3 435.0 609.0 45 68 457 76 100 406 8 M8 1.130

TR76-45L-4 580.0 812.0 45 68 610 76 100 559 8 M8 1.430

TR76-45L-5 725.0 1,015.0 45 68 762 76 100 711 8 M8 1.780

TR83-48L-1 180.0 252.0 48 73 152 83 106 102 8 M8 0.480

TR83-48L-2 360.0 504.0 48 73 305 83 106 254 8 M8 0.930

TR83-48L-3 540.0 756.0 48 73 457 83 106 406 8 M8 1.380

TR83-48L-4 720.0 1,008.0 48 73 610 83 106 559 8 M8 1.810

TR83-48L-5 900.0 1,260.0 48 73 762 83 106 711 8 M8 2.260

TR99-60L-1 270.0 378.0 60 88 152 99 130 102 8 M8 0.790

TR99-60L-2 540.0 756.0 60 88 305 99 130 254 8 M8 1.290

TR99-60L-3 810.0 1,134.0 60 88 457 99 130 406 8 M8 1.940

TR99-60L-4 1,080.0 1,512.0 60 88 610 99 130 559 8 M8 2.660

TR99-60L-5 1,350.0 1,890.0 60 88 762 99 130 711 8 M8 3.100

TR99-60L-6 1,620.0 2,268.0 60 88 914 99 130 864 8 M8 3.700

TR99-60L-7 1,890.0 2,646.0 60 88 1,067 99 13 0 1,016 8 M8 4.300

TR143-86L-1 600.0 840.0 86 127 152 143 191 76 22 M16 1.440

TR143-86L-2 1,200.0 1,680.0 86 127 305 143 191 203 22 M16 2.900

TR143-86L-3 1,800.0 2,520.0 86 127 457 143 191 355 22 M16 3.880

TR143-86L-4 2,400.0 3,360.0 86 127 610 143 191 508 22 M16 5.420

TR143-86L-5 3,000.0 4,200.0 86 127 762 143 191 660 22 M16 6.590

TR143-86L-6 3,600.0 5,040.0 86 127 914 143 191 812 22 M16 7.890

TR143-86L-7 4,200.0 5,880.0 86 127 1,067 143 191 965 22 M16 9.190

TR188-108L-1 1,100.0 1,540.0 108 165 152 188 245 76 26 M16 2.340

TR188-108L-2 2,200.0 3,080.0 108 165 305 188 245 203 26 M16 4.640

TR188-108L-3 3,300.0 4,620.0 108 165 457 188 245 355 26 M16 6.890

TR188-108L-4 4,400.0 6,160.0 108 165 610 188 245 508 26 M16 9.190

TR188-108L-5 5,500.0 7,700.0 108 165 762 188 245 660 26 M16 11.390

TR188-108L-6 6,600.0 9,240.0 108 165 914 188 245 812 26 M16 13.640

TR188-108L-7 7,700.0 10,780.0 108 165 1,067 188 245 965 26 M16 15.940

1Energy capacity per stroke during continuous duty.

All data are nominal dimensions. Tolerances are available on request.

Profile Dampers TR-L (radial damping, long version)

Manual

Other STABILUS Industrial Equipment manuals

STABILUS

STABILUS ACE TUBUS TC Service manual

STABILUS

STABILUS ACE MC33-V4A Service manual

STABILUS

STABILUS ACE TUBUS TR-HD Service manual

STABILUS

STABILUS ACE FRT-D2 Service manual

STABILUS

STABILUS FYT-LA3 Service manual

STABILUS

STABILUS ACE FYT-H1 Service manual

STABILUS

STABILUS ACE FRT-F2 Service manual

STABILUS

STABILUS ACE FRT-C2 Service manual