Page | 3 of 46

FREMCO A/S

ELLEHAMMERVEJ 14 |DK9900 FREDERIKSHAVN, DENMARK |VAT NO.: DK30815416

8.1. TRANSPORTING THE MACHINE..............................................................................22

8.2. START/STOP .............................................................................................................22

8.3. WORK AREA..............................................................................................................22

8.4. ENERGY SUPPLY CONNECTION/DISCONNECTION ..............................................23

8.5. OVERVIEW OF THE JOB AND SETUP MENU..........................................................23

8.5.1. SETUP MENU ............................................................................................................23

8.5.2. JOB MENU.................................................................................................................24

8.5.3. SWITCHING BETWEEN JOB MENU AND SETUP MENU.........................................26

8.6. SELECTING AND CHANGING THRESHOLD PARAMETERS ON THE CONTROL

PANEL ...................................................................................................................................26

8.7. OPERATIONS MODE.................................................................................................27

8.7.1. AUTOMATIC MODE...................................................................................................27

8.7.2. MANUAL MODE.........................................................................................................28

8.7.3. SEMIAUTOMATIC......................................................................................................28

8.8. FEEDING AND REMOVING CABLES AND FIBERS..................................................28

8.8.1. CLOSING AND OPENING CHAINS............................................................................29

8.9. STARTING, PAUSING AND STOPPING A FIBER BLOWING PROCESS..................30

8.9.1. START, STARTING THE FIBER BLOWING PROCESS.............................................31

8.9.2. PAUSE, TEMPORARILY STOPPING THE BLOWING PROCESS.............................31

8.9.3. STOP, STOPPING THE FIBER BLOWING PROCESS ..............................................31

8.10. CHANGING THRESHOLD AND SETPOINT VALUES DURING FIBER BLOWING

PROCESS..................................................................................................................................32

8.10.1. SPEED ADJUSTMENT DURING FIBER BLOWING PROCESS.................................32

8.10.2. CHANGING PUSH FORCE SETTING........................................................................32

8.10.3. CHANGING GRIP FORCE SETTING.........................................................................32

8.10.4. CHANGING DISTANCE..............................................................................................33

8.10.5. CHANGING MAXIMUM ALLOWED PRESSURE THRESHOLD OR AIR PRESSURE

SETPOINT..................................................................................................................................33

9. MAINTENANCE, TROUBLESHOOTING AND REPAIR.............................................34

9.1. QUICK GUIDE TO MAINTENANCE, TROUBLESHOOTING AND REPAIR................34

9.1.1. CLEANING .................................................................................................................34

9.1.2. CORRECTIVE MAINTENANCE..................................................................................34

9.1.3. REPAIR ......................................................................................................................35

9.2. SERVICE AND REPAIR ADDRESS ...........................................................................35

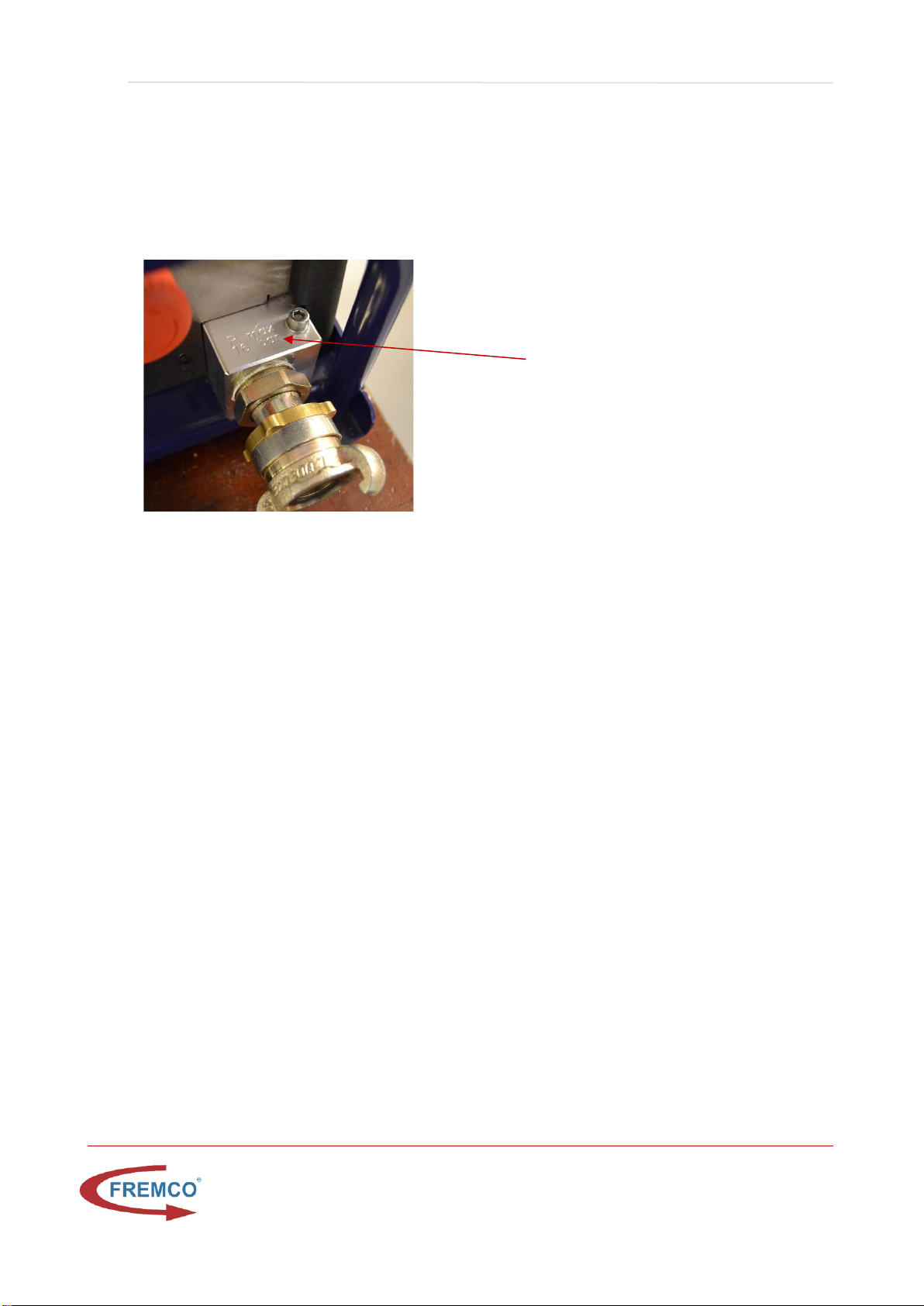

9.3. DISCONNECTION AND DEPRESSURIZATION OF ENERGY SOURCES ................35