Inmes IM-3 SE User manual

IM-3 SE

UNDERPINNER

0504226

SAP: 184

OPERATIONS MANUAL

!!! For your safety !!!

Read the manual carefullyinstructions

INMES Industrial Ltda –IM-3 SE

2

INMES Industrial Ltda –IM-3 SE

3

INTRODUCTION

Congratulations upon your purchase of the INMES IM-3 SE USA Underpinner, designed to fill your needs for

finishing and productivity!

The IM-3 SE USA Underpinner allows you to assemble frames of the size you want, using a full range of

profiles. It applies a wedge in the back of the moulding, making a strong frame. The INMES “SW” wedge is designed to

use in woods of normal density, and the “HW” wedge is for use with hard woods.

The IM-3 SE USA Underpinner has a mechanical action which eliminater, but does not significantly affect your

productivity.

The IM-3 SE USA Underpinner comes to you ready to use, requiring only installation. Please read on so as to

make the best use of your new equipment.

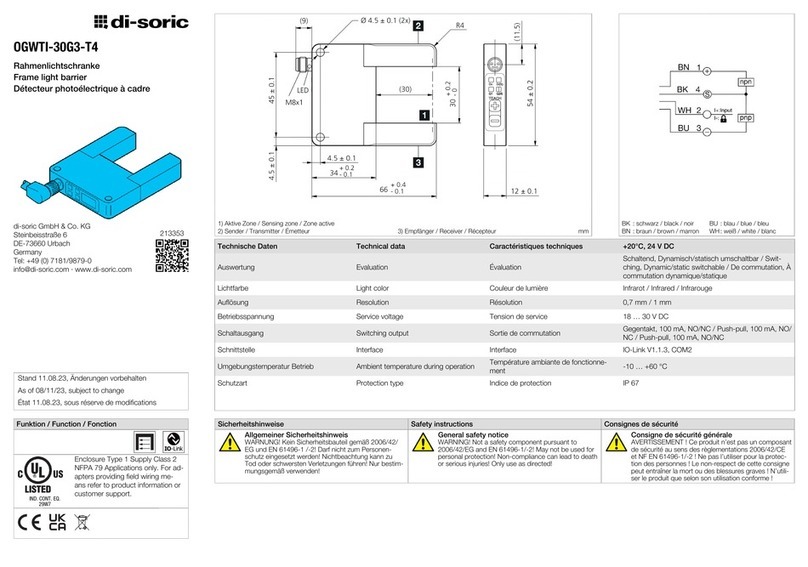

SPECIFICATIONS

•Weight ————————————————––--50 lbs.

•Height ————————————————––– 45”

•Width ————————————————––— 15”

•Depth ————————————————––— 15”

•Widths of moulding ————————————-3/8” - 4 3/4”

•Heights of moulding ————————————5/16” - 3 7/16”

•Wedge sizes ——————————————— 7-10-12-15mm (1/4”-3/8”-1/2”-5/8” )

Optional Accessories

•Large extender table

•“V03” and “D50” model pressure pad

Spare Parts included

•Small extender table

•6mm Allen wrench

•5mm Allen wrench

•3mm Allen wrench

•Spare bolt with spacer for attaching machine to floor

•Bracket of the pressure pad

•“V01” model pressure pad

•“V02” model pressure pad

•“D25” model pressure pad

•Magazine for 5mm and 7mm V-nails

•Magazine for 10mm V-nails

•Magazine for 12mm V-nails

•Magazine for 15mm V-nails

•Lubricant

•Manual

INMES Industrial Ltda –IM-3 SE

4

OPERATION

1) Setting the stops for positioning wedges

The table of your machine has a scale (Fig. 02 Part 02) with measurements from zero to 3 1/4”, that

allows you to

set the stops

(Fig. 02 Part

05 and Fig.02

Part 06), in

this manner

determining

where the

wedges will be

inserted in the

corners. The

rear stop (Fig.

02 Part 05)

determines the

distance the

wedge will be

inserted from

the outside of

the frame. The

distance

setting

between the

rear stop (Fig.

02 Part 05)

and the front

stop (Fig. 02

Part 06)

equals the

distance

between the outside and inside wedges.

If you want more wedges between the inside and

outside ones, you will use your judgement in moving and

stopping the slide guide as you move from the outside to the

inside of the frame. Make sure the wedges are not placed

too close to the edges of the moulding, so as not to split the

material (Fig. 03).

2) Stacking wedges

If you want to stack the wedges in a particularly tall moulding,

simply depress the foot-pedal twice, and two wedges will be

inserted, one on top of the other (Fig. 04 and Fig. 05), or three

times for a third wedge, etc.

3) Select proper wedge size

After you have selected the moulding and frame size, you can determine what size

wedge and how many you want to use on each corner. You want to get the most

rigidity possible to allow your glue to set. Make sure the wedge is not so tall as to

damage the moulding by coming through the top (Fig. 06).

Fig. 02

Fig. 03

Fig. 04

Fig. 05

Fig. 06

INMES Industrial Ltda –IM-3 SE

5

4) Select the proper magazine size

Select the magazine size according to the size of wedge

you will be using. The side of the magazine has a

number on it which indicates which size wedge it takes

(Fig. 07).

Important: The 7mm magazine has “7mm” marked on

one side, for the 7mm wedges, and “5mm” marked on

the other side, which takes the 5mm wedges.

5) Load the empty magazine into the machine

Pull back on the spring-loaded cable (Fig. 08 Part 03),

which allows you to slip the empty magazine into its slot

(Fig. 08 Part 02) in the table. Remember that the side

facing up should have the number indicating the size

wedge (in millimeters) stamped on it.

6) Load the V-nails into the magazine

Pull back on the cable again, and from the point of view of

the side of the table where the spring-loaded cable (Fig. 08 Part

03) is located (the back), put the wedges (Fig. 08 Part 04) in the

magazine (Fig. 08 Part 01) with the cutting side (the side with

the glue) facing up, and with the open end of the “V” facing

away from you, towards the front of the table. Release the cable

so that the spring pushes the shoe against the wedges, feeding

them into the head as they are used.

Fig. 07

INMES Industrial Ltda –IM-3 SE

6

7) Mounting the pressure pad

Remove the screw fig. 10 (02), and press the button (05). Insert the bracket (01)

into the upper support (04). Release the button (05) and insert the screw (02). So,

insert the pressure pad (03) in the bracket (01).

8) Set the position of the pressure pad

The height of the pressure pad (Fig.09 Part 01) should be adjusted according to

the moulding’s height, using the button of the bracket. Press the button to loosen the

pad”s arm. The pad should be set 3/8” above the top of the moulding, as shown in Fig.

09. Then release the button.

9) Reversing position for large mouldings

When making large

frames, you may find it

convenient to work from the

back side of the machine,

using extender tables

(available accessories) to

support the moulding pieces.

You only need to move the

position of the foot pedal from

the front to the back of the

machine.

When using “reverse” moulding profiles, when the

moulding rabbet on the inside of the frame is taller than the

outside, you should substitute the regular pressure pad with the

“V01” or “V03” model pressure pads, shown in Fig. 09. They will

not damage this type of moulding, as well as giving more

support and assuring a good seating of the wedge.

MAINTENENCE

1) Lubrication - All moving parts should be lubricated after every 40 hours of machine use. A lubricant comes with the

machine.

2) Location - The Underpinner should be protected from weather, humidity, dust, etc.

3) Replacing the nail driver rod - If the drive rod (Fig. 12 Part 04) breaks, replace it by following

the following procedure:

Remove bolt (Fig. 12 part 03), and pull the assembly head up through the top of the table.

Then remove the head screws (Fig. 12 part 01) and pull out the drive rod (Fig. 12Part 04).

Place the new one in the head, with the hole at the bottom to receive bolt (Fig. 12 Part 03). Put

a drop of sewing machine oil on the drive rod before reassembling. After reassembling, make

sure the drive rod moves freely up and down. When putting the head back on the machine, be

sure it is level with the top of the table, and that the drive rod continues to move freely. You

may do this by operating without wedges, and with the pressure pad rotated off to one side.

Keep hands away from pad!

4) Cleaning -

a) The pressure pad (Fig. 09), should be cleaned periodically with warm water, no soap, in

order to remove the glue applied to the joints of the frames.

b) The slot where the wedge comes up through the table should always be kept clean, as

should the entire table top. Dried glue should be removed with warm water, never scraped

off.

c) The drive assembly - Periodically you should clean the drive assembly head. Proceed as

described above to replace the assembly. Wash with warm water, wipe thoroughly, then

put a drop of sewing machine oil on the drive rod before reassembling. Remember to

keep hands away from pad when testing! If the drive rod does not come out easily, do

not beat it with a hammer.

INMES Industrial Ltda –IM-3 SE

7

TROUBLESHOOTING

Drive rod stuck - This can happen if:

a) Residues /dirt have gotten into the driver head assembly causing the drive rod to stick after it pushed up the wedge,

not returning to its original position.

b) The wedges were placed in the cartridge upside down, i.e. with the glue side down. The glue side of the wedges is the

cutting edge, and must face up. If the wedges are placed glue side down, instead of the drive rod pushing against the

base of the wedge, the bevel on the cutting edge will act as a guide that directs the drive rod along the side of the

wedge, causing the rod to get stuck, since it and the wedge are occupying the space designed for the drive rod alone.

To release the drive rod, simply pull down on the air cylinder. This will pull back the drive rod to its original position. Then

make sure that the wedges have the glue side facing up in the cartridge. If they are in the proper position, you should

clean the drive head assembly. If you cannot pull the air cylinder down, you should then perform the procedure described

in paragraph 3 in the Maintenance section of this manual.

PARTS LIST FOR IM-3 SE

CODE DESCRIPTION CODE DESCRIPTION

0301003 Base for positioning stops 0408046

Bolt M10X90mm

0301005 Bushing 0408069

Nut M10

0301011 Guide bar for wedge spring loader 0408113 Bolt M4x12mm

0301013 Nut M16 0408140 Bolt Hex. M8x25mm

0301014 Chain’s protector 0408144 Steel Rivet 3,2x10,2mm

0301015 Chain’s guide 0408160 Nut M4

0301022 Down support arm 0416012 Spring

0301029 Spring-loaded cable shoe plate 0417008 Flex pin

0301031 Magazine for 7mm wedges 0417009 Flex pin

0301032 Magazine for 10mm wedges 0417010 Flex pin

0301033 Magazine for 15mm wedges 0417011 Flex pin

0301038 Bolt M5 0417012 Bushing

0301042 Pressure pad assembly shaft 0417088 Flex pin 5x14mm

0301054 Main Shaft washer 0504015 Label

0301060 Anti-Sliding sticker 0408007

Bolt M4X10mm

0301079 Magazine for 12mm wedges 0408155 Allen wrench 3mm

0301080 Base leg 0408139 Allen wrench 4.0mm

0301081 Moulding guide and Teflon pad 0408075 Allen wrench 5.0mm

0301087 Guide for drive piston 0408076 Allen wrench 6.0mm

0301201 Aluminum table top 0408205 Allen wrench 8.0mm

0301207

Main shaft IM-2/IM-3/3P

0408258 Wrench 17x19mm

0301212

Chain IM-2/IM-3

P0301051 Spring loaded cable IM-2

0301397

FootPedal IM-2/IM-3

P0301164 Bushing IM-2/ IM-3/3P

0301398

Foot pedal support IM-2/IM3

P0301028 Position Stop IM-2

0301600

Bracket

P0301030 Wedge shoe

0301601

Pin Button

P0301200 Drive head assemblyIM-2/IM-3/3P

0301602

Screw M8

P0408016 Bolt M6X16mm

0301604 Upper Support IM-2/IM-3/IM-3P (Z) P0301199 Drive rod IM-2

0403003 Plastic foot P0301005 Bushing IM-2

0405120 Label P0301208 Bushing IM-2/IM-3/3P

0408005 Bolt M3x16mm P0301606 Button (Z)

0408009 Bolt M4x20mm P0301632 V01 Pressure Pad

0408012 Bolt M5x8mm P0301633 V02 Pressure Pad

0408018 Bolt M6x20mm P0301634 V03 Pressure Pad

0408025 Bolt M8X16mm P0301635 Round Pressure Pad D50mm

0408029 Bolt M8x35mm P0301636 Round Pressure Pad D25mm

0408037

Bolt M10X25mm

P0416002 Spring IM-2

INMES

®

R o d . S C 4 3 8 - K m 1 8 4

Caixa Postal 65 - CEP 88750-000

Braço do Norte - SC - Brasil

h t t p : / / w w w . i n m e s . c o m . b r

e-mail: vendas@inmes.com.br

S A C 0 3 0 0 7 8 8 2 0 2 2

+ 5 5 ( 4 8 ) 3 6 5 1 2 3 0 0

Table of contents

Popular Industrial Equipment manuals by other brands

Miltenyi Biotec

Miltenyi Biotec MultiMACS X user manual

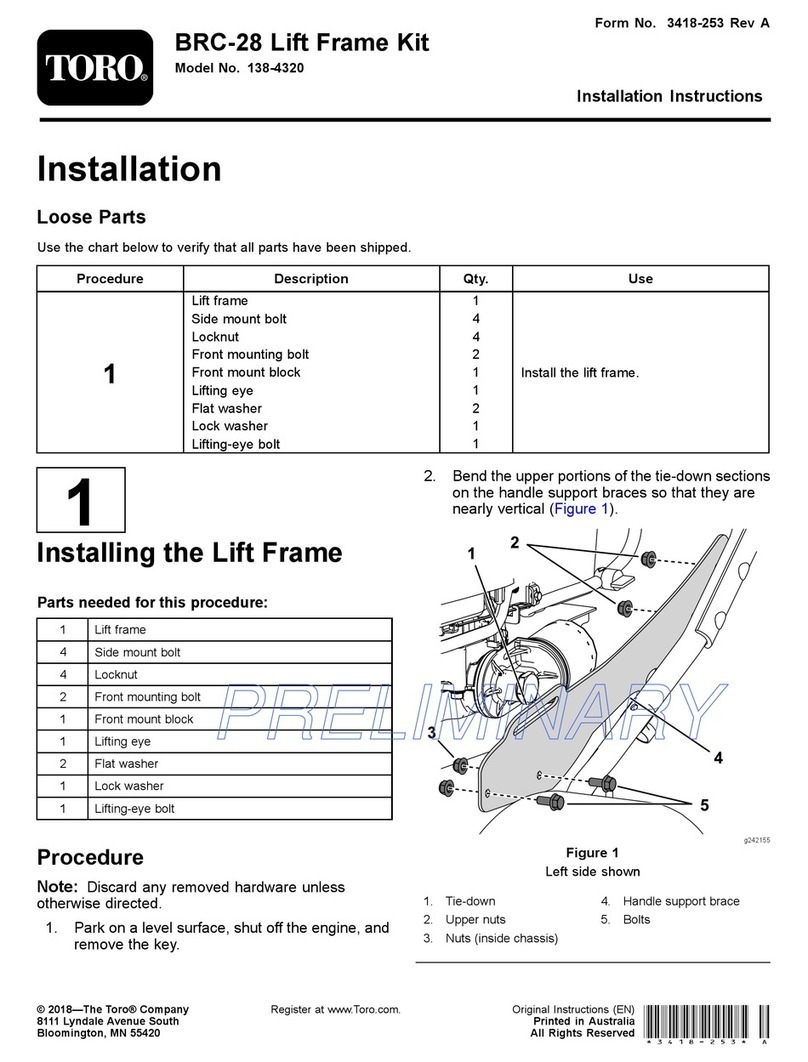

Erskine Attachments

Erskine Attachments 110X Safety and operating instructions

Baileigh Industrial

Baileigh Industrial 1000568 Operator's manual

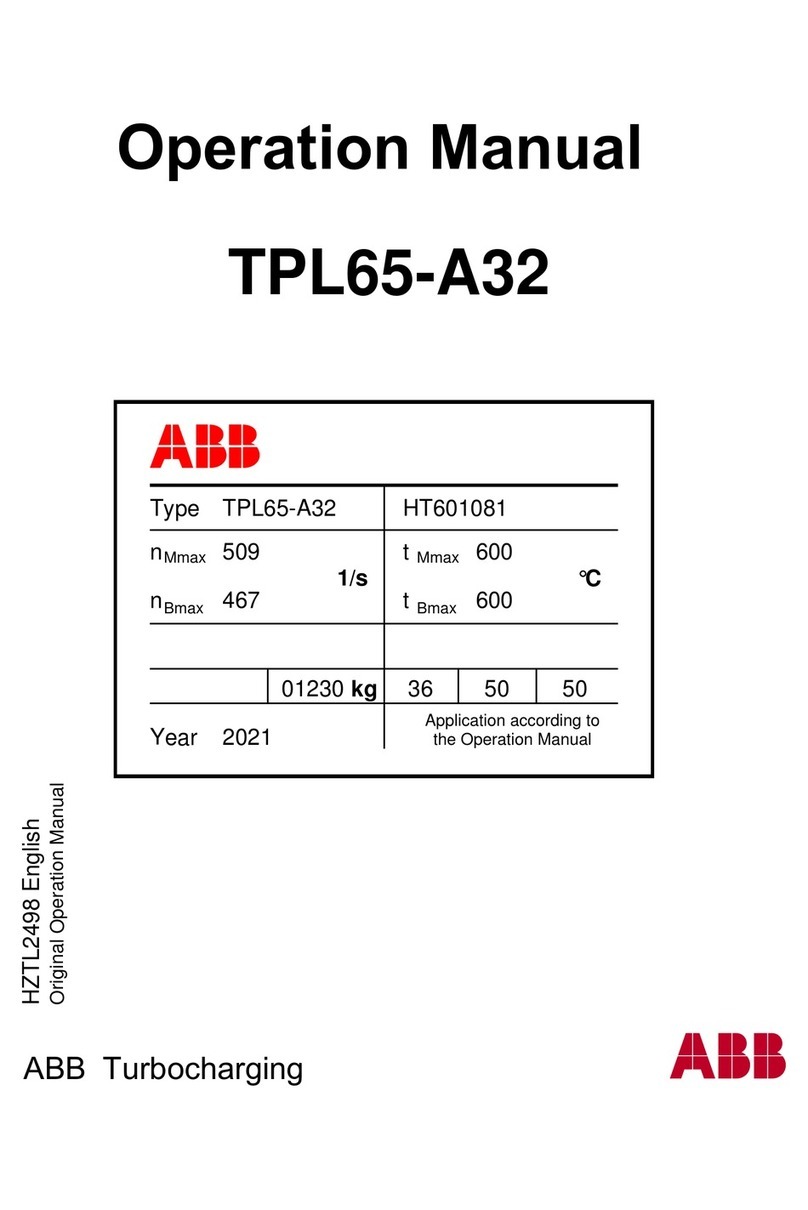

ABB

ABB HT601081 Operation manual

STRIPMEISTER

STRIPMEISTER Electric Series owner's manual

Niko

Niko 10-803 Product information