208080 July 2014

IMPORTANT SAFEGUARDS:

•For your protection, please read these safety

instructions completely before installing and

operating this equipment.

•Keep this manual on file for future reference.

•This manual contains material that may be

required to be on site at all times to comply

with various authorities.

• Carefully observe and adhere to all warnings,

precautions and instructions for this equipment.

WARNINGS:

Failure to comply with the following

warnings could result in property damage,

injury or death.

•Dispensing system must be tested to determine if a

separation force of 350 pounds would damage it.

•Dispenser must be securely attached to the dispensing

island.

•Keep gasoline / fuel away from your eyes and skin.

•Keep gasoline / fuel out of reach of children

•Do not use power tools (Class I Division I and Class I

Division II) during installation process and maintenance

of equipment.

•CHEMICAL EXPOSURE HAZARD: Always wear

appropriate safety equipment during installation or

maintenance of equipment.

•FIRE HAZARD: Do not install an unlisted ad/billboard or

other unlisted after-market device on any breakaway.

Doing so may interfere with proper operation of the

breakaway. Breakaway may not separate properly,

causing a fuel spill, property damage, injury or death.

Reference: sensitivity test per Underwriters Laboratories

specification UL842.

FLOWFL

68EZR RECONNECTABLE BREAKAWAY

FOR THE 68EZR–7575

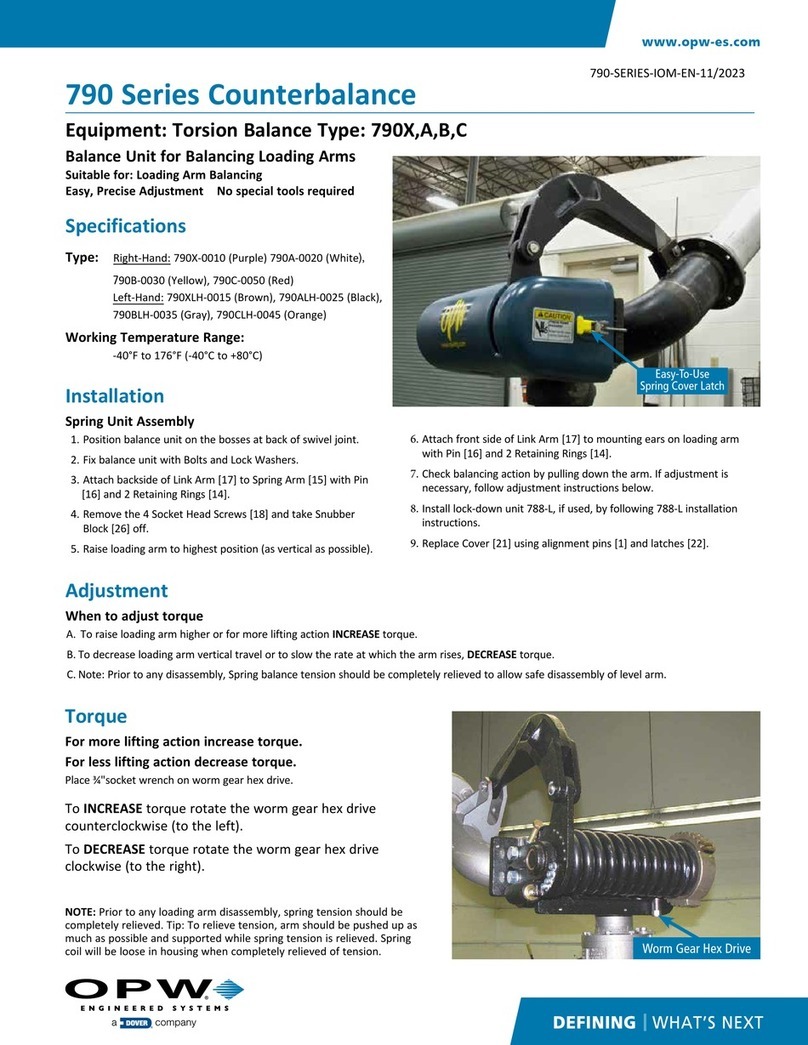

The OPW 68EZR is manufactured to properly function up to a disengagement

force of 350 lb (158 kg). Per U.L. requirements, after installation of the new OPW

68EZR, it must be tested to verify that a pull force of 350 pounds will not damage

the hose assembly or dispensing device (See Figure A for test). The dispensing

device must be securely bolted to the dispensing island.

Valve should be installed according to the directional“flow-arrows”located on the

wrench-flats.

PULL FORCE TEST: (SEE FIGURE A)

Attach a spring scale to the location where the breakaway will be installed. Apply

a 350 lb (158 kg) pull force at various angles and check the emergency valves,

dispenser and hose assembly.

Although the valve can be installed with flow in either direction, it is

very important that the OPW 68EZR be installed according to the directional

“flow-arrows”located on the wrench-flats of the inlet and discharge ports of the

OPW 68EZR breakaway bodies.This is suggested for ease of reconnection and

weather protection. Dispensers with high hanging-hose and low-hose

applications are also suitable for this method.

SIDE HOSE CONNECTION: (SEE FIGURE B)

Install the OPW 68EZR downstream of the hose retractor clamp. Install a

9”(230 mm) minimum length hose or OPW 66H-0075 between OPW 68EZR

and nozzle. Total length of hoses and breakaway valve is not to exceed local,

state or federal codes.

OVERHEAD HOSE CONNECTION: (SEE FIGURE C)

Install the OPW 68EZR with a 9”(230 mm) minimum length hose or OPW

66H-0075 onto dispenser as shown. Install hose between OPW 68EZR and nozzle.

Total length of hoses and breakaway valve is not to exceed local, state or federal

codes. If dispenser is equipped with a hose retractor, install the OPW 68EZR

downstream of the hose retractor clamp.

Figure A

Rope 1" or 3/4" NPT

Female Nipple

Force

350 lb (158 kg)

INSTALLATION

Use wrench on wrench-flats to attach breakaway to the hose.

DO NOT use wrench or clamp on the upstream cover to install the breakaway.

DO NOT use the upstream cover to thread breakaway on the hose.

Doing so may interfere with proper operation of the breakaway.

DO NOT use thread or Teflon® tape. Use U.L. recognized pipe sealant on

threaded connections.

IMPORTANT