Stafer V6RX.E3 Operating instructions

Dear Customer, thank you for purchasing a STAFER product. This manual describes the operations necessary for the correct

installation of the V6RX.E3 / V7RX.E3 products. These tubular motors with electronic limit switches are suitable for handling the

most popular types of rolling shutters. The motor's technical specifications are shown on the label affixed to the motor tube.

These devices have not been designed for round-the-clock use. Any use of the product other than what is provided herein is

improper and prohibited, and involves warranty voidance and liability disclaimer by the Manufacturer. The product must be

assembled and installed only by a qualified technician. At the end of installation, all the manuals accompanying the product

must be delivered to the end customer, who must keep them for future reference. Visit the site www.stafer.com to view updated

documents, if any.

The motor's technical features are shown on the label affixed to the motor tube. Before installing the motor, we recommend that

you copy the technical data (including the full product name) and store them in a safe place. These data could be useful at the

time of maintenance or technical assistance. Additional features common to the V6RX.E3/V7RX.E3 motor family.

Power supply : 230 Vac 50 Hz

Idle consumption : < 0,5W

Minimum V6RX.E roller diameter : 50 x 1.5 mm

Minimum V7RXE roller diameter : 60 x 1.5 mm

Protection grade : IP44

Insulation class : H

Maximum limit switch revolutions : ∞

Revolving operating time : 4 minutes

Radio frequency : 433.42 MHz

Storable portable transmitters : 40

Storable sun/wind radio sensors: : 1

01. TECHNICAL SPECIFICATIONS

Protecting the environment is everyone's duty! STAFER uses recyclable packaging materials. Dispose of materials in proper

containers, in compliance with laws in force in your location. If you are an installer and use a large number of motors, ask your

dealer or the Company about receiving motors in “honeycomb pads”, an environmentally friendly choice that limits clutter and

waste by significantly reducing the amount of packaging materials. This product may contain substances that are polluting for

the environment and dangerous to health. At the end of the product life cycle, carefully comply with the appropriate waste

disposal rules. It is hazardous, and thus strictly forbidden to dispose of the product in the domestic waste.

Let's protect the environment

01. Technical specifications of motors and remote controls

02. Warnings

03. Rating tables and motor components

04. Electrical connection

05. Some information on motor operation

06. Movement control functions

07. Installation via command buttons

08. Installation via remote control

09. Add/delete a radio device

10. Upper limit switch fine-tuning

11. Lower limit switch fine-tuning

12. Button logic

13. Third limit switch (preferred position)

14. Third limit switch inversion

15. Sun/wind anemometer

16. Radio test for anemometer

17. Shutter release

18. Orientation (micro movements)

19. Reset to factory values

Index

It is advisable to avoid using radio systems in areas with strong interference (for example, near police stations, airports, ports,

banks, etc.). A technical inspection is in any case advisable before installing any radio system in order to identify sources of

interference. Radio systems can be used where possible disturbances or malfunctioning of the transmitter or the receiver do

not cause a risk factor, or if the risk factor is cancelled by suitable safety systems. The presence of radio devices operating on

the same transmission frequency (433.42 MHz) can interfere with the radio receiver of the device and thus reduce the range of

the system and limit the functionality of the entire system.

Notes on radio systems

01

USER AND MAINTENANCE MANUAL

Ø 45 mm and Ø55 mm tubular motors with electronic limit switch and radio receiver

V6RX.E3 - V7RX.E3

version 1.0

recycled paper

Compatible STAFER remote controls

595.T.X1.00

(1 channel)

596.T.X1.00

(1 channel)

596.T.X5.00

(15 channels)

595.M.X1.00

(1 channel)

www.stafer.com

VIDEO TUTORIAL

Check that the package is intact and has not been damaged during transport. ● A heavy shock and the use of unsuitable tools

can cause the damage of the external or internal parts of the motor. ● Do not pierce or tamper with the motor in any way. Do not

modify or replace parts without the Manufacturer's permission. ● Do not handle the motor by the power cable. If the power cable

is damaged, the product cannot be used. Do not attempt to replace the power cable. ● Make sure that screws required to

complete the installation do not come into contact with the motor. ● The motor must be of power adequate to the charge (check

the rating plate data on the motor). ● Some programming phases and/or normal operation leverage the mechanical stops of the

rolling shutter. It is essential to select the motor with the torque deemed most suitable for the application, considering the actual

traction of the rolling shutter; therefore, we recommend avoiding very powerful motors. ● Use coilers with a minimum thickness

of 10/10. ● Leave 1-2 mm clearance on right/left on the coiler. ● Check that the drive pulley and the adapter crown are of shape

and dimensions appropriate for the coiler used. Motor accessories, adapters and supports must be selected exclusively from

the STAFER catalogue. ● If the product is installed at a height of less than 2.5 m from the floor or other supporting surface, it is

necessary to protect the moving parts with a cover, in order to prevent accidental access. In any case, guarantee access for

maintenance operations. ● The power cable must be positioned in such a way as to avoid contact with moving parts. ● The

product power cable is suitable for indoor installation only. If installing outdoors, lay the cable in a protective tube. ● If there are

several radio appliances in the same system, make sure they are at least 1.5m apart. ● Do not install the product near metal

surfaces. ● Position the buttons in view of the rolling shutter, but away from its moving parts. Place the buttons at a height greater

than 1.5 m from the floor. ● The motors are designed for residential use; they are designed for a continuous maximum work time

of 4 minutes. ● During operation, the motor body reaches high temperatures: use caution. ● The motor is internally fitted with a

self-restoring thermal safety device, which stops the motor in the event of overheating. The motor returns to normal operation

when its temperature drops below the safety limit (normally from 5 to 10 minutes). ● The motor must be installed in such a way

that it does not come into contact with liquids and, in any case, in a location protected from the elements. ● The antenna cable is

subjected to mains voltage. It is forbidden and dangerous to tamper with the antenna cable. Replace the product if the antenna

cable is damaged. ● For your safety, do not work near the coiler while the motor is powered.

The product is not intended to be used by persons (including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they are supervised or given instructions about the product way of use by a person

responsible for their safety. ● Before operating the rolling shutter, make sure that people or things are not in the area affected by

the movement of the rolling shutter. Check the automation during operation and keep people at a safe distance until the end of

operation. ● Do not allow children to play with the appliance or with control devices. ● Do not operate the rolling shutter when

maintenance operations are being carried out (e.g. window cleaning, etc.). If the control device is automatic, disconnect the

motor from the power line.

02.2 Installation warnings

02.3 Use warnings

02

02. WARNINGS

Incorrect installation can cause serious injuries. ● Keep these instructions for future maintenance operations and the disposal of

the product. ● All the product installation, connection, programming and maintenance operations must be carried out only by a

qualified and skilled technician, who must comply with laws, provisions and local regulations, and the instructions provided

herein.● Wiring must comply with current CEI standards. In compliance with the provisions of Italian Ministerial Decree 37/2008,

the final electrical system must be installed only by an electrician. ● Some applications require “man present” operation and can

exclude the use of radio commands or require particular safety devices. ● To prevent potentially dangerous situations, regularly

check the operating condition of the rolling shutter/awning.

02.1 Safety warnings

MENU PROG

sun/wind sensor function

third limit switch function

Back of remote control

Back of the remote control,

inside the battery compartment.

596.T.X1.00

596.T.X5.00

595.T.X1.00

PROG

button

Back of remote

control

LED

595.M.X1.00

Back of button

LED

01.1 Remote control “function” buttons

PROG

button

03. RATING TABLES AND MOTOR COMPONENTS

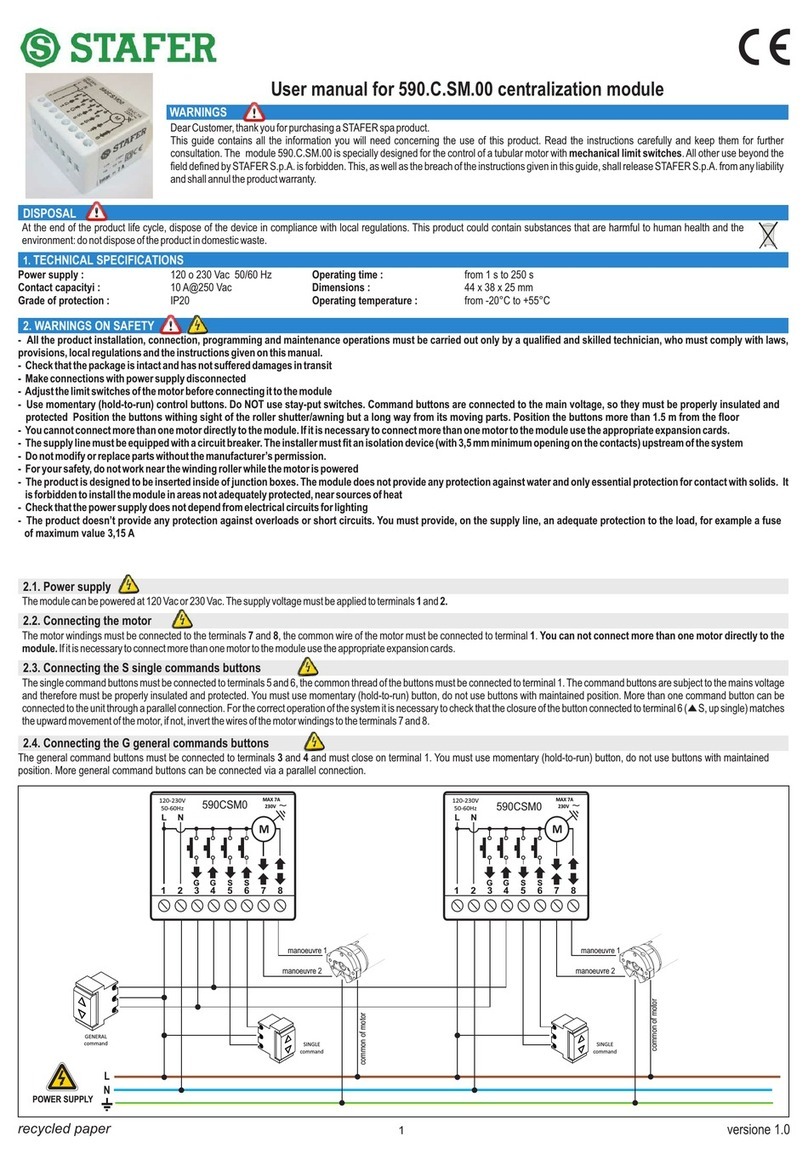

04. ELECTRICAL CONNECTION

L (phase)

N (neutral)

grey

brown

blue

yellow/green

black

MAIN POWER

SUPPLY

motor

cable

Command

buttons (optional)

04.1 Warnings for the electrician

04.2 Power supply

The supply voltage must be applied to the BROWN (phase) and BLUE (neutral) wires. Always connect the YELLOW-GREEN wire to the earthing system. The motor's technical

specifications are shown on the label affixed to the motor tube.

04.3 Command buttons

The command buttons are optional. If used, the command buttons must be applied to the BLACK and GRAY wires and must close on the BROWN wire (phase). You must use buttons

with spring return (“man present” type), do not use switches with maintained position. Multiple command buttons can be connected via a parallel connection. The command buttons are

subjected to the mains voltage and, therefore, must be adequately insulated and protected. If the command buttons are not used, insulate the gray and black wires.

04.4 Motor connection to home automation control units

There are different types of home automation control units. Some home automation control units allow programming the closing time of the output contacts, while others do not allow it;

some home automation control units measure the current absorption of the devices applied to the output contacts, while others do not; some home automation control units work with

proprietary protocols, while others work with “standard” protocols (for example KNX, MODBUS, etc...). Given the range of features of different home automation control units available

on the market, the motor's Manufacturer cannot know in advance whether the motor is compatible with the home automation control unit installed. The command outputs of the home

automation control unit must be connected to the push-button inputs of the motor (GRAY and BLACK wires), replacing the manual command buttons. Consequently, the home

automation control unit must comply with the operating rules of the command buttons, keeping into account whether the latter function in PULSE (factory setting) or in MAN PRESENT

mode (see section 12 “Button logic”).

Rules for the home automation control unit to comply with to control motors with PULSE-operated buttons.

a) The home automation control unit MUST NOT measure the current absorbed by the button inputs of the motor (which absorb currents lower than 1 mA).

b) The home automation control unit must be connected to the motor as shown in the diagram, replacing the command buttons with the command outputs of the home automation

control unit.

c) To operate the motor, the home automation control unit must close the contact (up or down) for more than 0.5 seconds (typically a 1 second pulse is used).

d) When the contacts are open, the home automation control unit must close a contact (up or down) for less than 0.5 seconds to stop the motor (typically a pulse of 0.2 seconds is

used).

Rules for the home automation control unit to comply with to control the motors with MAN PRESENT-operated push buttons.

a) The home automation control unit MUST NOT measure the current absorbed by the button inputs of the motor (which absorb currents lower than 1 mA).

b) The home automation control unit must be connected to the motor as shown in the diagram, replacing the command buttons with the command outputs of the home automation

control unit.

c) To allow the completion of the entire opening/closing manoeuvre, the home automation control unit must be able to close the up/down contact for the time necessary for the motor to

perform the complete opening/closing manoeuvre.

d) To stop the motor, the home automation control unit must be able to re-open the up/down contacts at any time.

At the time of printing of this document, no particular problems concerning the connection between STAFER SPA products and home automation control units are known (if the above

rules are complied with). In any case, STAFER shall not be liable in the event of lack of compatibility (even partial) with any home automation control unit. If the home automation control

unit uses KNX or similar protocols, contact the home automation system supplier to discuss the rules listed above. It is likely that the home automation control unit manufacturer can

provide adequate interfaces to connect the motor to the home automation control unit. For additional information, please contact your dealer.

03

V6RX.E3

V7RX.E3

A=power cable / B=base crown / C=insertion key / D=adapter crown E=output pinion /

F=drive pulley / G=washer / H=locking screw I=gearmotor body / J=nameplate data

A=power cable / B=base crown / C=insertion key / D=adapter crown / E=output pinion / F=drive pulley /

G=coupling tooth / H=coupling clips (to remove the pulley, widen the clips and pull lightly) / I=gearmotor

body / J=nameplate data

Make all connections with the power supply disconnected. ● Check that the power line does not feed on electrical circuits to be used for lighting. ● The power line must be equipped with

a magneto thermal or differential circuit breaker. A category III over voltage disconnection device must be fitted on the power supply line, i.e. at a distance of at least 3.5 mm between the

contacts. ● The section of the connecting cables must be proportionate to their length and to the power load absorption, and, in any case, not less than 1.5 mm. ● The product does not

provide for any protection against overloads or short circuits. Provide adequate protection for the load on the power supply line, for example a fuse with a maximum value of 3.15 A.

● Command buttons are connected to the main voltage, so they must be properly insulated and protected.

04

07. INSTALLATION VIA COMMAND BUTTONS

Installation must be carried out by a qualified technician. If in doubt, contact your supplier.

ON

Remove and restore

power

A

Bring the motor to

the intermediate

position

B(1) C(2)

Shortly press 3 TIMES the button that MOVES

THE MOTOR DOWNWARD

x3

D

The motor signals up/down

With Blinds

x1

press UP once

With Square Bar

Awning

x2

press UP twice

With Cassette

Awning

x3

press UP 3 times

E

The motor replicates the

number of movements. If

they do not match, repeat

the operation.

F

G

After 2 seconds the

motor moves

up/down

REGOLAZIONE FINE DURANTE PRIMA INSTALLAZIONE

(2)

We recommend thoroughly reading the entire procedure before performing the described operations, so as to make the procedure easier and less prone to errors.

Depending on your application, press

the UP button the corresponding number

of times (see below):

WARNING! with an ORIENTA type blind, stop the motor when the blind is

lowered and all the slats are completely open. To associate the fully closed

blind limit switch, see paragraph 13 “THIRD LIMIT SWITCH”, after

'completing point I.

The STAFER motor adjusts its operating principle according to the type of rolling shutter in which it is installed (blind, square bar awning or cassette awning).

Operation in BLIND mode

The motor activates the obstacle detection system during the ascent phase. If during the ascent phase an obstacle is detected in the vicinity of the lower limit switch, the ascent

manoeuvre is interrupted and the motor operates in descent mode, bringing the blind back to the lower limit switch position (the motor interprets the obstacle as an anti-intrusion stop).

If during the ascent phase an obstacle is detected in other positions, the ascent manoeuvre is interrupted and the motor is operated briefly in descent mode, so as to free the blind from

the traction to which it is subjected because of the obstacle. If the upper limit switch has been set through contact of the blind caps with the upper stop, every 30 complete closing

manoeuvres, the motor searches for the upper stop to compensate automatically for possible mechanical settling of the blind in such a way as to automatically recalibrate the limit

switch.

Operation in SQUARE BAR AWNING mode

The motor activates the obstacle detection system during the ascent phase, just as it does in blind mode. If the upper limit switch has been set by contact of the terminal with the

square bar, every 30 complete closing manoeuvres, the motor searches for the contact of the terminal with the square bar to automatically compensate for lengthening/shortening of

the shutter, always maintaining it at optimal tension.

Operation in CASSETTE AWNING mode

The motor activates the obstacle detection system during the ascent phase, just as it does in blind mode.

If the upper limit switch has been set by contact of the movable part of the cassette with the fixed part of the cassette (a typical feature in cassette awnings), at each closing of the

cassette, the motor restores the limit switches so as to automatically compensate for lengthening/shortening of the shutter, always keeping it at the optimal tension and enabling

correct cassette closing. In this mode, it is also possible, through the specific function (paragraph 17), to activate and adjust the time to release the shutter immediately after cassette

closing.

05. SOME INFORMATION ON MOTOR OPERATION

If you want to better adjust the position of the limit switches using the buttons, proceed as described in paragraphs 10 or 11. Sometimes, it is

possible that, once the procedure has been completed, the motor will move opposite to the pressed button. In this case, we recommend turning

the buttons or inverting the gray and black wires.

If you want to store a remote control at a later time, follow the procedure in paragraph 9.2.

Bring the blind/awning to the desired lower limit switch

while pressing the DOWN button. At the end release,

and briefly press UP.

YES

NO Stop manually.

Briefly press

DOWN.

Hold down until

contact, then release

HBring the blind/awning to the desired upper limit switch while pressing the UP button. At the end, release and

briefly press DOWN.

Upper

Stop?

After the position

is reached,

wait 2 seconds

(1)

Notes:

If the motor makes 4 short up/down movements, it means that it is waiting for a command. After signalling 3 times, if no commands are given, the motor will exit programming; in

this case, it will be necessary to cut off power and start again from point A.

(1) the motor moves in “man present” mode: by pressing UP or DOWN, the motor moves in a certain direction until the button is released.

(2) briefly press 3 times, about 0.5 seconds between one press and the next.

I

After 2 seconds the

motor moves up/down.

END!

The motor

performs a

down/up

movement

(1)

06. MOVEMENT CONTROL FUNCTIONS

Depending on the type of installation, the motor may or may not use some electronic commands and optimises its operation based on the rolling shutter. It is however possible to

operate some electronic commands by manually activating/deactivating them according to specific needs. Below is a list of available commands and how these are set by the motor at

the end of the installation.

A = function active, cannot be deactivated

B = function active, can be deactivated

N = function inactive, can be activated

- = function not available

As = function active, cannot be deactivated, present only if the upper limit switch has been stored by contact with an obstacle

Ascent obstacle detection

As soon as an obstacle is

detected during the ascent

phase, the motor stops and

makes a brief downward

movement to free the structure

from traction.

Blinds: A

Square bar awning: A

Cassette awning: A

Stop detection

As soon as a safety stop is

detected during ascent, the

motor stops operation and

closes the rolling shutter.

Blinds: A

Square bar awning: A

Cassette awning: A

Automatic operation reset

If the ascent limit switch is

stored by contact with an

obstacle, the motor

automatically recalibrates

operation, as appropriate by

circumstances.

Blinds: As

Square bar awning: As

Cassette awning: As

Shutter release

Specific function for cassette

awnings. When the cassette

closes a brief downward

movement is commanded so as

to reduce the traction on the

shutter.

Blinds: -

Square bar awning: -

Cassette awning: N

See par. 17

Orientation

The function allows for the

stroke-operation of the rolling

shutter. Function designed

specifically for Adjustable Blinds

(Tapparella Orientabile), but can

also work on other shutter

types.

Blinds: B

Square bar awning: B

Cassette awning: B

See par. 18

05

08. INSTALLATION VIA REMOTE CONTROL

The product must be installed only by a qualified technician.

This motor is compatible with remote controls of the 595 and 596 series.

If in doubt, contact your supplier.

ON

Remove and

restore power

A

Within 15 seconds, briefly press the

transmitter's PROG

BCDoes the motor move

upwards?

Briefly press UP YES

NO

Press the transmitter's

PROG button Bring the motor to the

intermediate position

D

(1) (2)

E(3)

Press 3 times on STOP

After 2 seconds, the

motor moves up and

down

x3

F

With Blinds

x1

With Square

Bar Awning

x2

The motor replicates the same number of movements. If they do not

match, press the desired number again.

With Cassette

Awning

x3

(3)

YES

NO Stop manually

J

Notes:

If the motor makes 4 short up/down movements, it means that it is waiting for a command. After signalling 3 times, if no commands are given, the motor will exit programming; in

this case, it will be necessary to cut off power and start again from point A.

(1) from the moment the transmitter PROG is pressed, the push-buttons are inhibited for the entire installation procedure.

(2) the motor moves in “man present” mode: by pressing UP or DOWN on the transmitter, the motor moves in a certain direction until the button is released.

(3) briefly press 3 times, about 0.5 seconds between one press and the next.

We recommend thoroughly reading the entire procedure before performing the described operations, so as to make the procedure easier and less prone to errors.

Depending on your

application, determine

how many times you

wish to press the UP

button:

WARNING! with an ORIENTA type blind, stop the motor when the blind is lowered and all the

slats are completely open. To associate the fully closed blind limit switch, see paragraph 12

“THIRD LIMIT SWITCH”, after completing point P.

Item 596 Item 595T

H

If the movements match,

press STOP 3 times. If they do

not match, repeat point F.

LBring the blind/awning to the desired lower limit switch (2)

After you reach the

desired position,

press STOP 3 times (3)

x3

M

NBring the blind/awning to the desired upper limit switch (2)

Automatic

upper

stop?

After you reach the

desired position, press

STOP 3 times (3)

x3

After 2 seconds, the

motor moves down

and up

O

After 2 seconds, the motor

moves down and up.

END!

P

SHOULD THE LIMIT SWITCHES BE ADJUSTED BETTER OR DO THEY NEED FINE TUNING? See paragraphs 10 and 11 (page 6).

(3)

After 2 seconds the

motor replicates the

movements.

G

After 2 seconds the

motor moves

up/down

After 2 seconds, the

motor moves up and

down

I

Press and hold until the

caps touch, then

release the button

09. ADD/DELETE A RADIO DEVICE (REMOTE CONTROL OR ANEMOMETER)

01. Bring the motor to the intermediate position.

02. Briefly press PROG of a remote control already stored. Motor makes 2 upward movements.

03. Within 15 seconds....

to add a remote control: press STOP or UP on the remote control to be added;

to add an anemometer: turn the impeller counterclockwise for a few seconds;

to delete a remote control already stored: press DOWN on the remote control;

to delete an anemometer already stored: perform function 27 (see anemometer manual)

04. 2 UP movements: device stored!!

1 DOWN movement: device deleted!!

PROG button

NOTES:

If, after pressing PROG, no signal is sent to the motor within 15 seconds, the motor will exit the menu without signalling anything.

The only stored remote control can also be deleted. To associate another one at a later time, it is necessary to proceed with the buttons (paragraph 09.2)

09.1 USING THE REMOTE CONTROL (Only if a remote control has already been stored)

STOP

01. Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times.

The motor moves up/down.

04. Within 15 seconds, briefly and quickly press UP once and DOWN once.

Motor makes 2 upward movements.

05. Within 15 seconds....

to add a remote control: press STOP or UP on the remote control to be added;

to add an anemometer: turn the impeller counterclockwise for a few seconds;

06. The motor performs 2 movements up: device stored!!

09.2 USING THE COMMAND BUTTONS (If there is no functioning device stored)

STOP

1 x UP

1 x DOWN

3 x UP

3 x DOWN

ON

NOTES:

If, after pressing UP 3 times and DOWN 3 times, no signal is sent to the motor within 15 seconds, the motor leaves the menu without signalling anything.

x3

Item 595M

Item 596 Item 595T Item 595M

06

10. FINE-TUNING OF UPPER LIMIT SWITCH

(*) The buttons must be pressed shortly, max 1 second between two pressures.

01. Bring the motor to the intermediate position.

02. Press MENU with 596. Display shows: - - . Press 3 times on PROG* with 595. The motor moves up/down.

03. Press DOWN once. The 596 display shows 01.

04. Press STOP. The motor performs a brief up/down movement.

05. Press UP. The motor moves to the upper limit switch. Wait until it stops.

06. Adjust the new position with UP / DOWN.

07. Once you have found the position, press PROG. The motor performs a brief DOWN/UP movement.

08. Press MENU with 596. Press 3 times on PROG* with 595.

10.1 USING THE REMOTE CONTROL

01. Bring motor to the upper limit switch.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times. The

motor completes 1 UP/DOWN movement.

04. Within 15 seconds, briefly press UP once.

The motor moves to the upper limit switch. Wait until it stops.

05. Adjust the new position with UP / DOWN.

06. Once positioned, wait 5 seconds.

The motor completes 1 down/up movement. Limit switch setting stored!!

10.2 USING COMMAND BUTTONS

WARNING:

Fine-tuning of the upper limit switch is not possible if the limit switch has been set by contact with a stop plate.

3 x PROG

Wait for 5

seconds

12

39

6

1 x SU

ON

3 x DOWN

Item 596 Item 595T

MENU

3 x UP

11. FINE-TUNING OF LOWER LIMIT SWITCH

(*) The buttons must be pressed shortly, max 1 second between two pressures.

01. Bring the motor to the intermediate position.

02. Press MENU with 596. The display shows - - / Press PROG* 3 times, with 595. The motor moves up/down.

03. Press DOWN once. The 596 display shows 01.

04. Press STOP. The motor performs a brief up/down movement.

05. Press DOWN. The motor moves to the lower limit switch. Wait until it stops.

06. Adjust the new position with UP / DOWN.

07. Once you have found the position, press PROG. The motor performs an UP/DOWN movement.

08. With the 596, press MENU. / With the 595, press PROG. 3 times*.

11.1 USING THE REMOTE CONTROL

01. Bring motor to the upper limit switch.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times.

The motor completes 1 UP/DOWN movement.

04. Within 15 seconds, briefly press DOWN once.

The motor moves to the lower limit switch.

05. Adjust the new position with UP / DOWN.

06. Once positioned, wait 5 seconds.

The motor completes 1 up/down movement. Limit switch setting stored!!

11.2 USING COMMAND BUTTONS

Wait for 5

seconds

12

39

6

1 x DOWN

ON

3 x DOWN

3 x UP

Advanced Info

12. BUTTON LOGIC

12.1 USING THE REMOTE CONTROL Item 596

The command buttons can work in PULSE logic or in MAN PRESENT logic.

PULSE: to move the motor, press a button for at least 0.5 seconds, to stop the motor, briefly press (less than 0.5 seconds) one of the two buttons.

MAN PRESENT: to move the motor, press a button for at least 0.5 seconds, release the button to stop the motor.

The factory sets the motor to work in PULSE logic. To modify this parameter, follow the instructions provided below.

10.1 UTILIZZANDO IL TRASMETTITORE (solo Atom e Leg)

01. Bring the motor to the intermediate position.

02. Press MENU. The motor performs an up/down movement. Display shows: - - .

03. Press 4 times on DOWN. 04 appears on the display.

04. Press STOP. The motor shows:

1 UP = man present, 1 DOWN = pulse.

05. To select “Pulse”: press DOWN

To select “man present”: press UP

06. After pressing, the motor shows:

1 UP = man present, 1 DOWN = pulse.

07. Press MENU to exit.

10.1 UTILIZZANDO IL TRASMETTITORE (solo Atom e Leg)

01. Bring the motor to the intermediate position

02. Press 3 times on PROG*. The motor performs an up/down movement.

03. Press 4 times on DOWN. The motor performs an up/down movement.

04. Press STOP. The motor shows:

1 UP = man present, 1 DOWN = pulse. Advanced Info

05. To select “Pulse”: press DOWN.

To select “man present”: press UP.

06. After pressing, the motor shows:

1 UP = man present, 1 DOWN = pulse.

07. Press PROG 3 times to exit.

12.2 USING REMOTE CONTROL Item 595

01. Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times*.

The motor performs an up/down movement.

04. Within 15 seconds, briefly and quickly press DOWN 4 times.

The motor shows: 1 UP = man present, 1 DOWN = pulse.

05. To select “Pulse”: briefly press DOWN.

To select “Man present”: briefly press UP.

06. The motor shows: 1 UP = man present, 1 DOWN = pulse.

07. Wait for 5 seconds. The motor exits the menu without any movement.

12.3 USING COMMAND BUTTONS

(*) The buttons must be pressed shortly, max 1 second between two pressures.

Wait for 5

seconds

12

39

6

4 x DOWN

ON

3 x DOWN

3 x UP

Item 595M

3 x PROG

Item 596 Item 595T

MENU

Item 595M

07

13. THIRD LIMIT SWITCH (PREFERRED POSITION)

13.1 USING REMOTE CONTROL Item 596

13.3 USING COMMAND BUTTONS

In the case of blinds with ADJUSTABLE slats, it is possible to decide whether to associate the THIRD LIMIT SWITCH to the fully lowered blind position with open slats or to the

lowered blind position with closed slats. In any case, it is better to initially associate the THIRD LIMIT SWITCH to the completely lowered position with slats closed, since the

LOWER limit switch has already been stored and associated with the completely lowered blind position with open slats. Subsequently, it is possible to invert the LOWER LIMIT

SWITCH with the THIRD LIMIT SWITCH at will and at any time (see paragraph 14).

13.2 USING REMOTE CONTROL Item 595

To store the THIRD LIMIT SWITCH:

01. Bring the motor to the intermediate position.

02. Press 3 times on PROG* on the back. The motor performs an up/down

movement.

03. Press DOWN twice. The motor performs an up/down movement.

04. Press STOP. The motor moves to the lower limit switch.

04. Move the motor to the desired position (with ADJUSTABLE

slats, close blind and slats completely).

05. Press PROG 3 times to exit.

To call up:

01. Briefly press STOP 3 times

14. THIRD LIMIT SWITCH INVERSION

14.1 USING REMOTE CONTROL Item 596

01. Bring the motor to the intermediate position

02. Briefly press MENU on the back. The motor performs an up/down movement.

Display shows: - - . Press 3 times on DOWN. 03 appears on the display.

03. Press STOP. The motor moves to the lower limit switch position.

04. Press UP once. The lower limit switch has been reversed with the third limit switch.

05. The motor signals UP.

06. Press MENU to exit.

14.3 USING COMMAND BUTTONS

14.2 USING REMOTE CONTROL Item 595

01. Bring the motor to the intermediate position

02. Press 3 times on PROG* on the back. The motor performs an up/down movement.

03. Press DOWN 3 times. The motor performs an up/down movement

04. Press STOP. The motor moves to the lower limit switch position.

05. Press UP once. The lower limit switch has been reversed with the third limit switch.

06. The motor signals UP.

07. Press PROG 3 times to exit.

Wait for 5

seconds

12

39

6

2 x DOWN

ON

3 x DOWN

3 x UP

To store:

01. Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times*.

The motor completes 1 up/down movement.

04. Within 15 seconds, briefly and quickly press DOWN twice.

The motor shows: up/down.

05. Press the buttons bringing the motor to the desired position.

06. Wait for 5 seconds. The motor exits the menu without any movement.

To call up:

01. Quickly press DOWN 3 times.

01. Bring motor to the lower limit switch.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times*.

The motor moves up/down.

04. Within 15 seconds, briefly and quickly press DOWN 3 times.

The motor moves to the lower limit switch position.

05. Briefly press UP to invert the third limit switch.

06. The motor signals UP.

07. Wait for 5 seconds. The motor exits the menu without any movement.

15. SUN AND WIND ANEMOMETERS

The sun/wind sensors generate automatic operations without warning, which can be a source of danger. The installer is responsible for informing the end user and possibly integrating

appropriate safety systems to the installation. In some situations, (e.g., loss of motor or sensor voltage, motor or sensor failure, radio disturbances, etc.), it is possible that the

command given by the sensor may not be detected by the motor. The sensor must therefore not be understood as a safety device designed to guarantee the integrity of the rolling

shutter under all conditions, but a means to reduce the probability that the rolling shutter will be damaged by adverse weather events.

(*) The buttons must be pressed shortly, max 1 second between two pressures.

(*) The buttons must be pressed shortly, max 1 second between two pressures.

16. SUN/WIND ANEMOMETER RADIO TEST

As soon as a sun/wind radio anemometer is stored in the motor, a communication check is automatically activated between radio anemometer and motor. Communication between

the two devices occurs every 15 seconds. If communication fails twice consecutively, the motor performs an ascent manoeuvre to protect the rolling shutter. The automatic protection

manoeuvre is performed only once, remaining in place until radio communication is restored. It is possible to “query” the motor on the alarm status. Please refer to the anemometer

manual.

15.1 ANEMOMETERS COMPATIBLE WITH RX-E3 MOTORS

The V6.RX-E3 and V7.RX-E3 motors feature an integrated radio receiver and require the use of radio anemometers. Use model 595.K.XS.00 (sun/wind sensor for one or more

motors). The sensor constantly communicates to the associated motors wind intensity and brightness. Each motor, depending on the thresholds set inside it, decides whether to

trigger the wind or the sun alarm. In the event of wind alarm, the motor engages the upward mode, also inhibiting the manual commands until the end of the alarm. In the event of sun

alarm, the tuned motors activate a descent mode. When the sensor detects the absence of sun, the message “no sun” is sent to the motors. In turn, the motors activate the ascent

mode. For more information, refer to the relevant anemometer manual.

Wait for 5

seconds

12

39

6

3 x DOWN

ON

3 x DOWN

3 x UP

1 x UP

Sun function activation with remote control Item 596

Press the SUN button on the remote control until the

state of the YELLOW LED varies (about 2 seconds).

The motor moves up/down to confirm the change.

Select the channel associated with the motor

(except “SE” Sequencer)

YELLOW LED LIGHT ON/OFF:

“sun” function active/off

For clarification, refer to the manual of your sun-wind sensor.

Sun function activation with remote control Item 595

For clarification, refer to the manual of your sun-wind sensor.

01. Bring the motor to the intermediate position.

02. Press 3 times on PROG on the back. The motor shows:

up/down.

03. Press UP twice and DOWN twice, then press STOP.

04. The motor shows: up/down.

05. To activate, press UP once.

To deactivate, press DOWN once.

06. After 2 seconds, the motor replicates the movement.

07. Press PROG 3 times to exit (the motor does not show

anything).

To store the THIRD LIMIT SWITCH:

01. Bring the motor to the intermediate position.

02. Briefly press MENU on the back. The motor performs an up/down Display

shows: - - . Press DOWN twice. 02 appears on the display.

04. Press STOP. The motor moves to the lower limit switch.

04. Move the motor to the desired position (with ADJUSTABLE

slats, close blind and slats completely).

05. Press PROG to store settings. The motor performs an up/down movement.

06. Press MENU to exit.

To call up:

01. Press the THIRD LIMIT SWITCH button on the remote control.

In the case of blinds with ADJUSTABLE slats, it is possible to decide whether to associate the THIRD LIMIT SWITCH to the fully lowered blind position with open slats or to the lowered

blind position with closed slats. In any case, it is better to initially associate the THIRD LIMIT SWITCH to the completely lowered position with slats closed, since the LOWER limit switch

has already been stored and associated with the completely lowered blind position with open slats.

If you try to invert the THIRD LIMIT SWITCH before storing its settings, an error is signalled by 4 movements of the motor. It is possible to invert the LOWER LIMIT SWITCH with the

THIRD LIMIT SWITCH at any time, proceeding as follows:

08

17. SHUTTER RELEASE (FOR CASSETTE AWNINGS ONLY)

This is a specific function available only in the CASSETTE AWNING installation mode. The factory sets this function as “inactive”. If the

function is activated, when the cassette closes a very brief downward movement is commanded so as to reduce the traction on the

shutter with closed cassette. The duration of the movement can be set (see Table 01 - Shutter Release) following the procedure below.

No. of movements Threshold

1

2

3

4

5

Function not active

10 msec

20 msec

30 msec

40 msec

Tab. 01 - Shutter Release

17.1 USING REMOTE CONTROL Item 596

01. Bring the motor to the intermediate position.

02. Briefly press MENU on the back. The motor performs an up/down movement.

03. Display shows: - - . Press DOWN 6 times. 06 appears on the display.

04. Press STOP. The motor performs an up/down movement.

05. Press UP. The motor shows the current value (from 1 to 5 movements).

06. Press UP as many times as the setting you want (from 1 to 5).

07. Press STOP. The motor shows the new setting (from 1 to 5 movements).

08. Press MENU to exit.

01. Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times*.

The motor performs an up/down movement.

04. Within 15 seconds, briefly and quickly press DOWN 6 times.

After 2 seconds, the motor signals the current value (from 1 to 5 movements).

05. Briefly press UP the number of times equal to the desired setting (from 1 to 5). After

2 seconds, the motor signals the new setting (from 1 to 5 movements).

06. Wait for 5 seconds. The motor exits the menu without any movement.

17.3 USING COMMAND BUTTONS

Wait for 5

seconds

12

39

6

6 x DOWN

ON

3 x UP

3 x DOWN

press UP

from 1 to 5

times

01. Bring the motor to the intermediate position.

02. Press 3 times on PROG*. The motor performs an up/down movement.

03. Press 6 times on DOWN. The motor performs an up/down movement.

04. Press STOP. The motor shows the current value (from 1 to 5 movements).

05. Press UP as many times as the setting you want (from 1 to 5).

06. Press STOP. The motor shows the new setting (from 1 to 5 movements).

07. Press PROG 3 times to exit.

17.2 USING REMOTE CONTROL Item 595

(*) The buttons must be pressed shortly, max 1 second between two pressures.

18. ORIENTATION (MICRO MOVEMENTS)

01. Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times*.

The motor moves up/down.

04. Within 15 seconds, briefly and quickly press DOWN 7 times.

The motor shows the current value (from 1 to 5 movements).

05. Briefly press UP as many times as the setting you want (from 1 to 5).

06. After 5 seconds, the motor signals the new setting (from 1 to 5 movements).

To adjust:

01. Briefly press a button, then immediately press and hold it

18.3 USING COMMAND BUTTONS

Allows you moving the motor in short strokes. Useful function for situations in which the rolling shutter consists of adjustable slats.

The function is already active, but can be deactivated and customised.

If the function is active, you can use both the wall-mounted buttons and the remote control to move the motor in strokes:

- with the wall-mounted buttons (only with pulse logic), briefly press a button, then immediately press the same button again, keeping it

pressed.

- with remote control Item 596, keep pressed the two special buttons with curved arrows (if necessary, refer to the manual of the

remote control supplied).

- with remote control Item 595, briefly press STOP twice, then immediately afterwards hold down the UP or DOWN button (if

necessary, refer to the manual of the remote control supplied).

It is possible to adjust the duration of the strokes (see Table 02 - Orientation Time). To modify this parameter, follow the instructions

provided below.

10.1 UTILIZZANDO IL TRASMETTITORE (solo Atom e Leg)

01. Bring the motor to the intermediate position.

02. Briefly press MENU. The motor moves up/down. Display shows: - - .

03. Press 7 times on DOWN. 07 appears on the display.

04. Press STOP. The motor shows: up/down.

05. Press UP. The motor shows the current value (from 1 to 5 movements).

06. Press the UP button a number of times equal to the desired setting (from 1 to 5)

07. After 5 seconds, the motor signals the new setting (from 1 to 5 movements).

08. Press MENU to exit

To adjust:

01. Press the ORIENTATION button on the remote control.

No. of movements Threshold

1

2

3

4

5

Function not active

50 msec

100 msec

150 msec

200 msec

Tab. 02 - Orientation Time

Advanced Info

18.2 USING REMOTE CONTROL Item 595

10.1 UTILIZZANDO IL TRASMETTITORE (solo Atom e Leg)

01. Bring the motor to the intermediate position.

02. Press 3 times on PROG*. The motor shows: up/down.

03. Press 7 times on DOWN.

04. Press STOP. The motor shows: up/down.

05. Press UP. The motor shows the current value (from 1 to 5 movements).

06. Press UP as many times as the setting you want (from 1 to 5).

07. After 5 seconds, the motor signals the new setting (from 1 to 5 movements).

08. Press PROG 3 times to exit.

To adjust:

01. Briefly press twice on STOP, and then hold down UP or DOWN.

18.1 USING REMOTE CONTROL Item 596

UP

Wait for 5

seconds

12

39

6

7 x DOWN

ON

3 x UP

3 x DOWN

press UP

from 1 to 5

times

UP

(*) The buttons must be pressed shortly, max 1 second between two pressures.

09

19. FACTORY VALUE RESET

19.1 USING REMOTE CONTROL Item 596

01. If possible, bring motor to an intermediate position.

02. Cut off the power supply.

03. Connect as shown in the diagram on the side.

04. Power up the motor. The motor signals 6 up/down movements.

06. Cut off the power supply.

07. Restore the connections. (REFER to diagram in paragraph 4)

08. Install the motor again (see paragraph 5 or 6 of this manual).

19.4 USING THE POWER CABLES

01. Bring the motor to the intermediate position.

02. Press MENU. The motor moves up/down. Display shows: - - .

03. Press UP twice and DOWN 9 times, 29 appears on the display.

04. Press STOP, the motor makes 6 movements up and down. Wait until it stops.

05. Press UP twice until the motor signals that the reset has been completed

(1 double movement).

06. Press MENU to exit.

07. Install the motor again (see section 6 or 7 of this manual).

L (phase)

N (neutral)

motor

cable

grey

brown

blue

yellow/green

black

ELECTRICAL

DIAGRAM FOR RESET

All rights reserved.

STAFER S.p.a. - via Malpighi, 9 - 48018 Faenza (RA) ITALY

Tel. (+39) 0546.624811 - Fax (+39) 0546.623141 - www.stafer.com

All products and technical specifications given in this document are subject to variation without prior notice.

Unless previously and specifically authorised by STAFER, the device must be used exclusively with transmitters produced by STAFER.

STAFER cannot be considered responsible for damage caused by improper, incorrect or unreasonable uses.

SIMPLIFIED DECLARATION OF CONFORMITY

The manufacturer STAFER s.p.a. declares that the product complies with Directives 2014/53/EU, 2014/35/EU, and 2014/30/EU.

19.2 USING REMOTE CONTROL Item 595

01. Bring the motor to the intermediate position.

02. Press 3 times on PROG*. The motor shows: up/down.

03. Press twice on UP and 9 times on DOWN.

04. Press STOP, the motor makes 6 movements up and down.

Wait until it stops.

05. Press UP twice until the motor signals that the reset has been completed

(1 double movement).

06. Press PROG 3 times to exit.

07. Install the motor again (see section 6 or 7 of this manual).

(*) The buttons must be pressed shortly, max 1 second between two pressures.

16.1 UTILIZZANDO IL RADIOCOMANDO

19.3 USING THE WALL-MOUNTED BUTTON (IF ANY)

01. USING THE REMOTE CONTROL Bring the motor to the intermediate position.

02. Turn off the power, wait a few seconds, then power up again.

03. Within 15 seconds, briefly and quickly press UP 3 times and DOWN 3 times.

The motor moves up/down.

04. Within 15 seconds, briefly and quickly press UP twice and DOWN 9 times.

The motor performs 6 up/down movements.

05. At the end of the movements, briefly press UP twice.

06. The motor signals that the reset has been carried out (1 double movement).

This manual suits for next models

1

Table of contents

Other Stafer Control Unit manuals

Popular Control Unit manuals by other brands

Control Techniques

Control Techniques UD77 DeviceNet Startup guide

Crest Audio

Crest Audio CC-STS datasheet

Extron electronics

Extron electronics DVCM 50 user manual

TLV

TLV JH-B series instruction manual

NIPPON VALVE CONTROLS

NIPPON VALVE CONTROLS Vpro Z instruction manual

GAMMA SYSTEM

GAMMA SYSTEM GP02R quick start guide