2702 - 3

Contents

english

List of content Type

Generales notes .................................................................................................................................................5

Symbols............................................................................................................................................................................. 6

Intended use .................................................................................................................................................................... 6

General safety notes ...................................................................................................................................................... 6

Contact addresses ......................................................................................................................................................... 7

Warranty ............................................................................................................................................................................ 7

Transport , storage .......................................................................................................................................................... 7

Disposal ............................................................................................................................................................................ 8

Information in internet .................................................................................................................................................... 8

technical Data .......................................................................................................................................................9

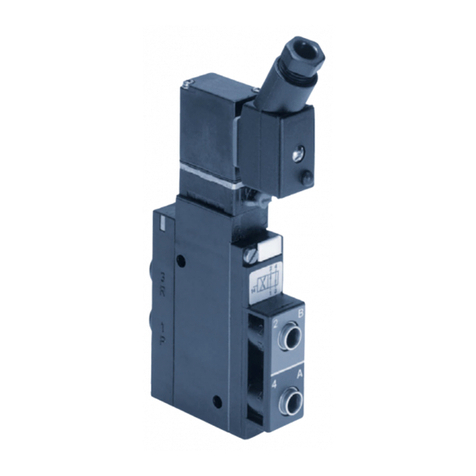

Construction of the control valve ..............................................................................................................................10

Media ...............................................................................................................................................................................10

Kv values .........................................................................................................................................................................11

commissioninG .................................................................................................................................................... 13

Installation of the valve .................................................................................................................................................14

Procedure for TopControl Type 8630...........................................................................................................14

Procedure for SideControl Type 1067 .........................................................................................................15

Pneumatic installation for TopControl Type 8630 ................................................................................................17

Fluid connections of the TopControl Continuous ......................................................................................17

Electrical connection - multipole connectors (TopControl Type 8630) ...........................................................18

Marking of the multipole plugs or sockets and the contacts ...................................................................18

Output signals for SPS (circular plug M 16) ..............................................................................................19

Operating voltage (circular plug M 12) ........................................................................................................19

Inductive proximity switches (circular socket M8) .....................................................................................19

Process value (circular plug M 8) ..................................................................................................................20