Stafsjö XV Technical specifications

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

Maintenance instruction

This maintenance instruction is a step-by-step instruction for service

and maintenance on Stafsjö’s knife gate valve XV. The instruction

shall be available for persons responsible for service and maintenance

on Stafsjö’s knife gate valves. The following procedures are described

in the service instruction:

A –Change of seat

B –Change of gate and box packing

C –Change of box packing when the valve is installed in a system

D –Torque for nuts on gland

E –Change from hand wheel (HW) to pneumatic cylinder (AC)

For more detailed information on technical data of valves, actuators or accessories, please see

data sheets on www.stafsjo.com, or contact Stafsjö Valves AB or your local representative.

Each knife gate valve is identified with a label containing the article number and serial number.

When corresponding with Stafsjö Valves AB or your local representative, please have these

numbers available.

Stafsjö Valves AB does not accept any responsibility for the product if service and maintenance

on the knife gate valve is not performed according to this instruction. Nor does Stafsjö Valves

AB accept any responsibility of the product if any significant change has been done to the prod-

uct.

Spare parts

Recommended spare parts are described in spare part data sheets for each knife gate valve

type on www.stafsjo.com. Stafsjö recommends the customer to keep one set of spare parts for

each valve type and size in store.

Spare parts can be ordered from Stafsjö Valves AB or your local representative. Spare part data

sheets and addresses are available on www.stafsjo.com.

Safety information

No work is allowed on the knife gate valve when the system is pressurised or the actua-

tor is connected. The system must be free from pressure and empty. Actuator and ac-

cessories must be disconnected before any work is commenced.

All gate guards must be installed after finished maintenance on the knife gate valve.

Information is only for informational purpose. All specifications are subject to change without notice.

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

2

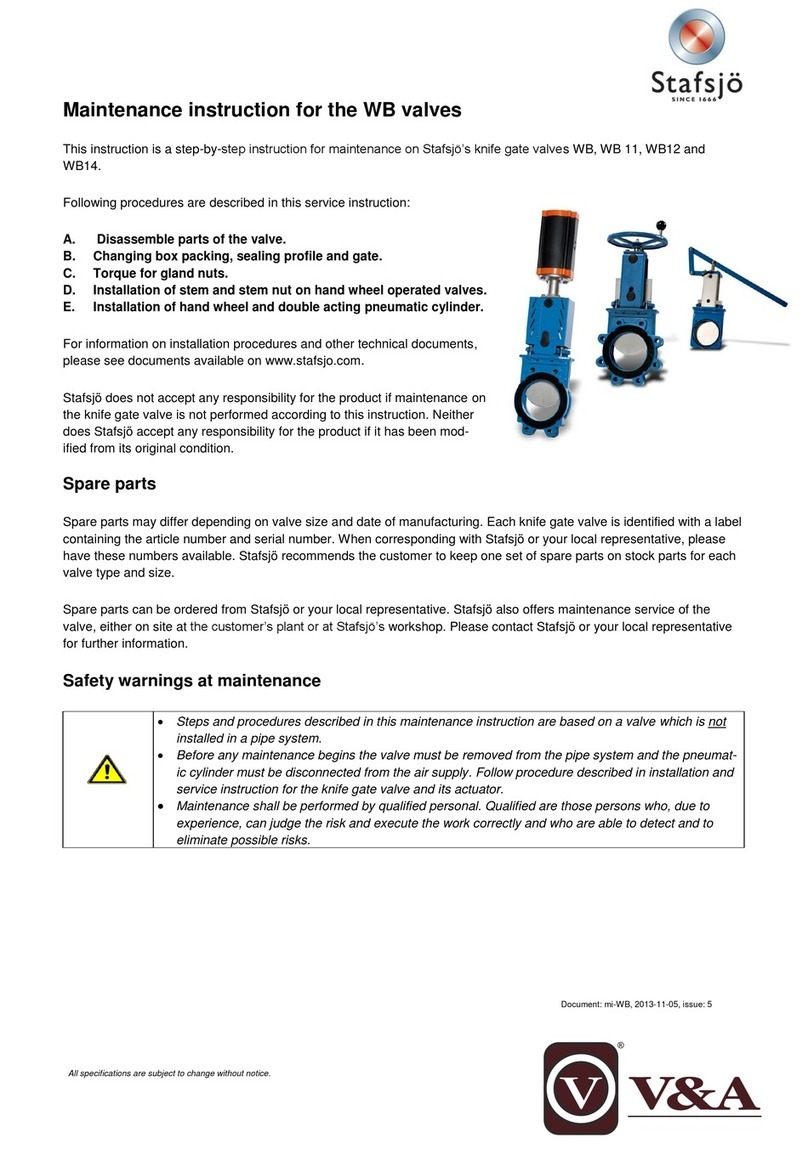

Main components in the Stafsjö knife gate valve XV

Figure 1

Gland

Valve body

Box packing

Retainer ring

Gate

Stud bolt

Nut and washer

O-ring

Seat

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

3

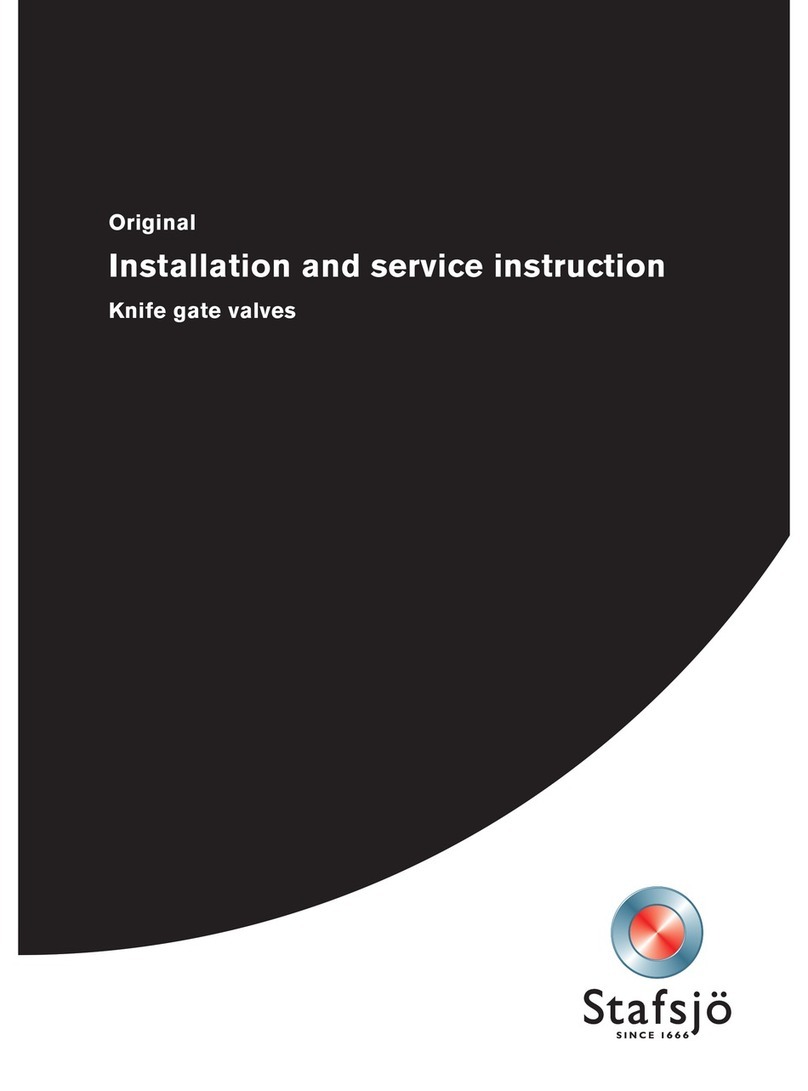

Part list of the Stafsjö knife gate valve XV

Figure 2

Pos

Part

Pos

Part

Pos

Part

Pos

Part

1

Hand wheel

5a

Washer

10d

Screw

18

Cylinder

2

Yoke

5b

Nut

10e

Washer

19

O-ring

2a

Bearing

6

Gate

10f

Nut

20

Clevis pin

2b

Slide washer

7

Beam

11

Body gasket

21

Split pin

2c

Bearing

8

Gland

12

Retainer ring

25

Piston rod

3

Stem

8a

Stud bolt

12a

Locking screw

28

Locking nut

4

Stem nut

8b

Washer

13

Seat*

*

Recommended spare parts

4a

Washer

8c

Nut

14

Guide strips

4b

Screw

9

Box packing*

16

Gate guard, not

for HW

5

Tie rod

10a

Valve body

17

Gate clevis

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

4

Service and maintenance

See figure 1-3 for identification of parts on the XV valve. Parts may differ depending on the

valve size and manufacturing date. Please contact Stafsjö Valves AB or your local representa-

tive if you have any questions.

For more information on installation and operation of the knife gate valve and pneumatic cylin-

der, please see Operating instruction for knife gate valves and pneumatic cylinders at

www.stafsjo.com or contact Stafsjö Valves AB or your local representative.

Stafsjö Valves AB offers the customer service and maintenance of Stafsjö knife gate valves, ei-

ther in the customer’s plant or at Stafsjö workshop. Please contact Stafsjö Valves AB or your lo-

cal representative for more information.

For procedures A, B and E the knife gate valve must not be installed in a system.

No work is allowed on the Stafsjö knife gate valve when the system is pressurized or the

automatic actuator is connected. The system must be empty and free from pressure be-

fore dismantling of the valve begins. The actuator and accessories must be discon-

nected.

If the valve is equipped with gate guards, they must be mounted after finished mainte-

nance on the knife gate valve.

A - Change of seat

Place the valve horizontally for simple change of seats.

1. Close the valve. The valve must be closed at all time until it is installed into the system. If

not the seat could be damage and causing leakage.

2. Loosen the locking screws (12a) the retainer ring (12) is locked with.

3. Lift of the retainer ring (12). If the retainer ring is stuck, use a screw driver or similar and

bend carefully between the retainer ring and the valve body in several places around the

bore until the retainer ring is loose.

4. Check the gate (6) for damages such as dents and scratches. If the gate is damaged it can

wear out the box packing (9) and the seat (13), causing leakage. Stafsjö recommends

changing the gate if it is damaged to ensure the function of the valve.

5. Clean the area of the seat on the retainer ring and the valve body.

6. Install a new seat (13) on the retainer ring (12) and place the retainer ring in the valve body

(10). For PTFE seat (13); o-rings (19) must be installed on the retainer ring (12) before the

seat is installed, see fig.3.

7. Lock the retainer ring (12) with the locking screws. Note! The function of the screws is only

to keep the retainer ring in place. The retainer ring function come into force when the valve

is installed in a system between pipe flanges. Make sure that the locking screw is not above

the valve body. That could cause leakage between flange and the valve.

8. Install the valve in the system according to the operating instruction.

9. Operate the valve a few times before the system is pressurised.

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

5

Figure 3

B - Change of gate and box packing

Place the valve upright in for example a screw vice for simple change of the gate and box pack-

ing. Large valves should be placed horizontally on a work bench.

1. Close the valve completely.

2. Demount the actuator and top.

Hand wheel (1)

a. Demount the hand wheel (1).

b. Loosen the nuts (5b).

c. Lift off the bearing (2c), bearing washer (2b), yoke (2), bearing washer

(2b) and bearing (2a) from the stem (3).

d. Demount the beams (7) and tie rods (5).

e. Loosen the screw (4b) from the stem nut (4) and gate (6).

f. Lift off the stem (3) and stem nut (4).

Pneumatic

cylinder (18)

a. Loosen the gate guards (16).

b. Demount the split pins (21) and clevis pin (20).

c. Loosen the nuts (5b) keeping the cylinder in place.

d. Lift off the cylinder (18).

e. Demount the beam (7) and tie rods (5) from the valve.

3. Loosen the nuts (8c) on the gland (8).

4. Lift of the gland (8) from the stud bolts (8a).

5. Remove the box packing braids (9).

6. Clean the box from residues.

7. Remove the gate (6) and look for damages such as dents and scratches. If the gate is

damaged it can wear out the box packing (9) and the seat (13), which could cause leakage.

Stafsjö recommends changing the gate if it is damaged to ensure the function of the valve.

8. Check that the guide strips (14, on XV valves DN 500-DN 800) in the valve body are not

worn out and that they are in correct position.

9. Remove the retainer rings (12) and the seat sets (13) together with the o-rings (19). The

procedure is described in A –Change of seat.

10. Put the gate (6) in the valve body (10). Check that the gate is placed correctly on the bump

in the bottom of the valve body, see fig. 3.

11. Start the installation of the first braid (9) on one of the long sides of the gate (6). Use a blunt

tool in plastic or wood and a hammer to push the braid into the box. Make sure that the

braid ends meets properly. It is important to push the first braid evenly into the bottom of the

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

6

box. The joint of the second and third braid must be placed on the opposite long side of the

joint of the previous braid, not on top of each other.

12. Place the gland (8) on the stud bolts (8a).

13. Add the washers (8b) and nuts (8c).

14. Make sure the gate is completely closed

15. Install the retainer rings (12) and the seat sets (13) together with the o-rings (19). The pro-

cedure is described in A –Change of seat.

16. Put pressure on the gland (8) by tightening the nuts (8c) gradually and crosswise, see figure

4. The box packing must be equally compressed all around. Recommended torque for

gland nuts, see chapter D.

17. The gland (8) must put a uniform pressure on the box packing (9). The gland (8) must also

be in line with the gate (6) with the same distance between the gland and the gate all

around. Check that there is no metal contact between the gland (8) and the gate (6).

18. Install the other components in reversed order, step 2.

19. Make sure that the valve is closed.

20. Function test of the knife gate valve.

21. Install the valve in the system according to the operating instruction.

22. Operate the valve a few times before the system is pressurised.

Note:

The box packing may start to leak when the system is pressurised and the temperature in-

creases. This is caused due to that the box packing, which is a soft material, moves depending

on pressure and temperature and when the valve is operated. If the box packing is leaking,

tighten the gland nuts (8c) gradually and crosswise according to chapter D.

C –Change of box packing when the valve is installed in a system

No work is allowed on the Stafsjö knife gate valve when the system is pressurised or the

automatic actuator is connected. The system must be empty and free from pressure be-

fore any work begins and the actuator and accessories must be disconnected.

Work on the knife gate valve when the system is under pressure can cause damages on

persons and equipment.

Check that the system is free from pressure by:

oObserving the pressure measurement on the system

oOpening the drain on the pipe

When the system is free from pressure and empty:

1. Before starting the procedure open the valve and check the gate (6) visually for damages

such as dents and scratches. If the gate is damaged it can wear out the box packing (9) and

the seats (13), which could cause leakage. Stafsjö recommends changing the gate if it is

damaged to ensure the function of the valve. The procedure of changing the gate is de-

scribed in B –Change of gate and box packing.

2. Close the valve.

3. Loosen the nuts (8c) on the gland (8).

4. Lift the gland (8) and connect it to the stem nut (4) or gate clevis (17) with a wire to be able

to reach into the box packing (9).

5. Remove the box packing braids (9).

6. Clean the box from residues.

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

7

3

1

2

4

7. Start the installation of the first braid (9) on one of the long sides of the gate (6). Use a blunt

tool in plastic or wood and a hammer to push the braid into the box. Make sure that the

braid ends meets properly. It is important to push the first braid evenly into the bottom of the

box. The joint of the second and third braid must be placed on the opposite long side of the

joint of the previous braid, not on top of each other.

8. Place the gland (8) on the stud bolts (8a).

9. Add the washers (8b) and nuts (8c).

10. Put pressure on the gland (8) by tightening the nuts (8c) gradually and crosswise, see figure

4. The box packing must be equally compressed all around. Recommended torque for

gland nuts, see chapter D.

11. The gland (8) must put a uniform pressure on the box packing (9). The gland (8) must also

be in line with the gate (6) with the same distance between the gland and the gate all

around. Check that there is no metal contact between the gland (8) and the gate (6).

12. Operate the valve a few times before the system is pressurised.

Note:

The box packing may start to leak when the system is pressurised and the temperature in-

creases. This is caused due to that by the box packing, which is a soft material, moves depend-

ing on pressure and temperature and when the valve is operated. If the box packing is leaking,

tighten the gland nuts (8c) gradually and crosswise according to chapter D.

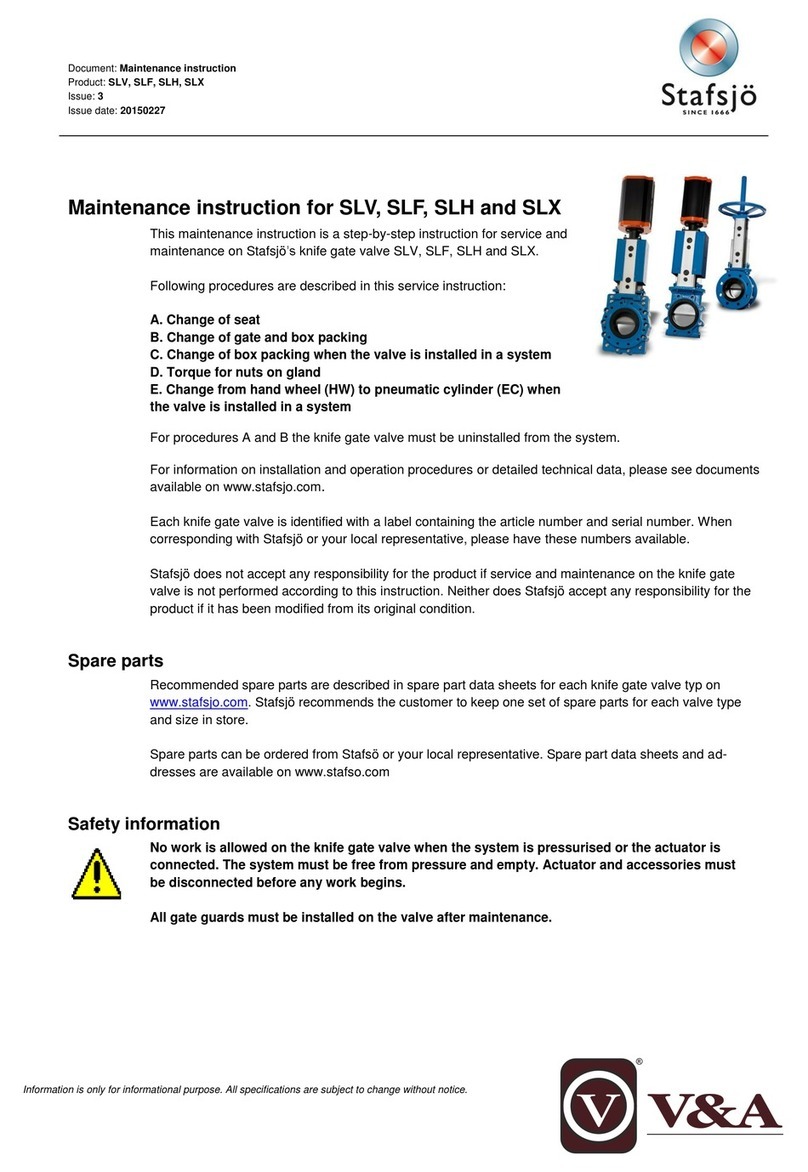

D - Torque for gland nuts

The torque TGin the table below is a recom-

mended value for tightening the gland nuts (8c).

If the box packing is leaking, tighten the gland

nuts (8c). Each nut shall be tightened gradually

and crosswise until the leakage stops and the

gate moves smoothly without tipping in the

opening or closing instant. Figure 4: Tighten gland nuts crosswise

TG

DN

Nm

lbf x ft

50 –80

25

18

100 –150

30

22

200 - 1000

35

26

If the gland nuts are tightened to hard, it shortens the lifetime of the box packing and increases

the force needed to operate the valve.

Check that the gland (8) is equally compressed all around and that there is no metal contact be-

tween the gland (8) and the gate (6).

E –Change from hand wheel (HW) to pneumatic cylinder (AC)

To be able to adjust the cylinder stroke, the pneumatic cylinder must be installed on the knife

gate valve when the valve is not installed in a system.

Large pneumatic cylinders installed horizontally must be supported to not cause tensions in the

valve which might affect the valve tightness and ability to manoeuvre.

Document: Maintenance instruction

Product: XV

Issue: 2

Issue date: 2010-10-05

1. Close the valve completely.

2. Demount the hand wheel manoeuvre. See B: 2.

3. Screw the locking nut (28) and the gate clevis (17) halfway on to the cylinder piston rod

(25).

4. Install new beams (7) with holes on the tie rods (5). The holes on the beam are placed on

different distances from the short side of the beam. The side of the beam with the longest

distance between the hole and the short side should be turned toward the top of the valve

body (10).

5. Mount the cylinder (18) on top of the beams and fixate with washers (5a) and nuts (5b).

6. Attach the gate clevis (17) to the gate with the clevis pin (20) and the split pins (21).

7. Open the valve completely by gently operating the pneumatic cylinder (18). In this position,

the bottom edge of the gate (6) should be in line with the retainer ring edge (12). If it is not,

close the valve, demount the split pins (21) and clevis pin (20) and adjust the gate clevis

(17) on the piston rod (25) until the gate edge and retainer ring edge are in line with each

other when the valve is open.

8. Lock the gate clevis (17) with the locking nut (28).

9. Function test of the knife gate valve.

10. Mount the gate guards (16).

11. Make sure that the valve is closed

12. Install the valve in the system according to the operating instruction.

13. Operate the valve a few times before the system is pressurised.

Table of contents

Other Stafsjö Control Unit manuals

Popular Control Unit manuals by other brands

ITRON

ITRON EquaScan hMIURFV2 Assembly instruction

Pressroom Electronics

Pressroom Electronics PressCam 8 Installation and operation manual

Toshiba

Toshiba Adjustable Speed Drive H7 Series specification

RIB

RIB R10-CRX manual

oventrop

oventrop Cocon 2TZ installation instructions

ehang

ehang G-BOX operating manual