Standa 1VIS10 User manual

P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

Manufacturer of Opto-Mechanical equipment for research, industry and education http://www.standa.lt

Vibration isolation system 1VIS10

User manual

Standa

2018

P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

Manufacturer of Opto-Mechanical equipment for research, industry and education http://www.standa.lt

2

Table of contents

1. General information

1.1. Introduction

1.1.1. Safety

1.2. Location of the table

1.3. Air supply requirements

2. Mounting of the system

2.1. Assembly of the system

2.1.1. Safety

2.1.2. Assembly of the frame

2.1.3. Connection and installation of pneumatic vibration isolation components

2.1.4. Fitting the collector and the support plates

2.1.5. Assembly of the table

2.2. Preparation of the system for operation and vibration isolation of the table

2.2.1. Assembly of level controls

2.2.2. Connection of air supply pipes

2.2.3. Setting of level controls

3. Management of the system

3.1. Main principles

3.2. Adjustment of parameters of the system

3.3. Maintenance

3.3.1. Cleaning

3.3.2. Air quality

4. Packing list

P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

Manufacturer of Opto-Mechanical equipment for research, industry and education http://www.standa.lt

3

1. General information

1.1 Introduction

The pneumatic vibration isolation system is an ideal work platform for equipment, which is

sensitive to vibration, e.g. microscopes, scales, interferometers, and similar devices.

The work surface of the table is separated from the floor by means of a highly effective system

of pneumatic supports.

The system features solid and light optical tables of different sizes, which enable the production

of a wide selection of systems for a variety of tasks requiring different sizes and loads

Specification

Symbol

Value

Unit

Vertical movement range

lz

14

mm

Precision of automatic level control

Δ lz

± 0.3

mm

Pressure from source of air

p

600 (6 bar) (87 PSI)

kPa

Air supply opening

Ø

6

mm

Operating humidity (max)

φ

90 %

%

Operating temperature range

T

10 - 50

ºC

Load-bearing capacity (at 6 bar) per isolator

Q

160

kg

Fig. 1. Specification of 1VIS10

A specification of a pneumatic support is presented in fig. 1.

Although each support is intended for a load of up to 160 kg, you should prevent overloads of

the table at the edges, otherwise any one pneumatic support may become overloaded even if the total

weight fits within the limits set. Loads with the centre of gravity located very high may result in

instability of the entire system. Please refer to section 3.2 of the manual.

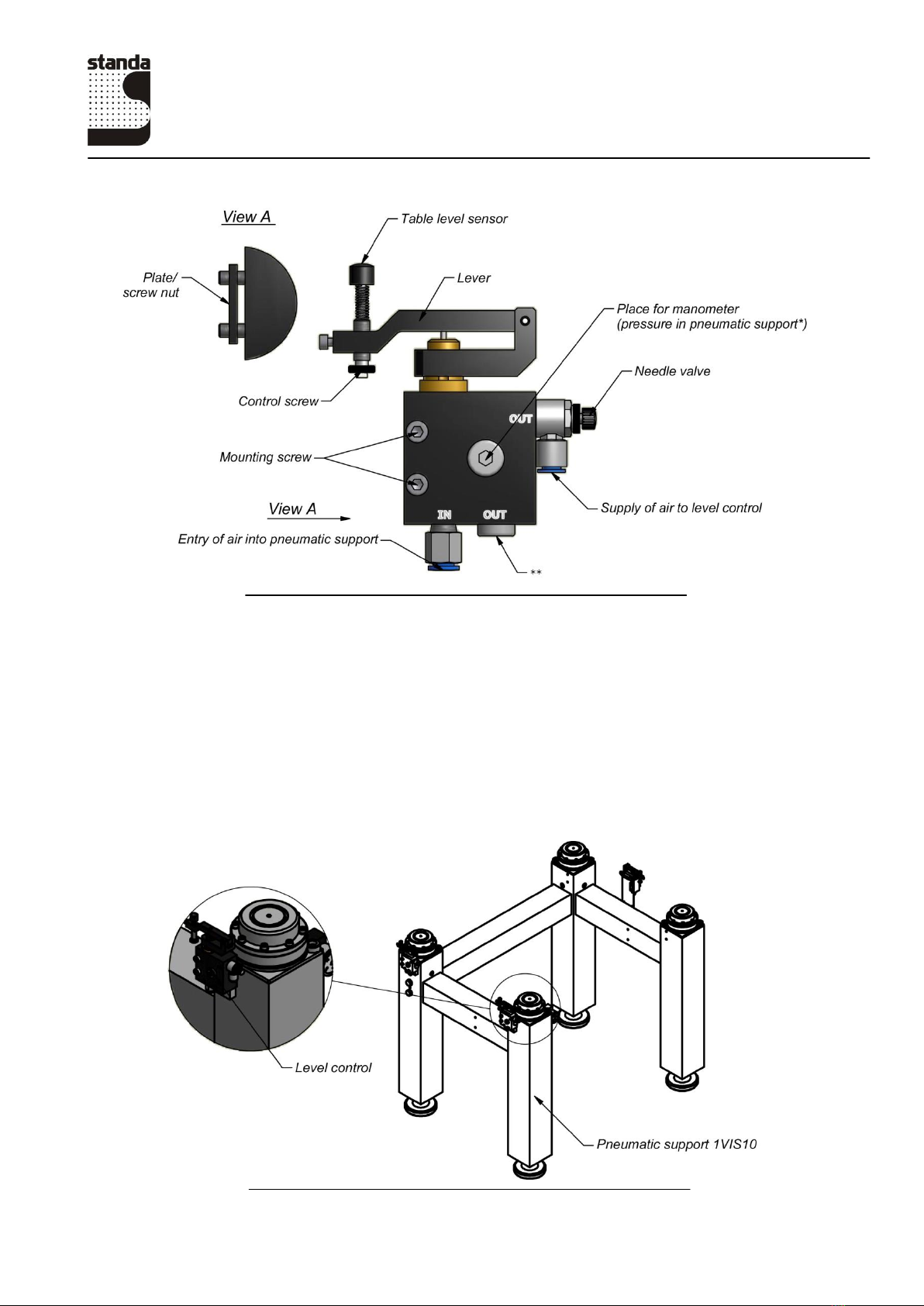

The system is managed by means of level controls; there are 3 controls per system. Please see

fig. 3.

P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

Manufacturer of Opto-Mechanical equipment for research, industry and education http://www.standa.lt

4

Fig. 2. Level control, model 1LV-1WM

* Optional.

** An overpressure relief valve can be provided.

1. Precision of level setting: ± 0.3 mm.

2. Materials:

Body and lever: anodised aluminium, brass, steel, plastic.

A typical vibration isolation system is shown in fig. 3.

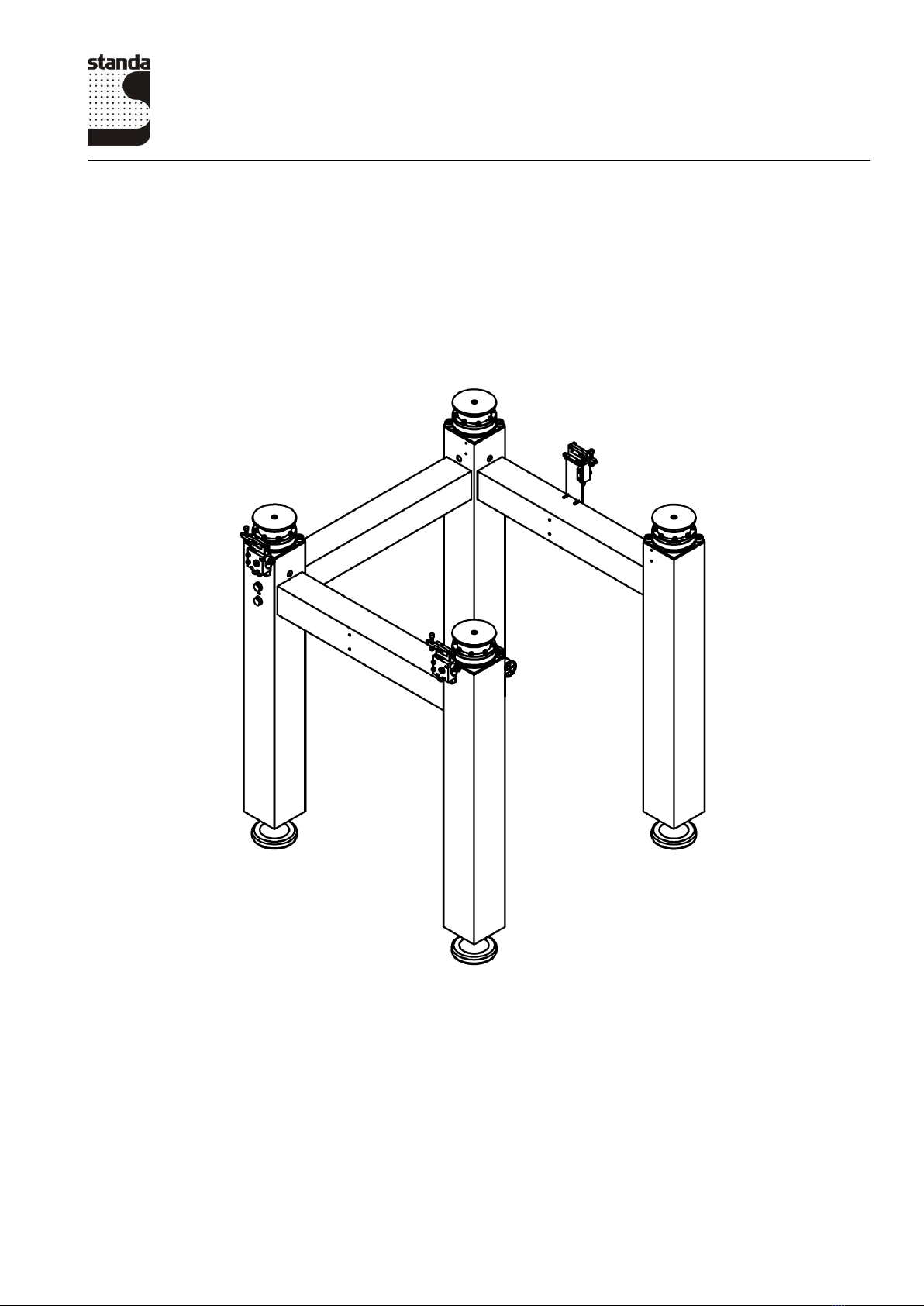

Fig. 3. A typical vibration isolation system

P.O. Box 2684

03001 Vilnius, Lithuania

Phone: +370-5-2651474

Fax: +370-5-2651483

Manufacturer of Opto-Mechanical equipment for research, industry and education http://www.standa.lt

5

1.1.1 Safety

This manual uses certain terms that are important for your safety.

Warning

Used to denote a danger that may result in injury.

Attention

Used to denote a situation that may result in damage to components of the system.

1.2 Location of the table

To ensure optimal operation of the system, it must be installed on a surface that satisfies certain

requirements.

The surface must be even.

It is important that an appropriate location for the system is chosen. The system must be installed

in the vicinity of bearing walls or columns, where the impact of low-frequency oscillation is smaller.

Furthermore, it is advisable to avoid placing the system in the vicinity of other sources of vibration such

as elevators, ventilation systems, industrial equipment, and airflows.

Warning

The system is a metal-made current conductor. If used together with electrical devices, the

table must be earthed.

1.3 Air supply requirements

The operation of the system requires a constant supply of air. After the system has been filled in

and set, air is used only for the operation of level controls when the load on the table changes.

Compressed air tanks (receivers) may be used for keeping the system operative.

The air supply should be clean and dry for the best long-term results. The filtering degree must be at least

10 µm. The filter prevents impurities and water from entering the level controls, thus preventing them

from clogging.

The working pressure of the system is The required minimum working

pressure for the support with the maximum load may be computed using the following formula:

Where:

Pmeans the required pressure in atm (bar).

Qmeans the load on the support with the maximum load including weight of the table top (kg).

Example:

Q= 100 kg

Table of contents