Standart Imaging HDR 1000 User manual

HDR 1000 QA Tool

REF 70008

DOC #80012-04

R

STANDARD IMAGING, INC.

7601 Murphy Drive

Middleton, WI 53562

TEL 800.261.4446

TEL 608.831.0025

FAX 608.831.2202

May / 2004 ©2004 Standard Imaging, Inc. www.standardimaging.com

General Precautions

CAUTION:

Proper use of this device de-

pends on careful reading of

all instructions and labels.

CAUTION:

This device should never

be submerged to clean or

scrubbed with an abrasive

cleaner.

CAUTION:

Insure source freely moves

within secured catheter.

Proper location of source is

necessary to assure proper

calibration.

Warnings and Cautions alert users to

dangerous conditions that can occur if

instructions in the manual are not obeyed.

Warnings are conditions that can cause

injury to the operator, while Cautions can

cause damage to the equipment.

2

!

!

!

Table of Contents

3

2

3

3

4

4

4

5

6

7

8

8

8

9

9

11

11

12

Overview

PAGE

General Precautions

Overview

Wall Mount for QA Measurements

Description

Operation Procedure

A. Initial Procedure

B. Calibrations for Constant, K

C. Standard QA Procedure

Table 5

Documentation of Results

Table 6

Table 7

Parts and Accessories List

Maintenance

Service Policy

Customer Responsibility

Warranty

Accurate delivery of doses using an high dose

rate (HDR) brachytherapy remote afterloading

system depends on predicting the strength of

the radioactive source at the time of treatment,

the precision and consistency of the timer, and

the ability of the unit to position the source at

the proper dwell location along the catheter.

Periodic quality assurance on HDR ma-

chines is a part of the standard protocol of

the user. The HDR QA tool for an HDR 1000

Plus well chamber is designed to verify the

consistency of source positioning, dwell time

accuracy and source activity.

Wall Mount for QA Measurements

A wall mount is available from Standard Imag-

ing for convenient mounting and storage of

the HDR 1000 ion chamber. It is important that

the chamber be located in a consistent loca-

tion for QA measurements. The QA tool can

be placed in the open holder space in the wall

mount that is next to the HDR 1000 chamber

opening. The HDR 1000 chamber can be con-

nected to a standard triax cable while mounted

on the wall.

Note: The HDR 1000 can be used mounted on the

wall for QA measurements, but should not be used

any closer than 25 cm to any wall for calibration

purposes. (See Medical Physics 19: 1311-1314

(1992)). Refer to the Instruction Manual received

with the HDR 1000 for calibration procedures.

7601 MURPHY DRIVE

MIDDLETON, WI 53562

Description

4

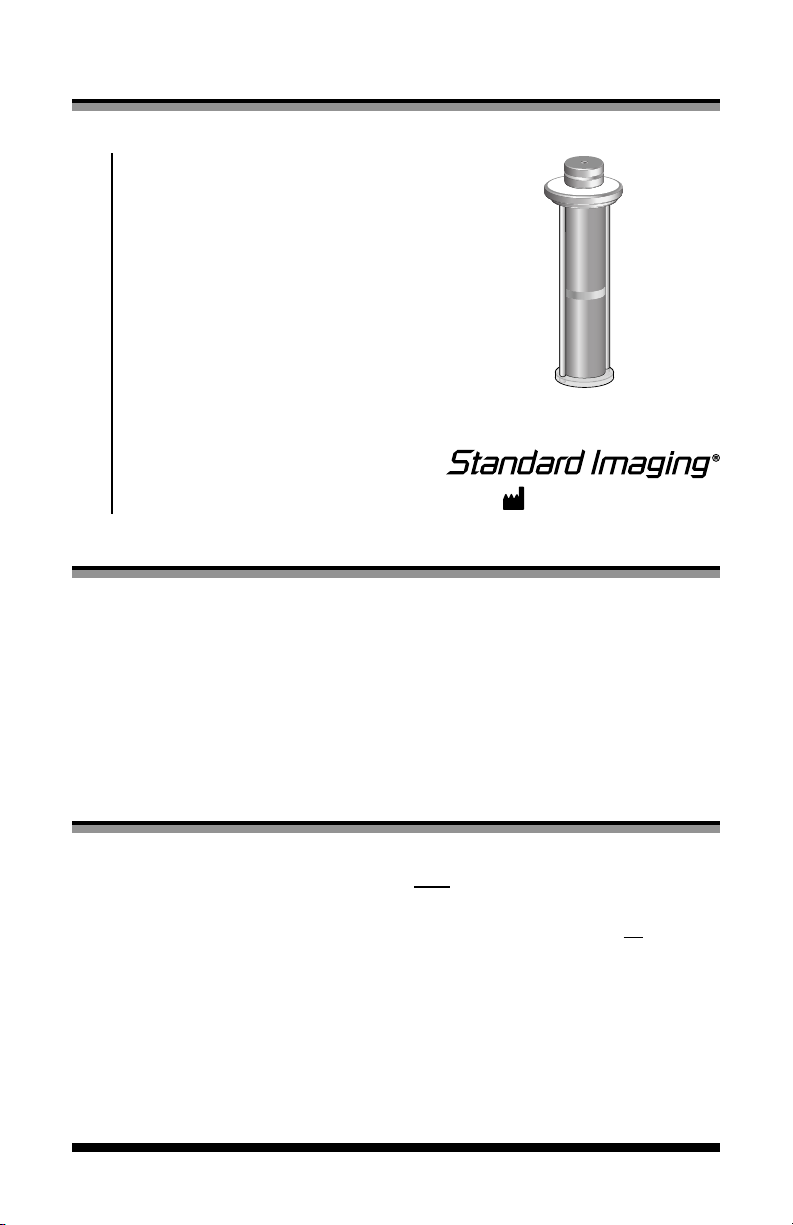

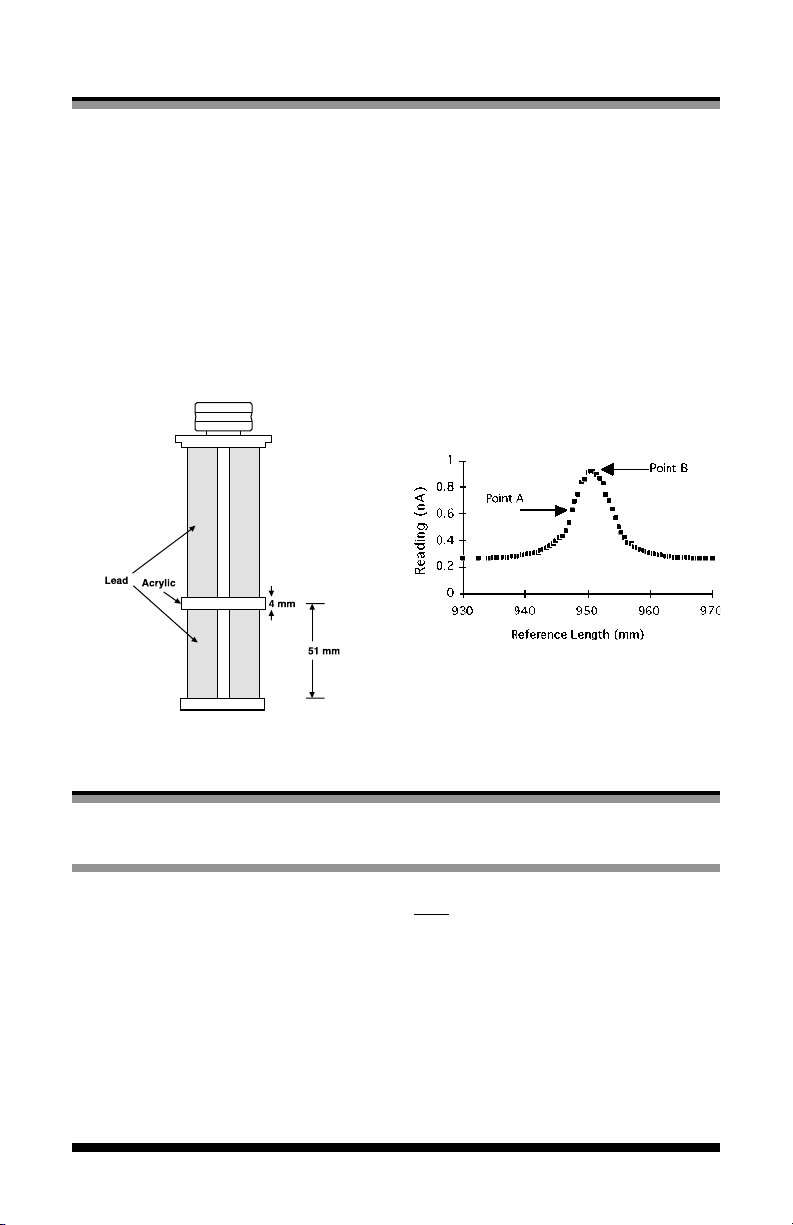

Figure 1 shows a schematic drawing of the

lead lined HDR QA tool insert. This tool is

inserted in the HDR 1000 Plus well chamber

in place of the standard source holder insert.

The distance from the bottom of the tool to

the center of the 4 mm spacer is 51 mm.

The HDR QA tool insert tightly collimates

the radiation received by the chamber to

a narrow plane. When the source lies in

that plane, the chamber responds with a

large signal; when the source falls partially

or completely out of the plane, the signal

greatly diminishes.

Operational Procedure

A. Initial Procedure

1. Insert the HDR QA tool into the well of the

HDR 1000 Ion chamber.

2. Insert the catheter from the HDR after-

loading machine through the opening in the

top of the HDR QA tool. Push the catheter

to the bottom of the chamber and lock the

catheter in place with the provided holding

device. Secure the catheter with the knurled

catheter holding device.

Note: Take care not to kink the catheter and insure

that the catheter is secured and unable to move.

If possible dedicate a catheter to this purpose and

once locked in place, let it remain in the QA tool.

The catheter should have a gentle arc when con-

nected to the HDR unit. Moving the HDR unit can

result in differences in the recorded values; always

keep the unit in the same position. For greater

rigidity a needle catheter is recommended.

This response curve is shown in Figure 2.

For checking positional accuracy, the high

slope regions of Figure 2, designated point

A, are the most useful. For checking dwell

time and activity, a plateau, designated point

B in Figure 2, rather than a peak is desired.

With this tool, the source position verication,

timer accuracy and consistency of the source

activity can be measured in a simpler manner

by using the method described below.

Figure 1: Schematic drawing of HDR QA Tool

Figure 2: Representative response curve

using HDR QA Tool insert of Fig. 1. The high

slope region is designated A and the plateau

region is designated B.

Operational Procedure

5

3. The rst time the tool is used, take data to

determine points A (slope) and B (plateau) as

shown in Figure 2 to document the position

on the HDR system. Point A should be where

the reading equals about 0.5 of the difference

between the maximum value and the trough

value. Point B should lie in the middle of the

maximum plateau. Program the HDR unit to

begin 40 mm from the bottom of the well, and

move by the nest increments to 60 mm from

the bottom, stopping for 10 seconds at each

dwell position. Record the current reading at

each position. If your HDR unit is unable to

determine millimeter sized steps, reprogram

the unit starting with different beginning loca-

tions to ll in the readings between the rst

set of dwell positions.

4. Correct the readings for temperature and

pressure.

5. Determine the values of the constant, K

(See section B. “Calculations for constant,

K” below), for points A and B, corrected to a

standard temperature and pressure. When

the HDR QA tool is rst used, a determination

of the value of K for each of points A and B as

measured above, must be made; thereafter,

it will be a constant for your HDR unit. Thus,

thereafter, only measurements of points A

and B need to be made.

B. Calculations for constant, K

Constant, K, can be determined from mea-

surements of the charge and current at

Points A and B. The concepts behind these

calculations are given in Med. Phys. 22:

435-440 (1995). The following expression

for a constant, K, can be determined from the

measurements for each point taken above:

1) K(x, t) = Q(x,t) * Ctp /Aoe(−λτ) * t

OR

2) K(x) = I(x) * Ctp /Aoe(−λτ)

Where:

K(x,t) is the function that relates the response of

the system to x and time t; this function will be a

constant for a given point of measurement.

Q(x,t) is the charge measured when the source

is in position x for time t, where x is the position of

the source in the QA insert and t is the exposure

time, if using a gated measurement system, or

otherwise the effective time, adjusted for transit-

time effects.

I(x) is the current measured when the source is

at position x

Ctp is the correction for temperature and atmo-

spheric pressure for the ionization chamber.

Ao is the source strength at the time of calibration

of the Ir-192 source

τ is the time since the calibration

λ is the decay constant of Ir-192

When an analysis is done for the uncer-

tainties associated with the parameters

of measurement, the total contribution is

equivalent to 0.7% (See Table 1 for uncer-

tainties for individual measurements). There-

fore, any changes in the value of K greater

than 1.5% may be considered signicant.

Therefore, a 1 mm error in position would

become approximately a 20% change in the

current-based KA, or greater than 10 times

the measurement uncertainty. The standard

deviation of a number of trials without any

changes has been shown to be within 1%.

Table 1: Showing uncertainty in test of K.

Test

Source Position

Dwell Time

Source Activity Consistency

Uncertainty in Test

< 0.1 mm

< 0.7 %

< 0.7 %

Operational Procedure

6

Table 2 lists the ranges of error for position-

ing based on the difference in the value of KA.

If the determinations of ∆KA remain less than

10%, the error in positioning is < 0.5 mm.

Table 3 has listed ranges of error based on

the difference in the value of KB from the av-

erage value of KB. The values given in Table

3 are based on two standard deviation limits

and the uncertainty analysis given above.

For example, if all of the determinations of

∆KB remain within 1%, the user can be as-

sured that the source activity calibration has

remained constant to within 0.1Ci, and the

error in the dwell time is less than 0.1 second

(See Table 3). Table 4 is based on the value

of ∆K and can be used to determine which

item, e.g. source positioning or dwell time,

is in error depending which value or values

of K are out of criterion.

Table 2: Deviation of KA and limits of error for QA Measurements

QA Test

Source Positioning

QA Test

Source Activity

Dwell Time

∆KA < 10 %

< 0.5 mm

∆KB < 1 %

< 0.1 Ci

< 0.1 s

10 % < ∆KA < 20 %

0.5 < x < 1.0 mm

1 % < ∆KB < 2 %

0.1 < A < 0.2 Ci

0.1 < t < 0.2 s

∆KA > 20 %

> 1.0 mm

∆KB > 2 %

> 0.2 Ci

> 0.2 s

Table 3: Deviation of KB and limits of error for QA Measurements

Table 4: Table for determining item in error depending on difference in value(s) of K

Source of error

appears as

Source Activity

Dwell Time

Source Positioning

minor

major

∆K(x)A

off

on

off

off

∆K(x)

off

on

on

off

∆K(x,t)

off

off

on

off

∆K(x)A/∆K(x)B

on

on

off

off

Parameter

Where:

∆K(x)A, ∆K(x)B are for current measurements and ∆K(x,t)B is an integrated measurement.

On means ∆KB < 1%, and ∆KA < 10%, Off means ∆KB > 1% and ∆KA > 10%.

Operational Procedure

7

Note that the values of K are unique for

your chamber and the electrometer used.

Your chamber and electrometer should be

calibrated to give calibration values, e.g. Nx,

unique to your setup. The Nx value and the

electrometer correction factors must be used

as a multiplier for Q and I in the above equa-

tions 1 and 2 for activity calibrations.

If the timer is suspected to be in error, the

timer accuracy can be determined at a

plateau position, Point B, by measuring the

charge accumulated in the amount of dwell

time set on the HDR control. The measured

amount of time can be calculated from equa-

tions 1 and 2 as follows:

3) Q (B, tset) = Q (B) + Q(transit)

Where:

Q(transit) is the reading accumulated while the

source moves into, and returns from, its dwell

position.

Approaching this analogously to that typical

of cobalt units, dene an effective transit

time, tef,tr such that

4) tmeas = β tset + tef,tr

Where:

β is a proportionality factor that should be equal

to unity if the HDR timer is accurate

tef,tr is the equivalent time to account for that part

of the reading produced with the source in transit

going to and returning from its dwell position

tmeas can be calculated by

5) tmeas = Q(B, tset) / I(B)

To solve for the unknowns, b and ttransit, two

different set times must be measured.

(See Table 5).

An assumption could be made that for ease

of use in daily performance of the timer

check, the program should be stored on a

program card or as a “standard” if the unit has

these capabilities. Dwell times in such stored

programs often increase exponentially over

time to compensate for radioactive decay of

the source. Thus, this procedure should not

be done; see Med Phys 22: 435-440 (1995)

for further explanations.

Date

24 May

1 June

2 June

3 June

8 June

9 June

10 June

11 June

I(B)

(nA)

11.780

11.170

11.030

10.890

10.260

10.080

10.180

10.160

Q(B, t1)

(nC)

62.85

59.70

59.45

58.15

54.95

54.65

54.75

54.05

Average

Std Dev

Q(924, t2)

(nC)

121.90

115.70

114.10

112.20

105.80

104.45

104.95

104.50

β

1.003

1.003

0.991

0.993

0.991

0.988

0.986

0.993

0.994

0.006

ttransit

(s)

0.32

0.33

0.44

0.38

0.40

0.48

0.45

0.35

0.39

0.06

Table 5: Example determining of β and ttransit of Equations 4 and 5 for 8 separate measurements.

Operational Procedure

8

C. Standard QA Procedure

1. Set up catheter and QA Tool as described

in steps A1 through A2.

2. Set the HDR unit to move the source to the

selected points A and B from above. Take

current measurements at these points. Then

take a charge measurement each for times

t1 and t2 (e.g. 10 seconds and 5 seconds) at

point B. Record data and calculations on a

chart as shown in Table 6.

3. Correct to a standard temperature and

pressure.

4. Determine the day’s values of the con-

stant, K, at points A and B.

5. Compare the day’s value for K to the ini-

tial value. Determine a percent difference

for the present value of K versus this initial

or average value for each measurement at

points A, and B.

Documentation of Results

Date

Point A

(current)

KA

(nA/Ci)

Point B

(current)

KB

(nA/Ci)

KB

(nC/Ci)

QB(t1)

(nC)

Table 6: QA Chart for HDR Source

Sample QA charts are given in Tables 6 and 7 to retain a record of the QA measurements.

In lieu of using these charts, columns can be added to the facility’s regular QA form.

Initials

QB(t2)

(nC)

HDR UNIT DISTANCE INDICATION

Point B

(integrated)

Date

1/18

1/19

1/20

1/21

1/24

1/25

1/26

Point A

(current)

KA

(nA/Ci)

1.543

1.512

1.508

1.515

1.510

1.559

1.557

Point B

(current)

KB

(nA/Ci)

2.004

2.002

2.005

2.002

2.006

2.009

2.008

KB

(nC/s)/(Ci)

2.003

2.003

2.004

2.002

2.008

2.008

2.008

QB(t1)

(nC)

62.85

63.12

62.80

63.04

62.85

62.95

62.93

Table 7: QA Chart for HDR Source

Initials

SCD

SCD

SCD

SCD

SCD

SCD

SCD

QB(t2)

(nC)

121.90

121.64

121.04

121.48

121.14

121.33

121.28

HDR UNIT DISTANCE INDICATION

Point B

(integrated)

9

Parts and Accessories List

REF

70008

70007

80012

10040

10041

30053

Description

HDR QA Tool

Wall Mount Bracket

HDR QA Tool Instruction Manual

O-Ring, QA Tool

Torque Wrench, QA Tool

Catheter Fixator, QA Tool

Maintenance

If assistance is desired in the proper disposal of this product (including accessories and

components), after its useful life, please return to Standard Imaging.

There are no servicable parts on the QA Tool Insert.

10

Notes

This product and its components will perform

properly and reliably only when operated and

maintained in accordance with the instruc-

tions contained in this manual and accompa-

nying labels. A defective device should not be

used. Parts which may be broken or missing

or are clearly worn, distorted or contaminated

should be replaced immediately with genuine

replacement parts manufactured by or made

available from Standard Imaging Inc.

CAUTION: Federal law in the U.S.A.

and Canadian law restrict the sale,

distribution, or use of this product

to, by, or on the order of a licensed

medical practitioner. The use of this

product should be restricted to the

supervision of a qualified medical

physicist. Measurement of high activ-

ity radioactive sources is potentially

hazardous and should be performed

by qualied personnel.

Should repair or replacement of this product

become necessary after the warranty pe-

riod, the customer should seek advice from

Standard Imaging Inc. prior to such repair

or replacement. If this product is in need of

repair, it should not be used until all repairs

have been made and the product is function-

ing properly and ready for use. After repair,

the product may need to be calibrated. The

owner of this product has sole responsibility

for any malfunction resulting from abuse,

improper use or maintenance, or repair by

anyone other than Standard Imaging Inc.

The information in this manual is subject to

change without notice. No part of this manual

may be copied or reproduced in any form or

by any means without prior written consent

of Standard Imaging Inc.

11

Customer Responsibility

!

If service, including recalibration, is required,

please contact Standard Imaging’s Customer

Service department by phone or email prior

to shipping the product. Standard Imaging’s

Customer Service and Technical Service

staff will attempt to address the product is-

sue via phone or email. If unable to address

the issue, a return material authorization

(RMA) number will be issued. With the

RMA number, the product can be returned

to Standard Imaging. It is the responsibility

of the customer to properly package, insure

and ship the product, with the RMA number

clearly identied on the outside of the pack-

age. The customer must immediately le

a claim with their carrier for any shipping

damage or lost shipments. Return shipping

and insurance is to be pre-paid or billed to

the customer, and the customer may request

a specic shipper. Items found to be out of

warranty are subject to a minimum service

fee of 1 hour labor (excluding recalibrations)

for diagnostic efforts and require a purchase

order (PO) before service is performed. With

concurrence from customer, the product may

be replaced if it is unserviceable or if the

required service is cost prohibitive. Products

incurring service charges may be held for

payment. Standard Imaging does not provide

loaner products. See the Standard Imaging

Warranty and Customer Responsibility for

additional information.

Service Policy

12

Warranty

Standard Imaging, Inc. sells this product under the warranty herein set forth. The war-

ranty is extended only to the buyer purchasing the product directly from Standard Imaging,

Inc. or as a new product from an authorized dealer or distributor of Standard Imaging, Inc.

For a period provided in the table below from the date of original delivery to the pur-

chaser or a distributor, this Standard Imaging, Inc. product, provided in the table is

warranted against functional defects in design, materials and workmanship, provided

it is properly operated under conditions of normal use, and that repairs and replace-

ments are made in accordance herewith. The foregoing warranty shall not apply if

the product has been altered, disassembled or repaired other than by Standard Imag-

ing, Inc. or if the product has been subject to abuse, misuse, negligence or accident.

Product Warranty Period

Standard Imaging Ionization Chambers 2 years

Standard Imaging Well Chambers 2 years

Standard Imaging Electrometers 2 years

Standard Imaging Software Products 1 year

All Other Standard Imaging Products 1 year

Standard Imaging Custom Product 90 days

Consumables 90 days

Serviced Product 90 days

Resale Products As dened by the Original Equipment Manufacturer

ADCL Product Calibration

(Standard Imaging uses the UW-ADCL for

recalibrations required under warranty)

0 - 90 days = 100% of ADCL Calibration Costs

91 - 182 days = 75% of ADCL Calibration Costs

183 – 365 days = 50% of ADCL Calibration Costs

366 – 639 days = 25% of ADCL Calibration Costs

(days from date of shipment to customer)

Standard Imaging’s sole and exclusive obligation and the purchaser’s sole and exclusive

remedy under the above warranties are, at Standard Imaging’s option, limited to repairing,

replacing free of charge or revising labeling and manual content on, a product: (1) which con-

tains a defect covered by the above warranties; (2) which are reported to Standard Imaging,

Inc. not later than seven (7) days after the expiration date of the warranty period in the table;

(3) which are returned to Standard Imaging, Inc. promptly after discovery of the defect; and (4)

which are found to be defective upon examination by Standard Imaging Inc. Transportation

related charges, (including, but not limited to shipping, customs, tariffs, taxes, and brokerage

fees) to Standard Imaging are the buyer’s responsibility. This warranty extends to every part

of the product except consumables (fuses, batteries, or glass breakage). Standard Imaging,

Inc. shall not be otherwise liable for any damages, including but not limited to, incidental

damages, consequential damages, or special damages. Repaired or replaced products are

warranted for the balance of the original warranty period, or at least 90 days.

This warranty is in lieu of all other warranties, express or implied, whether statutory or otherwise,

including any implied warranty of tness for a particular purpose. In no event shall Standard Im-

aging, Inc. be liable for any incidental or consequential damages resulting from the use, misuse

or abuse of the product or caused by any defect, failure or malfunction of the product, whether

a claim of such damages is based upon the warranty, contract, negligence, or otherwise.

This warranty represents the current standard warranty of Standard Imaging, Inc. Please refer

to the labeling or instruction manual of your Standard Imaging, Inc. product or the Standard

Imaging, Inc. web page for any warranty conditions unique to the product.

This manual suits for next models

1

Table of contents

Other Standart Imaging Medical Equipment manuals