8

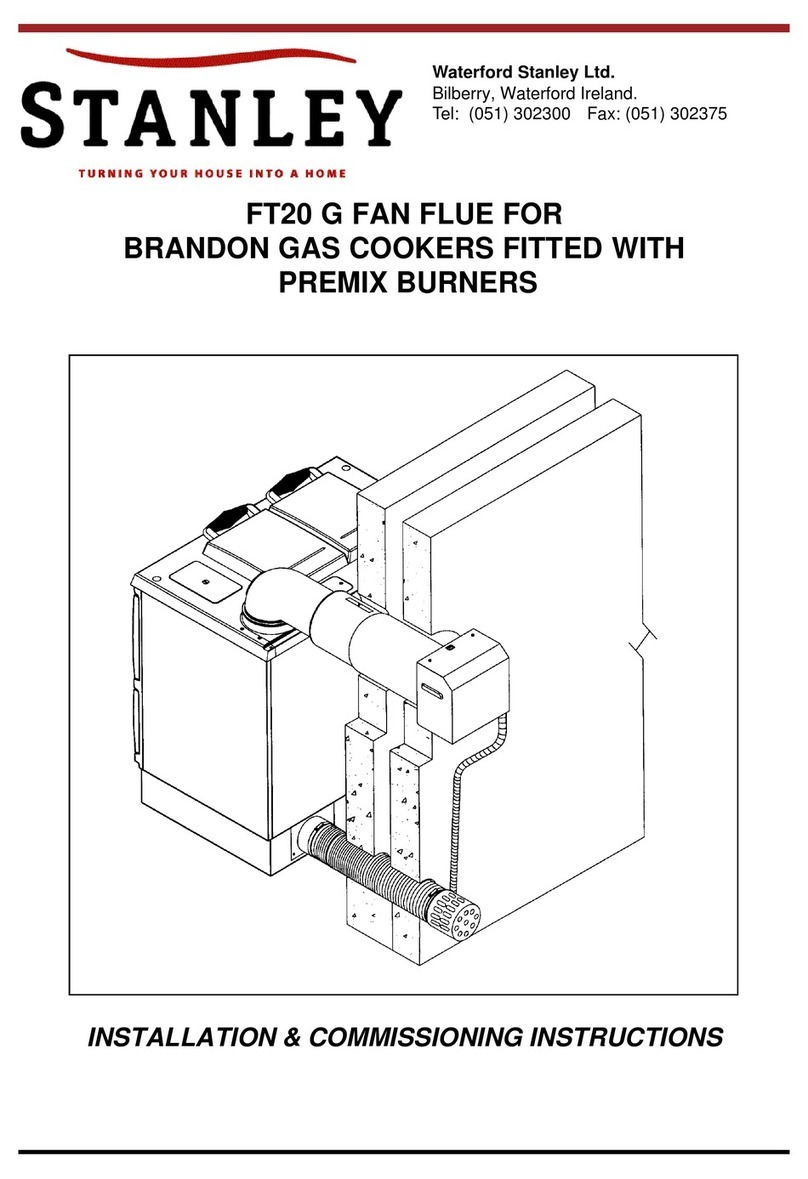

FLUES

The flue pipe must be fitted with a cleaning access.

The flue and chimney must be inspected at least

twice annually and cleaned when necessary. During

periods of non-use, the flueway through the appli-

ance should be ventilated. By leaving the spinwheel

or ashdoor open, this will prevent the build up of

condensation.

The position of all flues and chimneys must comply

with Building Regulations.

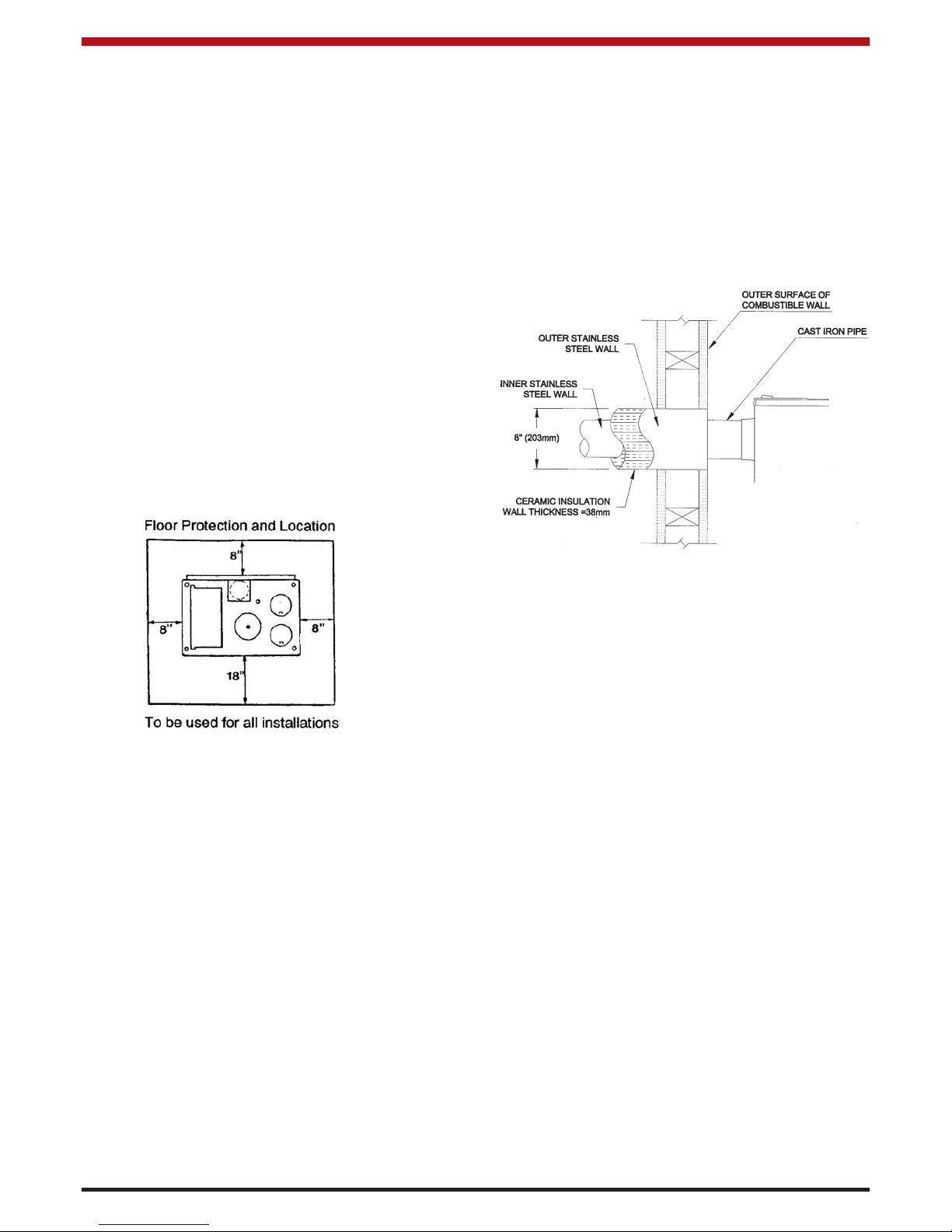

FLUE PIPES

A flue pipe should only be used to connect an appli-

ance to a chimney and should not pass through any

roof space.

Flue pipes may be of any of the following materials:

(a) Cast iron as described in BS 41:1973 (1981)

(b) Mild steel with a wall thickness of at least

3mm.

(c) Stainless steel with a wall thickness of at least

1mm and as described in BS EN 10095:1999

specification for stainless and heat resisting

steel plate, sheet and strip, for grade 316 S11,

316 S13, 316 S16, 316 S31, 316 S33, or the

equivalent Euronorm 88-77 designation.

(d) Vitreous enamelled steel complying with

BS 6999: 1989.

FLUE CLEANING

The flue pipe must be fitted with a cleaning access.

the flue and chimney must be inspected at least

twice annually and cleaned when necessary. During

periods of non-use, the flueway through the appli-

ance should be ventilated. By leaving the spinwheel

or ashdoor open, this will prevent the build up of

condensation.

CHIMNEY

The Waterford Stanley Solid Fuel Range must be

connected to a Factory-Built Chimney, installed in

accordance with the manufacturer’s instructions or a

lined masonry chimney, acceptable to the authority

having jurisdiction. An existing masonry chimney

should be inspected and if necessary repaired by a

competent mason or be relined using an approved

relining system.

THE CHIMNEY SERVING THIS WATERFORD

STANLEY SOLID FUEL RANGE SHOULD NOT

SERVE ANY OTHER APPLIANCES. If you intend

to use a fireplace chimney, the fireplace opening

must be sealed. The overall height of the chimney,

measured from the floor on which the Range is

installed must be at least 4.572 meters (15ft).

Do not use more than two elbows.

Chimneys for use with solid fuel appliances should

be capable of withstanding a temperature of 1100oC

without any structural change which would impair

the stability or performance of the chimney.

Chimney’s should be built in accordance with BS EN

15287-1:2007, Design, installation and commission-

ing of chimney.

USE OF EXISTING FLUES AND CHIMNEYS

The spigot of this appliance will accept a 5” flue pipe.

Stanley cast iron pipes are highly recommended for

interior use. When connecting to an existing chim-

ney it is necessary to line the flue using either 6”

(150mm) rigid or flexible stainless steel flue liner. It

is not premitted to reduce the diameter of the con-

necting pipe to less than the appliance outlet

between the appliance and the chimney.

An existing flue pipe or chimney that has proved to

be satisfactory when used for solid fuel can normal-

ly be used for this appliance provided that its con-

struction, condition and dimensions are acceptable.

Flues that have proven to be unsatisfactory, particu-

larly with regard to down draught, must not be con-

sidered for venting this appliance until they have

been examined and any faults corrected. If there is

any doubt about an existing chimney, a smoke test

should be carried out.

Before connecting this appliance to a chimney or

flue pipe which has previously been used with

another fuel, the chimney or flue pipe must be thor-

oughly swept and/or lined accordingly.

All register plates, restrictor plates and dampers etc.

which could obstruct the flue at a future date must

be removed before connecting this appliance.

The combustion products from this appliance will

have a descaling effect on hardened soot deposits

left from burning solid fuels.

ALTHOUGH THE CHIMNEY MAY HAVE BEEN

CLEANED OF LOOSE SOOT PRIOR TO INSTAL-

LATION, IT IS IMPERATIVE THAT THE CHIMNEY

IS INSPECTED FOR SCALED SOOT PARTICLES

AFTER THE FIRST MONTH OF OPERATION AND

ANY LOOSE MATERIALS REMOVED TO AVOID

BLOCKAGE.