STEP 7.

(a) Connect the air inlet terminal

(item 6) to the flexible duct

(item 5) and tighten using the

remaining jubilee clip (item 7).

ELECTRICAL CONNECTION

STEP 1.

Isolate the mains supply to the

cooker.

STEP2.

Open the right hand side of the

cooker and pull out the control tray

which holds the printed circuit board.

Fix the speed controller to the tray

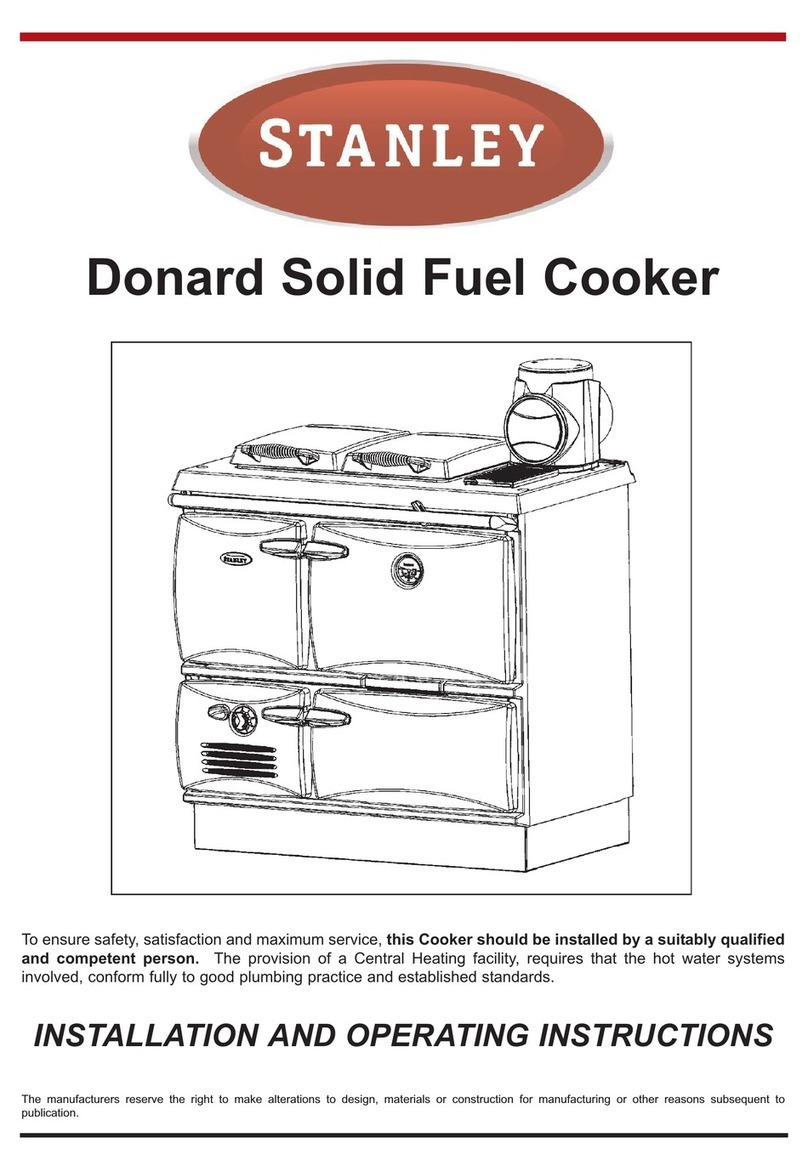

as shown in Fig.9.

STEP 3.

Feed the connection cable through

the air inlet terminal until it can reach

both the fan flue terminals and the

speed controller terminals. It is rec-

ommended to protect the section of

connection cable from the fan flue to

the air inlet terminal with galvanised

trunking.

4

STEP 4.

Connect the speed controller to the

cooker loom by first removing the

blanking 6-way connector and then

replacing it with the 6-way connec-

tor coming from the speed con-

troller. Connect the live (brown

wire) and neutral (blue wire) to the

two terminals on the speed con-

troller and also to terminals 1 & 2

on the fan flue. Connect the earth

wire to the eyelet provided on the

fan flue and to the earth connection

block on the printed circuit board

near to the speed controller.

STEP 5.

Reinstate the electrical supply.

COMMISSIONING

STEP 1.

Turn the 3 speed controllers to the

max position (fully clockwise).

STEP 2.

Turn on the boiler burner on its own

and adjust the draught to .04” wg

(1mm wg) using the speed con-

troller marked boiler.

Turn on both burners together and

adjust the draught to the above

requirement using the speed con-

troller marked boiler & oven. Turn

off the boiler burner leaving the

oven burner running on its own,

adjust the draught to the above

requirement.

STEP 3

Run both burners for approximate-

ly 10-15 minutes, repeat Step 2. as

the draught will change as the

appliance heats up.

STEP 4

Check the combustion gas rate and

the combustion and compare to the

table below.

TABLE 2

NOTE: It is essential that the

draught be correctly set as it can

effect the input rate of the appli-

ance.

IMPORTANT: Air inlets to the

appliance and FT20 must NOT

be obstructed.

CO2 (%) FLUE DRAUGHT GAS RATE

(“ wg) LITRES/MIN

OVEN 9.3-9.9 .04 27.5

BOILER - 100K 8.5 - 9.3 .04 52

- 80K 9.3 - 9.9 .04 42

DUAL .04

Fig.9

Fig.8

Note: Seal around the joints where

the fan interfaces with the horizon-

tal flue section.

ALL ELECTRICAL CONNECTIONS

SHOULD BE CARRIED OUT BY

QUALIFIED ELECTRICIANS.