Stanwax Laser ILDA Gem Laser projector tool User manual

1

Thank you for purchasing Stanwax Laser ILDA Gem laser projector tool.

The ILDA Gem is a simple device that is essential for the toolbox of any laser pro or amateur and allows you to operate a

laser projector for set-up, testing or alignment without having your laser hardware and computer operational. Onboard

there is a quadrature generator that will output a single ended signal to the X/Y lines. The board outputs either a full 5V or

a variable level (0-5V) to the modulation signal lines (up to 6 lines). All this can be achieved with the device powered from

the supplied USB power adaptor or you can connect a laser controller to the device allowing the same 5v or variable level

to the modulation lines while displaying an ILDA X/Y signal from your laser hardware.

Powering the ILDA Gem

The board must be powered up using the supplied power adaptor cable, which can be plugged into any computer USB

1.0, or 2.0 socket or have its power provided by connecting it to the optional mains power adaptor. The board requires 5V

dc at <5mA so will not adversely load a computer USB socket.

Operation using the supplied power adaptor

When the board is powered from the supplied power adaptor the on board quadrature generator will operate and will

output to the scanner X/Y signals of the projector. The generator will produce a single ended quadrature output (square

pattern) at aprox. 18kpps. As its output is single ended the square will be output in one of the four quadrants of the

normal projector output area (see image below) The quadrant in which the output will appear will be dependant on the

wiring and configuration of the laser projectors scanners. This action is normal.

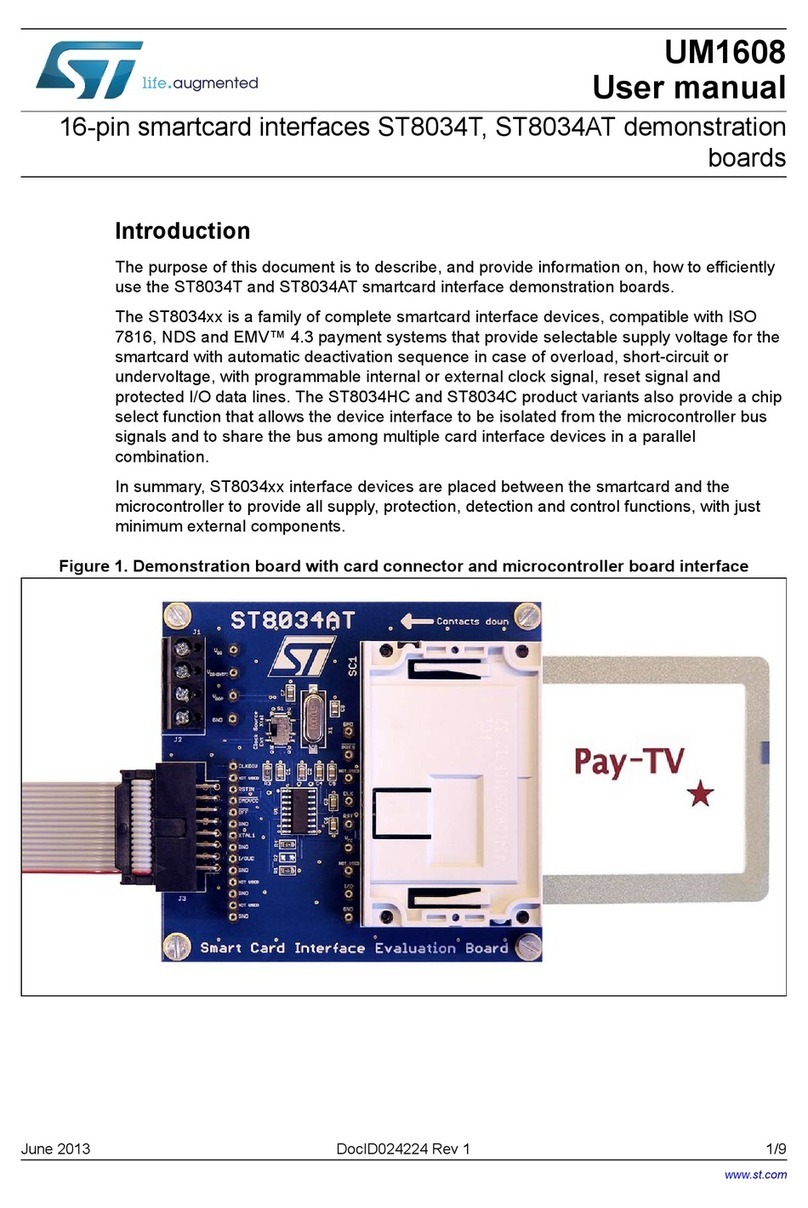

The board layout can be seen in the image right.

The 3 slide switches select full 5V output when moved toward

the output connector this is useful for testing the full power

output of the lasers in a projector. When the slide switches are

moved towards the input connector the level that is fed to the

colour outputs is controlled by the 3 pots providing a lower level

output. This is useful for alignment or fine adjustment purposes

making these tasks much safer.

The switched colour lines can also be routed to the additional

user defined colour lines (as per Ilda standard) by way of the 3

sets of solder links at the edge of the board as indicated (right).

The factory setting is for these solder pads to be left unused. If

they are utilised, each line must only be joined to one output or

damage to the board may occur.

Solder pad set UD1 is connected to Ilda pin 8, UD2 to pin 9 and

UD3 to pin 10. Each of these can receive its signal from the red

green or blue signals from the switches and pots.

Output will be in one of the four quadrants

shown above

Operation with an ILDA signal

If using an Ilda signal from a laser controller such as QM2000 or FB3

then power is supplied from the shutter signal line therefore the ILDA

Gem will only output a signal to the modulation lines in this mode when

the laser output is enabled in the software. When an ILDA signal cable

is attached then the onboard quadrature generator will automatically be

disabled and scanner output will be provided from the laser controller.

In this mode the laser controller hardware will NOT provide blanking to

the modulation inputs of the projector, the slide switches and pots on

the Ilda Gem board will provide these signals.

ILDA Gem Laser projector tool

Instructions

2

WARNING

It is possible when using this device to output a full power static beam. Precautions must be made to ensure the output is

adequately terminated to ensure injury or fire does not occur. Always use suitable laser eye protection when working on a

laser projector and ensure that no other humans or animals can become exposed to the laser beam. It is advised that

before starting one should make sure that the laser projector output is terminated to a suitable screen or surface that is

capable of absorbing the laser energy without adverse effects.

Note: To prevent damage to the scanners of the laser projector always connect, disconnect and power up the ILDA Gem

with the laser projector power off. Once connected as described below the laser projector can be powered.

ILDA Gem in use

To use the ILDA Gem, simply connect the ILDA output connector to a laser projector using a standard ILDA lead (25-way

M-F). By removing the nuts on the output connector it may be possible to connect the ILDA Gem directly to the laser

projector ILDA input negating the use of a cable (this will be dependant on the position of the ILDA input connector of the

projector). It is recommended to start with all the slide switches set to the variable output position (toward ILDA input

connector) and the pots turned to minimum. Connect the power adaptor cable to the ILDA input connector and put the

USB connection into a USB port on a computer or if you have an optional mains adaptor you can fit the USB lead into

this. Any USB power source with a standard USB socket will provide a power source for the ILDA Gem.

Power up the laser projector and increase the level of one or more of the pots until you see an output from the projector

which will be in the form of a quadrature square test pattern (see image below left).

To use an ILDA signal from a laser controller such as QM2000, turn the laser projector off and remove the ILDA Gem

power adaptor cable. Then connect the laser hardware to the ILDA Gem ILDA input connector using a standard ILDA

lead and start the projector. When laser output is enabled the 5V or variable level output controls will act as before but the

scanners will output the X/Y content sent from the controller. This output will appear with blanked lines visible as in the

image above right.

Note: when using with and ILDA signal if the slide switches are set for 5V and the scan size is reduced to zero in software

then a full power static beam can be produced. Take care to terminate this beam or injury or fire could result.

Using the UD (user defined) signal lines

The user defined signal lines (as defined by ILDA standard) can be used if required. Each or the lines has a set of 3

solder pads associated with it and each of these allows the user to connect one colour output (as provided by the slide

switches) to one UD line. Simply join the pair of pads required with a small blob of solder as shown below right – Note the

correct way of using these pads with only one pair in each group used at any time. If you choose to join UD1 with the red

channel then anything that is output to the red modulation line will be output to UD1 as well.

What you get in the package – Ilda Gem and 2.5m USB

power lead

Image left shows graphic with blanked lines.

Image right shows normal view without blanked lines

To output full 5V to any one of the

modulation signals change the slide

switch position so that it is towards the

Ilda output connector and that line will

go to full power.

Please note the warning at the top of

this page about output of a high power

beam when 5V output is used.

3

Selecting a different scanrate

The ILDA Gem’s built in quadrature generator outputs its test pattern at 18kpps by default, however with a small

modification the ILDA Gem will output at 12kpps or 30kpps. To change the scanspeed you must make a modification

using a soldering iron. If you are not competent with a soldering iron please get someone who is, to make the mod.

Alternatively we can provide the ILDA Gem pre configured to the scanrate you prefer.

ILDA Gem Specification

Power supply – 5VDC from USB port using supplied adaptor cable or 5V from ILDA shutter signal.

Current consumption – <5mA

Dimensions LxWxH – 75mm x 57mm x 32mm (inc switches and pot shafts)

Scanner output – Single ended 5V p-p quadrature output at 12,18 or 30kpps

Modulation output – 0-5V variable or 5V fixed

Accessories – 30cm ILDA Ribbon lead

– Mains USB power supply (UK Euro or US)

Note: When operating the ILDA Gem with an ILDA signal provided from a laser controller such as a QM2000 or FB3

some images may appear slightly distorted in one corner. This does not indicate a fault, reducing the scan size and

panning the image away from the corner where the distortion appears can alleviate the effect of this.

V1.03 © Stanwax Laser 2011

12k setting 30k setting

The default setting for the scanrate is 18kpps if this rate

is acceptable then no modification is needed.

Note: before carrying out the mods disconnect the ILDA

Gem form the laser projector and power source.

To set to 12k

Simply place a blob of solder across pins 7 & 8 of the

chip on the underside of the pcb as seen in the left of

the image. Once joined every time the ILDA Gem is

powered up it will set to 12kpps scanrate.

To set to 30k

You must first carry out the mod to convert to 12kpps

as described above. In addition a link should be placed

between the joined pins 7&8 and pin 3 of the chip as

shown in the right of the image.

Removing the mods at any time in the future will revert

the ILDA Gem to the factory default 18kpps scanrate.

To use an external switch to select the scanrate you

can wire a centre off toggle or slide switch using the

diagram left. The centre position will give the default

scanrate of 18kpps.

The scanrate will be applied to the ILDA Gem at

power up, changing the switch when running will not

affect the scanrate.

Other Stanwax Laser Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Saturn Systems

Saturn Systems Accelerator II Operation manual

Inalp Networks

Inalp Networks SmartNode 1000 Series installation guide

Fujitsu

Fujitsu FMC-16LX/FR user guide

ZALMAN

ZALMAN FC-ZV9 user manual

Renesas

Renesas Single-Chip Microcomputer M34551T2-MCU user manual

Intellinet

Intellinet 550512 user guide

Lexicon

Lexicon MPX - ADDENDUM REV 1 manual

CrossCore

CrossCore EZ-KIT Lite quick start guide

LG

LG Wowcast WTP3 owner's manual

Uctronics

Uctronics Raspberry Pi quick start guide

Acronova Technology

Acronova Technology Xymba XB-42 Operation manual

Mellanox Technologies

Mellanox Technologies MCX353A-FCCT user manual