Stara 14000 TRAILER Technical reference manual

WARRANTY CERTIFICATE

(CLIENT’S COPY)

DEALERSHIP INFORMATION

CLIENT INFORMATION

PURCHASED UNIT INFORMATION

INVOICE NUMBER:

TECHNICAL DELIVERY DATE: / /

IMPORTANT!

Warranty issues will only be address if this certificate is properly

filled-out at the time of delivery by technician. This certificate must be

presented with every warranty claim, along with the sales invoice.

NAME:

NAME PHONE:

MODEL:

MANUFACTURED DATE:

SERIAL NUMBER:

STAMP AND SIGNATURE:

ADDRESS

:

:

cut and send

We declare that the implement referenced in this document, is being delivered under normal

conditions of use, as described and, with the various adjustments and instructions.

_____________________________________, ______ / _______ / _______.

Place Date

INSTRUCTIONS AND DIRECTIONS

TECHNICIAN FUNCTIONS:

OPERATOR INSTRUCTIONS REGARDING:

( ) Check general conditions of the

( ) Wheel tightness.

implement (defects, dents and other issues).

NOTE: ( ) Using the security chain on the

hitch/goose-neck. .

( ) Using the support stand.

( ) Using the systems (hydraulic, eletric and

( ) Hook-up trailer to the tractor and check drive-shafts).

all systems (hydraulics, electric, drive-shafts). ( ) The instruction manual, warranty

( ) Operate all systems. certificate and warranty claims.

( ) Check all wheels for tightness. ( ) Operation of the treatment system and

( ) Deliver the instruction manual. calibrations.

( ) Test all output rates and calibrate

(Treatments and Defensive).

TECHNICAL DELIVERY TERMS

(this form must be completed by the technician and sent to stara)

CUSTOMER DATA

PURCHASED PRODUCT DATA

MODEL:

MANUFACTURED DATE

NAME: PHONE No.:

OPERATOR(S) NAME(S):

ADDRESS:

TECHNICIAN/DELIVERY AGENT:

INVOICE No.:

DELIVERY DATE / /

:

cut and send

ADDITIONAL INFORMATION

CUSTOMER SIGNATURE TECHNICIAN OR DEALER’S SIGNATURE

Instructions for Warranty Claims

Technical Delivery

A) Stara, claims the right of a Technical Delivery to the original owner/purchaser

of the equipment, touching on the following items like: assembly, adjustments,

operations, maintenance and warranty.

B) The owner of the machine should designate one or more operators to be

trained.

C) It shall be up to the owner, that all instructions listed in the Operation and

Maintenance Manual be adhered to and be rigorously followed.

D) Maintain the equipment and all respective manuals in a perfect state of

conservation, and on a regular maintenance schedule, thus preserving the right

to warranty claims.

Warranty Terms

1) The warranty here expressed is the responsibility of the equipment dealership

along with the owner/purchaser of said equipment. Thus, it is understood, that

there is no direct dealings between the said owner/purchaser and the factory.

2) It is here defined that the first purchaser of the equipment is the DEALERSHIP,

and the second ownership will be here established as the CLIENT.

3) The following conditions are basic and will be that, the dealership will submit to

Stara's judgment all warranty claims.

Conditions of the Warranty

A) Stara guarantees its product “only to” the DEALERSHIP, and for the period of

six months, starting on the day of delivery to the CLIENT, along with the original

invoice and warranty certificate, which must be presented at the time of claim.

B) Stara restricts its responsibility strictly to the terms herewith contained in this

warranty, which will become non-transferable an will terminate automatically, in

case of the resale of the equipment by the second owner, the CLIENT or warranty

termination by the CLIENT.

C) The warranty covers exclusively material defects and/or of fabrication defects,

being that, labor, freight, and other expenditures are not covered by the

Warranty, for they are the responsibility of the DEALERSHIP.

D) Requested revisions by the CLIENT, even though the equipment is still under

warranty, will be subject to charges.

E) The warranty of parts and components which were replaced, will end herewith

the warranty of the equipment.

F) In cases of warranty service delays, those will not warrant the purchaser the

right to indemnity for damages, or extension of the warranty.

Items Excluded from the Warranty

Not included are such items as: hydraulic oils and lubricants, filters, greases and

the like,charges for roadside assistance or help, on-site assistance and any

equipment maintenance or help by Stara personnel; all these are the

responsibility of the purchaser.

Also not inclusive are: tires, inner tubes, electrical and electronic equipment,

batteries, engine, starter motor, alternator, fuel injection pump, these again are

not inclusive of Stara's warranty since they have specific manufacturer's

warranty on each of said components.

Other charges or expenses such as: transportation or travel expenses, towing

services, material damages or damages against the owner or his agents , these

are the sole responsibilities of the purchaser, until otherwise proven through the

results of investigations done by qualified and certified agents of the state or

government.

Warranty Forfeiture

The warranty will become null and void at such time as:

A) it is established that the defects or damages are the result of, inappropriate

use of the equipment, through the failure of not following instructions as

specified on the supplied manual, or the failure of untrained or inexperienced

operators.

B) the product suffered repairs or modifications in repair shops which are not part

of Stara's authorized dealerships.

C) the parts or components present damages due to inappropriate use, or

damaged by other parts which are not genuine or original parts of the equipment,

by the end user.

D) the product suffers any type of misuse, even to the extent of causing safety

issues,concerns or breaches, and it will be per the company's judgment on such

matters, and it will carry the final word, until otherwise proven through the results

of investigations done by qualified and certified agents of the state or

government.

E) the equipment is not up to date on all current revisions or upgrades, and/or if

the owner will not furnish solicited documentation.

F) the hydraulic system is contaminated by impurities of unauthorized or non-

recommended fluids.

G) the equipment is found to have damaged, scraped, illegible or no ID plate.

H) the warranty is found to have incomplete or erroneous information or any

unauthorized alterations.

I) the equipment was adversely misused in situations such as: working or was

driven at speeds which exceeded recommended speeds, overloading

equipment during work, etc.

Note: Any fabrication defects and/or material defects, the object of this

warranty, will not constitute, and under no hypothesis will it be a motive to rescind

any purchase or sales contracts/agreements, nor will it warrant the purchaser the

right to indemnity of any nature, save only those established by Consumer

Rights or Civil Codes; as specified in the country of purchase or sale.

TECHNICAL ASSISTANCE

Besides the instruction manual, the users of Stara products can call the nearest

authorized dealership to obtain any needed assistance. The dealership, by its

own merit, can seek information and assistance from the After-Sales

Department at Stara, whenever a difficult situation presents itself, or the need

arises to resolve any problems.

REPLACEMENT PARTS

Parts replacement should only be done using original parts from Stara,

the which , besides preserving the warranty rights as a consumer, will

not compromise the operation and the maintenance of the equipment.

PROJECT MODIFICATIONS

Stara S/A reserves the right to introduce project modifications of its

products for the end of its improvements or refinement, regardless of

any obligations to upgrade any previously manufactured equipment.

Stara S/A Agricultural Machinery and Implements, Ind.

Não-Me-Toque, RS, Brazil

INSTRUCTION AND

PARTS MANUAL

STARA S.A. - Agricultural Machinery and Implements Industry

AV. STARA, 519

Não-Me-Toque,RS - Brazil

CEP 99470-000

Phone/Fax:+55 54 3332-2800

e-mail: [email protected]

Home page:

August 2009 - Rev.:A

www.stara.com.br

Constant Evolution

14000 TRAILER

INTRODUCTION

TECHNICAL SPECIFICATIONS

SAFETY MEASURES

Mounting the Protective Screens,Above‑box and the Enclosure Center

Joint.Mounting the Universal Conveyor Screw System o250mm

Mounting the Funnel

Mounting the Conveyor Screw Supports and Rests

Mounting the Conveyor Screw.......................

Mounting the Conv.Screw,Tension Cable and Telescopic Tube.

Mounting the Hydraulic System.

Installing the Independent Hydraulic System

Mounting the Tarp Arches

Installation of the Rear Hydraulic Braking System

(optional)

Brake Adjustments.

TRACTOR HOOK‑UP

USING AND ADJUSTING THE CONVEYOR SCREW ‑250 mm

Operation of the Independent Hydraulic System

Mounting and Using the Auto‑fill Package

Use and Cautions of the Hydraulic System

Loading Planters and Spreaders in the Field using the o250mm Conveyor

Screw

Gear Box System Adjustments

Procedures for Maneuvering During Jobs

Installing the Conveyor Screw Chassis Supports

Installing the First Stage of the Conveyor Screw onto the Chassis...

Installing the Second Stage of the Conveyor Screw

Operating the Independent Hydraulic System

...............................................................................................06

1 - ....................................08

2 - ....................................09

3 - . ..... ...........................................................09

4- ...................................................................................12

5 - ..........................................................................................12

5.1 - Caring for the Reservoir.........................................................................12

5.2 - Tightening and Lubrication....................................................................13

5.3 - Caring for the Paint Job and Clean-up....................................................13

5.4 - Tire Pressure.........................................................................................13

6 - FIELD ASSEMBLY........................................................................................14

6.1 - Mounting Wheels onto the Wheel Axle...................................................14

6.2 - Mounting Wheel Axle and Chassis Support Stands...............................14

6.3 - Mounting the Hitch/Goose-neck...........................................................15

6.4 - Mounting Auxiliary Accessories.............................................................16

6.5 - Reservoir Installation............................................................................17

6.6 -

..................................................................................................................18

6.7 - ....................19

6.7.1 - ......................................................................19

6.7.2- ........................19

6.7.3 - ................................20

6.8 - ...........20

6.9 - ............................................................21

6.10 - .......................................22

6.11 - ....................................................................23

6.12 -

...........................................................................................................23

6.13 - .............................................................................23

7 - ...................................................................................24

8 - CONVOY HOOK-UP.....................................................................................25

9 - ...................26

9.1 - ....................................26

9.2 - ..............................................26

9.3 - ............................................27

9.4 -

................................................................................................................28

9.5 - ..............................................................29

9.6 - ..............................................30

10 - INSTALLATION OF THE 350 mm CONVEYOR SCREW SYST.(OPT.)........31

10.1 - .................................31

10.2 - ....31

10.3 - .............................32

10.4 - ......................................32

MAIN COMPONENTS..............................................

IDENTIFICATION PLATE..........................................

MAINTENANCE

TABLE OF CONTENTS

10.5 - .......33

10.6 - ...............................................33

10.7 - ................................................34

10.8 - ........................................................35

10.8.1 - ...........................................................35

10.8.2 -

........................................................................................................35

11 -

36

12 - ...................................37

13 - ..37

14 - .......................................................................................40

14.1 - .......................................................40/41

14.2 - .........................................................................42

14.3 - .....................................................................................43

14.4 - .........................................................44/45

14.5 - .........................................................................46

14.6 - ...........................................................................47

14.7 - .........................................................................48

14.8 - ...............................................................................49

14.9 - .................................................................................50

14.10 - .....................................................................................51

14.11 - ...........................................................52

14.12 - .........................................................53

14.13 - .....................................................................54

14.14 - Protective/ ......................................................55

14.15 - .....................................................................................56

14.16 - ...................................................................57

14.17 - ...............................................58

14.17 - ..........................................58

14.18 - .................................................59

14.19 - .................................60

14.19 -

14.20 - ...........................................................62

14.21 - ..................................................63

14.22 - ............................................................64

14.23 - ............................................65/66

14.24 - ...........................................................67

14.25 - ....................................................................68

Using the Chute for Grains and the Telescopic Tube for Fertilizers

Field Loading Planters and Spreaders.

Shadowing the Harvesters in the Field

Use and Adjustments..................

Adjusting the Slide‑Gate

Adjusting the Conveyor Screw Gear Box Chain using the Tension

Adjustment

HYDRAULIC SYSTEM PROBLEMS,POSSIBLE CAUSES AND/OR

SOLUTIONS.....................................................................................................

AVAILABLE OPTIONS FOR THE 14000 TRAILER...

ADDITIONAL OPTIONS AVAILABLE FOR THE 14000 TRAILER.............

PARTS CATALOG

Standard Package Assy..........

Rear Wheel Axle Assy

Rear Hub Assy

Lower Front Wheel Axle Assy

Front Left Hub Assy....

Front Right Hub Assy

Boxed Standard Parts

Chassis Sub-assy

Above-Box Assy

Ladder Assy

Wheel Frame Support Bracket

Upper Front Wheel Frame Assy

Hitch/Goose-neck Assy

Cat-walk Screen Assy

Funnel Assy

Supply/Feed Chute Assy

Conveyor Screw-250mm/Motor 50l ...

Conveyor Screw-250mm/Motor 80l.........

Telescopic Conveyor Screw-250mm

Output Conveyor Tube-250mm/50l..................

Output Conveyor Tube-250mm/80l...................................................60

Motor Gear Assy.....................

Universal Conv. Screw Hyd.System

Pressure Filter Assy (Hidrafil)

Lower Conv. Screw Support-250mm

Conv. Screw Support-250mm

Front Conv. Screw Rest

14.26 - ......................................................................69

14.27 - ..........................................................70

14.28 - .............................................................................71

14.29 - ....................................................................72

14.30 - ....................................................................................73

14.30 - ...........................73

14.31 - .......................................................74/75

14.31 -

14.32 - ..............................................................................76

14.33 - .... ........................................................................77

14.34 - .......................................................78

14.35 - ............................79

14.36 - .....................................80

14.36 - ......................80

14.37 - ...............................................................81/82

14.37 - .......................................................81/82

14.38 - .......................................................................83

14.39 - .............................................84

14.40 - .............................................................................85

14.41 - .................................................86

14.42 - ....................................................87

14.43 - .................88/89

14.44 - .............................................91

14.45 - ................................................................92

14.46 - ....................................................................93

14.47 - ..........................................................94

14.48 - .............................95/96

14.49 - C ......................97

14.50 - Decal Set..........................................................................................98

Rear Conv. Screw Rest

Conv. Screw Support Arm........

Supply Link-Chain

Chassis Support Stands

Brake System

Brake System-Optional (f/Wheel 7"x20"Mercedes)

Indep. Hyd. System-SHS 80L

Indep. Hyd. System-SHS 50L.......................................................74/75

Drive-Shaft Assy

Door Frame Assy

Second Stage Conv. Screw Assy

Telesc. Conv. Screw-350mm-w/Fertilizer Opening

Conv. Screw Support / First Stage................

Conv. Screw Support / First Stage-Rice.......................

First Stage Conv. Screw

First Stage Conv. Screw-Rice

Central Bushing Assy

Conv. Screw Support Brackets-350mm

Conv. Screw Rest

Frontal Conv.Screw Support Bracket

Rear Conv.Screw Support Bracket

Indep. Hyd. System Assy-80l/min................................

Slide-gate Stop Kit-f/ Fertilizer..............

Electrical System- w/Lamp

Slide-gate Hydraulic Kit

Conv. Screw Hyd. Kit...............

Indep.Hyd.Sys. Kit- SHS/Conv. Screw 350mm

onvoy/Tow Hook-up Assy..........................................

INTRODUCTION

Dear Client,

STARA makes available to you exclusive call-ins to the After-Sales

Department, to better assist you and your dealer, so that you will optimize the

usage of your equipment.

NOTE: This manual is available on our site: along with

information on our complete line of products.

Stara S/A Agricultural Machinery and Implements, Ind.

Não-Me-Toque, RS, Brazil

You have just become the proud owner of an implement manufactured

with the highest cutting edge technology, which also had the direct participation of

rural producers in its development.

Fertilizers in general are highly corrosive when used on steel based

materials (high oxidation). Due to the nature of this problem and at the request of

our customers, Stara sought out new alternative materials, with the vision in mind

to end the corrosion problem of its products.

The 14000 Trailer has stream-line characteristics on its chassis structure

and other components, which avoid fertilizer built-up and thus the ease of clean-

up, which when coupled with good maintenance, will guaranty a long working life

cycle. Besides these, the product reservoirs and output openings are also made of

non-corrosive materials such as, polyethylene and stainless-steel. The conveyor

screw tube is of a synthetic material(PVC), also non-corrosive.

During clean-up or maintenance, the reservoirs can be remove and lifted

to gain access to residue built-up on the chassis, they will not need to be painted or

bathed with oil for preservation.

The 14000 Trailer, besides its primary function, which is to fill the planters

with fertilizers, can also be used to transport and store grain during the harvest,

since the 250mm conveyor screw is sized to this end, thus reducing damages to

the grain.

The 250 mm conveyor screw can be exchanged by the 350 mm conveyor

screw, which increases the output rate thus allowing it to support, increasing their

capacities by 50%. The 250 mm conveyor screw can also be used as an auto-

filler.

The 14000 Trailer being used properly and following a scheduled

maintenance program, will have a long fruitful life, turning your investment highly

profitable. Even with all these advantages, it is necessary to use this implement

correctly, and that it should be properly stored. Thus, carefully read the instruction

manual and keep it in good conditions, for future references.

www.stara.com.br,

6

7

1 -

The 14000 :

MAIN COMPONENTS

Trailer is made up of some basic components

A- Front Road Wheel Axle J - Telescopic Tube f/ Fertilizer

B - Rear K - Protective Screen

C - Chassis L -

D - M - Tarp Arches

E - N - Support Stands

F - Steering Axle O - Above-box

G - Doorway- ø250mm P - Auto-filler (optional)

H- Independent Hyd. System Hyd. Brake System (Optional)

I - Conv. Screw- ø250mm

Road Wheel Axle

Ladder

Hitch/Goose-neck

Reservoir

A

D

L F

H

C

E

O

MJ

K

I

B

G

P

N

Figure 01

8

Figure 02

3 - TECHNICAL SPECIFICATIONS

Dimensions:

- Total Length w/Conveyor Screw.......................................................6,650mm

- External Wheel Width w/Dbl wheels 9.00”x20”.................................3,420mm

- External Wheel Width w/Single wheels 9.00”x20”............................3,120mm

- Height w/o top covers.......................................................................2,900mm

- Height w/ top covers.........................................................................3,250mm

- Wheels:

- Front: W16”x26” - 8 holes (Optional)..........................................02

7.50”x20” - 8 holes (Standard).........................................02

7.00”x20” - 8 holes (Optional)..........................................04

- Rear: 15”x30” - 8 holes (Optional)...................................................02

15”x34” - 8 holes (Optional).............................................02

7.00”x20” Merc. RC213410DU - 8 holes (Standard).......04

-Tires:

- Front: 18.4”x26” (Optional)..........................................................02

9.00”x20” or 10.00” x 20” (Standard)................................02

9.00”x20” or 10.00” x 20” (Optional).................................04

- Rear: 18.4”x30” (Optional)..........................................................02

18.4”x34” (Optional)..........................................................02

9.00”x20” or 10.00”x20” (Standard)..................................04

2 - ID PLATE

The ID plate (Figure 02) shows the model no. of the machine, weight, serial

no., and also the date manufactured. This information is fundamental in the

traceability of the machine

during its life cycle. The ID plate

is placed on the chassis of the

implement.

..

9

- Wheel Axles: - Rear - With rigid dis-mountable spindles.

- Front - With spinning dis-mountable

- With an irregular pantog. steering system.

- With a balancing beam type system.

Grain Reservoir: - Reservoir made of polyethylene, with orange

pigmentation, with storage capacity of 5m³

each, mounted on carbon steel chassis.

- Output chute and slide-gate made of

stainless steel.

- Maximum load capacity: - Leveled with above-box: 12.4m³ or 14tons.

- Total weight w/o tires and wheels: 2,310 kg

- Paint (predominant colors): - Chassi: Polyester Green; Ral 6010.

- Reservoir: Pigmented orange.

Output System:

- Output Tube for grains and fertilizers, has a dia. of 238 mm and a length of 5.2m,

moved by a hydraulic motor made by Parker, model no.TE50(Optional

TE80).

- Rates: 600 to 900 kg/min. (Recommended working press.: 120 kg/cm²; 230 to

450rpm on screw).

- Conv. Screw working angle: 45 degrees.

- : 3.8 m

-Hydraulic Braking System(optional): activated by the tractor’s hydraulic controls,

and applied to the trailer’s rear wheels.

NOTE: When using tires sized at 9.00”x20” or 10.00”x20”, use the proper

support stands to compensate for the lower heights of the wheels.

spindles.

Conv. Screw output height

10

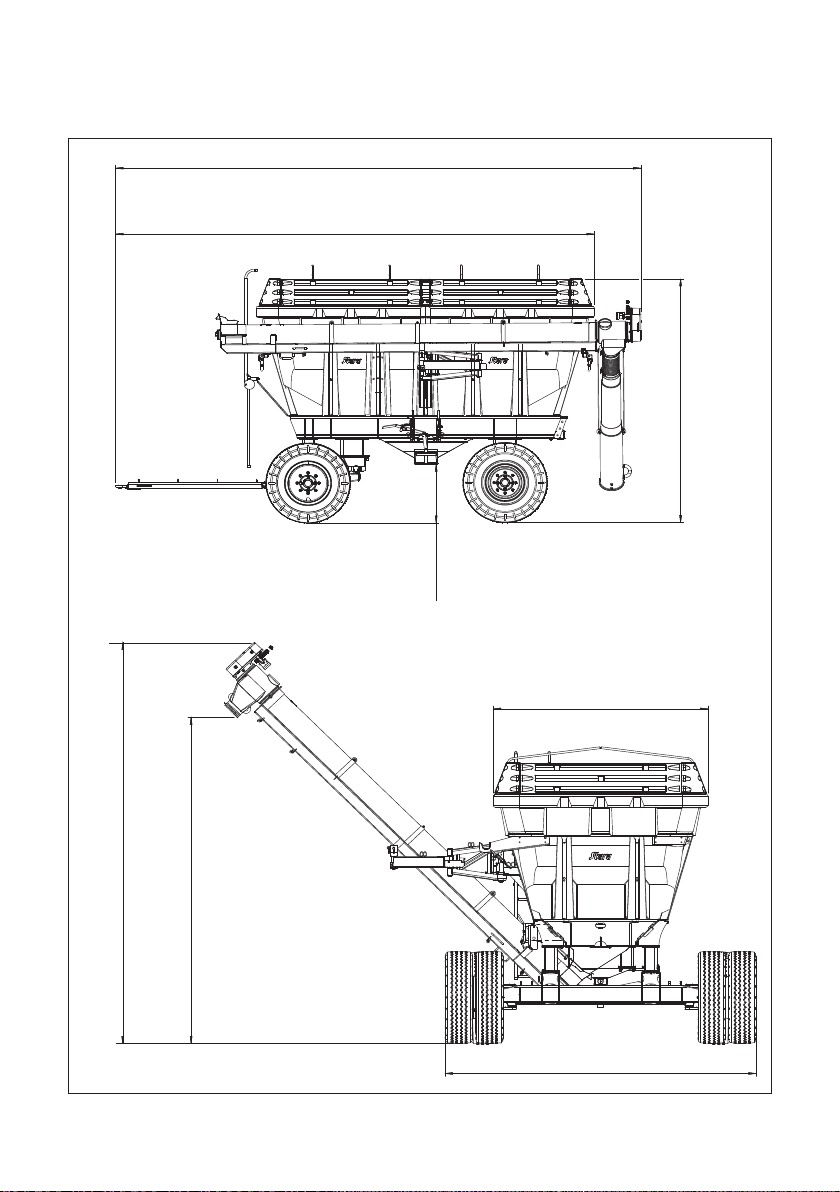

Dimensions:

Figure 03

6650 mm

6060 mm

2360 mm

3420 mm

3250 mm

780 mm

4647 mm

3781 mm

11

4 -

The 14000

any other implement or agricultural machinery, it is necessary to take

precautionary safety measures, to avoid accidents:

- implement, use the same gears used while

climbing (braking motor).

- Before unhooking the trailer from the tractor, block the tires securely;

- After covering the trailer with a tarp, avoid walking on the edges of the reservoir

and use the ladder, thus you will reduce the chances of falling and accidents;

- Read and follow the instructions listed on the decals of the implement, which

inform you regarding operations and maintenance;

- Never perform any inspections inside the conveyor screw when the tractor is

turned on;

- Stay clear of the drive-shaft while it is operating.

SECURITY MEASURES

Trailer is a piece of equipment relatively simple to use, but, like

-

- Scan the area around the implement and tractor, before performing any

maneuvers, so as to not hurt or damage personnel, animals or obstacles.

- After engaging the trailer to the tractor’s traction bar, remember to install the

locking pin onto the hitching pin.

When going down-hill with the

5. -

5.1 -

The reservoir is made of medium-high density polyethylene and has

characteristics for high durability, even while being exposed to sun, rain and

temperature variations. But, applying certain cares will further extend the usable

life of the reservoirs, like:

• Maintain the trailer under cover when not in use.

• Avoid erratic and high impacts which can cause fractures and cracking.

• Do not drag sharp objects on the surfaces of the reservoir.

• Do not drop solid or hot objects inside the reservoir.

• Use smooth movements when mounting or dismounting the reservoir.

NOTE: The 14000Trailer was designed in such a way the its components

will not impregnate with product residue, for all its parameters are bent outward or

downward.

Verify that the trailer and tractor are in good working conditions.

SPECIAL CARE AND MAINTENANCE

Caring for the Reservoir

12

Table of contents

Other Stara Farm Equipment manuals

Popular Farm Equipment manuals by other brands

KINZE Manufacturing, Inc.

KINZE Manufacturing, Inc. 3700 Operator's manual

greenhouse sensation

greenhouse sensation Hydropod Assembly and maintenance instructions

Landoll

Landoll 9630FH Operator's manual

Land Pride

Land Pride RCM4715 Operator's manual

J&M

J&M nitro gro 6018 manual

MASCHIO GASPARDO

MASCHIO GASPARDO DC - DC RAPIDO Use and maintenance