TM

Model 3700M0275-01

Rev. 10/18 i

Table of Contents

OVERVIEW

To The Owner ..................................1-1

Warranty ......................................1-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

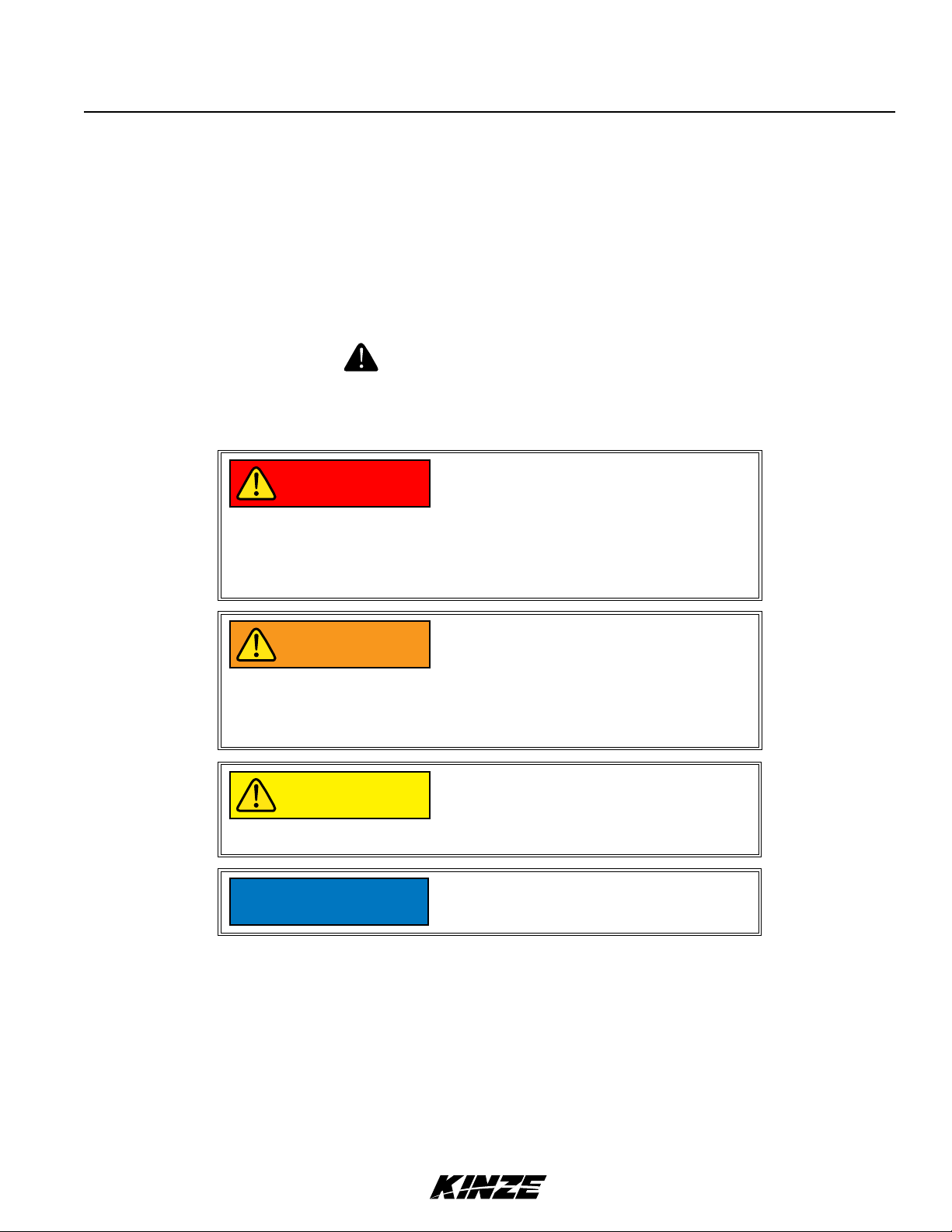

General Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

MACHINE OPERATION

Planter Lift Safety Lockup .........................2-1

Row Marker Safety Lockup ........................2-1

Hitch Parallel Linkage Lockup ......................2-2

2-Speed Jack Assembly ..........................2-2

Initial Planter Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Tractor Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Vacuum Tractor Mounted PTO Pump and

Planter Mounted Hydraulics .....................2-5

Tractor Preparation and Hookup ....................2-6

Transporting Planter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cylinder Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Hydraulic Hose Information .......................2-11

Level Planter ..................................2-16

Contact Wheel Spring Adjustment. . . . . . . . . . . . . . . . . . 2-16

Contact Wheel Drive Sprockets . . . . . . . . . . . . . . . . . . . . 2-17

Seed Rate Transmission Adjustment . . . . . . . . . . . . . . . . 2-17

Wrap Spring Wrench Operation ...................2-18

Shear Protection ...............................2-18

Sliding Hitch Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Hydraulic/Electric Operation ......................2-20

Transport to Field Sequence ......................2-21

Field Operation ................................2-25

Field to Transport Sequence ......................2-26

Row Marker Operation...........................2-30

Row Marker Speed Adjustment . . . . . . . . . . . . . . . . . . . . 2-31

Row Marker Chain Adjustment ....................2-32

Row Marker Length And Disc Blade Adjustment.......2-33

Vacuum System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Vacuum Fan Valve Block Assembly . . . . . . . . . . . . . . . . . 2-34

Analog Vacuum or Pressure Gauge. . . . . . . . . . . . . . . . . 2-34

Ag Leader Integra Display . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Ag Leader Monitoring Control Package (PMM) . . . . . . . . 2-35

Ag Leader InCommand 1200 Display ...............2-35

Point Row Clutches .............................2-37

Two-Speed Point Row Clutches. . . . . . . . . . . . . . . . . . . . 2-38

Piston Pump ..................................2-39

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Low-Rate (Pop-Up) Liquid Fertilizer System ..........2-40

Rear Trailer Hitch (24 Row 70 CM Only) .............2-40

Field Test .....................................2-41

Field Check Seed Population. . . . . . . . . . . . . . . . . . . . . . 2-41

Determining Kilograms Per Hectare (Brush-Type Meter)

. . . . . 2-42

Determining Liters Per Hectare ....................2-42

Field Check Granular Chemical Application ..........2-43

Water Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

ROW UNIT OPERATION

Planting Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

“V” Closing Wheel Adjustment (Rubber or Cast Iron)

.....3-1

Closing Wheel Shield

(Rubber or Cast Iron “V” Closing Wheels) . . . . . . . . . . . 3-1

Drag Closing Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Covering Discs/Single Press Wheel Adjustment ........3-2

Seed Hoppers ..................................3-3

Seed Meter Drive Release. . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Row Unit Extension Brackets. . . . . . . . . . . . . . . . . . . . . . . 3-3

Row Unit Chain Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Quick Adjustable Down Force Springs Option

(Standard or Heavy Duty) .......................3-5

Pneumatic Down Pressure ........................3-6

Brush-Type Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Finger Pickup Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Vacuum Settings ...............................3-10

Seed Meter Cleanout. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Additives .....................................3-14

Bayer Fluency Agent ............................3-15

Frame Mounted Coulter (Pull Row) .................3-16

Residue Wheels (Frame Mounted Coulter) ...........3-16

Row Unit Mounted Disc Furrower (Pull Row) .........3-17

Row Unit Mounted Residue Wheel .................3-18

Spiked Closing Wheel ...........................3-19

Row Unit Mounted No Till Coulter ..................3-20

Coulter Mounted Residue Wheels . . . . . . . . . . . . . . . . . . 3-20

Granular Chemical Hopper and Drive ...............3-21

Spring Tooth Incorporator ........................3-21

Granular Chemical Banding Options . . . . . . . . . . . . . . . . 3-22

Granular Chemical Bander Shield . . . . . . . . . . . . . . . . . . 3-22

RATE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1