IMPORTANT SAFETY INFORMATION

Dress properly. Do not wear loose clothing, dangling objects, or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in moving parts.

Wear the proper personal protective equipment when necessary. Use ANSI Z87.1 compliant

safety goggles (not safety glasses) with side shields, or when needed, a face shield. Use a dust mask

in dusty work conditions. Also use non-skid safety shoes, hard-hat, gloves, dust collection systems,

and hearing protection when appropriate. This applies to all persons in the work area.

Always test the function of the engine control module before operating the trowel. DO NOT operate

the trowel if the engine control module is not functioning properly.

2

DANGER: Internal combustion engines present special hazards during operation and fuelling. Read

and follow the warning instructions in the engine owner’s manual and the safety guidelines below.

Failure to follow the warnings and safety guidelines could result in severe injury or death.

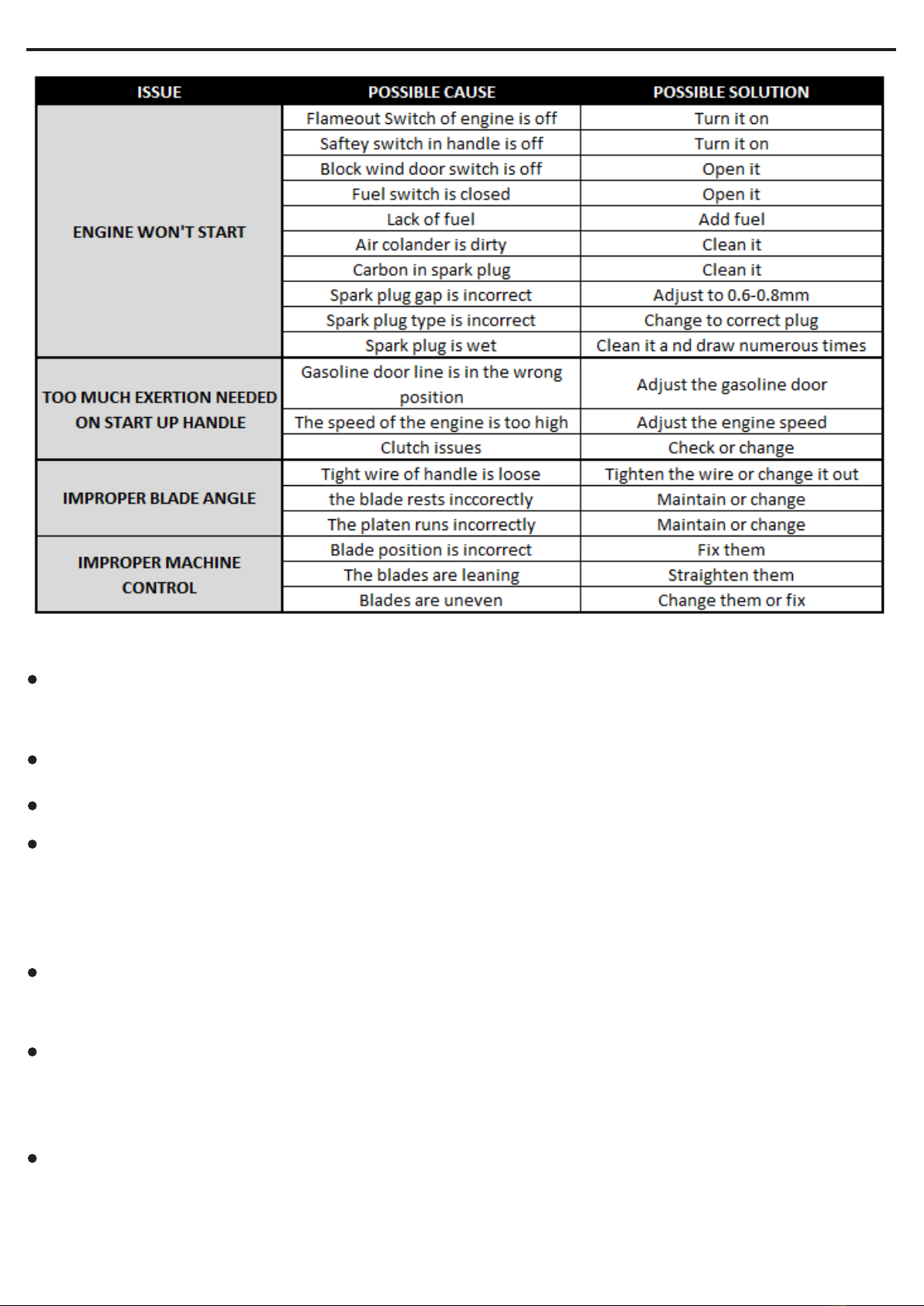

Check for damaged parts before each use. Carefully check that the product will operate properly

and perform its intended function. Replace damaged or worn parts immediately. Never operate the

product with a damaged part.

DO NOT run the machine indoors or in an enclosed area such as a deep trench unless adequate

ventilation, through such items as exhaust fans or hoses, is provided. Exhaust gas from the

engine contains poisonous carbon monoxide gas; exposure to carbon monoxide can cause loss of

consciousness and may lead to death.

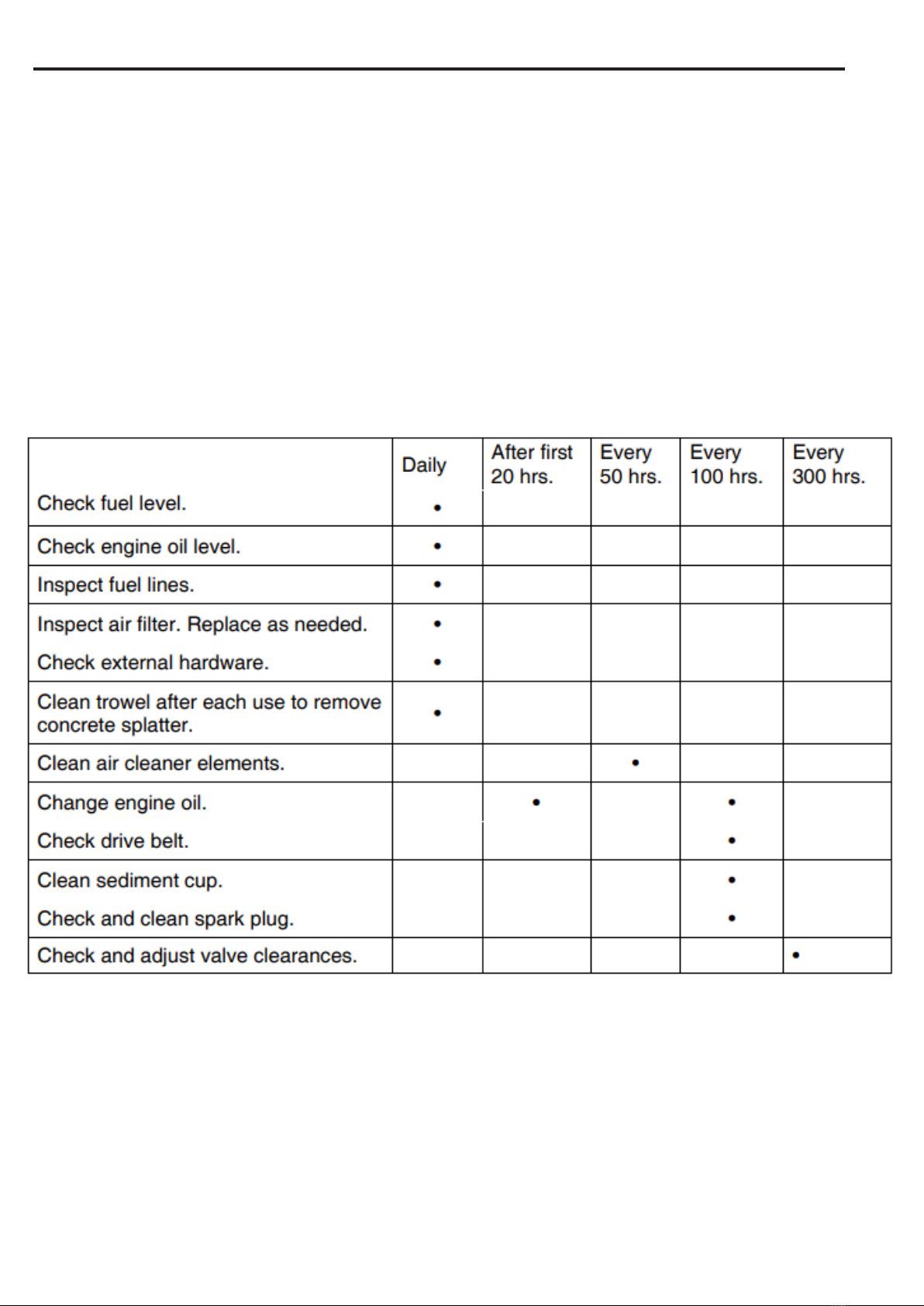

WARNING: Poorly maintained equipment can become a safety hazard! In order for the equipment to

operate safely and properly over a long period of time, periodic maintenance and occasional repairs

are necessary.

DO NOT attempt to clean or service the machine while it is running. Rotating parts

can cause severe injury.

DO NOT crank a ooded engine with the spark plug removed on gasoline-powered engines. Fuel

trapped in the cylinder will squirt out the spark plug opening.

DO NOT test for spark on gasoline-powered engines if the engine is ooded or the smell of gasoline

is present. A stray spark could ignite the fumes.

DO NOT use gasoline or other types of fuels or ammable solvents to clean parts, especially in

enclosed areas. Fumes from fuels and solvents can become explosive.

DO NOT remove blades while the machine is hanging overhead.

ALWAYS support the machine securely before changing blades.

ALWAYS disconnect the spark plug on machines equipped with gasoline engines, before servicing,

to avoid accidental start-up.

ALWAYS keep the machine clean and labels legible. Replace all missing and hard-to-read labels.

Labels provide important operating instructions and warn of dangers and hazards.

ALWAYS handle blades carefully. The blades can develop sharp edges which can cause serious

cuts.