Start Shaphon SH-2012AH-QG User manual

ModelSH-2012AH-QG

(V5.0-1.0)

CNC

CuttingMachine

User'sManual

Contents

FunctionalOverview

MainMenu

AUTO

MAN

EDIT

Command System

SETUP

LIBMINIT

DIAGNOSE

I/OInterface

Appendix

1. Pin definitionsofheightcontroller

2. SH-2012AH-QG Software

UpgradingInstructions

3. InstallationDimensionalDiagrams

4. Troubleshooting

5. Wiring InstructionsofExtended

ManualControlBox

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Beijing StartM&E Technology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG切割机数控系统说明书(C002)

1

All rights reserved

Forbiddentodistributeorduplicateanyfileforthepurposeofcommercial,communicationorotherswithoutparticular

authorization.Compensationwillbeincurredifanyclauseisviolated.AllrightsbelongtoBeijingStartMicrostep

Control TechnologyCo., Ltd.

Disclaimer

Wehavemadeaconsistency inspectiontothecontentsoftheprintedfileagainsttheproductdescribed.However, we

can tguarantee absoluteaccuracy duetotheimpossibilitytoeliminateinaccuracy completely.Nevertheless,wewill

verifytheinformationinthefileregularlyandmake necessaryamendmentsintherevisedversion.Anysuggestionfor

laterimprovementisgreatlyappreciated.Microstepreservesall the rightstomakenecessaryamendmentsonthebasis

oftechnicalimprovement.

*PleaseReadThis ManualCarefullyBeforeOperatingTheSystem.

Precautions

1.Afterthecontainerisunpacked,pleasecheckthesystemforanydamageand verifyif

thecontentsinthecontainerare physicallyinconformancewiththepackinglist.

2.Thisuser'smanualisapplicabletoModelSH-2012AH-QGCNCSystemfor

CuttingmanufacturedbyMicrostepControlTechnologyCo., Ltd.

3.Pleaseverifytheconformanceoflocalmainsvoltage. BesuretouseanAC220V

isolationtransformerbetweenthepowersupplynetworkandthesystemtoguarantee

personalsafetyandoperatingreliability.

4.TherequiredambienttemperaturefortheCNCisrangedfrom0to+40and the

relativehumidityisfrom0to85%.

Specialprotection isrequiredincaseofoperating inahightemperature, highhumidity

orcorrosivegasenvironment.

5. MakesuretheCNCiscorrectlywiredandsecurelygrounded.

6.Nevertrytohotplug/unplug any cableon therearpaneloftheCNC,forthedamage

incurredtherebyisbeyond ourqualitywarranty.

7.Nocablefromtheoutputportoftherearpanelshouldbeshortedwithanypower

cable;otherwise, theCNCmightbeburned.

8.Workinginaverydustyenvironment,thewholesystemshouldbeprovidedwithdust

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Beijing StartM&E Technology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG切割机数控系统说明书(C002)

2

protection inaddition toregulardustcleaning.

9. TrainedoperatorshouldbespeciallyassignedfortheCNC.

10.TheinternalAC/DCpowersupplydedicatedfortheCNCshouldneversharewith

any otherelectricappliance.

11. Thegraphicprogramming softwareinstalledinthesystemisabetaversion asking for

advices,whichissubjecttoimprovementinserviceandnottakenasarequisite

functionand itemforacceptance.Pleaseadviseustimelyincaseofanydebug in

youruse.

12. Pleasecontactthemanufacturerincaseofanyproblem.Neverdisassemble, assemble

ormodifythesystemthesystemwithoutpriorauthorizationand qualification.

13.Besuretomaintainthesystemand thecuttingmachineproperly--routine

maintenanceand checkpershift,secondarymaintenancepermonthand primary

maintenance halfayear.

14.Settheparametersinstrictaccordancewiththisuser'smanualorthesupplemental

instructionsgivenatplacingorder.TheCNCmightpoorlyfunction orevenbe

damagediftheparametersaresetbeyond therange.

15. TheLCDscreenisfragileand propercareisnecessaryintheprocessofoperation.

16. Thetechnicalspecificationsaresubjecttochangewithoutpriornotice.

17. Attention

TheprovidedUSBportisverysmallinpoweroutput,onlygoodforUSBdiskand

notrecommendedforanyotherUSBdevicetopreventdamage.

18.Thesystempowermustbecutoffwhenalternatingtheinternalkeyboardandan

extendedkeyboard.

19. SpecialStatement

Thequalitywarrantyofthisproductistwelvemonthssinceitsmanufacturing date

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Beijing StartM&E Technology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG切割机数控系统说明书(C002)

3

coveringthefaultsspecifiedbythisuser'smanual.

Paidserviceisavailableforfaultscaughtbeyond thewarrantyperiod and outsidethe

qualitywarrantycoverage.

Thefollowingcasesare notcoveredbythemanufacturer'squalitywarranty:

A:Damagecausedbymisuseduetoviolating the operatinginstructions,and

B:Damageduetoforce majeure,

Theforcemajeureisgenerallyinclusiveoftwocases:

Naturalcausessuch asthunderstroke,flood,drought,snowstorm, earthquake,etc.

Societycausessuchaswar, strike,governmentprohibition, etc.

C:Damage causedbyunauthorizedactionssuchasdisassembly, modification, repair,

etc.

20.Thefinalpowerofinterpretationtothisuser'smanualissubjecttoBeijing Start

MicrostepControlTechnologyCo., Ltd.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Beijing StartM&E Technology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012H-QG 切割机数控系统说明书(C002)

1

Contents

ChapterI. FunctionalOverview..........................................................................................................1

1.1. SystemFunctions..............................................................................................................................................1

1.2Technicalspecifications......................................................................................................................................1

1.3Microstepalsosupplies thefollowingauxiliaryproductsforcompact CNC cuttingmachine.............................3

ChapterII.MainMenu .......................................................................................................................5

2.1.MenuFeatures ......................................................................................................................................................5

2.2.DescriptionofMainMenu......................................................................................................................................5

ChapterIII.AutomaticFunction(AUTO)..................................................................................................6

3.1.DescriptionofAutomaticModeWindow.................................................................................................................6

3.2.FunctionselectioninAUTO mode...........................................................................................................................8

3.3. Startup ofspeedmode(multiplyingfactor)and automaticmode...............................................................10

3.4. Controland adjustmentofcuttingpositioninautomaticmode.................................................................10

3.5. OriginalPathReturn .....................................................................................................................................12

3.6.BreakpointRestorationProcess....................................................................................................................14

3.7.SECTION(sectionselection)...............................................................................................................................14

3.8.MOVEHOLE for ThickPlate.......................................................................................................................15

ChapterIV.MAN(ManualMode).....................................................................................................17

4.1.DescriptionofManualModeWindow..................................................................................................................17

ChapterV. EDITMode..........................................................................................................................19

5.1. DescriptionofEDITMenu ............................................................................................................................19

ChapterVI. CommandSystem .........................................................................................................21

6.1. DescriptionofProgramingSymbols.............................................................................................................21

6.2.CoordinateSystem...............................................................................................................................................21

6.3.G:BasicPreparatoryCommands.........................................................................................................................21

6.4.MAuxiliaryCommands.................................................................................................................................27

ChapterVII. SETUP(ParameterSetting)................................................................................................29

7.1.ParameterDescription...................................................................................................................................29

7.2. SETUP(parametersetting) ............................................................................................................................30

7.3.FlameCuttingParameters.................................................................................................................................32

7.4.PlasmaParametersSetting...................................................................................................................................33

7.5.Control Parameters Setting ..................................................................................................................................34

7.6.ControlParametersSettingofHeightController..................................................................................................35

ChapterVIII. LIBMINIT(LibraryofPatterns)........................................................................................36

8.1.LIBMINITSetting...............................................................................................................................................36

8.2. Selection ofPatternElements........................................................................................................................37

8.3.Arrangementand LayoutofPatternElement .............................................................................................37

8.4.UserDefinedModule....................................................................................................................................39

ChapterIV.Diagnose.........................................................................................................................40

9.1 CheckInput/outputPorts .........................................................................................................................40

9.2 OutputCheck.............................................................................................................................................40

9.3 InputCheck................................................................................................................................................40

ChapterX. ConnectionsofInput/outputPorts.................................................................................41

10.1.SystemInputPrinciple.................................................................................................................................41

10.2.SystemOutputPrinciple..............................................................................................................................41

10.3 DefinitionsofInput/OutputPorts............................................................................................................42

10.4 Definitionsof15-pinPortsfor Motor......................................................................................................44

10.5TypicalWiringforFlameCuttingOperation(DB15).................................................................................44

10.6TypicalWiringforPlasmaArcCuttingOperation....................................................................................46

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Beijing StartM&E Technology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG切割机数控系统说明书(C002)

2

10.7CompatibleConnectionforFlame/plasmaOperations..............................................................................48

10.8 PinDefinitions.............................................................................................................................................48

AppendixI:TheWiringDiagramandPinDefinitionsforModelSH-HC30 HeightController

ManufacturedbyMicrostep..............................................................................................................50

Appendix II:InstructionsforSoftware Upgrading OperationofSH-2012AH...............................52

Appendix III:InstallationDimensionalDrawing.............................................................................54

Appendix IV:Troubleshooting..........................................................................................................55

Appendix V:Wiring InstructionsforExtendedExternalManualControlBox..............................58

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

1

ChapterI. FunctionalOverview

1.1. SystemFunctions

lModelSH-2012AH-QG CNCSystemforCuttingisdesigned toworkwithtorch/plasma,high-pressure

waterjetand lasercuttingmachinesand extensivelyusedinmetalworking, advertisementfabricationand

stonemachiningbusinesses.

lHighreliabilityaswellas goodresistancetoplasmadisturbance, lightningandsurge.

lAppliedtorch/plasmacuttingtechnology, abletoperformcornerspeedcontrol andheightcontrol

automatically;

lKerfcompensation,reasonabilitycheckand report foruser'soption;

lBreakpointrestoration, automaticpower-backrecoveryandautomaticbreakpointmemory,

lRandomsectionandpiercingpointselection,

lExtendedpiercingforthickplateand bridgingfeatureforthinplate,

lOptionalpiercingpositionfeatureinmodeofRETURN,SECTION(sectionselection)and

RESBREK(breakpoint restoration), veryconvenient forusercontrol,

lReadyfortransitional cuttingoperationatanymoment,

lSpecialshort line machiningfeaturebasedonsmoothtravel, extensivelyapplicabletometal blankingas

wellas advertisementand ironworkfabrication,etc.

lPartslibraryof24-typepatterns,extensibleandcustomizable, includingthecommonmachiningparts,

lCompatiblewithmanyblankingsoftwaresuchasIBE(Germany), FASTCAM,etc.

lOperationmenu bothinChineseandEnglish,dynamicgraphicdisplay,8-times zoom,freepointautomatic

tracking,USBdiskprogramandtimelysoftwareupgrade.

1.2Technicalspecifications

lProcessor:IndustrialARM7CPU

lDisplay: 7"ColorLCD

lInput/output:13 channelsofopticalisolationinputand8channelsofopticalisolationoutput

lInterlocked axles:2axles, extensibleto4interlockedaxles

lMaximumspeed:<24m/min

lPulse equivalency:variable,electronicgearnumeratorand optionaldenominatorintherange from1to

65535

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

2

lMemoryspace:32M-64Moversizedmemorycapacityforuserprogramand norestrictiontomachining

program

lMachinecase size:298×202×95.2(mm)

lOperationtemperature: 0to+40;storagetemperature: -40 to+60

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

3

1.3MicrostepalsosuppliesthefollowingauxiliaryproductsforcompactCNCcutting

machine.

SH-GDC3 压板 ModelSH-GDC3DividerBoard

等离子电源 PowerSupplyUnitforPlasma

SH-HC30 火焰/等离子割炬高度控制器 ModelSH-HC30HeightControllerfor

Flame/plasmaCuttingTorch

SH-2012AH 切割机数控系统 ModelSH-2012AHCNCCuttingMachine

PDF 件使用 "pdfFactory Pro" 试用版本创建 Àwww.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

5

ChapterII. MainMenu

2.1.Menu Features

Thedesignofhierarchy-basedfunctionalwindowsisadoptedforsystemoperatingdisplay.Ifafunctionisinvokedinthemain

menu window, thecorrespondingsubwindowmenu will popup.Press [F1]to[F7]toselectthecorrespondingfunctionaccordingto

windowprompt.Press ESCtoabandontheselectionandreturntotheupperlevelofmenu.

2.2.DescriptionofMainMenu

VER: Theversioninformationofsoftwareandhardwareisindicatedatthebottomleft cornerforyourinformation.

[F1]AUTO:Programmedcontrolofautomaticmachining

[F2]MAN: Tomanuallycontrolthepositionofcuttingnozzle

[F3]Edit: Toedit/modify/input/outputthemachiningprogram

[F4]SETUP: Toset systemparameters

[F5]DIAGNOSE: Tochecktheinput/outputinformationofcuttingmachine

[F6]LIBMINIT:Tosetnormalpatternandplan material

[G][G][3]InitialSetting: Adialogboxas followswill appear:

Fig.2.2Initialsettingdialog

box

Fig.2.1Mainmenu

displayofsystemafter

Display

space of

system

Software

MainMenu

Fileformat:toformat user'sprogramspace;

Parameter:Torestorethefactoryparametersetting;

ENGLISH:AlternatingbetweenChinese and

English

PDF 件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

6

ChapterIII.AutomaticFunction(AUTO)

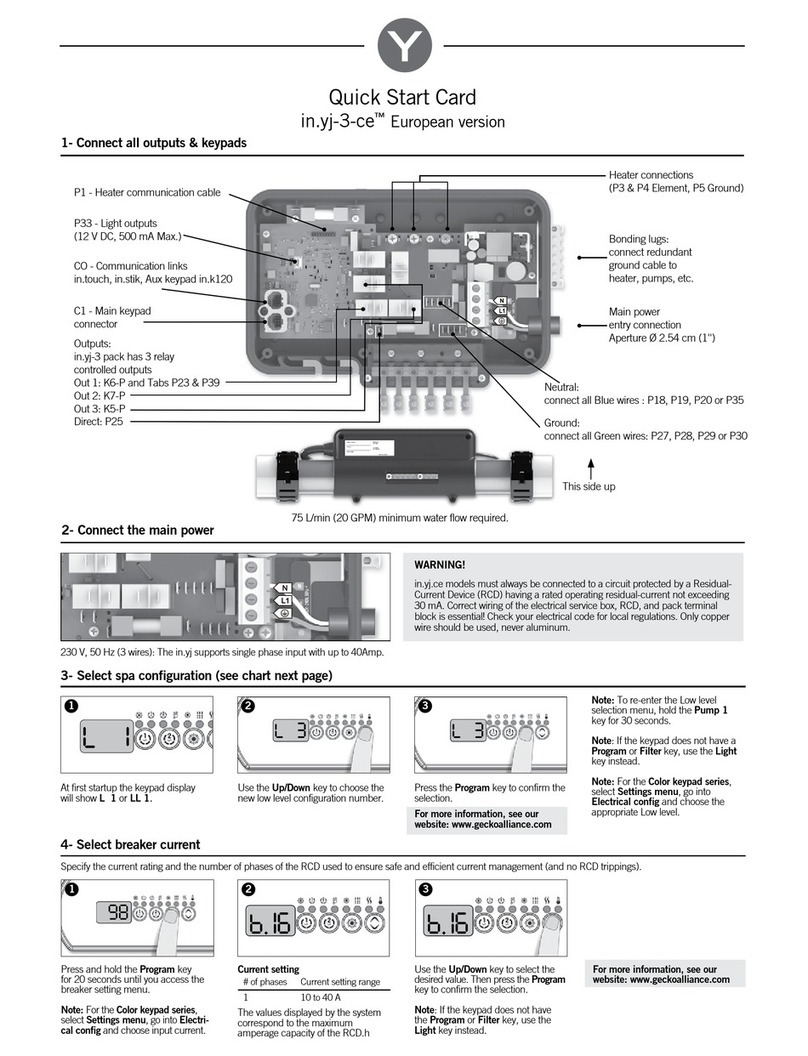

Inthemainmenu,press[F1]toentertheautomaticfunctionwindow,as showninthefigurebelow.

Flamemode

Fig. 3.1AutomaticFunction(AUTO)Window

3.1.DescriptionofAutomaticModeWindow

Plasma Mode

Active speed Program Heavy-current

Piercing Kerf

Input/output

Functio

nkeys

Coordinate

Pa

tte

rn

Di

sp

la

Machini

ng

paramete

Workmode

Machining

program

PDF 件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

7

3.1.1SPEED

1) Inautomaticmode,atthetopleft cornerofthescreen,itshowsF×(multiplyingfactorofautomaticmachiningspeed)=set

machiningspeed.

2) Inmanualmode,atthetopleftcornerofthescreen, itshowsF×(multiplyingfactorofmanualspeed)=manualspeed.

3) SPEEDindicatestheactualspeedwhiletheactive speedmultiplyingfactorisadjustablewith[F↑]and [F↓].

4) Itisallowedtoadjustthespeedquicklybypressing[F]keyinthiswindow.Apull-downmenuwill appearwith8speed

multiplyingfactorsavailableforselectionwith[↑]and/or[↓]key:5%,20%,30%,40%,50%,60%, 80%and 100%.And

then,press ENTERkeytoacknowledgetheselection.

5) Attention: Thespeedmaybeindicatedin Metric or English systemdependingontheMetric/EnglishSelectionin SETUP

(Referto Parameter Control).

3.1.2PROG, PIERCEandKERF

They areusedtoindicatethe nameofmachiningprogram,serialnumberofpiercedhole(automaticclearinautomaticmachining

mode)and theactivecompensatingwidthofkerfrespectively.

3.1.3WORKMODE, OPERATE

WORKMODEfieldindicatestheactiveoperatingmodesuchasrotationselection,breakpointrecovery,mirroringandsection

selection.

OPERATEfieldindicatessuchinformationasmachining/pause, limitalarmsand timedelay.

3.1.4Input andoutput

Belowtheheavy-currentswitches,thereare3rows×8indicators ○.

Thetopindicatorsshowthestatusof13inputports, ○indicatingnosignalinputand ●indicatingsignalinput.

Thebottomindicatorsshowthestatusof8outputports, ○indicatingnosignaloutputand ●indicatingsignal

output.

See the descriptionof DIAGNOSE functionforthedefinitionsofinput/outputports.

3.1.5Machining ParametersIndication

Thiszoneindicates variousparametervaluesinthecurrent machiningmode.

3.1.6Selectionofcoordinateunit

Thecoordinatesmaybe indicatedin Metric(millimeter) or English system(inch)dependingonthe

Metric/EnglishSelectioninSETUP(RefertoParameterControl).

3.1.7The sixheavy-currentcontrolkeys onthefrontpanelaredesignedtoexertheavy-currentcontrolof

externalsource.

[IGN]:Referto M20 forignitionfeature.

[PREHEA]:Toopenthe solenoidvalveofpreheatingoxygen.Referto M24 fordetails.

[GAS]:Toopen the solenoidvalveofacetylene(gas).Referto M10fordetails.

[CUT]:Toopen the solenoidvalve ofcuttingoxygen;referto M12 fordetails.Toturnonthearcingswitch

ifit is plasma.

[PIERCE]heavy-current controlkey

Tocarryoutapiercingprocess, thespecificoperationprocedureisasfollows:

Flamemachiningcase: risethe cuttingtorch(M72),openthecuttingoxygen(M12)and lowerthe

cuttingtorch(M73).

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

8

Plasmamachiningcase:execute M07 command.

Note: Thisisaveryimportant feature.It will beusedrepeatedlyinpause,returnand extend piercing

operations.Whenpreheatisdone,pressing[PIERCE]keywill startuppiercingoperation

directly.

[SWOFF]:Toshutoffalltheheavy-currentoutput.

[S↑]: Pushitdowntorisethe cuttingtorchand release tostopthetorch.

[S↓]: Pushitdowntolowerthe cuttingtorchandrelease tostopthetorch. ;

3.1.8[1]BLOWUP

Thepatternwillbemagnifiedonetimesbyone keystrokeand itcanbemagnifiedtoeighttimes maximumby

threekeystrokes.

3.1.9[2]RESTIT

Torestoretonormalpatternsize.

3.1.10[X]TEST

If[X]keyispressed,thesystemwillrun theprogramattopspeed withoutexecuting Mcommand.This

featureisoftenusedtopositionquicklyorcheck theworkingsizeofsteelplate.Thisoperationcan bepausedatany

moment orcancelled bypressing[X]key one moretimes.

3.1.11[Y]AU-SPD

Since the manualspeedand automaticspeedisseparateinthe system,thiskey isusedtoswitchedbetween

automaticmodeand manual mode toadjustthespeedmultiplyingfactor.

3.2.FunctionselectioninAUTOmode

Itisallowedtoinvokeamachiningprogrambymeans of EDIT feature.If aprogramhasbeeninvoked(as longas itisthe same

programname), itcanberun directly.Iftheprogramisinvokedfroman USBdisk,especiallyalargeprogram,itcan berundirectlywith

USBdiskconnectedinsteadofsavingitintothesystem.

3.2. 1[F1]SECTION

Toassignsystemtostart upmachiningoperationfromany sectionorpiercingpoint.

It isoftenusedwhenmachiningneedstostart fromacertainsectionoronlyapartneedsbeingprocessed.

Referto SECTION featurefordetails.

3.2.2[F2]MAN

Toswitchthesystemtomanualmode.

3.2.3[F3]RESBREK

Afterthisfunctionisselected,pressing[START]keytofulfillbreakpointrestoration.Referto RESBREK

featurefordetails.

3.2.4[F4]VIEW

It isusedtotesttheprogramforanyerror. Whenthisfeatureisselected, thepatternofmachiningprogramwill

bedisplayedwithacross cursorat theorigin.

[S]key isusedtomagnifythe pattern,onetimesbyonekeystrokeandeighttimesmaximumbythree

keystrokes. [Q]keyisusedtoreturnthepatterntooriginalsize.Thedisplaypositionofpatternismoveableby

pressing[↑],[↓],[←]and/or[→]key.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

9

3.2.5[F5] KERF

Thiskey isusedtoreminderinputofkerfcompensatingwidth;ifnonecessarytocompensate(usuallyin

blanking),simplyenter0.

3.2.6[F6]ASSI

Thiskey isusedtoenterthe nextlowerlevelofmenu,asshowninFig. 3.2below.

3.2.7. [F3]ROTATE(steelplatecorrecting feature)

3.2.7.1Machiningatrotationangle

Thisfeatureisusedwhenthesteelplateisnot positionedperfectlyorthesteelplateneeds torotatean angle

beforemachining.It isallowedtouse Rotate functionalongwith BEG. PT. and ENDPT. in Manualmode or

inputtheexpectedangledirectly.Afteracknowledged,thesystemwillstartthemachiningprogramatthe

appointedrotationangle.

Note:Counterclockwisedirectionistakenaspositiveangle.

3.2.7.2Example

Thesystemisabletoidentifyandcalculatethe rotationanglebymeasuringthe originpointand the endpoint

ofanedge ofsteelplate(astraight line).The procedureisasfollows:

1) Determine thedatumline.Take one borderlineofsteelplateasbaseline andmovethecuttingtorchtothe

originpoint ofthisbaseline. Press[F2]tosetthe beginningpoint ofmeasurement.

2) Controlthecuttingtorchandletitmovealongthebaselinetotheendpoint.Thelargerdistance between

the beginningpointandtheendpoint, themoreaccurateofthemeasurement. Aimthe cuttingtorchat the

baseline andpress[F3]tosettheend point ofmeasurement.

3) Atthismoment,therotationangleofthe datumlineiscalculated.Afterthe rotatefunctionisfulfiled,the

rotationanglewillappearintheOPERATEfield, as showninFig. 3.2below.

3.2.8[F4]MIRR

Itispossibletoselect XMirror, YMirror and NoMirror if press [F5]key continually.WhenXMirroris

selected,themachiningprogramwillrun alongthesymmetrydirectionofX-axis,asappearsinverted

Fig. 3.2 ASSI window

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

10

horizontally.

WhenYMirrorisselected, themachiningprogramwill run alongthesymmetrydirectionofY-axis,asappears

invertedvertically.Whendefault NoMirrorisselected,themachiningprogramwillrun normally.

3.2.9 [F5] SCALE

Thesystemwillreminderusertoinputscaleifthiskeyispressed.Whenthemachiningprogramisexecuted,

theworksizewill magnifyorminifyasperthisscale.Thisfeatureisveryusefulincuttinggraphiccharacter.

3.2.10 [F2] WENTAI

ThesystemwillprompttorunWENTAI-basedmachiningprogramifthiskey ispressed.WENTAIisaword

machiningsoftwareforCAD/CAM,widelyusedincuttinggraphiccharactersinadvertisement business. Thisfeature

isrequired torunaWENTAI-basedprogram.

3.3. Startup ofspeedmode(multiplyingfactor)and automaticmode

3.3.1Manualspeedandreturnspeed

Ineithermanualorreturnmode, manualmultiplyingfactorisusedtoadjustspeed.

EffectiveSpeed=maximumspeed limit *manualmultiplyingfactor,wherethe manualmultiplying

factorisadjustablewith[F], [F↑]and [F↓]key.

3.3.2MachiningSpeed

Automaticmultiplyingfactorisusedtoadjustmachiningspeed.

Machining Speed=machiningspeed limit*machiningmultiplying factor,wheretheautomatic

multiplyingfactorisadjustablewith[F],[F↑]and[F↓]key.

Thesetwospeed multiplying factorsarepermanentlysavedandsubjecttonoaffectfrompower-off

operationonce theyareset.

3.3.3Startofautomaticmode

1) Priortostartingautomaticmode,

Selectcorrectmachiningprogramand appropriatemachiningspeed(multiplyingfactor).Move the cutting

torch tothecuttingposition.The cuttingtorchwill belifted automaticallyafteramachiningprogramis

initiated(toexecuteM70).Andnow, itisreadytostart themachiningprograminautomaticmode.

2) Two startingmethodsinautomaticmode:

a)Pressthegreen[START]key onthe frontpanel.

b)Press an external"START"key(Seethedefinitionofinput/outputports).

3.4. Controlandadjustmentofcuttingpositioninautomaticmode

3.4.1 Onlythefollowing keysareenabledwhenthesystemstartsautomaticmode:

1)[PAUSE]:Ifthiskeyispressed,thesystemwillslowdownand stopmovement, shutoff cuttingoxygen(shut

offarcingswitch inplasmamachiningcase),turnofftheheightcontroller(M39)and remainthecurrent

displaystill.Afterthe systemoperationispaused,itisallowed toperformthefollowingoperations:

(a) Returnalongthe originalpath;(b)adjustposition;(c)exitmachiningoperation;(d)[START]:restore

systemoperation;and

(e)Press [ESC]key toexit the machiningprogramandreturntoautomaticmode window.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

11

2) [F↑]and[F↓]speedadjusting key:Toincreaseordecreasethemultiplyingfactoroffeed

speed.

3) [S↑]and [S↓]key:Tocontrolthe verticalmovementofcuttingtorch.Bypushingand holdingeitherkey,

the cuttingtorch willmoveupordownaccordingly, andthemovement willstopif thekey isreleased.

4)[Emergency Stop]key:It isan externalkey withsignalreceived fromthe inputport(referto"ExternalInput

Ports"fordetails).If emergency stopisvalidated,all the movementwill stopandnooutput willgo on.Itis

usedforemergencycase.

3.4.2. Adjustmentofcuttingposition

3.4.2.1Situationsnecessary toadjustthepositionofcuttingtorch:

1)Ifthecuttingtorchisblockedorreplacementisnecessary,the usualpracticeistomovethecuttingtorch to

somewheresafeand moveitback tothestartingpointafterthesituationisresolved.

2)Whenitisrequiredtopiercealongtheexteriormarginand notpositionthe piercingpointatthe exterior

edge,the usualpracticeistopinpointanappropriatepositionintheexteriorofworkpieceforpiercingand

thencuttheworkpieceback tothestartingpointalongastraightlinebeforecontinuenormalmachining

withoutstop.

3) Incaseoftransitionalcutting,too manyworkpiece orlarge size ofworkpiece,itmightbenecessaryto

relocatethe cuttingtorch.

3.4.2.2Situationsallowedtoadjustthecuttingposition:

(1)pauseprocess,(2)returnprocess,(3)piercing process,(4)sectionselection,(5)hole

selection and (6)breakpointrestoration

Ifoperatorintendstochange thepositionofcuttingtorch inthe above-mentioned states,itisallowedto

press[↑], [↓],[←]and/or[→]keytodoso(inthiscase,it ismanualmultiplyingfactor,adjustable).When

theexpectedpositionisreached,press [Start] key,asshowninthe followingdialogbox:

1)ORIPATHRET(originalpathreturn)

ReturnthecuttingtorchtotheadjustmentbeginningpointatspeedG00 and waitforotheroperation;at thisstep,itisallowed

topress an heavy-currentfunctionkeysuchasIGN(ignition),PREHEA(piercingpreheat),CUT(cuttingoxygen),etc. Tip:

The systemwillcontinuetoprocessfromthebreakpointlocationif[PIERCE]keyispressedafter preheating.

2)CUTRET(cut return)

Afterpiercing,the cuttingtorchreturnsfromthecurrentpositiontotheadjustmentbeginningpointalongastraightlineat

cuttingspeedand continuemachiningalongtheoriginalpathwithoutstop,whichissomewhatlikeextendedpierced,

makingthepiercingpointmoresmooth. ;

3)HOLE HERE(piercinghere)

Fig.3.3Dialog boxof

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

12

Afterpiercing,setthecoordinatesatcurrentpointas coordinatesof"adjustmentbeginningpoint",and continuemachining

alongtheoriginalpathtofulfill transitionalpiercingfunction.

4)Attention:

Besuretohavethesystempreheated sufficiently(forflamecutting)before takingsteps2)and3),forpiercing

operationwillstartrightawayonce the operationisselected.

It isrecommendedtopreheatthesystem(forflamecutting)andthenpress[START]keytoselectappropriateoperation.

3.5. OriginalPathReturn

Whenitisnecessarytoreturnthecuttingtorchalongthe originalpathduetofailuretocutthroughin

machiningoperation, handleitinthefollowingways:

3.5.1Returnalongoriginalpath

Press [PAUSE]key tosuspendtherunningsystem.A"pause"markwillappearonthesystemdisplayin

additiontopromptasshowninthefigurebelow.

Press [F6]keytoreturnthecuttingtorchalongthe original path.

Press [F7]keytoadvancealongtheoriginalpathafterreturning.Intheprocessofreturn, if the cuttingtorch

failstoreachtherequiredposition,press [PAUSE]keyagainand repeat the aboveprocedureuntil itreaches

the rightposition.

3.5.2 ReturnatG00(whenreachapiercingpoint)

Intheprocessofreturn,thecuttingtorchwillstopatG00orapiercingpointforoperatortoselect goingon

returnoradvancing.

3.5.3 Operationafter returned

Afterthecuttingtorch returnstothedesignatedposition, itisallowed toselect positionadjustmentofcutting

torch(referto3.4)orpiercingdirectlybypressingtheappropriateheavy-currentfunctionkey such as

PREHEA(piercingpreheat) andCUT(cuttingoxygen).

Itiscommonpracticeto--

Press[PIERCE]keyafterpreheatingoperationisdone,or

Forflamecuttingoperation,press CUT key(openthecuttingoxygen)if thecutting torchliftsor

continuemachiningifthecuttingtorchlowers;or

Forplasmacutting operation,ignitearc anddonotgoonmachininguntilthearcignition is

completed.

3.5.4 Repeattheaboveoperation procedureuntilthedesiredeffectisachieved.

3.5.5Toexitmachining mode

Inpausestate,press [ESC]key toexit machiningmode.

3.5.6Totalrownumberandbeginning rowinreturnprocess

Theprogramsegmentforreturnallows300rowsmaximum. Incase ofbreakpoint restoration(RESBREK)or

machiningsectionselection(SECTION),the returnbeginningrowistherowcontainingthecurrent

breakpointorthe sectionselectingrow,uponwhich howeverthecuttingtorch isnot allowedtoreturnalong

Fig.3.4Machining

pausedisplay

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BeijingStartM&ETechnology DevelopmentCo.,Ltd.北京斯达微步控制技术有限公司

SH-2012AH-QG 切割机数控系统说明书(C002)

14

3.6. BreakpointRestorationProcess

3.6.1.Breakpointrestoration

1) Incaseofmanualpauseorpoweroutageinmachiningoperation,thesystemwillautomaticallysave the

currentpositionofcuttingtorch asabreakpoint, whichwill bekept permanentlyinthesystem,whether

powerthe systemoffornot.

2) Inautomaticmode, press[F2]key toselectRESBREKfunctionandthen[START]key tostart breakpoint

restorationaslongasthereisnochange withthe currentprogram.

3) Ifthepositionofcuttingtorch doesnotchange,thesystemwill prompt "Breakpoint"when abreakpointis

found and waitforsubsequentcommand.User mayselectpiercingdirectlyorpositionadjustmentof

cuttingtorch. Referto3.4fordetails.

4) Ifthe positionofcuttingtorchdoeschange and isofffromthe breakpoint,thesystemwillprovidethree

optionswhenaprogrambreakpointisfound, whichisvirtually positionadjustmentofcuttingtorch.

ORIPATHRET: ToreturntothebreakpointatspeedG00,whichisoftenusedforthebreakpointsetforcuttingtorch

replacement;

CUTRET: littlebitofffromthebreakpointafterbreakpointrestoration,whicissomewhatlikepiercingalongtheexterior

margin, makingthebreakpointmoresmooth;

HOLE HERE: thesameoperationas previous,whichcanalsobe usedfortransitionalcutting.

Now,itisallowed topress aheavy-currentfunctionkeysuchasIGN(ignition),PREHEA(piercingpreheat),CUT(cutting

oxygen), etc.

Tip:The systemwillcontinuetoprocess fromthebreakpointlocation if[PIERCE]keyispressedafterpreheating.

Ifpress [ESC] keywhenabreakpointisfound,the systemwill exit machiningmode.

3.6.2Attention:

Nevertrytochange themachining program,rotationangleand scaling proportion whether itis

breakpointrestorationorpower-offrestoration,whichwillbe automaticallysavedby thesystemand

free fromaffectbypower-off operation;otherwise,thesystemcan notfind the breakpoint.

3.7.SECTION(sectionselection)

3.7.1. StartSECTIONfunction

SECTION:toassignsystemtostart upmachiningoperationfromanysectionorpiercingpoint.

Press [F1]toselectSECTIONfunctionand thesystemwillshowamenu as showninthefigurebelow:

Fig.3.5Dialog boxofrestartoptionsaftersystempause

and breakpointrestoration

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Table of contents