Exhausto EXact2 HMI2-350-TOUCH Installation guide

EXact2 HMI2-350-TOUCH Control

System

Basic instructions for VEX308

Original instructions

3006401-2022-05-04

EXHAUSTO A/S

Odensevej 76

5550 Langeskov, Denmark

Tel.: +45 65 66 12 34

Fax: +45 65 66 11 10

www.exhausto.dk

Symbols and software version

Symbols used in these instructions.................................................................... 4

Software version.................................................................................................... 4

Software version ............................................................................................. 4

1. Menu structure

Overview of menus and user levels..................................................................... 5

2. User mode

Operation................................................................................................................ 6

Use of control icons in the menus....................................................................6

Overview of HMI icons...........................................................................................7

3. Technician and service levels

3.1. Access codes for technician and service menus............................................... 9

Menu 3.2 - Selecting language............................................................................10

Menu 3.2.1 - Setting date and time..................................................................... 10

Menu 3.2 - Reset settings....................................................................................10

Menu 3.2 - Reload database................................................................................ 11

Menu 3.6 - Web server......................................................................................... 11

Menu 3.7 - Backup/restore.................................................................................. 12

3.2. IMPORTANT when servicing...............................................................................12

3.2.1. Connect service panel....................................................................................14

4. Starting up the unit for operation

4.1. Getting started..................................................................................................... 15

4.1.1. Menu 3.3 - VEX configuration........................................................................ 15

Menu 3.4 - Accessories..................................................................................16

4.2. De-icing method ..................................................................................................17

4.2.1. Bypass de-icing - example.............................................................................17

4.3. Temperature controlled frost protection -- choice of method......................... 18

Menu 3.5 - BMS............................................................................................. 18

Menu 3.5 - BMS............................................................................................. 19

4.4. What is an indoor air quality level?....................................................................19

Operation with CO2B, PIRB and RHB .......................................................... 20

Menu 1 - Selecting operating mode................................................................... 20

Menu 3.1.1 - Operating settings - Air regulation............................................... 21

Menu 3.1.1 - Operating settings Balance.......................................................21

Menu 3.1.1.5 Regulators ...............................................................................22

Menus 3.1.1.1.1 to 3.1.1.1.4 Configuring the selected indoor air quality levels

......................................................................................................................................23

Menu 3.1.1.1.x - Air set point ........................................................................ 23

Menu 3.1.1.1.x - Temperature set point ........................................................ 23

Menu 3.1.1.1.x - Absolute / Relative temperature .........................................23

Menu 3.1.1.1.x - Cooling relative start .......................................................... 24

Menu 3.1.1.1.x - Heating relative start .......................................................... 24

Menu 3.1.1.1.x - Cooling absolute start ........................................................ 24

Menu 3.1.1.1.x - Heating absolute start ........................................................ 25

Menu 3.1.1 - Operation settings - Temperature regulation.............................. 25

Compensation...................................................................................................... 26

Menu 3.1.2 - Air compensation........................................................................... 26

Menu 3.1.2.1 - CO2 compensation ............................................................... 26

Menu 3.1.2.2 - Humidity compensation of airflow ......................................... 27

Menu 3.1.2.3 - Airflow reduction ................................................................... 28

Menu 3.1.2.4 - Outdoor compensation of airflow .......................................... 29

Menu 3.1.3 - Temperature compensation.......................................................... 30

Outdoor air temperature compensation (menu 3.1.2.1) ................................30

Summertime compensation (menu 3.1.2.2) ..................................................31

Menu 3.1.4 + Menu 8.1 - Filter (monitoring with hour counter) ..................... 31

Menu 3.1.5 - Night-time cooling .................................................................... 32

Menu 3.1.6 - Cold recovery............................................................................34

Menu 3.1.7 - Fan limits...................................................................................34

Menu 3.1.8 - Temperature limits for supply air and room...............................34

Room temperature limits................................................................................35

3006401-2022-05-04

2/72

Menu 5 - Time and weekly plan.......................................................................... 35

Menu 5.1 - Date and time...............................................................................35

Menu 5.2 - Weekly plan ................................................................................ 36

Menu 7 - Safety functions................................................................................... 37

Menu 7.1 - Fire alarm.....................................................................................37

Menu 7.2 - Frost protection of HCW ............................................................. 38

Menu 7.3 - Frost protection heat exchanger ................................................. 39

5. Operation

Menu 2 - Operating readings.............................................................................. 41

Menu 2.1 - Air temperatures ......................................................................... 41

Menu 2.1.1 - Set points for regulators ...........................................................42

Menu 2.3 - Motor controller parameters (MC parameters) ............................42

Menu 2.4 - Temperature regulating units ...................................................... 42

Menu 2.6 - Heating unit .................................................................................42

Menu 2.8 - CCW cold water coil ....................................................................43

Menu 2.9 - CU cooling unit.............................................................................43

Menu 2.10 - MXCU external cooling unit....................................................... 43

Menu 2.11 - CO2/RH sensors (if mounted)....................................................44

Menu 6 - Versions................................................................................................ 44

Menu 8 - Service...................................................................................................44

Connect service panel....................................................................................46

Menu 8.2 - VDI 6022 (not applicable)............................................................ 47

Menu 8.3 - Forced start .................................................................................47

Menu 8.3.1 Fans............................................................................................ 47

Menu 8.3.3 Heating unit.................................................................................47

Menu 8.3.3 Cooling unit (not applicable)........................................................47

Menu 8.3.4 Dampers and relays....................................................................48

6. Alarms

6.1. Alarms and info (Menu 4).................................................................................... 49

6.2. Reset alarms.........................................................................................................49

6.3. Alarm display – causes of errors....................................................................... 50

6.4. List of alarms........................................................................................................51

Appendix 1 - Simplified diagrams

Simplified diagrams.............................................................................................68

VEX308 with water heating coil HCW ...........................................................68

VEX308 with electric heating coil HCE ......................................................... 69

Appendix 2 - Temperature resistance table

Temperature resistance table DC95................................................................... 70

3006401-2022-05-04

3/72

Symbols and software version

Symbols used in these instructions

Prohibition symbol Failure to observe instructions marked with a prohibition symbol

may result in serious or fatal injury.

Danger symbol Failure to observe instructions marked with a danger symbol

may result in personal injury and/or damage to the unit.

Software version

Software version

This manual applies from the following version:

AHUC: 3.11.1.0

HMI: 4.1.0.0

3006401-2022-05-04 Symbols and software version

4/72

1. Menu structure

Overview of menus and user levels

User menu: Technician and service menu:

23°C

60%

Select menu by using

arrow up and

arrow down keys.

Activate by pressing

on menu.

Press return arrow

to switch between

the user and

technician menu,

or to exit the menu.

Main menu

Operating mode >

Operating readings >

Settings >

Alarm and info >

Time and weekly plan >

Versions >

Safety functions >

Service >

Save settings >

1 Operating mode

Operation > Manual

2 Operating readings

Air temperature >

Airflows >

MC parameters >

Temp. reg. units >

Pressure >

Heating coil >

CH cooling unit >

CCW

CU cooling unit >

MXCU

MXHP

Timers >

CO2/RH sensorer >

3 Settings

Unit >

General >

Configuration >

Accessories >

BMS >

Web server >

Backup/restore >

4 Alarm and info

Information

Alarm

Warning

Reset alarms >

Current list >

Alarm log list >

Delete alarm log >

Yes

No

No

No

No

5 Time and weekly plan

Date and time >

Weekly plan >

6 Versions

PO Number >

Hardware >

Software >

About EXact >

1234567

7 Safety functions

Fire alarm >

Frost protection HCW >

Frost protection HR >

CH cooling unit >

8 Service

Filter >

VDI 6022 >

Forced start >

Calibration of MPT >

Light > Off

9 Save settings

Save settings >

Last saved:

Date

Time

No

xx.xx.xxxx

xx:xx.xx

Ventilation

60

Set temperature

23°C

3006401-2022-05-04 Menu structure

5/72

2. User mode

Operation

Use of control icons in the menus

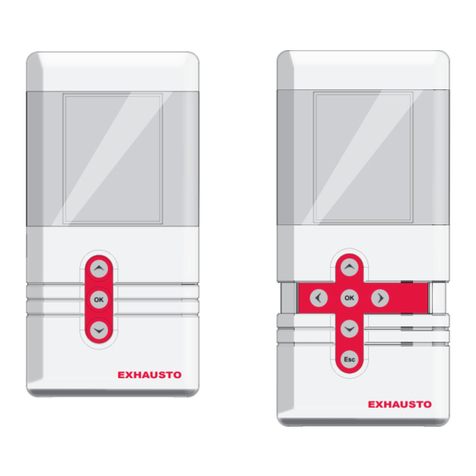

HMI - Human Machine Interface panel

Control icon Used for...

Menu icon

Navigation arrows up and down as well as setting val-

ues.

Approve icon for selection.

Undo icon.

Switch between daily user menu and technician/serv-

ice menu.

Exit a menu without making changes

3006401-2022-05-04 User mode

6/72

Overview of HMI icons

Icon Description

Manual operation

Timer overridden until next changeover in the timer schedule

Timer, current indoor air quality level is comfort

Timer, current indoor air quality level is economy

Timer, current indoor air quality level is standby

Timer, VEX/CX has stopped

Timer, no changeover times defined in timer schedule

BMS-controlled operation

Externally-controlled operation

Setpoint for temperature shown in °C

Setpoint for ventilation shown as percentage: 0% = no ventilation OFF

= Unit is switched off - timer operation cannot start up unit

BMS or Web server-controlled system overrides the OFF func-

tion. This means the system may start up even if set to OFF

The unit is running de-icing (De-ice)

Unit alarm. Contact the service technician who can help reset the

alarm. Icon is also shown in the technician menu

Warning. Contact the service technician who can help reset the warn-

ing. Icon is also shown in the technician menu

Temporarily

in service

Service display connected

3006401-2022-05-04 User mode

7/72

Icon Description

External start/stop disconnected. See Electrical Installation Guide for

further information

Summertime

Wintertime

No communication on the external BUS, or communication between the

VEX/CX and HMI is disconnected

Fire!

Fire alarm. Closed circuit open and the pre-set fire alarm function acti-

vated

Loading Linux...

Startup: Web server accessing database. The icon is displayed until the

HMI panel is ready for use.

3006401-2022-05-04 User mode

8/72

3. Technician and service levels

3.1 Access codes for technician and service menus

Step Action The display shows

1 If the display is in stand-by: Press the

display to activate full light.

Press the menu icon

2 Press the number in the code row to acti-

vate and select the number via the up/

down arrows

When the whole number code has been

selected, approve with

● The code for technician mode is1111

(some menus are hidden or read-on-

ly). EXHAUSTO recommends this

mode be used for normal service

tasks

● The code for the specialist level is

3142 (full access to all menus).

NB: incorrect settings

(wrong values) may have a nega-

tive impact on unit operation in

some menus

0

0 0 00

Password

1

1 1 11

Password

3

Press the up/down arrow

keys to find and select the desired func-

tion in the main menu.

Main menu

Operating mode

Operating readings

Settings

NB:

● Automatically logs out and returns to the user menu if no buttons are press-

ed in a five-minute period

3006401-2022-05-04 Technician and service levels

9/72

Menu 3.2 - Selecting language

The HMI is factory set to English – another language can be selected by:

Step Action

Unit >

General >

Configuration >

Accessories >

BMS >

Web server >

Backup/restore >

3 Settings

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

Main menu

Operating mode >

Operating readings >

Settings >

Alarm and info >

Time and weekly plan >

Versions >

Safety functions >

Service >

Save settings >

1 Select "Settings"

2 Select "General"

3 Select the required language in line 2 "Language"

4 Return to the main menu and select yes in "Save settings"

Menu 3.2.1 - Setting date and time

Step Action

Unit >

General >

Configuration >

Accessories >

BMS >

Web server >

Backup/restore >

3 Settings

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

3.2.1 Date and time

Date > 22-02-2009

Day >

Time >

Wednesday

13:11

1 Select"Settings"

2 Select "General"

3 Select "Date and time" to set these parameters in Menu 3.2.1

4 Return to the main menu and select yes in "Save settings"

Menu 3.2 - Reset settings

Selecting "Reset settings" resets the user settings. See the menu guide for details of

which menus are affected.

NB: This cannot be undone and the VEX/CX restarts.

3006401-2022-05-04 Technician and service levels

10/72

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

Menu 3.2 - Reload database

Selecting "Reset settings" resets the user settings. See the menu guide for details of

which menus are affected.

Database reloads

Waiting for

data...

Loading DB values

Menu 3.6 - Web server

Contact the network administrator for information on the correct IP address, etc. If

the admin password is lost, it can be reset to the factory setting. But note that this

cannot be reversed. See EXact web server instructions.

No

> 192.168.001.180

> 255.255.255.000

> 192.168.001.001

80

00:1F:79:00:00:D0

No

3.6 Web server

DHCP >

IP address

Subnet mask

Standard gateway

Port number >

MAC address

Reset password >

3006401-2022-05-04 Technician and service levels

11/72

Menu 3.7 - Backup/restore

It is recommended that a backup copy of the VEX/CX settings is made and saved in

a secure location. See the individual backup guidelines in the diagram:

+

Backup via the HMI panel

● Insert the USB plug in one of the web

server sockets

● Select menu 3.7 Backup/restore

● It can take up to 20 seconds before the

connection to the USB is established;

data will be lost if the process is inter-

rupted.

The backup file can only be saved on a

USB plug. Once the file has been saved it is

not possible to change the file name or type.

The file is named automatically as in this ex-

ample: backup_20110918.file

Backup via web server

Follow the backup/restore instructions in the

web server guide. The backup file may be

saved on any medium (USB, PC etc.).

A backup file saved via the web server may

be renamed, but the file type cannot be

changed.

Note:

If a backup file has been saved from the

web server and then renamed, it cannot be

retrieved (restored) via HMI until the name

has been changed back to the standard

form, see "Via HMI panel".

If it is necessary to make backup files for

several VEX/CX, it is recommended that

each file is saved on a separate USB stick,

or to create one folder per VEX /CX in which

the backup files are saved.

3.2 IMPORTANT when servicing

The VEX door must be opened to allow servicing and cleaning.

Disconnect the power by removing the plug from the socket before

opening the door.

The fan motors will run on for up to 5 minutes.

NB Do not use aggressive cleaners or abrasive/sharp objects for

cleaning.

3006401-2022-05-04 Technician and service levels

12/72

RD13235-01

Weekly plan It is important to set ventilation to OFF when the weekly plan is

active:

Set ventilation to OFF

Note - If the HMI panel shows 0% (VEX/CX

is inactive) and the unit is operating to a

weekly plan when servicing begins, there

is a risk that the program may be changed

by timer operation and re-start the VEX

unit.

21°C

0%

● Log on to technician menu, using password

1111

● Change to manual operation via menu 1

● Change back to user menu

● The icon for manual operation appears in

the right-hand corner of the menu

● Press the ventilation icon

● Set the ventilation to 0% using the arrows

● Press approve

23°C

0%

● OFF will now appear on the display next to

the ventilation icon

23°C

OFF

BMS unit or Web

server

If the VEX/CX is controlled via a BMS or Web server,

these controls could override the OFF function and the

VEX/CX may start up irregularly. To disconnect the BMS

or WEB server connection, you must remove the plug

from the EXact2 main board. Refer to the section on the

terminal board in the Electrical Installation Guide.

3006401-2022-05-04 Technician and service levels

13/72

3.2.1 Connect service panel

When connecting the service panel you are recommended to use an extra HMI panel

connected to the VEX at the connection box.

NB: The socket on the side of the VEX is only meant for the service HMI. For perma-

nent connection of the HMI, use the external bus connector on the EXact2 main

board.

EXact2 main board

Cable requirements The service panel cable can be ordered from EXHAUSTO (product number:

HMI2SERVICEC).

3006401-2022-05-04 Technician and service levels

14/72

4. Starting up the unit for operation

The Modbus connectors must not be connected or removed while the

units are powered up. Both Modbus units must be switched off before

making changes, otherwise the units may be damaged.

During commissioning, it may be necessary to work with the control

system boxes open. Components in these boxes must only be

touched with electrically-insulated tools.

Before doing any work on motor controls or motor cables and termi-

nal boxes, the power supply must be switched off for at least five mi-

nutes to allow the capacitors to discharge.

Before any commis-

sioning begins

● Check that the supply voltage is connected

● Set the HMI panel to specialist mode. See section "Access codes for technician

and service menus"

4.1 Getting started

4.1.1 Menu 3.3 - VEX configuration

Type >

Size >

Orientation

Exchanger

3.3 Configuration

300

8

C

Type K

Line in Menu 3.3 Factory-set and should not be changed.

VEX type x

VEX size x

Orientation x

3006401-2022-05-04 Starting up the unit for operation

15/72

Menu 3.4 - Accessories

Ice-detect. >

De-icing method >

Heating coil >

Cooling unit >

Power step HCE >

Filter detect. >

PIR >

TS >

CO2 >

RH >

Dining solution >

3.4 Accessories

Tice

6

None

None

4

Timer

None

None

None

None

No

AUX OUT setting > 1

Line in Menu 3.4 Factory-set and

should not be

changed.

Comments

Ice detection method ● Tice

De-icing method Selected automatically:

● Method 4, if a heating coil

is present

● Method 6, if no heating

coil is present

Heating unit Options:

● None

● MHCW (Water heating

coil)*)

● MHCE (Electric heating

coil)

● IHCW (set at the factory

for the the EXact2 main

board, if the VEX was

purchased with HCW)

*) Not applicable to VEX308

Cooling unit*) Options:

● None*)

● MXCU (external cooling

unit)*)

● CCW (cold water coil)*)

● CU (EXHAUSTO cooling

unit)*)

*) Not applicable to VEX308

Filter detection ● Hours

PIR Activating PIR sensor. Op-

tions:

● None

● PIR1 (MIOPIR connected)

● PIR2 (PIRB connected)

● Both (Both MIOPIR and

PIRB connected)

When the sensor(s) is/are acti-

vated by movement in the

room, the VEX will be overrid-

den and set to comfort level.

Comfort level will be main-

tained for the time set on the

rear of the sensor (PIRB), af-

ter which the VEX will return to

the previous indoor climate

level.

NB: The time interval for MIO-

PIR is a fixed 10 minutes and

cannot be changed).

3006401-2022-05-04 Starting up the unit for operation

16/72

Line in Menu 3.4 Factory-set and

should not be

changed.

Comments

TS Activation of external tempera-

ture sensor and selection of

type. Options:

● None

● TS ROOM

● TS DUCT*)

*) Not applicable to VEX308

CO2 Activation of CO2 sensor Op-

tions:

● None

● MIOCO2

● CO2B

● BMS

RH Activation of RH sensor. Op-

tions:

● None

● MIORH

● RHB

● BMS

4.2 De-icing method

4.2.1 Bypass de-icing - example

Extract

air

Supply

air

Exhaust

air

Outdoor

air

RD13238GB-01

+18°C 100% +14°C +20°C

+22°C

-10°C

80%

100%

100%

20%

+

Ventilator 1

Ventilator 2

+3°C

Detection meth-

od

Principle De-icing starts when...

Temperature con-

trolled

Temperature sensor Tice registers the temperature

in the heat exchanger and starts the de-icing proc-

ess when the indicated temperature is reached.

Temperature is below the set

value e.g. Tice < 0°C. (Menu 7.3)

3006401-2022-05-04 Starting up the unit for operation

17/72

4.3 Temperature controlled frost protection -- choice of method

RD13144GB-01

Heating coil

Yes No

METHOD 6

METHOD 4

The outdoor air gradually

bypasses the heat

exchanger

The outdoor air is

gradually reduced

The unit enters

hibernation mode

The unit starts every two

hours and monitors the

situation

The outdoor air is

gradually reduced

The unit enters

hibernation mode

The unit starts every two

hours and monitors the

situation

Air control method See section "Menu 3.1.1 Operating settings air control" for the air control method.

Start-up after hiber-

nation

The unit restarts after two hours of hibernation. If

● outdoor temperature is 2 Kelvin higher than when the unit went into hiberna-

tion, or

● if the temperature has risen above the level for activation of hibernation,

normal de-icing operation continues.

If neither of these two conditions are met within five minutes, the unit will enter hi-

bernation again.

Menu 3.5 - BMS

BMS >

Configuration >

3.5 BMS

None

Line in Menu 3.5 Comments

BMS Activating override control system BMS Op-

tions:

● None

● Modbus

● MTCP

● MLON

● BACnet MS

● BACnetIP

Configuration Configuration of Modbus and BACnet MSTP.

BMS configuration See detailed description in the instructions for the protocols.

3006401-2022-05-04 Starting up the unit for operation

18/72

Menu 3.5 - BMS

BMS >

Configuration >

3.5 BMS

None

Line in Menu 3.5 Remarks:

BMS Activating override control system BMS Op-

tions:

● None

● Modbus

● MTCP

● MLON

● BACnet MS

● BACnet IP

Configuration Configuration of Modbus and BACnet MSTP.

BMS configuration See detailed description in the instructions for the protocols.

4.4 What is an indoor air quality level?

Example

3.1.1.1.1 Comfort

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. /Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

Menu screen Parameters such as ventilation and temperature set points and control method for

a given indoor air quality level are grouped in a menu, as shown in the example

above.

Indoor climate levels Energy sav-

ing

People in

the room

Air-replace-

ment*

Deviation from desired room

temperature*

(Ventilation stopped) - No No ventilation No control of room temperature

Economy Menu

3.1.1.1.3

Large No Low Greatest temperature deviation

permitted*)

Standby Menu 3.1.1.1.2 Small No Low Least temperature deviation per-

mitted*

Comfort Menu 3.1.1.1.1 None Yes High Precise temperature

Manual Menu 3.1.1.1.4 Dependent

on setting

Yes/No Adjustable Adjustable

* Air-replacement and temperature deviation set via the HMI panel.

3006401-2022-05-04 Starting up the unit for operation

19/72

The current indoor air quality level can be controlled in five ways:

● Via a weekly plan, based on the given operating requirements. Set via the HMI

panel.

● Via an HMI panel in the room.

● Via sensor(s) positioned in the room or in the extract air duct (e.g. MIO-PIR,

MIO-CO2, MIO-RH, MIO-TS)

● Via a PC connected to the built-in Web server

● via a high-level control system (e.g. a BMS unit)

NB: The Comfort indoor climate level is the overall indoor climate level. The comfort

level is also activated if a mounted PIR sensor gives a signal (the unit

changes from an energy-saving indoor climate level/OFF).

Operation with CO2B, PIRB and RHB

See "VEX 308 EXact Operating and Servicing Instructions" for more details of VEX

operation with the following sensors:

● Operation with CO2 (CO2B) and motion sensor (PIRB)

● Operation with humidity (RHB) and motion sensor (PIRB)

● Also operation without activation from sensors

Menu 1 - Selecting operating mode

1 Operating mode

Operation > Manual

Select If

Manual The unit is intended to always operate at the same indoor air quality

level (set in menu 3.1.1.1.4) and operation is controlled manually via

the HMI panel or the Web server

Timer The unit is controlled automatically via a fixed weekly plan

Note for manual When the unit is operating in Manual indoor climate level, the values set for the

temperature setpoint (Temp. setpoint) and Air setpoint are shown immediately in

the user menu.

3.1.1.1.4 Manual

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

21°C

60%

3006401-2022-05-04 Starting up the unit for operation

20/72

Other manuals for EXact2 HMI2-350-TOUCH

1

Table of contents

Other Exhausto Control System manuals

Exhausto

Exhausto EXact2 VEX240 series Installation guide

Exhausto

Exhausto EXact2 VEX240 series User manual

Exhausto

Exhausto VEX150CF H User manual

Exhausto

Exhausto VEX260HX User manual

Exhausto

Exhausto VEX200 series Installation guide

Exhausto

Exhausto EBC11 User manual

Exhausto

Exhausto VEX370H User manual

Exhausto

Exhausto VEX160 Series User manual

Exhausto

Exhausto VEX320C User manual

Exhausto

Exhausto EXact2 HMI2-350-TOUCH Installation guide