Status Instruments SEM1600B User manual

D2534-01-04

SEM1600B

USER INSTRUCTIONS

Important - Please read this document before installing.

Every effort has been taken to ensure the accuracy of this document; however, we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice.

IMPORTANT – CE, UKCA & SAFETY REQUIREMENTS

Product must be DIN rail mounted, inside a suitable enclosure providing environmental

protection to IP65 or greater.

To maintain CE UKCA requirements, input and supply wires must be less than 30

metres.

The product contains no serviceable parts, or internal adjustments. No attempt must be

made to repair this product. Faulty units must be returned to supplier for repair.

Before attempting any electrical connection work, please ensure all supplies are

switched off.

ABSOLUTE MAXIMUM CONDITIONS (To exceed may cause damage

to the unit).

Supply voltage (SELV)

± 50 Vdc Protected for over-voltage

and reverse connection

Current with over-voltage

± 200 mA

Input voltage

± 10 VDC between any terminals

Input current

± 100 mA between any terminals

Environmental protection

IP65 or greater required

Ambient

Temperature (-30 to 75) °C

RH (10 to 95)% non-condensing

Important – Read this

document before installing.

--------------------------------------------------------------------------------------------------------------

1~DESCRIPTION.

The SEM1600B is a powered bridge amplifier for use with strain

gauges or load cell signals. The product has a built-in capability to

scale the input signal to a process value while the output stage offers

either voltage, bipolar voltage or active/passive current retransmission

signals. The device uses ratio metric measurement to obtain high

stability.

The product comes with an AC/DC power supply that will operate in

the range (10 to 48) VDC and (10 to 32) VAC making the device ideal

for battery operation. An additional volt-free contact input is available

for tare setting using a remote switch. The high precision input stage

of the device allows for a bridge excitation voltage of 5 VDC to be

used, as opposed to the traditional 10 VDC. This reduces the power

requirement for the bridge supply and up to four bridges (cells) may

be connected to the input.

To configure: connect a standard USB cable between the SEM1600B

and a PC. The free configuration software will guide you through any

changes you wish to make. The SEM1600B does not need to be

wired to a power supply for configuration.

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier immediately.

3~SPECIFICATION.

Refer to the datasheet for full specification. Download at www.status.co.uk

Factory

defaults

Calibration factor 2 mV/V, Balance 0.0

Sample rate 10 per s, Filter Off

Scale 2 points

Tare Setpoint 0, Tare Offset 0

Process Output 0 to 100 = (4 to 20) mA

Button locks Off

4~INSTALLATION AND WIRING.

Important safety requirements

This equipment is suitable for Environment Installation BS EN61010-1

Pollution Degree 2; Installation CAT II; CLASS I and is classed as

"PERMANENTLY CONNECTED EQUIPMENT". The equipment is

intended for industrial and commercial application only and is not

suitable for domestic or medical use.

The equipment must be mounted inside an enclosure that provides

protection >= IP65. In NORMAL USE, the equipment will only be

accessed for maintenance by qualified personnel.

Please ensure the equipment is mounted vertically with terminals (10,

11 and 12) at the bottom. This will provide maximum ventilation.

This equipment may generate heat. Ensure the enclosure size is

adequate to dissipate heat. Be sure to consider any other equipment

inside the enclosure.

The equipment surfaces may be cleaned with a damp cloth. Use a

mild detergent/water. Ensure the supply is off before cleaning and, on

completion of cleaning, the equipment is completely dry before the

supply is turned back ON.

This equipment must be installed by a qualified person. All electrical

wiring must be carried out in accordance with the appropriate

regulations for the place of installation.

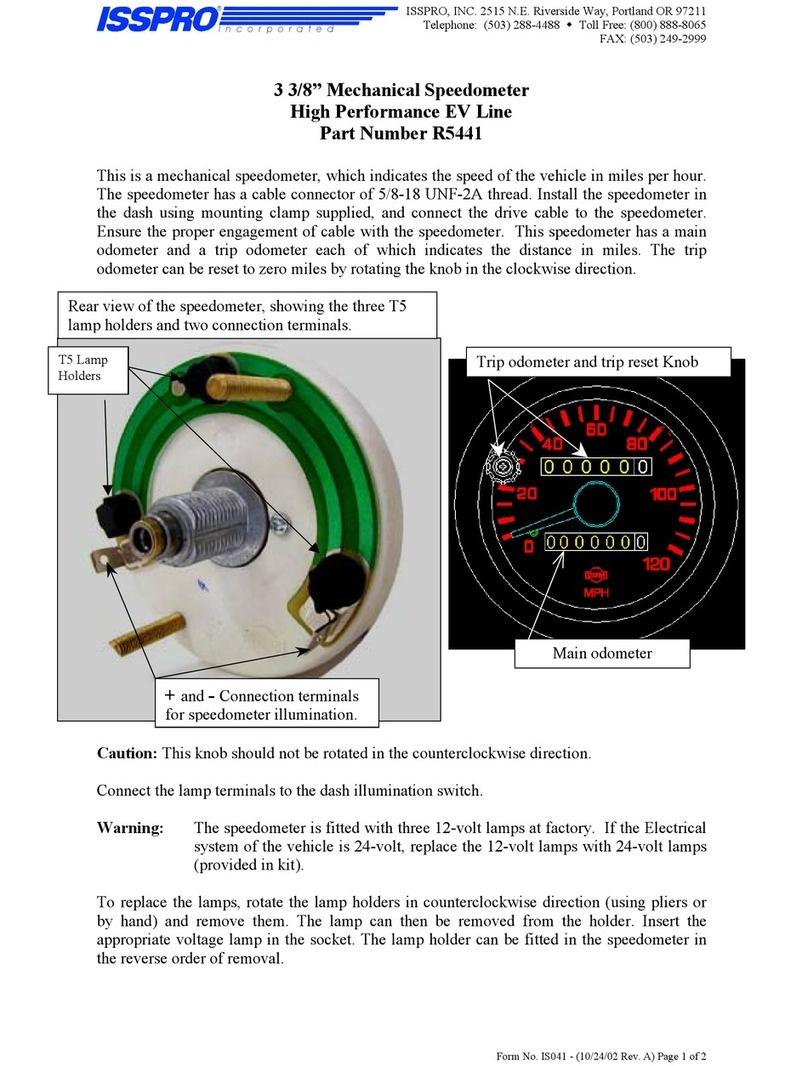

4.1~MECHANICAL.

Dimensions in mm

56.4 mm17.5 mm

1

2

11 1210

987

4 5 6

1 2 3

90mm

ADJUST

ST AT E

The equipment must be mounted on a DIN rail style DIN EN50022

inside a plastic or metal enclosure with a protection level >= IP65. All

wiring must be secured. Maximum cable sizes 2.5 mm². Connection is

via screw clamp terminals.

4.2~ELECTRICAL/CONNECTIONS

For wiring connections refer to the side label on the SEM1600B and

this document.

Supply (10 to 48) Vdc, (10 to 32) Vac

To maintain CE EMC requirements, input and supply wires must be

less than 30 metres.

Input cable lengths > 3 m it is recommended to use screened or

twisted pair.

Maximum mA output cable run = 1000 metres. The output loop

should be grounded at a single point.

Before installation, care must be taken to ensure enough voltage is

available in any loop to drive the total loop load.

D2534-01-04

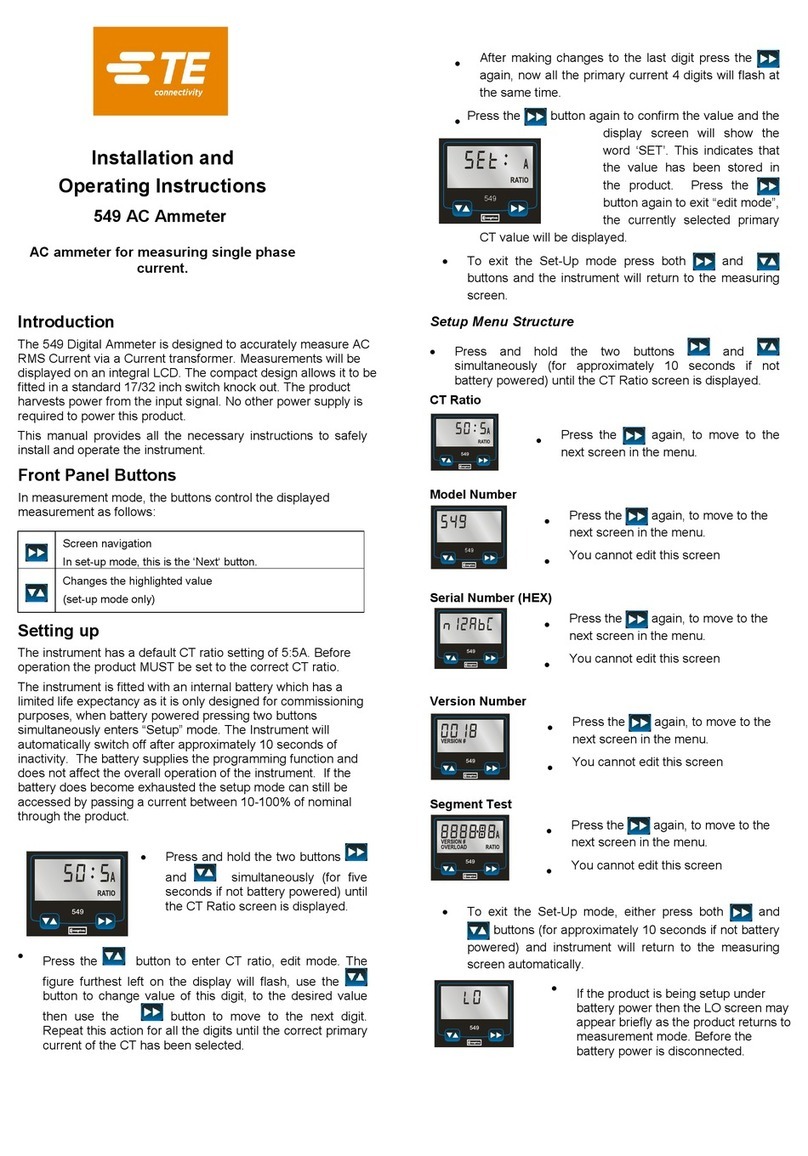

4.2~ELECTRICAL (continued)

SEM1600B Connections

1

+

SUPPLY

2

Vdc Vac

INPUT

4

Voltage

5

3

6

mA

6

5

mA Externally Powered

OUTPUT

Vs

Tare

Vexc

Bridge Input

Vexc

8

7

10

11

9

12

V

out

+

+

++

+

+

5~FEATURES.

5.1~STATE LED

The State LED is GREEN under normal run conditions indicating an

in-range input signal. If the input signal is out of range or is lost, the

State LED will light RED.

5.2~TARE

If PINs 9 and 12 are shorted (momentarily) the input value will be

overwritten by the TARE setpoint value (normally zero).

5.3~ACTIVE TRIM

Down Adjust button press: Configures the low scale output against the

live input signal.

Up Adjust button press: Configures the high scale output against the

live input signal.

Press and keep button pressed - the state light will go off for a few

seconds then flash at a fast rate before returning to a steady state.

Release button. Adjust operation complete. Output adjusts to levels

pre-set in the software configuration.

6~USER CONFIGURATION.

The SEM1600B can be configured using a Windows PC.

Live input and output values can also be viewed on a PC or a suitable

Android device.

6.1~PC CONFIGURATION USBSpeedLink Software

During configuration the equipment takes its power from the

USB port, therefore no power connection is required. The equipment

can be configured whilst powered but the computer used must be

portable battery-powered or a USB isolator should be used to isolate

the SEM1600B from the supply earth to avoid grounded earth loop

effects.

Observe any warning information given in the software.

PC Configuration steps

1

Download and install the USBSpeedLink software from

www.status.co.uk

2

Run the software and open to the correct screen for the SEM1600B

3

Connect to the PC using an A to Mini B USB lead.*1

4

Read the SEM1600B configuration into the software.

5

Configure the device to the required settings for operation.

5.1

SEM1600B configuration options:

Model:Free type field

Calibration factor: From sensors/Load cell datasheet.

Balance:From Load cell calibration certificate if available.

Tag:Free type field

Sample rate:Samples per second

Filter: Rate in seconds

Scale points:2 up to 6 points

mV to Process value table:mV input to process table

Units:Free type field for Engineering unit

Tare Clear: Removes Tare

Tare Setpoint:Value the input is set to on Tare action

Tare Offset:

Difference between input and Tare setpoint on

tare action

Output Signal:mA, V, ±V

Output Range:Any within limits

Button locks:On, Off

6

Read Data:Live data can be displayed showing input and output

values. This can only be done if the device is powered as well as

connected to the software via the USB lead.

*3

7

Write/Save:the configuration to the device. *2

*1 Once only, on the first time connecting to the SEM1600B, drivers will

install to the PC, allow time for this before proceeding.

*2 The configuration is not saved onto the device unless the configuration

screen is sent.

*3 The SEM1600B can be configured whilst connected and powered, but a

portable battery powered computer or USB isolator must be used to avoid

the effects of ground loops.

.

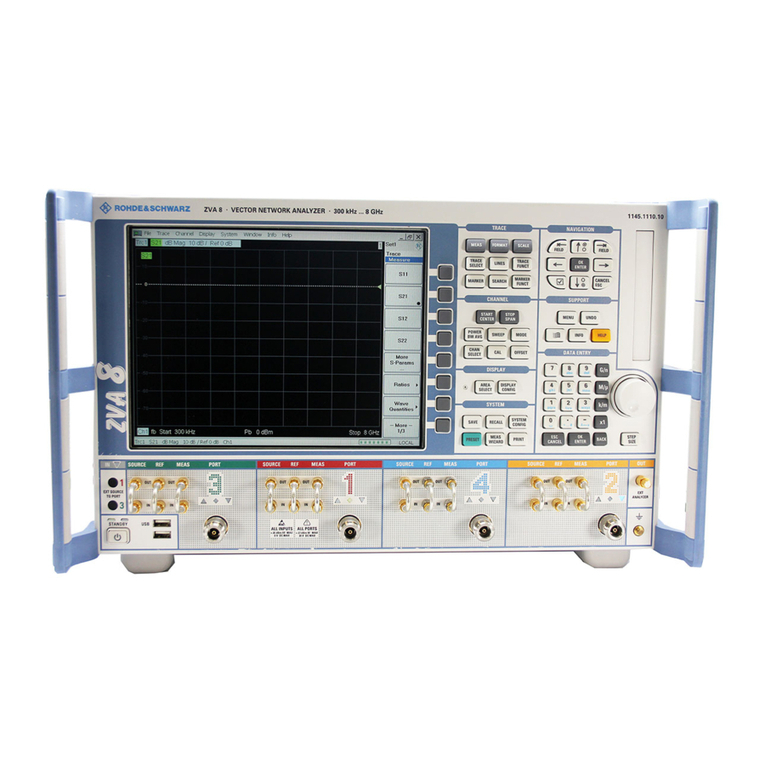

Configuration screen

6.2~ANDROID MONITORING USBView Software

Using a suitable OTG USB lead to connect the SEM1600B to an

Android device, live data reading can be taken.

The USBView app. can display input temperature/value, output mA/V

and the Tag information.

USB Software can be downloaded free of charge from

www.status.co.uk

www.status.co.uk

This guide is also available online at www.status.co.uk

Status Instruments Ltd, Status Business Park, Gannaway Lane, Tewkesbury, Gloucestershire, UK, GL20 8FD,

Web Page: www.status.co.uk,

Technical Support: support@status.co.uk

Tel: +44 (0) 1684 296818, Fax: +44 (0) 1684 293746

Other Status Instruments Measuring Instrument manuals

Status Instruments

Status Instruments DM4500U User manual

Status Instruments

Status Instruments DM3600A User manual

Status Instruments

Status Instruments DM3600U User manual

Status Instruments

Status Instruments DM650HM User manual

Status Instruments

Status Instruments DM4000U User manual

Status Instruments

Status Instruments SEM1620 User manual

Popular Measuring Instrument manuals by other brands

Signal Hound

Signal Hound SA44B user manual

Endress+Hauser

Endress+Hauser Micropilot M FMR231 operating instructions

Keysight Technologies

Keysight Technologies 34136A user guide

ColorLite

ColorLite ColorCube quick start guide

Endress+Hauser

Endress+Hauser Micropilot FMR50 Brief operating instructions

Honeywell

Honeywell W8710A manual