Status Instruments DM4000U User manual

Table of contents

Other Status Instruments Measuring Instrument manuals

Status Instruments

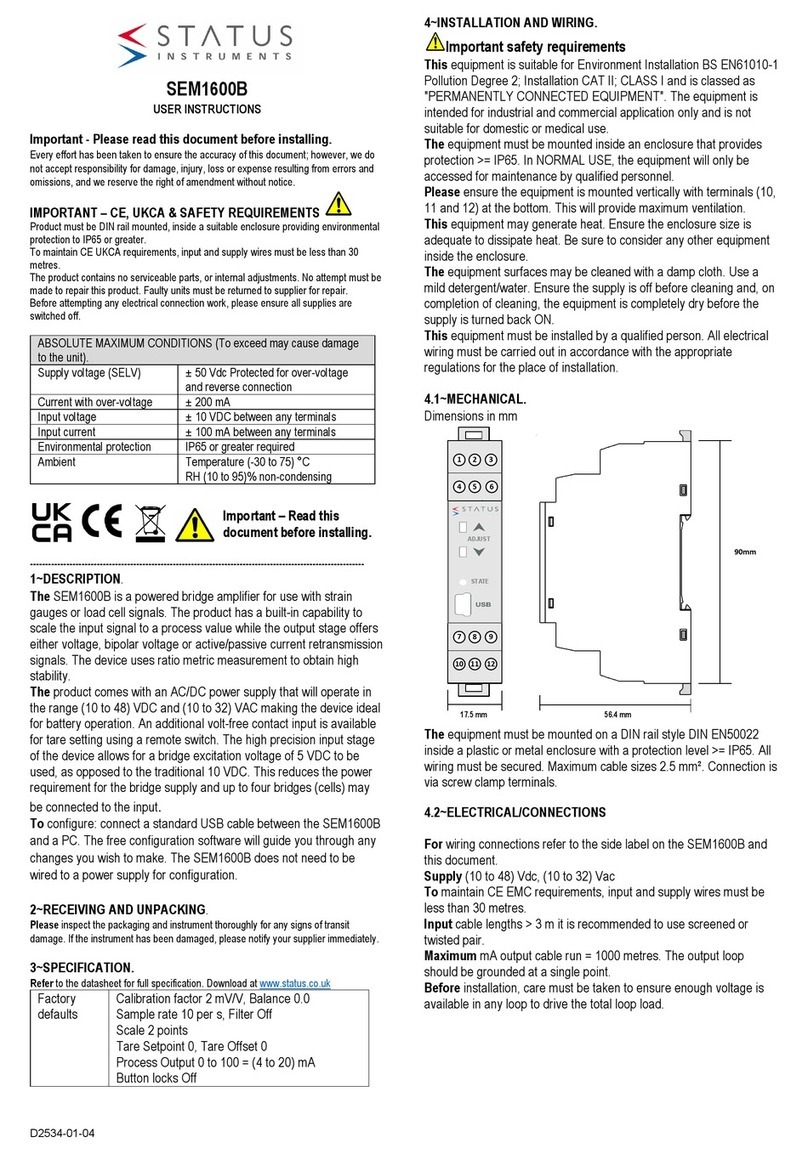

Status Instruments SEM1600B User manual

Status Instruments

Status Instruments DM3600A User manual

Status Instruments

Status Instruments SEM1620 User manual

Status Instruments

Status Instruments DM650HM User manual

Status Instruments

Status Instruments DM4500U User manual

Status Instruments

Status Instruments DM3600U User manual

Popular Measuring Instrument manuals by other brands

Amprobe

Amprobe TMA10A user manual

Industrial Temperature Sensors

Industrial Temperature Sensors Series P400 operating instructions

Renishaw

Renishaw SP600 Installation and user guide

Stocks AG

Stocks AG MM 117A Installation, Calibration and Operation

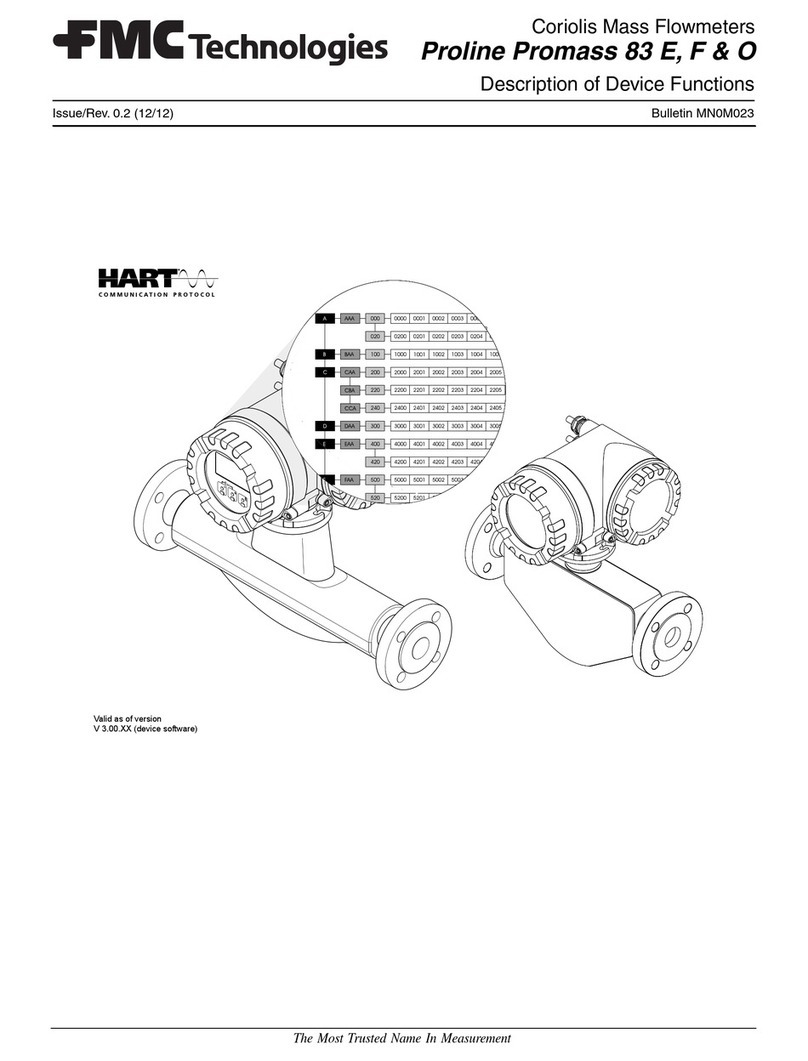

FMC Technologies

FMC Technologies Proline Promass 83 E Description of Device Functions

Krone

Krone OPTISOUND 3030 C operating instructions