Status Instruments DM4500U User manual

Page 1 of 54

PROCESS CONTROL

TEMPERATURE AND

LOAD CELL INDICATOR

INSTRUCTION MANUAL

DM4500U

Page 2 of 54

Page 3 of 54

INDEX

1. OVERVIEW ...................................................................................... 4

1.1. Introduction to DM4500U.................................................................... 4

2. GETTING STARTED ......................................................................... 5

2.1. Power supp y and connectors.............................................................. 9

2.2. Instrument front pane ....................................................................... 11

2.3. Programming instructions ................................................................... 11

3. INPUT CONFIGURATION................................................................ 13

3.1. Process input Programming................................................................. 15

3.1.1. Transducer connection (V, mA) .............................................. 15

3.1.2. Wiring diagram for mA input .................................................. 16

3.1.3. Wiring diagram for V input..................................................... 17

3.2. Load ce input Programming............................................................... 18

3.2.1. Load ce connection (mV/ V) ................................................. 19

3.3. Thermometer Pt 100 input programming ............................................. 20

3.3.1. Pt100 input connection .......................................................... 21

3.4. Thermocoup e input programming....................................................... 22

3.4.1. Thermocoup e input connection (J, K, T) ................................ 24

4. DISPLAY PROGRAMMING .............................................................. 25

4.1. Sca e ................................................................................................. 26

4.1.1. Sca e programming ............................................................... 28

4.2. Fi ter................................................................................................ 30

4.3. Round ............................................................................................. 30

4.4. Brightness........................................................................................ 30

4.5. Tare Mode ....................................................................................... 30

5. FUNCTIONS BY KEYBOARD AND BY CONNECTOR........................ 33

5.1. Functions by keyboard........................................................................ 33

5.2. Functions by connector....................................................................... 36

5.2.1. Logica functions diagram ...................................................... 37

5.2.2. Tab e of programmab e functions .......................................... 37

5.2.3. Functions programming ......................................................... 38

6. PROGRAMMING LOCK-OUT BY SOFTWARE .................................. 39

6.1. Security menu diagram....................................................................... 40

7. OUTPUT OPTIONS .......................................................................... 43

7.1. SETPOINTS OUTPUT .......................................................................... 44

7.1.1. Introduction.......................................................................... 44

7.1.2. Functioning description.......................................................... 44

7.1.3. Wiring .................................................................................. 46

7.1.4. Technica Specifications / setpoints ........................................ 47

7.1.5. Setpoints menu diagram ....................................................... 48

7.1.6. Direct access to programming of setpoints va ue .................... 49

7.2. ANALOG OUTPUT............................................................................... 50

7.2.1. Introduction.......................................................................... 50

7.2.2. Technica Specifications / ana og ............................................ 51

7.2.3. Ana og output menu Diagram ................................................ 51

TEC NICAL SPECIFICATIONS ....................................................... 52

Page 4 of 54

1. OVERVIEW

1.1 Introduction to model DM4500U

The DM4500U mode is a digita mu tifunction instrument which

a ows the user to program the input as a:

- PROCESS INPUT (V, mA)

- LOAD CELL INPUT (mV)

- Pt100 INPUT

- THERMOCOUPLE INPUT (J, K, T)

The basic instrument is a so dered assemb y composed of a main

board, a tricolor programmable display and a power circuit.

Standard features of the basic instrument inc ude the reading of the

input variab e as we as remote ho d, reading and memorisation of

max and min va ues (peak/ va ey), tare and reset function, and a

fu comp ement of programmab e ogic functions.

In addition, a variety of output options can be insta ed at the

factory from the ist be ow :

COMMUNICATION

OPT4500/485 Seria RS485

CONTROL

OPT4500/mA Ana ogue (4 to 20) mA

OPT4500/V Ana ogue (0 to 10) V

OPT4500/2R (2 x Re ays SPDT 8A)

OPT4500/4R (4 Re ays SPST 5A)

OPT4500/NPN (4 NPN output)

OPT4500/PNP (4 PNP output)

A the output options are opto iso ated from input signa and power

supp y.

This instrument conforms to the fo owing community

standards: 89/336/CEE and 73/23/CEE

Warning: Refer to the instruction manua to preserve

safety protection.

Page 5 of 54

2. GETTING STARTED

Packing contents

Instruction manua

Digita pane meter DM4500U

Accessories for pane mounting (sea ing gasket and fixing

c ips).

Accessories for wiring connections (p ug-in termina b ock

connectors with a fingertip key).

Wiring abe (fixed to the product housing).

Legend abe with engineering units.

Check the packing contents.

Programming instructions

The Instrument is programmab e via the front pane keyboard

and a ows access to severa independent programming menus

for configuration of the input, the disp ay and the ogic

functions. If additiona options are insta ed (seria outputs,

ana ogue output and re ays output) once recognised by the

instrument, they activate their own programming software.

Programming lock-out (See section 6).

The software can be configured to a ow tota programming ockout

but a so se ective ockout of the programming parameters.

The instrument is de ivered from the factory with un ocked

programming, e.g., with a the programming eve s accessib e

to the operator

TIP! - Write down the security code and keep it in a secure

place.

Page 6 of 54

Front: 96 x 48 mm

Depth: 60 mm

Panel cut-out: 92 x 45 mm

CLEAN NG:

Front cover should be cleaned only

with a soft cloth soaked in neutral

soap product.

DO NOT USE SOLVENTS

Dimensions and mounting

Page 7 of 54

Programming the instrument.

First, connect the instrument to the corresponding supp y;

automatica y, a disp ay test wi be done and the software version

wi be shown, then the instrument wi go to run mode.

Next, press the

key to enter into the programming mode;

the indication "-Pro-" wi appear on the disp ay.

ow to store programmed parameters?

To save the changes that have been programmed, the operator

must comp ete the programming of a the parameters contained in

the current routine. In the ast step of the routine, by pressing the

key, “StorE” wi be disp ayed and a changes are stored in

memory. Then the instrument wi return to the run mode.

ow is programming routine organised?

Programming software is composed by a number of menus and

submenus. In the diagram be ow, beginning with indication "-Pro-",

press repeated y to get access to programming menus. B ocks

3, 4 and 5 re ate to output options and wi on y be shown if the

option is fitted.

Se ecting one menu, access to the different programming

submenus is done by pressing

.

Modu e se ection eve

Page 8 of 54

Access to programmed parameters

Because of the menu structure, the programming routines a ow

access to change one parameter without passing through the who e

ist of parameters.

To advance through programming

Progress through programming routines is done by pressing

key.

In genera , push key a certain number of times to se ect an

option and push key to va idate the change and to go forward

to the next step of the program.

The numerica va ues are programmed digit by digit as exp ained in

the next paragraph.

Programming numerical values

When the parameter is a numerica va ue, the disp ay wi show the

first digit to be programmed f ashing.

Digit selecting: Press repeated y the key to shift from eft to

right over a the disp ay digits.

Changing the digit value: Press the

key repeated y to

increase the va ue of f ashing digit unti it has the desired va ue.

The minus sign is programmed depending on the variab e type. A

variab e that represents the va ue of an input wi be ab e to take a

va ue in the range -19999 to 99999, without taking into account the

decima point. When changing the first digit, this shows va ues from

(0) to (9), and then (-1), (-), and comes back to show va ues from

0 to 9.

A variab e that represents a disp ay va ue wi be ab e to take a

va ue in the range -19999 to 99999, without taking into account the

decima point. In these case the first digit shows 0, 1, -1 or -.

Page 9 of 54

Selecting an option from the list

When the parameter is an option to be chosen among different

possibi ities, the key a ows you to browse through the ist of

options unti you find the desired parameter.

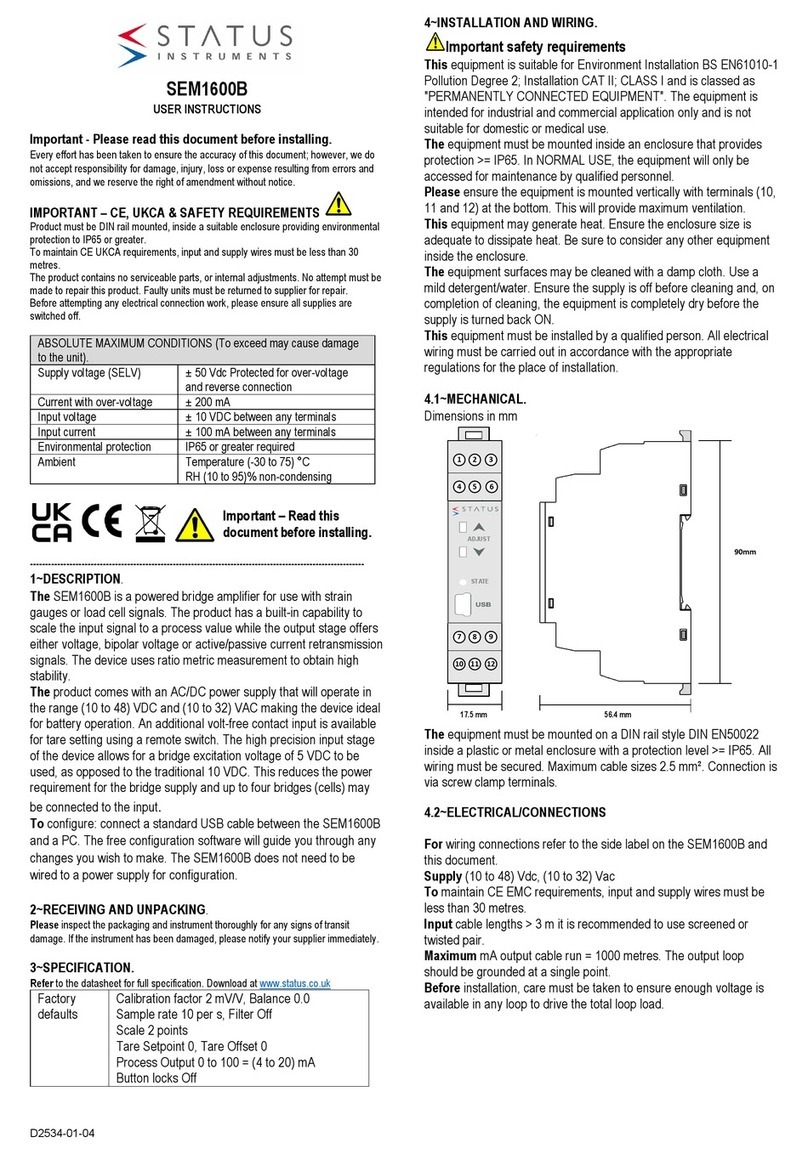

2.1 – Power Supply and connectors

WARNING: If not installed and used in accordance with

these instructions, protection against hazards may be

impaired.

In order to guarantee the e ectromagnetic compatibi ity, the

fo owing guide ines shou d be kept in mind:

-Power supp y wires shou d be

routed separate y from signa

wires.

-Never run power and signa wires

in the same conduit.

-Use shie ded cab e for signa

wiring and connect the shie d to

the ground of the indicator.

-The cab e section shou d be >0.25

mm2

INSTALLATION

To meet the requirements of the directive EN61010-1, where the

unit is permanent y connected to the mains supp y, it is ob igatory

to insta a circuit breaking device within easy reach of the operator

and c ear y marked as the disconnect device.

1

2

Page 10 of 54

WIRING and POWER SUPPLY RANGE

DM4500/S1

(85 to 265) VAC (50 to 60) Hz, or (100 to 300) VDC

DM4500/S2

(22 to 53) VAC (50 to 60) Hz, or (10.5 to 70) VDC

Pin 1: Live

Pin 2: Neutra

CONNECTORS

CN1 To perform wiring connections, strip the

wire eaving between (7 and 10) mm exposed

and insert it in the required termina whi e

pushing the c amp too down to open the c amp

inside the connector as indicated in the figures.

CN1 termina accepts cab es of section between

0.33 mm² and 2 mm² (22 to 14 AWG)

Recommended cab es size 2.0 mm²

CN2 & CN3 To perform wiring

connections, strip the wire eaving

between (5 and 6) mm exposed and

insert it in the required termina whi e

pushing the fingertip too in to open

the c amp inside the connector as

indicated in the figures.

Each termina accepts cab es of

section between 0.08 mm² and 0.5

mm² (28 to 20 AWG)

Recommended cab es size 0.5 mm²

Page 11 of 54

2.2 –Instrument frontal view

2.3 – Programming guide

To programme the product to accept different sensor types,

p ease see the sections be ow. To save time we have

marked paragraphs as ob igatory (O), recommendab e (R)

or optiona (op).

As Process indicator:

1. Input Configuration (Sec. 3.1) (O).

2. Input Connection (Sec. 3.1.1/2 & 3) (O).

3. Disp ay Configuration (Sec. 4) (O).

4. Program remote inputs (Sec. 5.2) (R).

5. Insta and configure output option(s) (Sec. 7) (op)

6. Programming ock-out (Sec. 6) (R).

As thermometer Pt100:

1. Input Configuration (Sec. 3.3) (O).

2. Input Connection (Sec. 3.3.1) (O).

3. Program remote inputs (Sec. 5.2) (R).

4. Insta and configure output option(s) (Sec. 7) (op).

5. Programming ock-out (Sec. 6) (R).

As Load cell indicator

1. Input Configuration (Sec. 3.2) (O).

2. Input Connection (Sec. 3.2.1) (O).

3. Disp ay Configuration (Sec. 4) (O).

4. Program remote inputs (Sec. 5.2) (R).

5. Insta and configure output option(s) (Sec. 7) (op).

6. Programming ock-out (Sec. 6) (R).

Page 12 of 54

As thermometer thermocouple:

1. Input Configuration (Sec. 3.4) (O).

2. Input Connection (Sec. 3.4.1) (O).

3. Program remote inputs (Sec. 5.2) (R).

4. Insta and configure output option(s) (Sec. 7) (op).

5. Programming ock-out (Sec. 6) (R).

Page 13 of 54

3. INPUT CONFIGURATION

The figure be ow shows the input configuration menu. Divided into

four submenus, each one of them separated by the dotted ine in

the manua , each menu corresponds to the programming of the

different types of input: process, oad ce , thermometer Pt100 and

thermometer thermocoup e. The data requested in each case is

indicated be ow.

Cn nP

ProC

10 V

- Pro -

20 mA

LoAd

15 mV

- Pro -

30 mA

Process:

Input type

and

ranges

±(0 to 10) V

or

±(0 to 20) mA

Load Cell:

Input ranges

±15 mV, ±30 mV, ±150 mV

150

mA

tEMP

Pt 100

°C °F

Thermocouple :

Type: J,K & T ranges

Units: °C, °F

Resolution: 0.1°, 1°

Offset -9.9° to +9.9°

-99° to +99°

0.1 °C 1 °C

00.0 Offset

- tC -

- J - - K -

- °C - - °F -

- T -

0.1 °C 1 °C

00.0 Offset

- Pro -

- Pro -

Pt100 :

Units: °C, °F

Resolution: 0.1°, 1°

Offset -9.9° to +9.9°

-99° to +99°

Page 14 of 54

Pro Top Level (Programming menu entry point)

CnInp Level 1

Channe Input; for se ecting the correct type of input configuration for the sensor

to be used.

Options avai ab e; Proc, LoAd, tEMP

Proc Level 2

(See Sec. 3.1)

LoAd Level 2

(See Sec. 3.2)

Process input type se ection. Load ce input se ection

Options avai ab e; 10 V, 20 mA Options avai ab e; 15 mV, 30 mV,

150 mV

10 V Sub level 15 mV Sub level

Input range +/ (0 to 10) V Input range (-15 to 15) mV

20 mA Sub level 30 mV Sub level

Input range +/ (0 to 20) mA Input range (-30 to 30) mV

150 mV Sub level

Input range (-150 to 150) mV

Temp Level 2

Temperature input type se ection. Options avai ab e are PT100 and TC

Pt100 Level 3 See 3.3 tC Level 3 See 3.4

Pt100 input type configuration,

options avai ab e are:

Disp ay unit, Disp ay reso ution, User

offset

Thermocoup e input type

configuration, options avai ab e are:

TC type, Disp ay unit, Disp ay

reso ution, User offset

J, K, T Sub level

TC type se ection.

°C or °F Sub level

The disp ayed temperature unit can be se ected.

0.1° or 1° Sub level

The disp ay reso ution can be se ected.

Offset Sub level

A va ue can be entered by the user which wi be app ied to the measured va ue

before it is disp ayed. The va ue entered is app ied across the entire measurement

range. This can be used to tune out system errors.

Page 15 of 54

3.1 – Program process input

When used as a process indicator, the parameter to configure is the

input type, in vo ts (-10 to 10) Vdc range or in mi iamperes (-20 to

20) mA range.

3.1.1 – Sensor connection (V, mA)

Refer to wiring guide ines in (Sec. 3.1.2/3)

Instrument rear view

CONNECTOR SIGNAL INPUT

CN2

PIN 1 = -EXC [excitation output (-)]

PIN 2 = +EXC [excitation output +24 V (+)]

PIN 3 = +EXC [excitation output +5 V or 10 V (+)]

PIN 4 = N/C [no connection]

PIN 5 = +IN [input mA (+)]

PIN 6 = +IN [input V (+)]

PIN 7 = N/C [no connection]

PIN 8 = -IN [input V (-), mA (-)]

CN2

1 2 3 4

5 6 7 8

Page 16 of 54

3.1.2 WIRING DIAGRAM FOR INPUT Ma

(±0 to 20) mA / (4 to 20) mA

-

+ EXC

+ OUT

- mA

+ mA

2 wire connection

[ only (4 to 20) mA ]

1

8

EXTERNAL

EXCITATION

SENSOR

(4 to 20) mA

- EXC

+ EXC

+ OUT

- OUT- mA

+ mA

4 wire

connection

1

8

SENSOR

(0 to 20) mA

(4 to 20) mA

+ mA

+ EXC

+ OUT

1

8

SENSOR

(4 to 20) mA

2 wire connection

[ only (4 to 20) mA ]

External Excitation

Internal Excitation

- EXC

+ EXC

+ OUT

- OUT

- mA

+ mA

1

8

EXTERNAL

EXCITATION SENSOR

(0 to 20) mA

(4 to 20) mA

4 wire

connection

EXTERNAL

EXCITATION

-

+ EXC

+ OUT

CO- mA

+ mA

SENSOR

(0 to 20) mA

(4 to 20) mA

1

8

3

wire connection

+ EXC

+ OUT

CO- mA

+ mA

1

8

SENSOR

(0 to 20) mA

(4 to 20) mA

3

wire connection

If the excitation supplied by the unit to

the sensor has to be (5 or 10) V connect

the +EXC wire to PIN3 instead of PIN2

Page 17 of 54

3.1.3 WIRING DIAGRAM FOR INPUT V (±0 to 10) V

If the excitation supplied by the unit to

the sensor has to be (5 or 10) V connect

the +EXC wire to PIN3 instead of PIN2

-

+

+ OUT

- OUT

- V

+ V

DM

4500U

1

8

EXTERNAL

EXCITATION

SENSOR

(0 to 10) V

3 wire

connection

- V

+ V

1

8

EXTERNAL

EXCITATION - EXC

+ EXC

+ OUT

- OUT

4 wire

connection

SENSOR

(0 to 10) V

DM

4500U

- V

+ V

DM

4500U

1

8

- EXC

+ EXC

+ OUT

- OUT

4 wire

connection

SENSOR

(0 to 10) V

- V

+ V

DM

4500U

1

8

+ EXC

+ OUT

- OUT

3 wire

connection

SENSOR

(0 to 10) V

+ OUT

- OUT

- V

+ V

DM

4500U

1

8

SENSOR

(0 to 10) V

2 wire

connection

+ EXC (10 V)

- V

+ V

1

8

+ OUT

- OUT

Poteniometer

DM

4500U

Page 18 of 54

3.2 – Programming of Load cell input

Refer to ce manufacturer’s documentation, particu ar y with

respect to the ce sensitivity and supp y vo tage specifications.

As oad ce indicator, the meter’s function is to measure forces

(weight, pressure, torque...) app ied to a sensing e ement

connected to severa bridge type transducers, such as oad ce ,

which supp y signa eve s up to ±150 mV.

The two excitation vo tages supp ied by this instrument are 10 V

and 5 V. The se ection is rea ised through the configuration of the

interna bridge excitation (see diagram be ow). This way up to 2

ce s can be connected in para e with 10 V excitation and up to 4

ce s with 5 V excitation, without need for an externa source (see

connection (Sec. 3.2.1)).

Examp e:

2 ce s with 2 mV/V output are supp ied with an excitation

vo tage of 10 V; the vo tage generated by each ce at fu

oad is 20 mV. Therefore 20 mV is the maximum output as

the ce s are connected in para e . In the same case but

with a 5 V excitation, the maximum vo tage generated wi

be 10 mV.

Software configuration requires programming of the input mV range

which can be se ected from a choice of 3 ranges to avoid ‘out of

range’ signa s. There are three ranges: ±15 mV, ±30 mV and ±150

mV

Examp e:

If a weighing process gives 12 mV to the meter input with

maximum oad, the best input range to se ect wi be "15 mV".

Selection of voltage excitation 10 V or 5 V

5 V Exc. Jumper on

10 V Exc. Jumper off

Page 19 of 54

3.2.1 – Load cell connection (mV/ V)

Refer to wiring guide ines (Sec. 2.1).

Instrument rear view

CONNECTOR SIGNAL INPUT (CN2)

PIN 1 = -EXC [excitation output (-)]

PIN 2 +EXC [no connection]

PIN 3 = +EXC [excitation output +5 V or 10 V (+)]

PIN 4 = N/C [no connection]

PIN 5 = N/C [no connection]

PIN 6 = N/C [no connection]

PIN 7 = +mV [input mV (+)]

PIN 8 = -mV [input mV (-)]

+

OUT

-

OUT

7

+IN

-

IN

1

3

8

-

+

+EXC

-

EXC

1

8

7

3

(0 to 100)

mV

CN2

1

2 3

4 5 6 7 8

Page 20 of 54

3.3 - Programming of Pt100 input

When configuring the meter as thermometer for 3 wires Pt100

sensors, the temperature ranges and reso ution avai ab e are:

Input Range (res. 0.1 º) Range (res. 1 º)

(-100.0 to +800.0) ºC (-100 to +800) ºC

Pt100 (-148.0 to +1472.0) ºF (-148 to+1472) ºF

The Pt100 software menu a ows se ection of temperature units

(Ce sius or Fahrenheit), reso ution (degree or tenth of degrees) and

a disp ay offset. Provision is made to a ow for a sensor offset. If

there is a difference between the temperature under measurement

and the temperature read by the sensor, this can be corrected by

programming an offset from -9.9 to +9.9, with 0.1 º reso ution, or

from -99 to +99, with 1 º reso ution. LED ‘TARE’ will light up

each time that an offset value is programmed.

Examp e:

In a process of temperature contro the Pt100 sensor is

ocated in a part of the process where temperature is 10

degrees be ow than in the point in where the contro has to

be done. By programming an offset of 10 points, with 1

degree reso ution, the deviation wi be corrected.

Configurab e parameters for this input are:

a) Reading units in degree Ce sius "ºC" or Fahrenheit "ºF".

b) Reso ution in tenth of degrees "0.1 º" or in who e

degrees "1 º".

c) Offset. Offset va ue is programmab e up to ±9.9 º with

tenths reso ution, or up to ±99 º with degree reso ution.

The instrument comes from the factory with offset=0

After entering these parameters, the disp ay range and inearization

are adjusted automatica y.

Table of contents

Other Status Instruments Measuring Instrument manuals

Status Instruments

Status Instruments DM650HM User manual

Status Instruments

Status Instruments DM4000U User manual

Status Instruments

Status Instruments SEM1620 User manual

Status Instruments

Status Instruments DM3600U User manual

Status Instruments

Status Instruments SEM1600B User manual

Status Instruments

Status Instruments DM3600A User manual