8

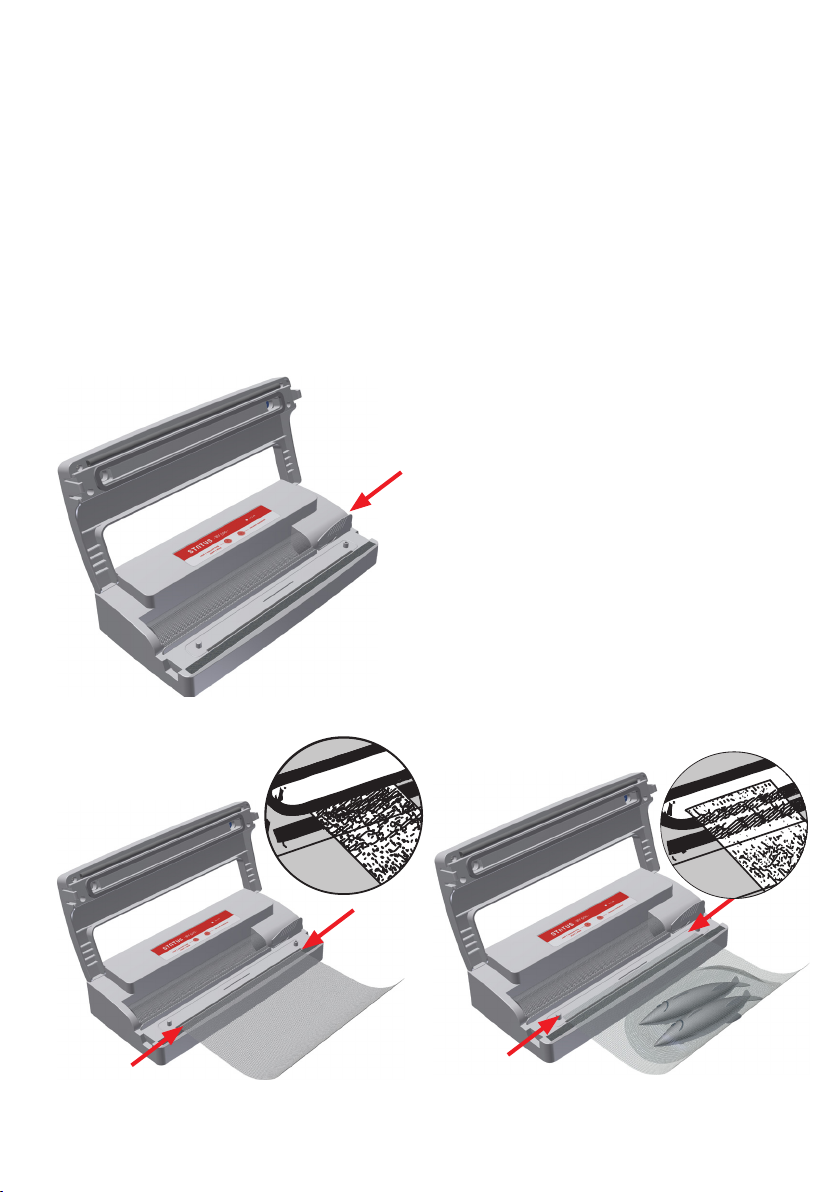

c.) Place the roll on the Sealing Strip and extend it

to the black Silicon Gasket (Item 7 in Figure 1,

see Figure 3). Make sure that the edge is straight

and level.

d.) Close the lid.

e.) Press the Bag/Start/Stop button (Item 1 in

Figure 1) and press down on lid with your hand

and hold it. The lid will automatically stick down

and seal the bag. If the Lid can be opened during

the process, you didn’t press down hard enough,

so repeat the procedure. During sealing, the light

(On/Off) will be illuminated 100%.

f.) When the sealing process is completed, push

Valve (Item 4 in Figure 1) lightly to move it asi-

de. Open the lid and check the seal. It should be

smooth and transparent over its whole width.

Figure 2: Cut the roll with the included cutter.

Figure 3: Place the roll on the Sealing Strip and extend

it to the black Silicon Gasket to seal (see arrows).

2.2.3. WHEN THE BAG IS MADE,

PLACE FOOD IN IT AND

VACUUM PACK

The bag should be at least 5 cm longer than the

space, occupied by the item to be vacuum packed.

a.) Place the items to be vacuum packed in the bag.

b.) Make sure that inner surfaces (for the sealing

edge) are clean, dry and free from food materials.*

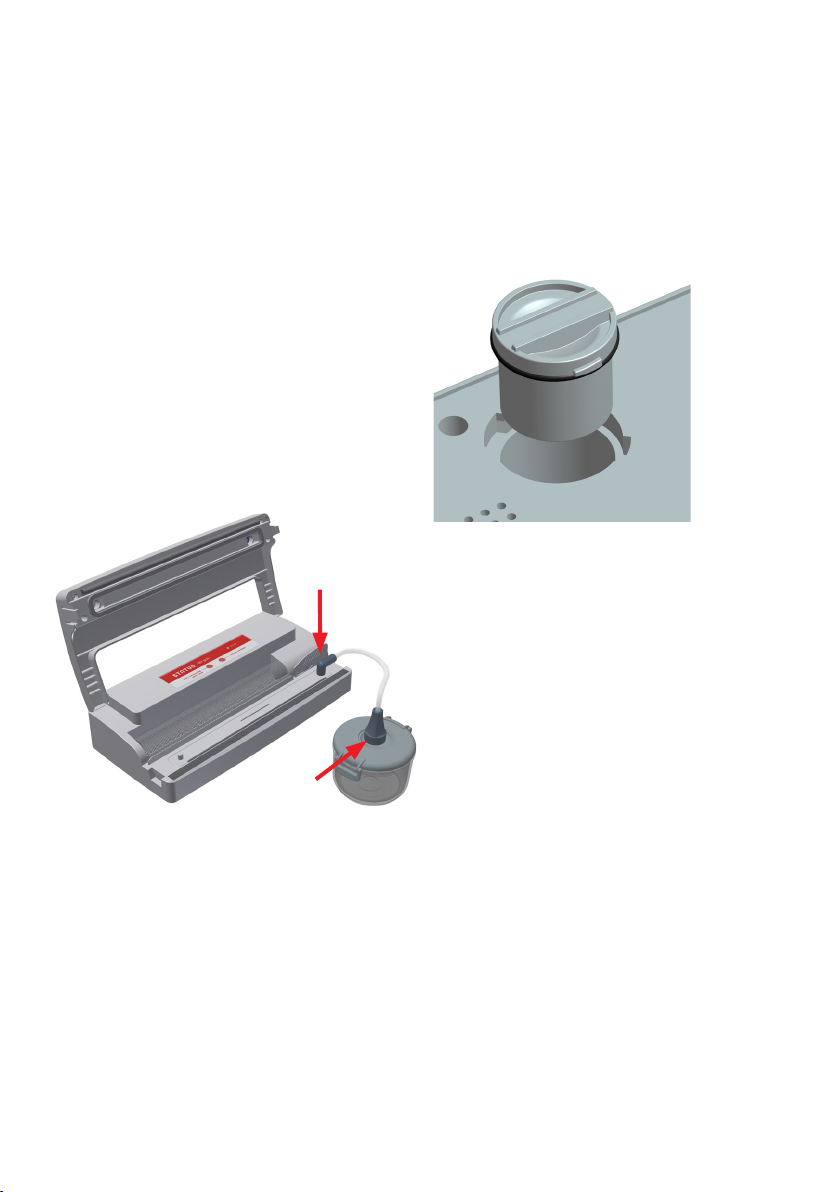

c.) Place the lled bag on the work surface in front

of the machine and pull it to the middle of the

Vacuum Compartment (see Figure 4 and Item 8

in Figure 1).

d.) Make sure that the bag placed on the Sealing

Strip is completely smooth (not creased).

e.) Close the machine, press on the lid and hold it

down.

f.) Activate the Bag/Start/Stop button (Item 1 in

Figure 1). Hold lid pressed until indicator light

begins to shine with its full power. The bag will be

vacuum packed and sealed automatically. Due to

high vacuum pressure the lid stays closed while

the machine operates. If the lid opens during this

process then press the lid down rmly.

g.) When the sealing process is complete, push valve

(Item 4 in Figure 1) lightly to move it aside for lid

to relax. Check the seal - it should be smooth and

transparent over its whole width.

*RECOMMENDATION: When vacuum packing greasy

products (especially bacon) it is strongly recommen-

ded to reverse the outside edges of bag, put the item

inside and reverse the edges back again. This keeps

the area to be sealed free of grease.

Figure 4: Place the lled bag in the middle of the

Vacuum Compartment (between salient circle line -

see arrows).