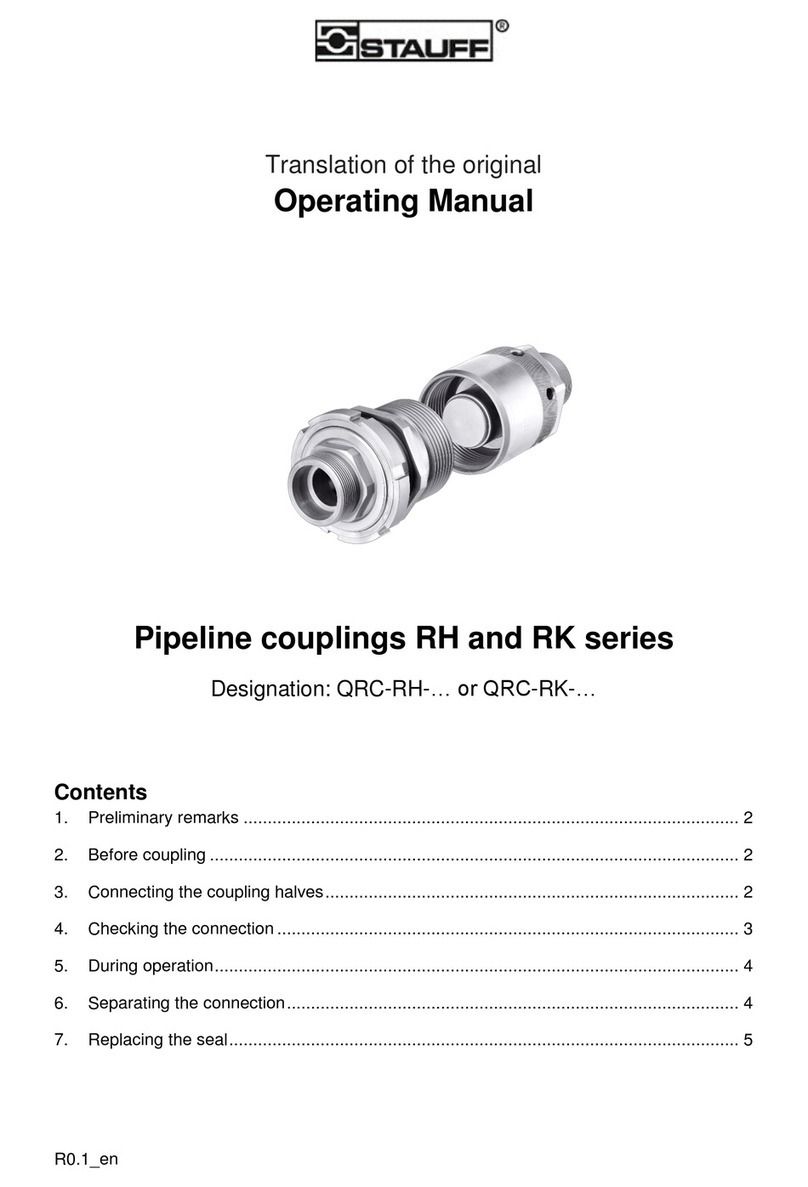

3. Before coupling

Remove the dust caps and store them in a locationprotected against dirt. If necessary, remove

the retaining device first. Carry out a visual check for cleanliness, damage and completeness

on both coupling halves, including the visible seal.

Use suitable products to clean the coupling halves if they are soiled. Use lint-free cloths and

never use products that could corrode the seals or metallic surfaces of the couplings or that

have a strong degreasing effect (e.g. brake cleaner).

Do not allow foreign substances, such as cleaning agents, water or dirt, to enter into the

hydraulic system during cleaning. For this reason, never direct high-pressure cleaners directly

at the valves of the coupling halves.

Replace any damaged couplings. Replace any coupling halves on which individual

parts have become detached. Always replace the components in pairs.

4. Connecting the coupling halves

Place the loose part (male tip) onto the fixed half (female body) without canting and connect

them with the screw sleeve.

Ensure that the coupling halves are not under pressure during coupling.

If the female body is not firmly clamped into a bulkhead wall by the locknut, use a face spanner

to counter the hexagon profile on the female body when screwing on the screw sleeve of the

male tip.

At the end of the coupling process, the screwing action becomes increasingly more difficult

due to the counteraction of the spring force. We recommend using a face spanner, if necessary

[fig. 2]. A pin with suitable diameter or a suitable hook spanner can be used as an alternative

if the screw sleeve has holes.

The coupling halves should be easily screwed together with atool. If this is not the case, check

the following:

•Are the connected lines depressurised?

•Are the threads of the coupling halves canted?

•Is there any damage/dirt?

For male tips with a retaining device, push the retaining device into the holes on the side of the

screw sleeve [fig. 3] after completing the assembly.