3Festo — ELGC-TB-KF — 2018-08a

1 Further applicable documents..................................................................................... 4

2 Safety........................................................................................................................... 4

2.1 Safety instructions........................................................................................................ 4

2.2 Intended use................................................................................................................ 4

2.3 Foreseeable misuse...................................................................................................... 4

2.4 Training of specialised personnel................................................................................. 4

3 Further information..................................................................................................... 4

4 Service..........................................................................................................................4

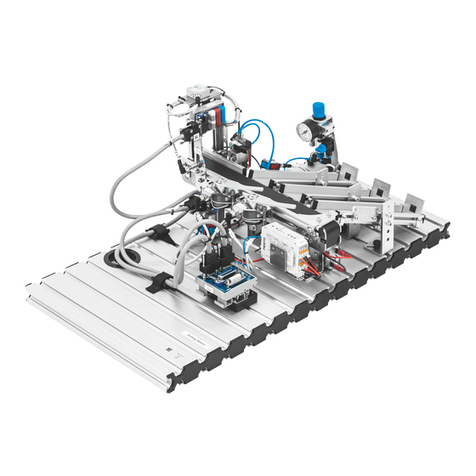

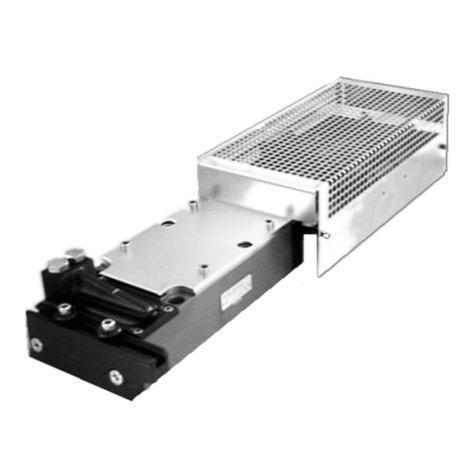

5 Product overview......................................................................................................... 5

5.1 Function....................................................................................................................... 5

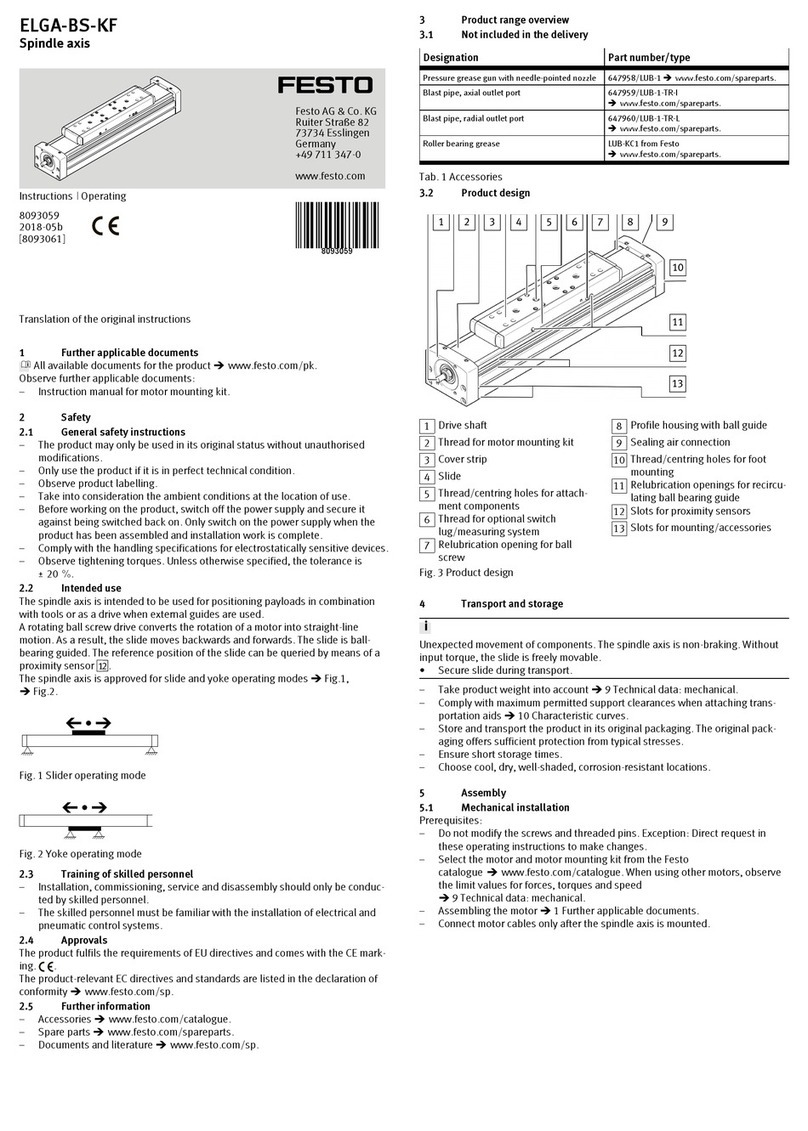

5.2 Product design............................................................................................................. 5

6 Transport..................................................................................................................... 5

7 Mounting..................................................................................................................... 6

7.1 Preparation................................................................................................................... 6

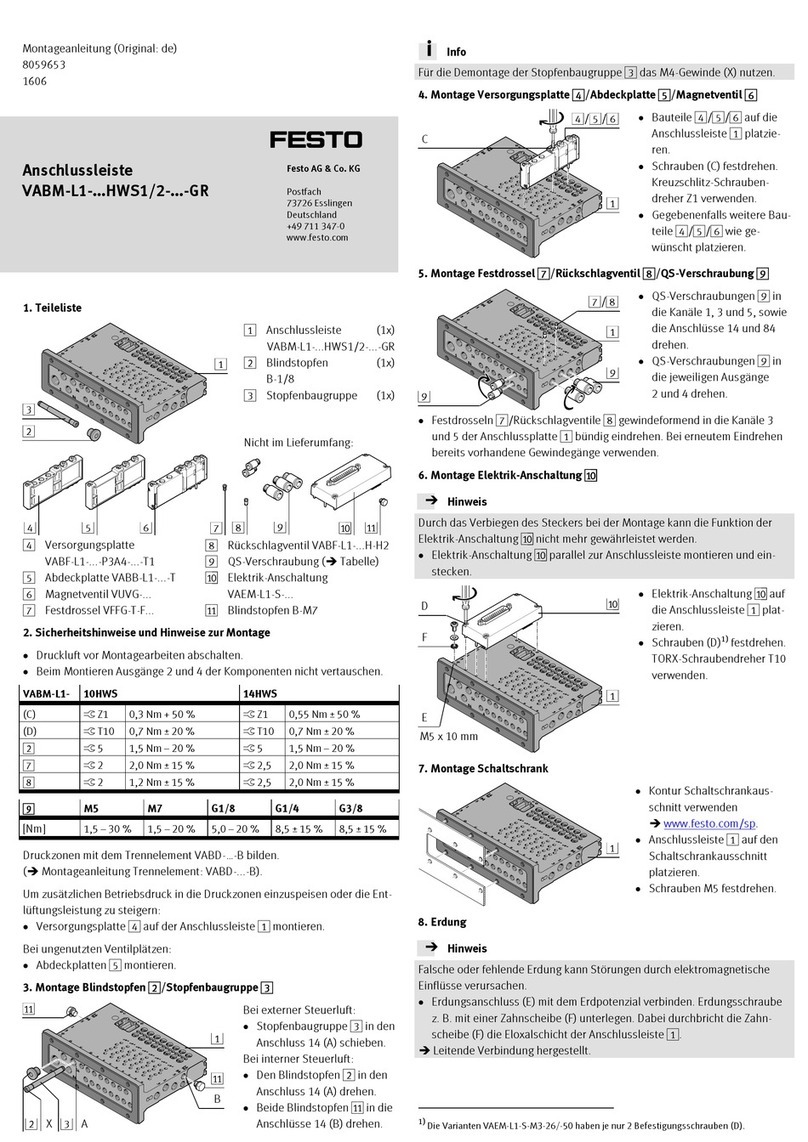

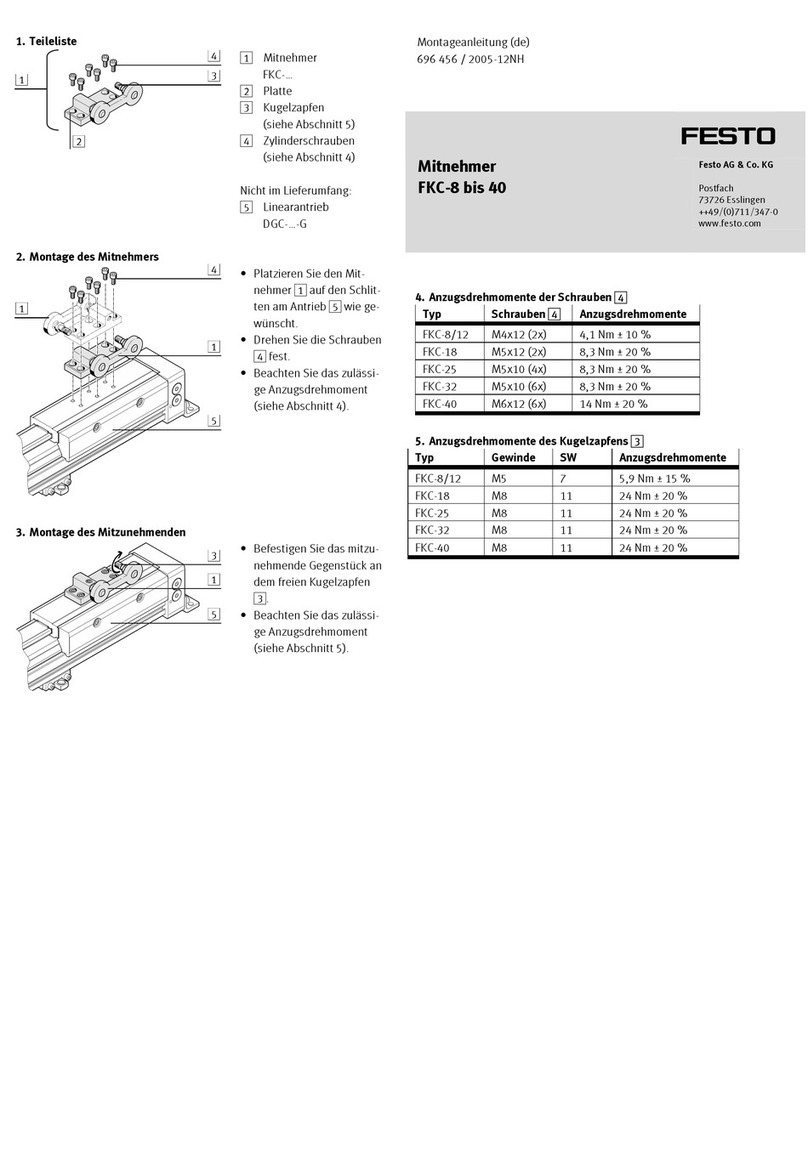

7.2 Mounting...................................................................................................................... 7

7.3 Attachment................................................................................................................... 7

7.4 Mounting accessories................................................................................................... 8

8 Commissioning............................................................................................................ 9

9 Service..........................................................................................................................10

9.1 Cleaning....................................................................................................................... 11

10 Fault clearance............................................................................................................ 12

11 Disassembly................................................................................................................ 13

12 Disposal........................................................................................................................13

13 Technical data............................................................................................................. 14

13.1 Technical data, mechanical........................................................................................... 14

13.2 Technical data, characteristic curves............................................................................ 16

Table of contents