3

4.2 Operation

5. Battery & Charger Use & Maintenance

5.1 Charger

②Float charging device effectively prevents over charging.The electrolyte will

not be turbid and the service life will be prolonged.

5.2 Battery Charging

①Connect the charger to battery charging socket, use the external charger to

recharge the battery.

②Keep good ventilation, no smoking or open flames during charging period.

③Cut charging power and remove charging cable after full charging.

④Battery maintenance and capacity check after charging.

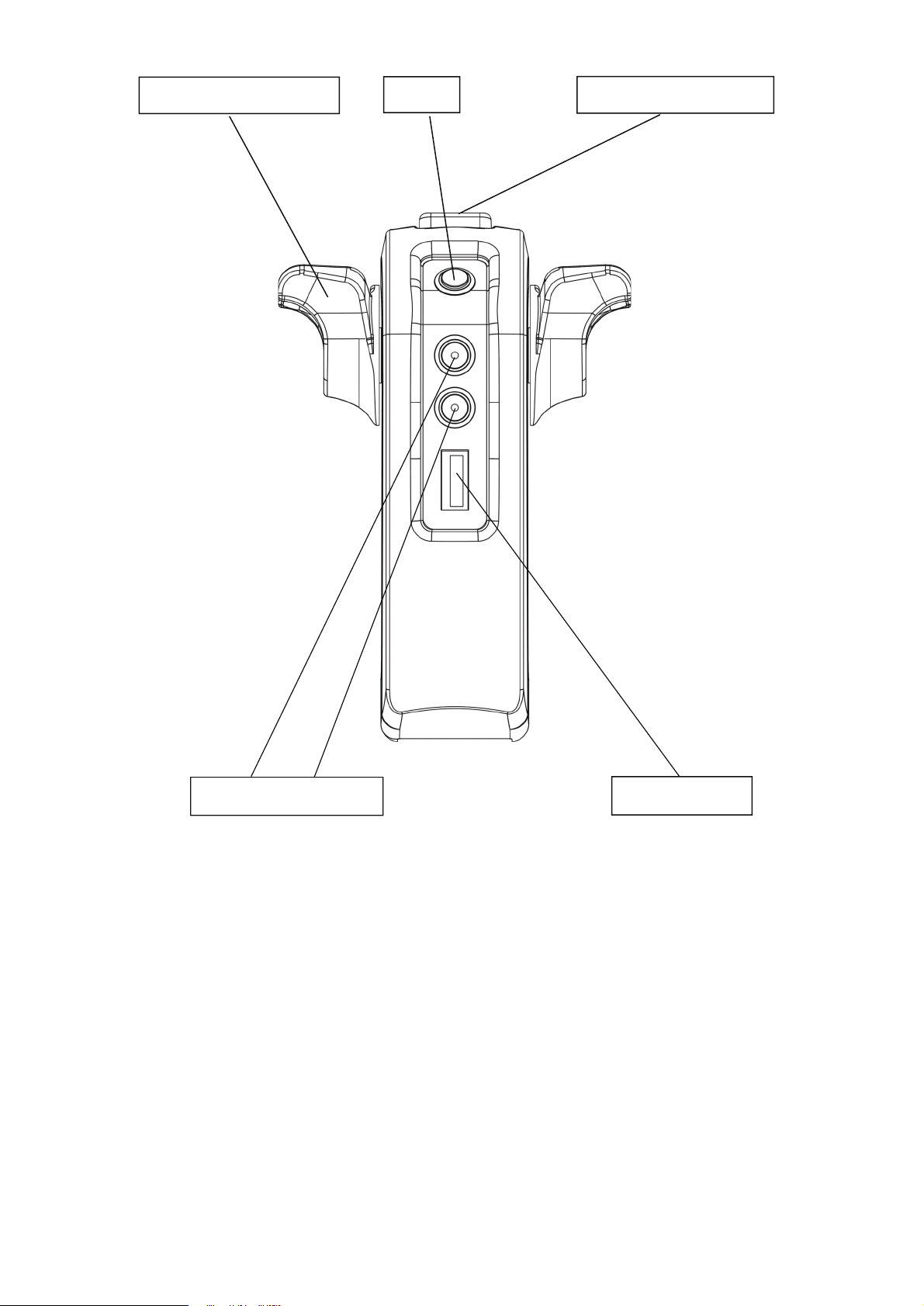

5.3 Button function description

Functions of the buttons on handle:

①The truck can only be allowed to use on hard ground.Do not work on oily

ground to avoid slipping.

②Turn on the switch,make sure the battery is full,then start to operate.

③Do not use the truck when battery is low. Low voltage use will damage battery.

Charge and discharge the battery on a regular basis when truck is unused for

long time (over one month).

④Press the lifting button to lift forks, release the lifting button and forks stop.

Press thelowering button to lower forks,release the lowering button and forks

stop.

⑤Keep a safety distance from the people around when the truck is loading and

unloading.Pay special attention when the cargo is too high or too heavy.

⑥Overloading is strictly prohibited to avoid mechanical damage or casualties.

⑦When truck is travelling, do not lift and travel at the same time. Slow down

when turning, climbing up or down a slope.To avoid danger, it’s prohibited

to turn on slope .

⑧Put forks at the lowest position after use. Do not park the truck at slope.

Switch off the truck for longer battery life one charge.

①The charger has excellent constant current characteristics and extremely

fast over-current protection, which automatically stabilizes the output

current when the voltage fluctuates.