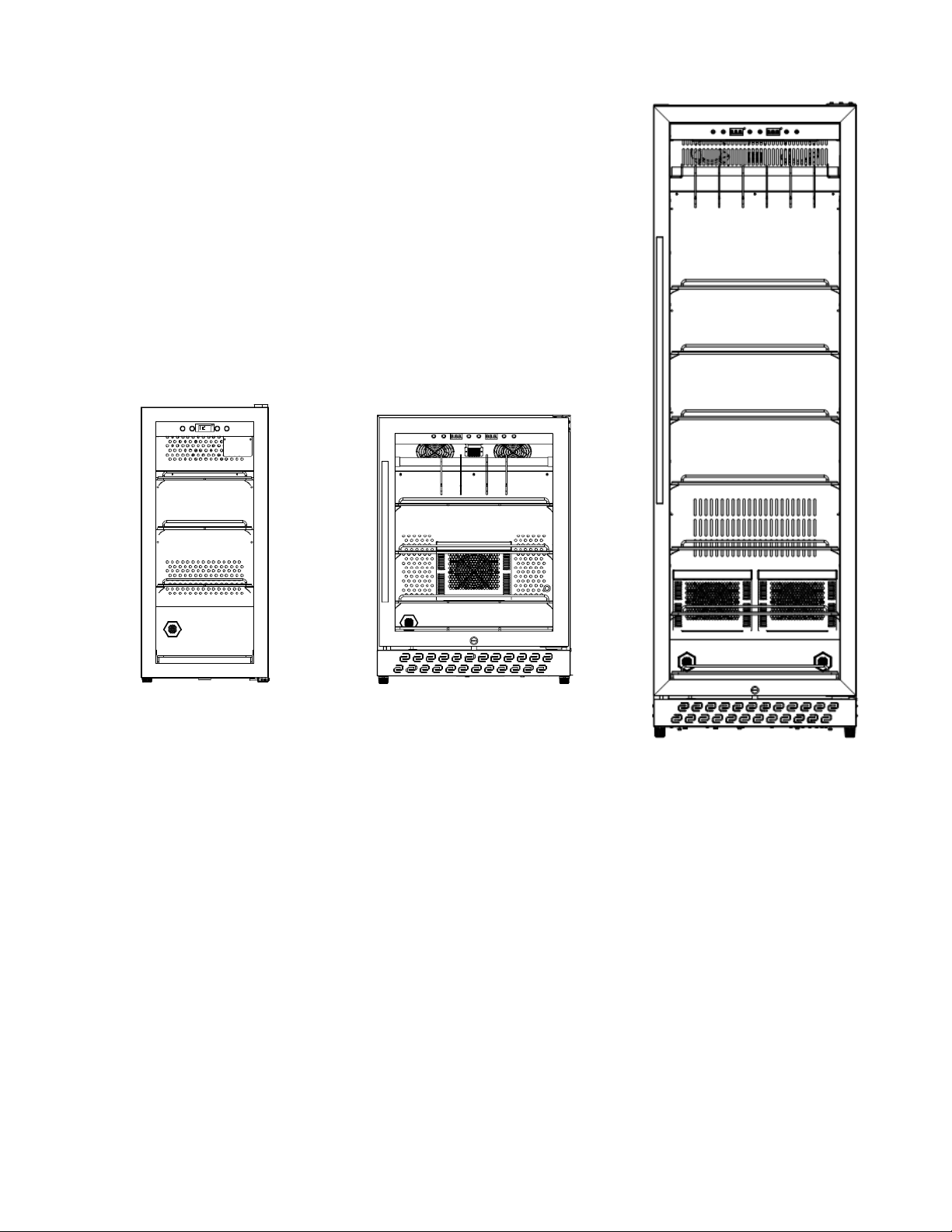

Steak Locker SL100 STUDIO EDITION User manual

SL100 STUDIO EDITION

SL150 HOME EDITION

SL520 PRO EDITION

2

Dimensions: Dimensions: Dimensions:

D 21.45 x W 15.55 x H 34.44 in D 22.56 x W 23.42 x H 32.28 in D26.77 x W 23.43 x H 73.43

(D545xW395xH875) mm (D573xW595xH820) mm D68 x W595 x H1865 mm

Capacity: Capacity: Capacity:

30 LBS / 14 KG 65LBS - 29 KG 350 LBS - 150 KG

Usable Volume: Usable Volume: Usable Volume:

78 L / 2.65 cu. ft. 119 L / 4.2 cu. ft. 520 L / 18.36 cu. ft.

WARRANTY: One Year Parts / Labor (includes Compressor)

Please read the user manual before operation and save for reference. Think Before Printing.

SL520 Pro

SL100 Studio

SL520 Home

3

TABLE OF CONTENTS

INSTALLATION INSTRUCTIONS

4

SL100 STUDIO EDITION - COMPLETE OVERVIEW

6

SL100 STUDIO EDITION –OPERATING ELEMENTS & DISPLAYS

7

SL100 STUDIO EDITION –MEASURMENTS & CLEARANCES

9

SL150 HOME EDITION - COMPLETE OVERVIEW

10

SL150 HOME EDITION - OPERATING ELEMENTS & DISPLAYS

13

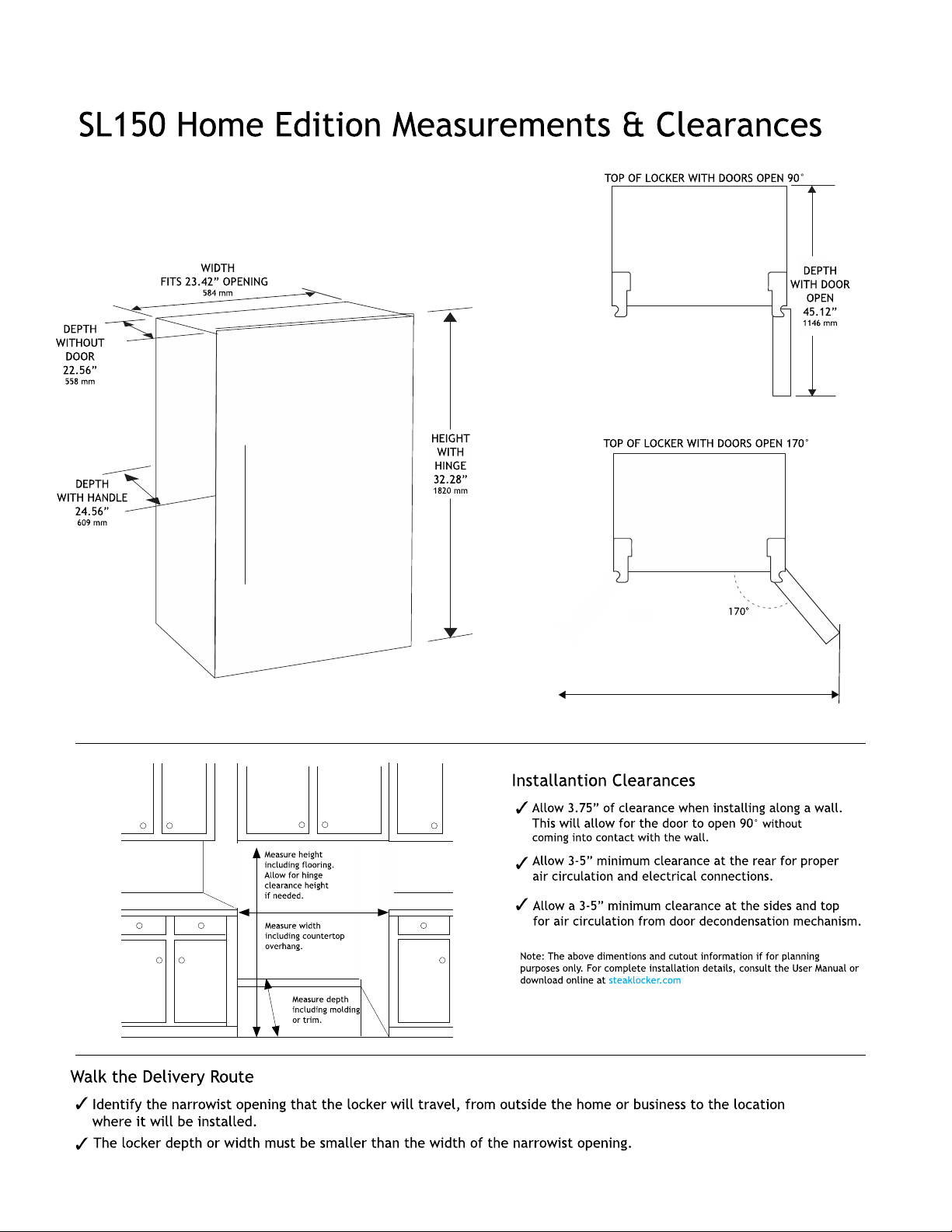

SL150 HOME EDITION –MEASURMENTS & CLEARANCES

14

SL520 PRO EDITION - COMPLETE OVERVIEW

15

SL520 PRO EDITION - OPERATING ELEMENTS & DISPLAYS

18

SL520 PRO EDITION –MEASURMENTS & CLEARANCES

19

CLEANING & MAINTENANCE

20

TROUBLESHOOTING - REFRIGERATOR

21-23

SYNC S4 WI-FI CONTROLLER –SL128 STUDIO; SL150 HOME, SL520 PRO

24

FULL RESET INSTRUCTIONS FOR WIFI SYNCING TROUBLE SHOOTING

25

PRECAUTIONS

26

HANDELING TIPS

27

GENERAL SAFETY INFORMATION

28-30

DISPOSAL OF STEAK LOCKER

31

4

INSTALLATION INSTRUCTIONS:

1. Setup location

Keep proper distance between the equipment and surrounding objects. To ensure the smooth flow of air around the

locker, when the machine is installed into a cabinet space, leave enough space on both sides, top and the back to the

wall. Keep at least 3 - 5 inches (8 - 13cm) away from the back wall. If the gap between the product and surrounding area

is too small, the side operation efficiency may be affected and the power consumption will increase.

2. Install in a dry, well ventilated location

Do not set up the locker in a wet or extremely damp environment, to prevent metal parts from rusting or causing

increased electricity usage.

3. Avoid heat or direct sunlight

If the environment temperature is too high, the refrigerant and humidity levels may fluctuate and cause the power

consumption to increase. Locate the appliance away from direct sunlight and sources of heat (stove, heater, radiator,

etc.). Direct sunlight may affect the acrylic coating and may increase electrical power consumption.

4. Place the SL on a floor that is strong enough to support the appliance when it is fully loaded

If the floor is uneven, use adjustable legs to keep the product be stable. It is not recommended to place the locker on

carpet or unsealed wood. If placed on carpet, it’s recommended to place a board below the locker to avoid heat or

water creating mold. Unstable installation can cause vibration, noise or door to misaligned.

5. Adjust the front of the device to be slightly higher than the rear

Check the locker for firmness to the floor, then re-adjust the front leveling feet brackets so that the front part of device

is slightly (approximately ½ inch) higher than the rear. If the front two feet are too low, the door may not close tightly

and may cause frost on the back wall.

6. Ground connection

The cord must be grounded to avoid electric shock. Connect socket to a grounded wire. If the socket has been

connected to the ground wire correctly, then, no need to connect another grounded wire.

7. Unable to connect ground position

If the location of the outlet cannot be connected via the grounded wire, connect the equipment to a surge protector

switch (the rated current can be checked on the rating label), then, connect the locker to the socket. Please Note:

Nonconductive plastic tubing cannot be used to connect ground wires. DO not connect ground wire to gas pipe, water

pipe, lightning arresters or telephone lines.

8. Electrical

It is essential that the Locker is plugged into an unencumbered 15AMP circuit and Non-GIF outlet. Do not place other

large appliances on the same circuit. Best practice is to place a Surge Protector on the outlet to the Locker.

After the equipment is installed, it should remain in place for at least 4 hours before connecting the power. This is

to avoid abnormal refrigeration pattern caused by the compressor oil that does not flow back into the compressor

during shipment.

After at least 4 hours, plug the locker into the wall outlet or surge protector, then allow the locker to run for at

least 5 hours prior to the first use of dry aging or charcuterie.

5

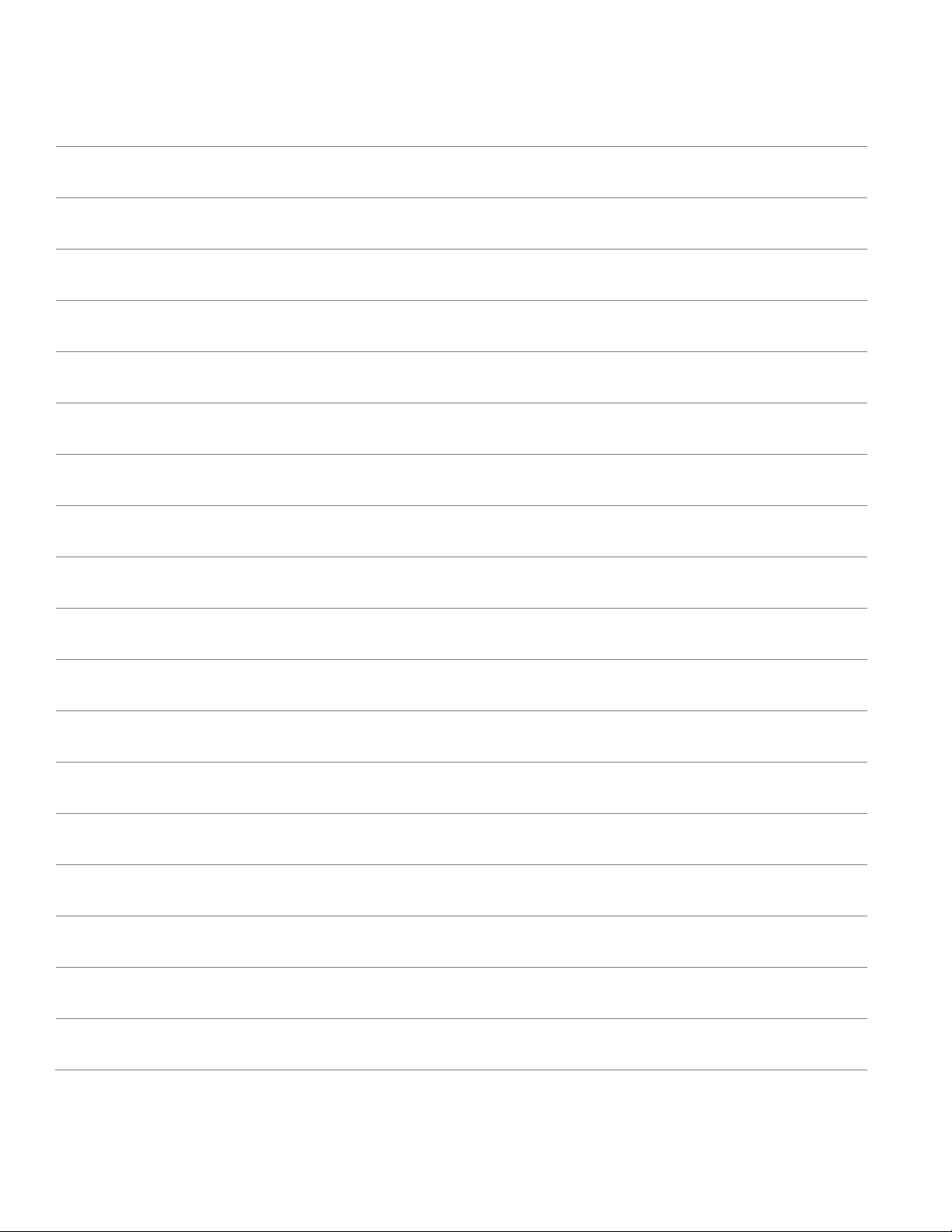

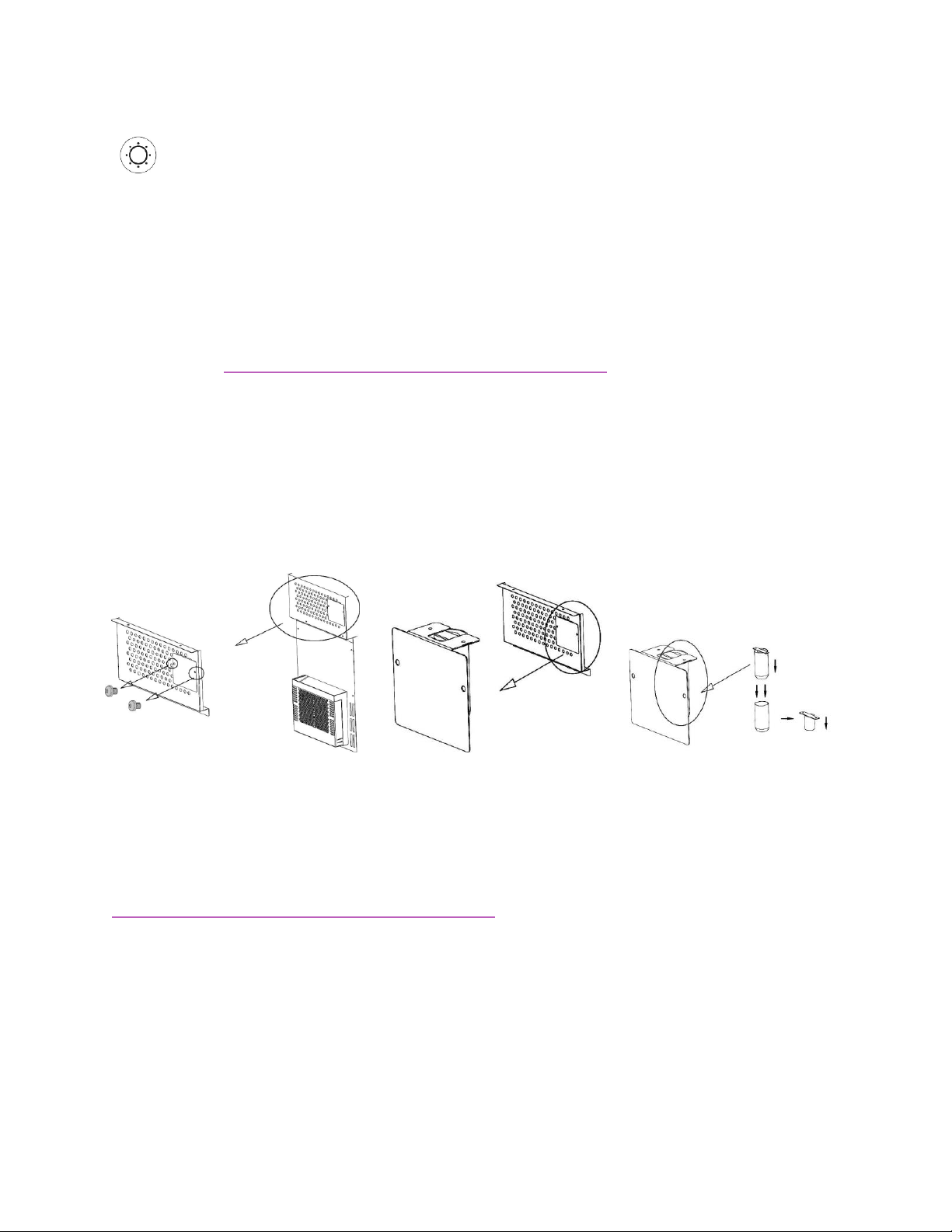

9. Handle Bar Installation; SL100 Studio, SL150 Home, SL520 Pro

All lockers include the Handle Bar and two supplied screws. To install, slide the rubber gasket on the inside of the door

to view the predrilled holes, then use a Phillip head screw driver to set into place.

6

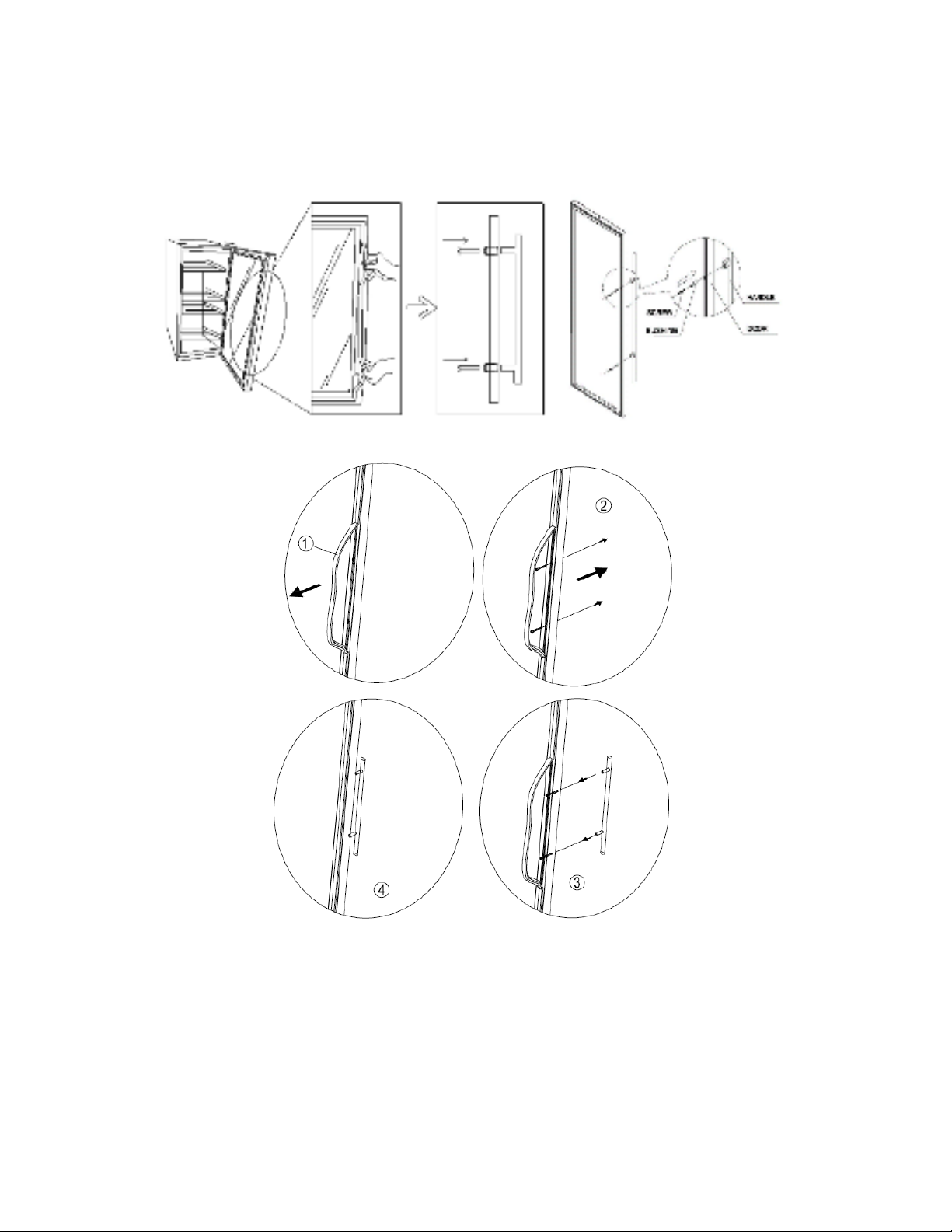

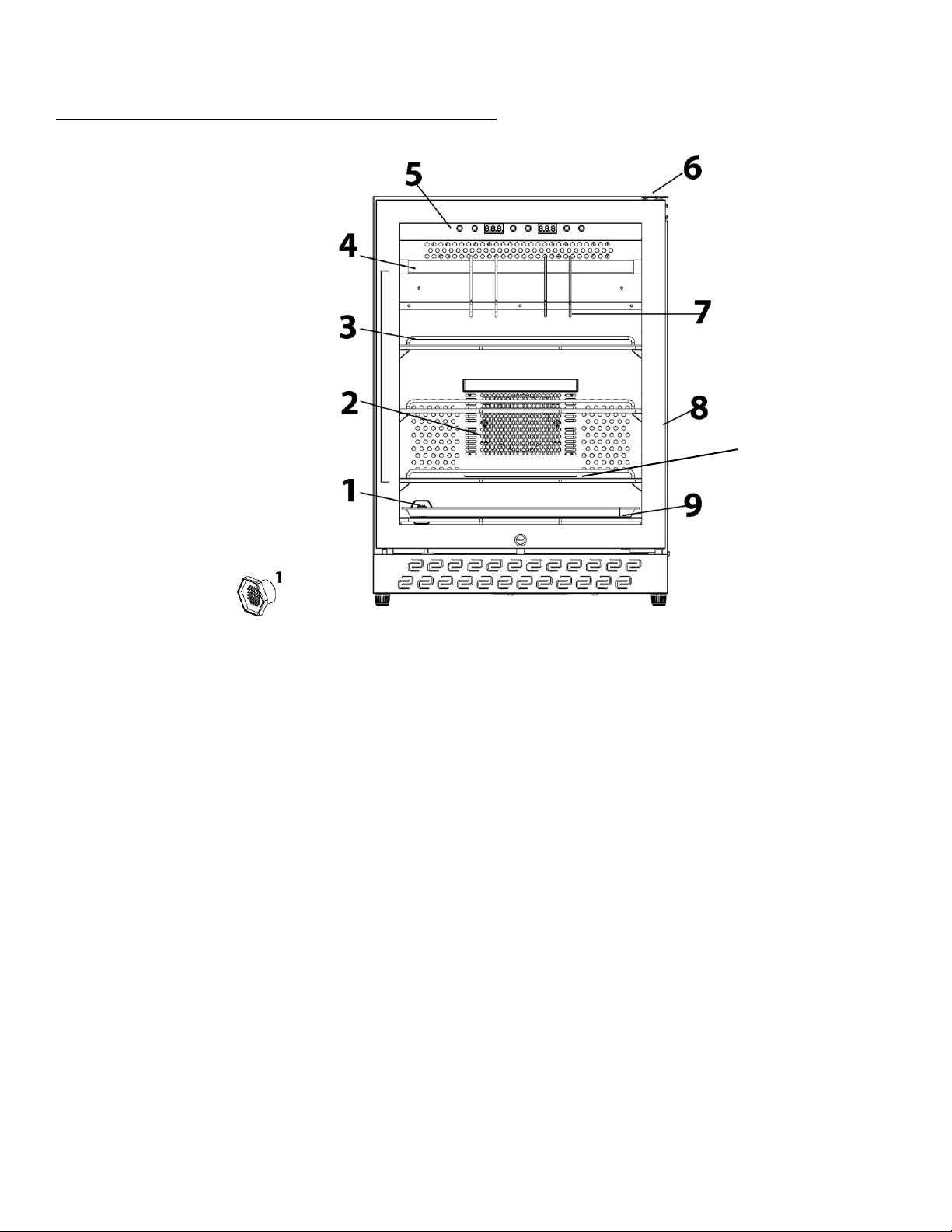

SL100 STUDIO EDITION - COMPLETE OVERVIEW:

1. Carbon Filter 6. Door Hinge

2. Water Reservoir 7. N/A

3. Stainless Steel Shelves 8. Door Frame

4. N/A 9. N/A

5. Control Panel 10. UV Light Bulb

7

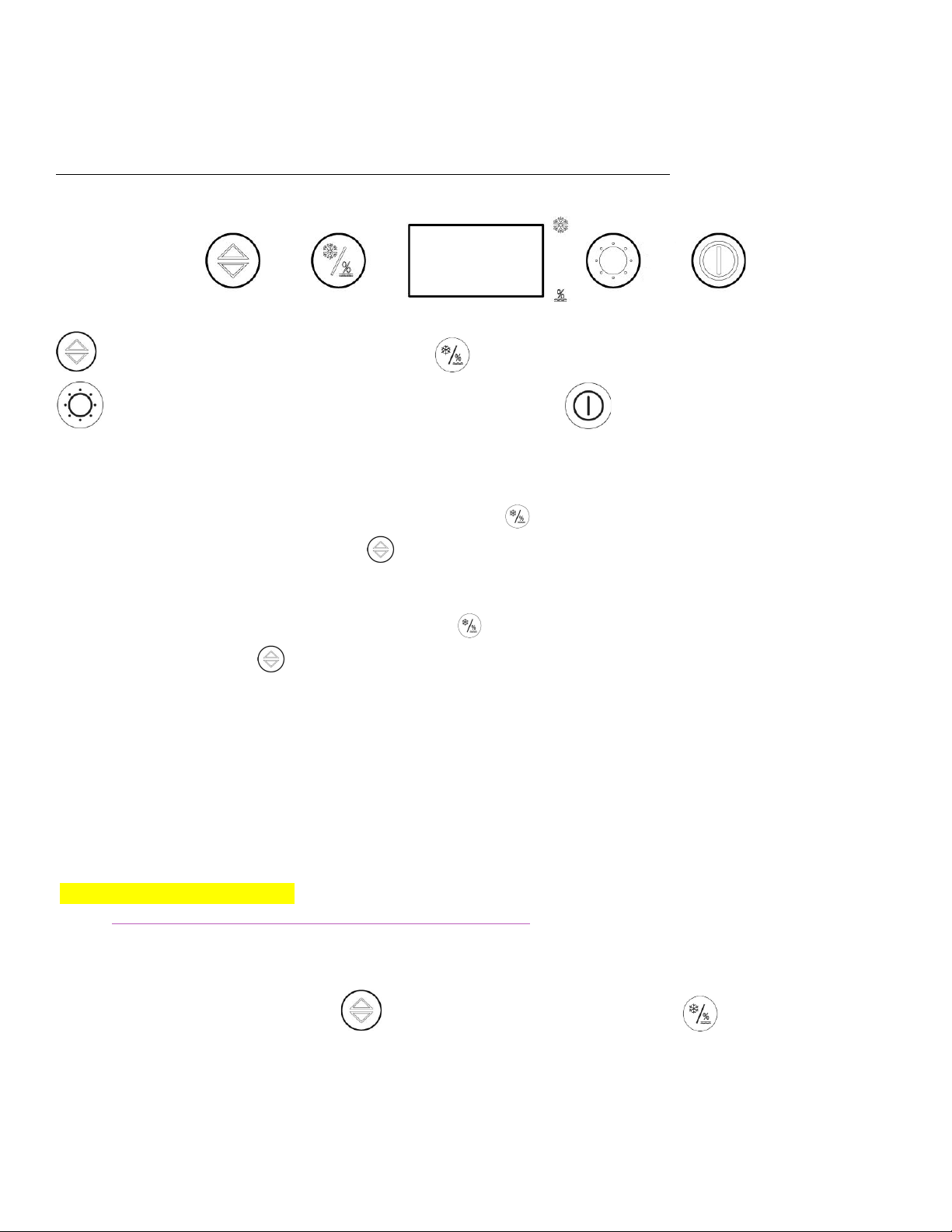

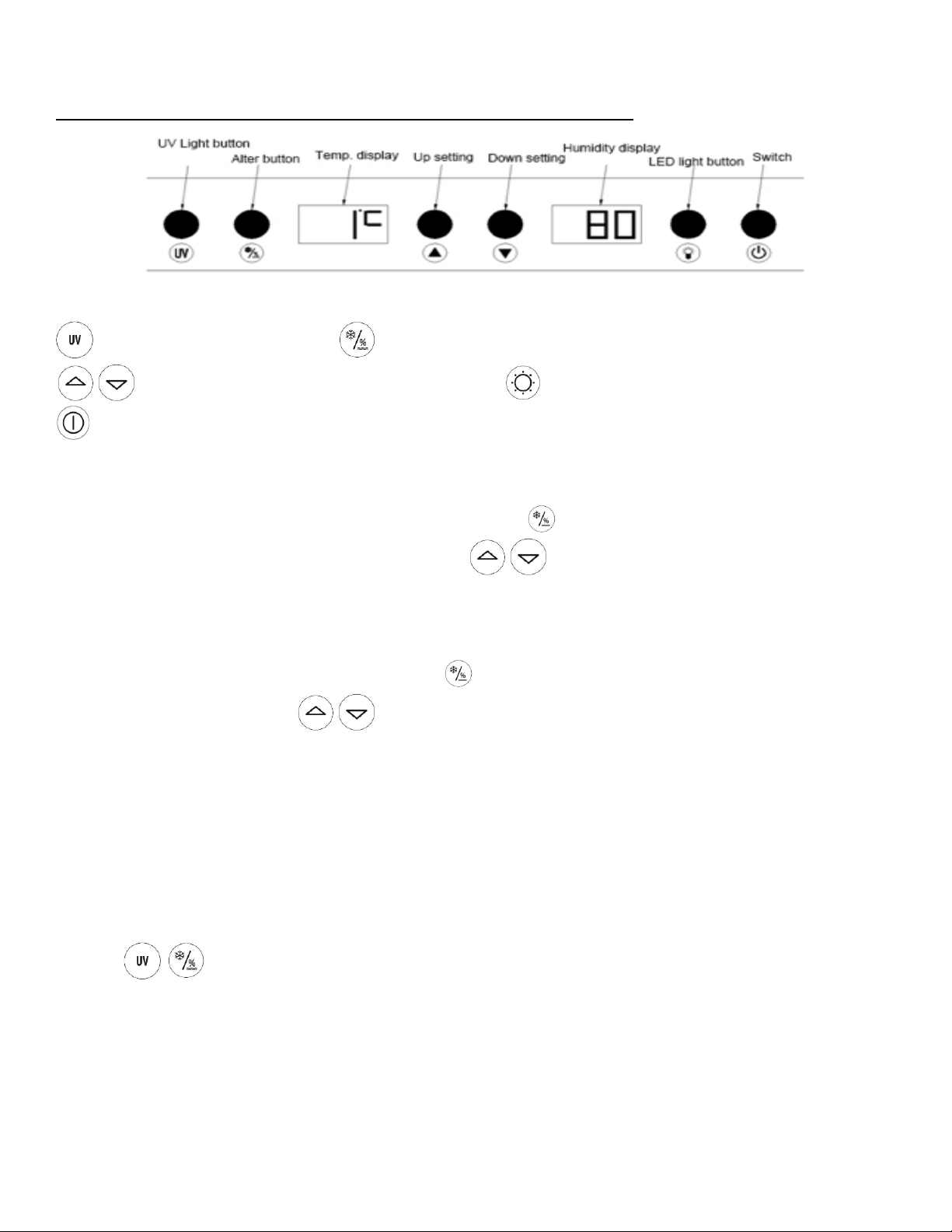

SL100 STUDIO EDITION –OPERATING ELEMENTS AND DISPLAYS:

Increase / Decrease Temperature / Humidity Toggle between Temperature and Humidity

Press 1x: LED Light On/Off or Hold 5 seconds: UV Light On/Off Locker On/Off

a. Temperature control:

The temperature range is 35-46°F(2-8°C), press the toggle key once and the temperature display will start to flash,

then adjust the temperature by pressing the button.Recommended for Dry Aging: 35°F

b. Humidity control:

The humidity range is 50%~85%, press the toggle button twice, the humidity display will start flashing, then adjust

the humidity by pressing the button.Please note: If you do not change the setting within 3 seconds, then the

device will return to its previous setting. Recommended for Dry Aging: 70%

c. Tankless –Water Humidity System:

►Current versions contain this system.

►Take one cup of water, no preference on distilled or not, add to the water slot located within the Air Filter on

back wall inside the locker. To remove the Reservoir Holder, pull the black cage forward until released then fill the drip

with water, place the filter inside then return the black cage into place.

It is recommended to remove the Reservoir and Tray every Three (3) Months to clean and replenish water.

*See Pg 13 for Reservoir Diagram

https://steaklocker.com/collections/replacement-parts

d. Toggle the LED display between Celsius or Fahrenheit readings

By pressing both the Increase/Decrease button and the Temperature / Humidity button at the same time

for three (3) seconds, the panel will toggle between Celsius and Fahrenheit readings.

8

e. LED light

►Press to turn on the LED Light, it turns off automatically after 4 hours

►The LED light will turn off automatically after 5 seconds when the door is closed and the switch is off.

f. UV light:

►The door has a safety switch, if the door of the locker is opened, the UV light will automatically

switch itself off in order to protect your eyes. Never look directly at the UV light.

►The UV light is used to keep bacteria from replicating through the aging process.

►The UV light may burn out within 6-8 months.

https://steaklocker.com/collections/replacement-parts

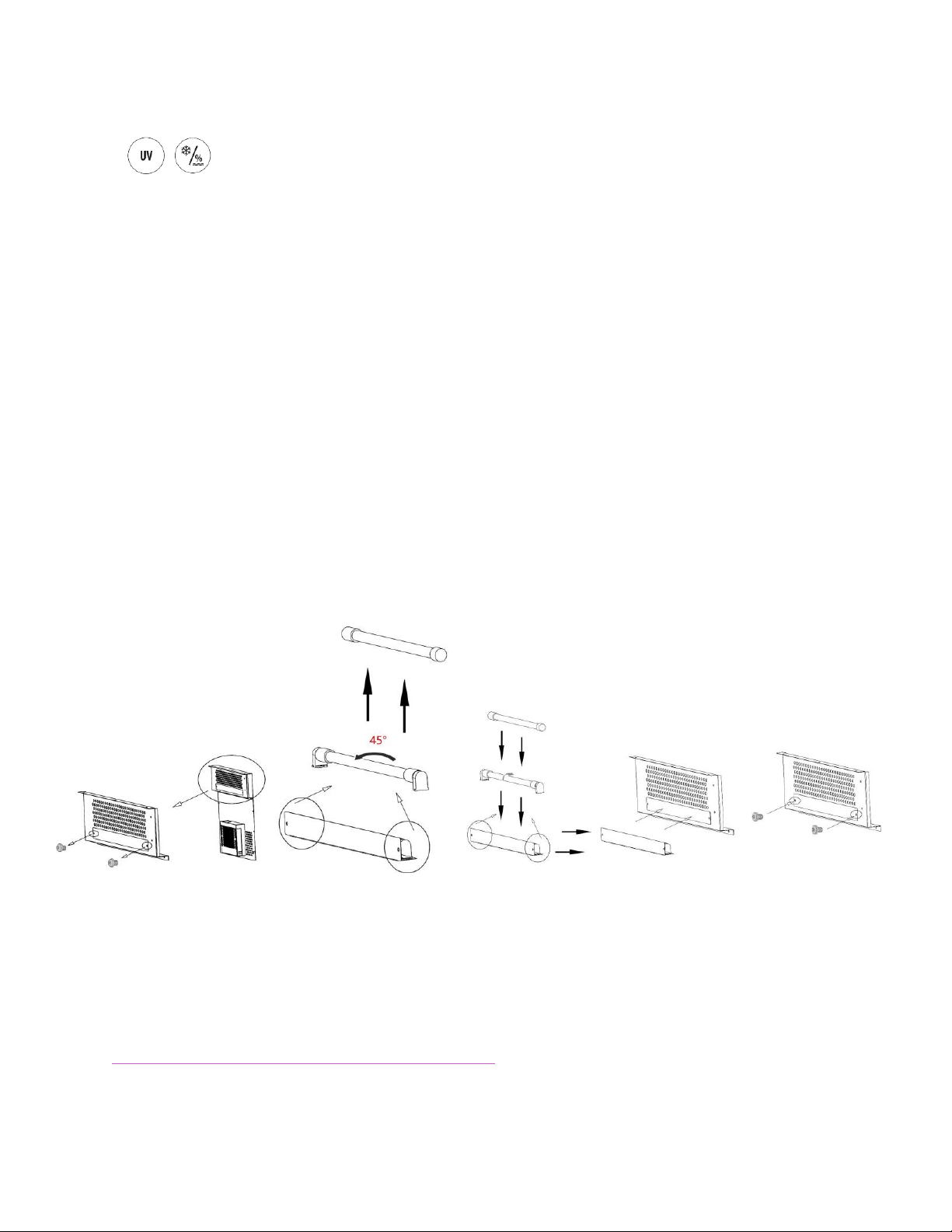

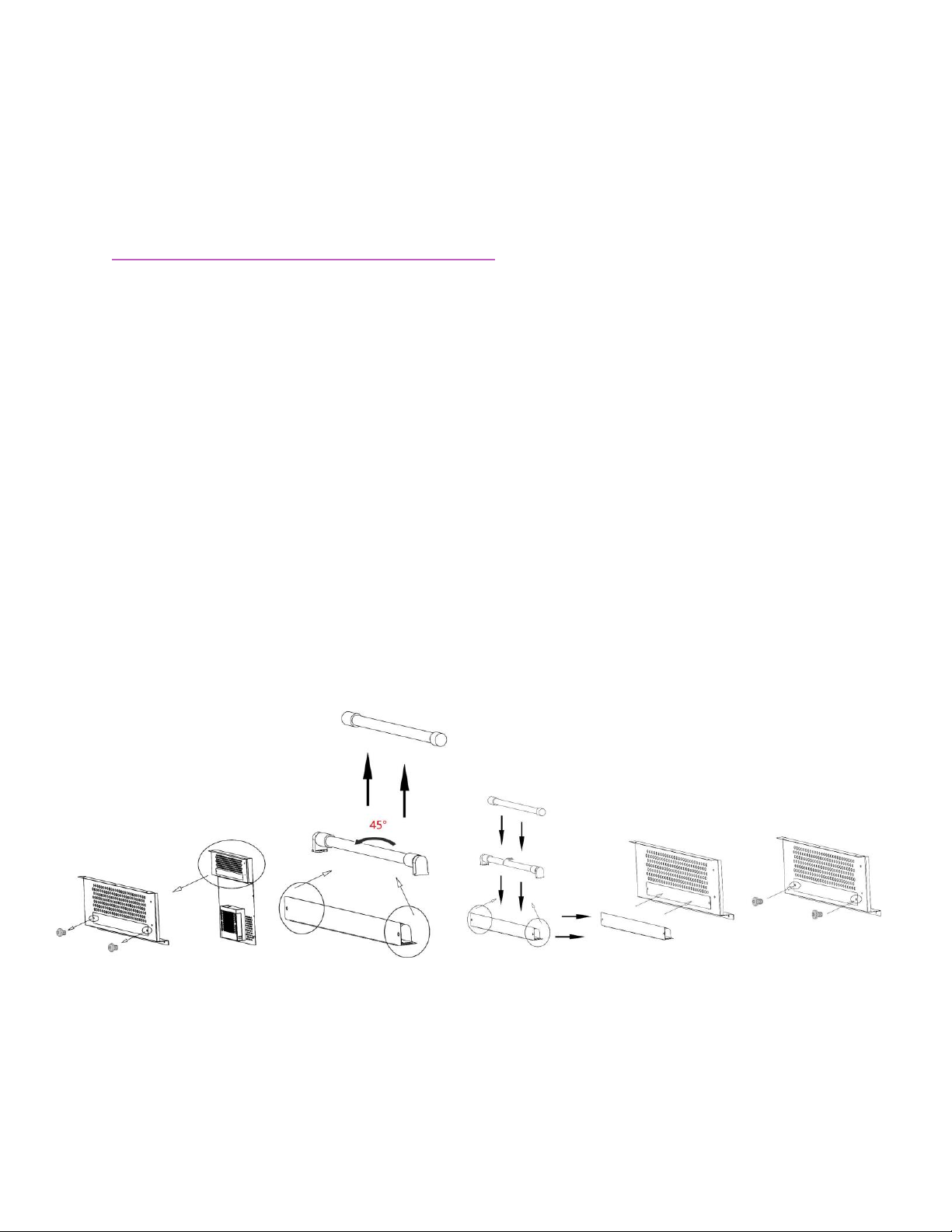

To Change the UV Light:

Turn the Locker Off. Carefully loosen two screws located on back wall of locker.

Remove the cover to the ballast by pulling downward.

Replace the UV Light bulb, then reverse the instructions to replace the cover and screws.

g. Carbon Filter:

►Please use this link to purchase the replacement carbon fiber filter filler. Remove the carbon fiber container,

uncap the top, remove the old carbon and replace with the new. This should be done about once a year.

https://steaklocker.com/collections/replacement-parts

9

10

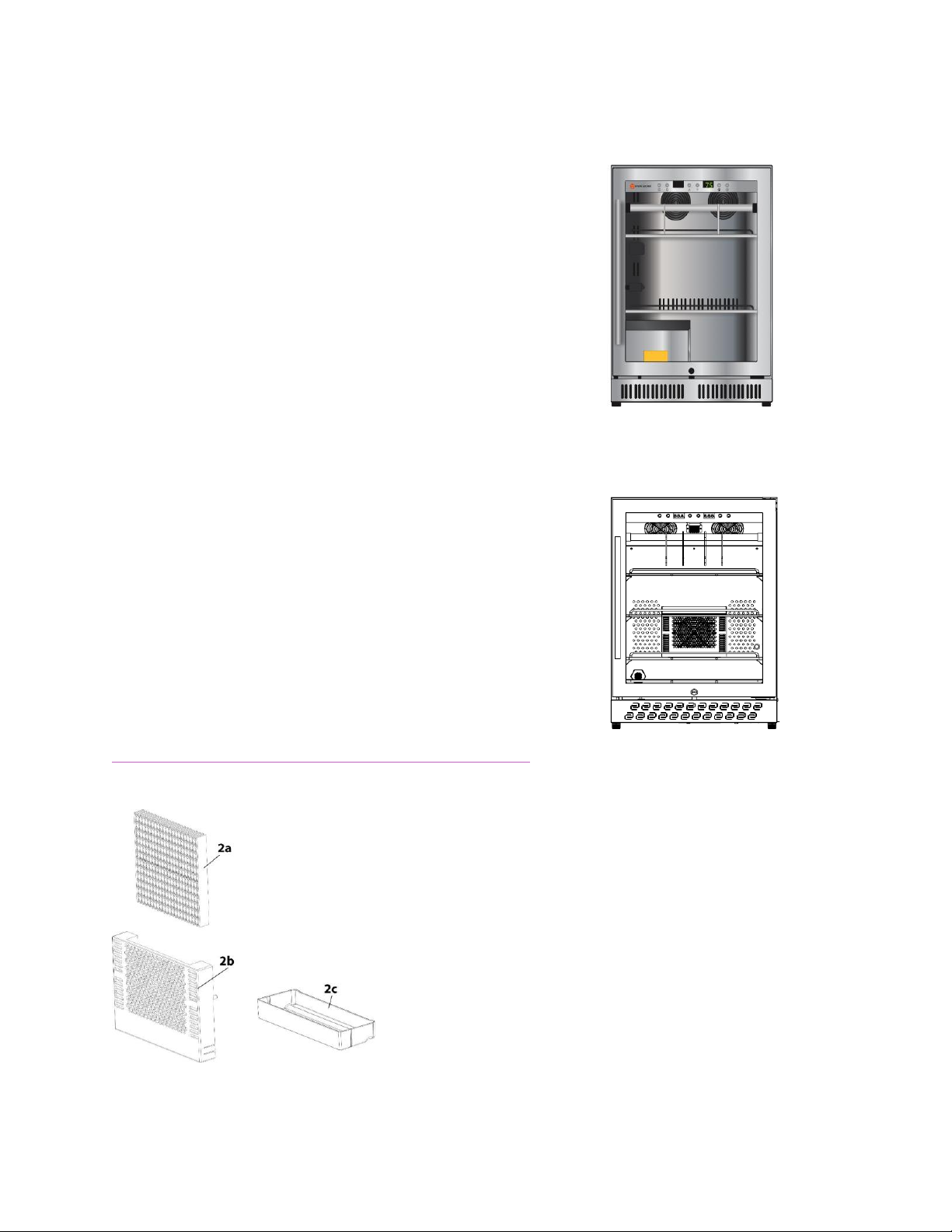

SL150 HOME EDITION - COMPLETE OVERVIEW:

1. Carbon Filter 6. Door Hinge

2. Water Reservoir 7. Butcher Hooks

3. Stainless Steel Shelves 8. Door Frame

4. Hanging Bar 9. N/A

5. Control Panel 10. UV Light (Below the Reservoir)

10

11

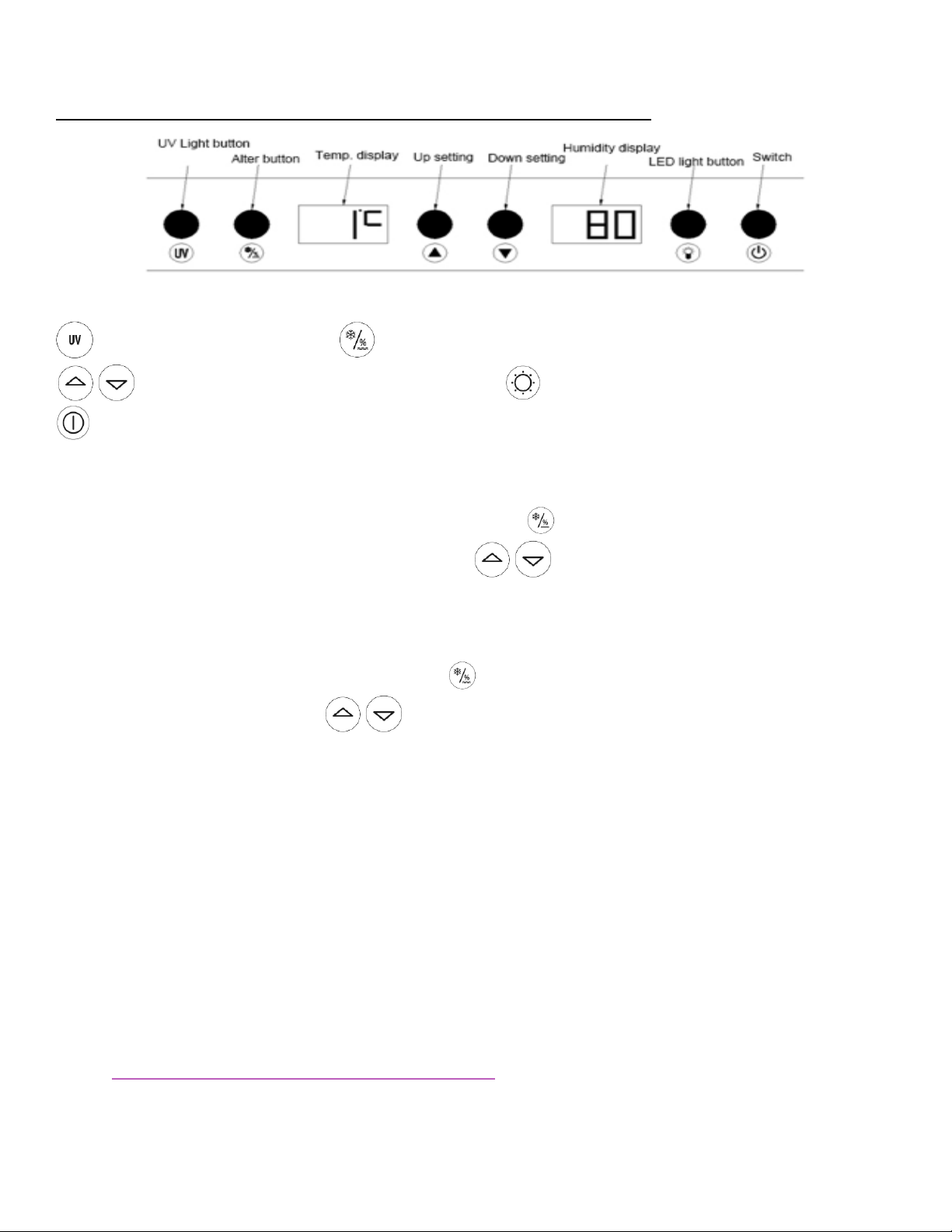

SL150 HOME EDITION - OPERATING ELEMENTS AND DISPLAYS:

a. Key Introduction:

Toggle UV Light On/Off Alternate between Temperature and Humidity in Display

Increase or Decrease Temperature or Humidity LED Light On/Off

Locker On/Off Switch

b. Temperature control:

The temperature range is 32 - 72° F (1-22°C)press the alter button once and the temperature display will start

flashing. Adjust the temperature by pressing either button up or down to increase or decrease by one

degree at a time. Recommended for Dry Aging: 35°F

c. Humidity control:

The humidity range is 50%~85%,press the alter button twice and the humidity display will start flashing.Adjust

the humidity by pressing either button up or down to increase or decrease by one percent at a time. Please

note: If you do not change the setting within 3 seconds, then the locker will return to its previous setting.

Recommended for Dry Aging: 70%

d. LED light

►To complement the look of your device, LED lighting has been built into the locker. When the door is open, simply

push the "Light" button and the light comes on, push again to turn off. For maximum energy efficiency, leave light off

when not viewing your collection.

►The LED light will turn off automatically after 5 seconds when the door is closed and the switch is off.

e. UV light:

►The door has a safety switch, if the door of the locker is opened, the UV light will automatically switch itself off in

order to protect your eyes. Never look directly at the UV light.

►The UV light is used to keep bacteria from replicating through the ageing process.

►The UV light may burn out within 6-8 months.

https://steaklocker.com/collections/replacement-parts

12

f. Toggle the LED display between Celsius or Fahrenheit readings

Press the buttons simultaneously for 3 seconds to toggle the LED display between Celsius and Fahrenheit

readings.

To Change the UV Light: (Previous versions contain this system)

•Turn the Locker Off. Then Unplug the Locker.

•Remove the four screws around the cage surrounding the UV Light. Once cage is removed, twist

the light out in one direction, then twist the replacement into the ballast in the opposite

direction. Should be able to hear or feel it click into place.

To Change the UV Light: (Current versions contain this system.)

•Turn the Locker Off. Then Unplug the Locker.

Carefully loosen two screws located on back wall of locker.

•Remove the cover to the ballast by pulling downward.

•Replace the UV Light bulb from the ballast by twisting the bulb out at a 45° angle, twist

replacement bulb in opposite direction and click into place.

•Then reverse the instructions to replace the cover and screws.

g. Carbon Filter:

►Please use this link to purchase the replacement carbon fiber filter filler. Remove the carbon fiber container,

uncap the top, remove the old carbon and replace with the new. This should be done about once a year.

https://steaklocker.com/collections/replacement-parts

13

h. Reservoir –Water Humidity System:

►Some previous versions contain this system.

►Prior to powering on the locker, ADD approximately

three fourths of a gallon of Distilled Water purchased

from the grocery store.

►Remove the plastic wrapping from the orange filter

prior to use inside the reservoir.

►When the reservoir is low on water, an audible alarm

will sound and an E6 error message will display in the

temperature display screen.

►If E6 alarm and error continues with plenty of water,

check that the wires connecting the reservoir drawer

to the locker have full contact. If not, unplug the clips,

then reconnect.

►The Orange Filter should be replaced yearly.

i. Tankless –Water Humidity System:

►Current versions contain this system.

►Take one cup of water, no preference on distilled or not,

add to the water slot located within the Air Filter on

back wall inside the locker. To remove the Reservoir Holder,

pull the black cage forward until released then fill the drip

with water, place the filter inside then return the black cage

into place.

It is recommended to remove the Reservoir and

Tray every Three (3) Months to clean and

replenish water.

*See below for Reservoir Diagram

https://steaklocker.com/collections/replacement-parts

2a: Water Reservoir

2b: Reservoir Holder

2c: Reservoir Drip Tray

14

15

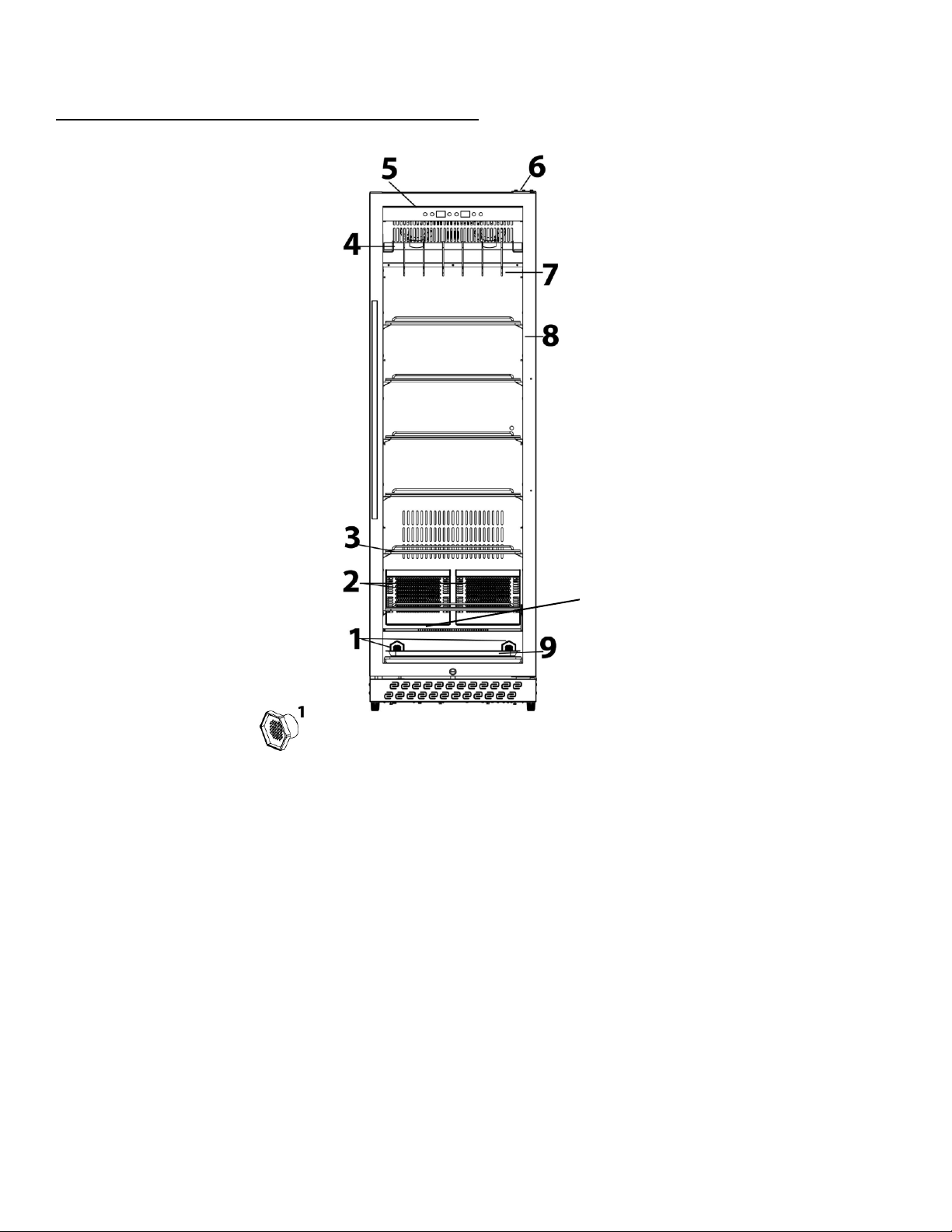

SL520 PRO EDITION - COMPLETE OVERVIEW:

1. Carbon Filter 6. Door Hinge

2. Water Reservoir 7. Butcher Hooks

3. Stainless Steel Shelves 8. Door Frame

4. Hanging Bar 9. N/A

5. Control Panel 10. UV Light (Below the Reservoir)

10

16

SL520 PRO EDITION - OPERATING ELEMENTS AND DISPLAYS:

a. Key Introduction:

Toggle UV Light On/Off Alternate between Temperature and Humidity in Display

Increase or Decrease Temperature or Humidity LED Light On/Off

Locker On/Off Switch

b. Temperature control:

The temperature range is 32 - 72°F (1-22°C)press the alter button once and the temperature display will start

flashing. Adjust the temperature by pressing either button up or down to increase or decrease by one degree

at a time. Recommended: 35°F

c. Humidity control:

The humidity range is 50%~85%,press the alter button twice and the humidity display will start flashing.Adjust the

humidity by pressing either button up or down to increase or decrease by one percent at a time. Please note: If

you do not change the setting within 3 seconds, then the locker will return to its previous setting. Recommended: 70%

d. LED light

►To complement the look of your device, LED lighting has been built into the locker. When the door is open, simply

push the "Light" button and the light comes on, push again for off. For maximum energy efficiency, leave light off when

not viewing your collection.

►The LED light will turn off automatically after 5 seconds when the door is closed and the switch is off.

e. Toggle the LED display between Celsius or Fahrenheit readings

Press the buttons simultaneously for 3 seconds to toggle between the LED display Celsius or Fahrenheit

readings.

17

f. UV light:

►The door has a safety switch, if the door of the locker is opened, the UV light will automatically switch itself off in

order to protect your eyes. Never look directly at the UV light.

►The UV light is used to keep bacteria from replicating through the ageing process.

►The UV light may burn out within 6-8 months.

https://steaklocker.com/collections/replacement-parts

.To Change the UV Light: (Previous versions contain this system)

•Turn the Locker Off. Then Unplug the Locker.

•Remove the four screws around the cage surrounding the UV Light. Once cage is removed, twist

the light out in one direction, then twist the replacement into the ballast in the opposite

direction. Should be able to hear or feel it click into place.

To Change the UV Light: (Current versions contain this system.)

•Turn the Locker Off. Then Unplug the Locker.

Carefully loosen two screws located on back wall of locker.

•Remove the cover to the ballast by pulling downward.

•Replace the UV Light bulb from the ballast by twisting the bulb out at a 45° angle, twist

replacement bulb in opposite direction and click into place.

•Then reverse the instructions to replace the cover and screws.

18

g. Carbon Filter:

►Please use this link to purchase the replacement carbon fiber filter filler. Remove the carbon fiber container,

uncap the top, remove the old carbon and replace with the new. This should be done about once a year.

https://steaklocker.com/collections/replacement-parts

h. Reservoir –Water Humidity System:

►Some previous versions contain this system.

►Prior to powering on the locker, ADD approximately three fourths of a gallon of Distilled Water purchased

from the grocery store.

►Remove the plastic wrapping from the orange filter prior to use inside the reservoir.

►When the reservoir is low on water, an audible alarm will sound and an E6 error message will display in the

temperature display screen.

►If E6 alarm and error continue with plenty of water, check that the wires connecting the reservoir drawer to

the locker have full contact. If not, unplug the clips, then reconnect.

►The Orange Filter should be replaced yearly.

https://steaklocker.com/collections/replacement-parts

i. Tankless –Water Humidity System:

►Current versions contain this system.

►Take one cup of water, no preference on distilled or not, add to the water slot located within the Air Filter on

back wall inside the locker. To remove the Reservoir Holder, pull the black cage forward until released then fill the drip

with water, place the filter inside then return the black cage into place.

It is recommended to remove the Reservoir and Tray every Three (3) Months to clean and replenish water.

*See Pg 13 for Reservoir Diagram

https://steaklocker.com/collections/replacement-parts

19

20

CLEANING AND MAINTENANCE:

This chapter provides you with important information in regards to cleaning and maintaining the locker. These

practices are to prevent damages due to cleaning the locker incorrectly and to ensure a trouble-free operation.

►Before cleaning, switch the locker off, un-plug from the wall outlet and remove all the meat.

►Interior space: Wash the inside with a damp cloth in lukewarm water and a bit of mild detergent. Do not spill any

liquid into fan space or air ways.

►Door gasket: The door gasket can be removed to clean with a mild detergent. After cleaning, to replace the door

gasket, fix the four corners first then embed it segment by segment.

►Do not use boiled water, detergent, acid alkaline detergent, soap, grinding powder, gasoline, alkenes, alcohol,

benzene, organic solvent to scrub. A light amount of dish soap works best.

►Do not flush the cabinet with water directly as it may cause electrical failure.

►After cleaning, check for damage to the power cord and outlet. If there is any damage to the cord, like fraying of the

wires, the locker must be repaired by professional electrician.

►If you do not use the equipment for a fairly long period of time, you should remove all the metal shelves, the metal

suspension system and the meat hooks and you should clean the equipment thoroughly, then leave the door open for

2~3 days. After the interior is fully dried, the activated carbon can be replaced to avoid mold and odor.

►The UV light is a consumable and may burn out within approximately 6-8 months.

It is custom made for this locker. https://steaklocker.com/collections/replacement-parts

This manual suits for next models

2

Table of contents

Other Steak Locker Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Amitek

Amitek AK400WLUX Installation, operating and service instructions

JAC

JAC Integra IMP 800 manual

Lotus

Lotus LIBR.ISTR.F110E Installation and operating instructions

Electrolux

Electrolux E9BSGLIUFE Spare Parts Diagram

Vogue

Vogue GJ500 Assembly instructions

Vollrath

Vollrath Stoelting U411 Service manual

Proluxe

Proluxe DOUGHPRO DP1100BZ Series Operation manual

saro

saro ES 901 S/S Top 0/4 operating instructions

Igloo

Igloo Wojtek 1.0 W user manual

Fri-Jado

Fri-Jado GO Combi Two-GO Mounting instruction

Keysight Technologies

Keysight Technologies 11636C Operating and service manual

CookMax

CookMax AK100EF Installation, operating and service instructions