STEAMCORE SPA II User manual

OPERATION & INSTALLATION MANUAL

STEAM GENERATORSTEAM GENERATOR

aobsessed with qualiy...

aquality of life

TM

Auto Drain Equipped - Whisper Quiet - Quick Start - Continous Steam

SAUNACORE PHONE: 905-951-6662 www.saunacore.com

ÖØ

Òª

:

Prologue

Users instruction

Óû§ÐëÖª

¾¯

¸æ

:

Caution:

We are not responsible for the malfunction and damage from

installation that does not comply to the user manual.

Important:

Choosing a right location

Install an exhaust fan outside of the steam room so it can expel

the excessive steam from the shower room.

User Manual

Certified to CAN/CSA Std. No. 88

Conforms to UL. Std. 499

It is strongly recommended that the water intake solenoid be connected to a water supply using a braided hose line.

Teflon tape is required to make a liquid tight seal between the threads and a rubber gasket (washer) is used to seal

between the solenoid and the braided hose attachment. Incorporate thread sealant (teflon tape) on both the water intake

and drain solenoid for a tight seal to avoid leaks.

Technical Hotline 905-951-6662

1. Make surethe model and output are correct, including the voltage.

2. Make sure the power are matched with the steam room dimensions. Pay attention to the

steam room's cubic footage and wall finish materials. If you have any problems, please refer

page 11 for steam generator sizing and selection.

3. Read this entire manual before installation.

4. Saunacore will not be responsible for any damage or malfuntion due to the product by improper

installation.

5. Steamcore SpaII Series are pre-tested and inspected prior to packaging, please inspect package when received

to assure all is in proper condition. If you find any damage to the package, immediately put in a claim with the

delivering (courier) company for a claim of compensation.

6. The steam generator use in a heated indoor space only.

7. This unit must be completely installed with unions for easy removal, the steam lines must be 3/4" diameter

pipe for each steam line. Do NOT reduce steam line pipe diameter, do not connect steam lines, and a pressure

reducer valve must be used to reduce water pressure to 15-20 psi. Do NOT heat solenoids with any flame or

soldering torch.

Recommended installation locations.

1. The distance between the steam room and the steam generator should be 20ft or less. The steam generator is

supplied with a control cable of 20ft long. It can be extended if needed to a max of 60ft (with purchase of

additonal 20ft length control cables).

2. The steam generator should NOT be installed inside the steam room.

3. Do NOT install the steam generator outdoors or any place that will influence the operation, function, security

of the steam generator by the surrounding environment.

4. Do NOT expose generator to any place it may freeze, or near any combustible objects or chemicals.

5. Install steam generator in a dry well ventilated location.

NOTE: Do NOT apply any heat or source of flame to the intake/drain solenoids during installation. This can cause

damage or malfunction of components.

1

Steam generator

Water Drain Valve

Water Inlet Pipe

Steam outlet pipe

Control panel

Supply

Steam Outlet

Pressure

relief

valve

!

The steam generator( including the controller)

comply with CE , CSA

and UL certificat ion standards.

!

Attention:

Attention:

Installation drawing of the steam generator

The drawing isonly

for sample. As for practical

design of steam room, please

consult with qualified designer,

architect or builder.

User Manual

Control Cable

(20ft max)

7. The steam generator should be securely mounted. Make adequate care that the generator

is stable and level, horizontally. The steam generator has hanging holes in the back side for

mounting onto a wall.

8. The steam generator requires a minimum of 12 inch clearance of space on both sides, top and front.

9. The steam generator must be installed in a place that is easily accessible, and convenient for removal,

or disassembly.

10. The installation area must have access to a drain.

11. The steam line(s), pressure relief valve, drain valves, water supply line, and steam outlets

are VERY HOT during and after use for some time. Keep the steam outlets away from any

body parts or bathers. Bodily injury or burn may occur if coming into contact or in the visinity

of the steam nozzles. Provide appropriate protection to avoid bodily injury.

(10.5 kw and higher require 2 steam outlets)

Intake or Drain Valves 2

×°ÔÚÁÜÔ¡ÕßÈÝÒ×¾-

ÕßµÄΣÏÕ¡£

Òâ

:

!

Õô

°²×°ÔÚÁÜÔ¡ÕßÈÝÒ×¾-

³£

ÓÃÕßµÄΣÏÕ¡£

×¢

Òâ

:

!

Installation of pipeline

The installation of all the pipes should be done by a qualified

licensed plumber.

Warning:

Attention:

Atte ntion:

Attention :

User Manual

DO NOT HEAT AUTO FILL / DRAIN VALVES WITH TORCH DURING INSTALLATION.

This will cause damage to the plastic solenoid valve which will cause malfuction or leakage.

WATER SUPPLY LINE (1/2" WITH SHUT OFF VALVE)

1. Connect cold water supply with a shut off valve that is located in a that makes it

easily operated in an emergency.

2. Make sure the water supply line is clean before attaching to steam generator intake solenoid.

It is recommended that a 3/8 inch braided hose is used to supply water to the steam generator.

3. The water pressure should be between 15-20 psi. If necessary, decrease the pressure accordingly. Excess

pressure may cause leakage or malfunction of parts. The water flow rate should be aprox 8 gpm.

4. If necessary, install equipment to prevent water hammer noise. Also install an approved backflow preventer

as required by local codes. It is suggested that a thread on braided hose (3/8") with a rubber washer be used

for the water supply line attachment to the intake solenoid. Create a tight seal between the two fittings.

STEAM LINE PIPE (PIPE DIAMETER: 3/4" PER STEAM LINE - NO LESS!)

1. Do NOT install any valves in the steam line pipes. The steam should never be obstructed.

2. Steam generators up to 9KW require (1) 3/4 inch diameter steam line, 10.5 KW and higher steam generators

require (2) 3/4 inch diameter steam lines. Do NOT use or install steam lines in any configuration, in any less diameter

pipe, or connect them together.

3. The steam lines must be 3/4 inch diameter, the steam heads (nozzles) are 3/4 inch threaded. Steam lines must be

copper or brass material. Do NOT use ABS, galvanized, or PVC pipe. Use threaded unions to install all components

of the steam generator.

4. If steam lines are insulated, the insulating materials should be resistant to a temperature of no less then 250F.

5. The steam lines should be installed horizontally with a slight incline to allow condensate to run off. Incline can be towards

the steam room or the steam generator. Do NOT allow steam pipe to sag, or create any sort of trap that will allow condensate

to build up and block steam flow within the steam lines.

6. The shorter the steam lines, the better performance of the steam genarator. Keep the number of elbows and abrupt turns in

the steam lines to a minimal. Do NOT combine the steam lines if the generator has more then one steam line, do NOT attach

the steam line(s) to the pressure reducer valve line, or drain line.

Do NOT install steam line in an upper or lower direction repeatedly. This will

affect the output of steam and can create a blockage to the flow of steam.

Avoid installing the steam heads (nozzles) in an area that will come into contact

with any body parts or bathers traffic. Add appropriate protection to avoid bodily

injury or burns. It is VERY HOT in the vicintiy of the steam heads outlets.

The steam nozzles should be installed between 10 - 12 inches high from the finished floor. If

the steam bath is within a bath tub enclosure, the steam nozzles should be minimum 6 inches above

the bath tub. If the steam shower materials is acrylic or non-heat-resistance material, install

additional heat insulators.

The steam nozzles need to be intalled so the steam outlet escapes down towards the floor.

Do NOT install with any wrench or tool that will damage it finish. Best to hand tighten and

silicone to the wall finish. Do NOT use corrosive materials to clean the steam nozzle(s) or any

harsh cleaning products.

Flush water supply line before connection to eliminate sediments.

If necessary, install a Hydro pneumatic device which reduces pressure spikes.

Steam nozzles need to be a minimum of 6 inches from a corner.

3

!

!

Important:

1. Please consult your distributors of building materials like acrylic, fiber glass or other

anti-heat sheet about the installation position of steam nozzle. It is suggested that MS-

103412 anti-heat material can be used.

2. In the entire steam room, it is required that steam must not leak out. The pipes, its

accessories and the holes in the wall should be airproof by applying silicone so

that no steam will enter the holes in the wall.

Attention:

User Manual

DO NOT HEAT AUTO FILL / DRAIN VALVES WITH TORCH DURING INSTALLATION.

Aroma Essence Reservoir

(apply a few drops prior to heating) If non-heat-resistant material such as acrylic

is used a wall material, create a gap of no less

then 1.4" and fill with silicone.

Inside wall of steam room.

Use silicone to fill in the gaps in the wall

to achieve the proper water proofing

and damp proof effect.

Apply Silicone

The drain pipe should not incline to prevent gravity flow of draining water.

This may cause damage, leakage or malfunction to intake/drain solenoid valves

DRAIN PIPE: (1/2 inch diameter)

Steam generators up to 9 KW are equipped with an auto drain solenoid valve. The steam generators 10.5 KW and higher

are also equipped with an auto drain solenoid valve, plus an additional manual drain port that is capped. The manual drain port

is to remain capped at all times. This secondary port is for back up manual draining if required for

maintenance use only.

SAFETY PRESSURE RELIEF VALVE: Rated 15 psi.

1. Pressure relief valve is a safety device in order to prevent too much pressure build up within

the steam generator. Build up of pressure can be created by many different reasons; steam line

line blockage, undersized steam line pipr diameter, steam line traps, or vandalism. This build up

of excessive back pressure may cause the auto & manual high temperature limiting switches to

trip and cut power to the heating elements to stop producing steam.

2. The steam generator is shipped with plastic caps over the steam outlets, these are to be removed

and discarded only when making connection to the steam lines. The purpose of these caps is to

avoid any particles getting into the boiler tank while installing or handling the steam generator during

installation.

3. Steam bath generators that are 18 KW and Higher will have a factory installed pressure switch. This

pressure switch will cut power to the steam generator heating elements when the internal steam pressure

within the boiler tank or steam line(s) reaches over the manufactures recommended limit. The switch will

reset automatically when the excessive pressure has been substantially reduced. This will re-occure until

the cause of excessive pressure has been rectified. Usuall causes are listed in point 1.

4. Safety pressure relief valve is an automatic system that is actuated by pressure in order to prevent steam pressure

increasing in the interior of the generator. The pressure limit range of the saftey is 15 PSI and the pressure will begin

to decrease if pressure should come over this value. If it is allowed by local codes, provide the safety valve with exterior

drainpipe. Do NOT dismantle the pressure relief valve while generator is in operation. To maintain the proper automatic

operation of the safety valve, make sure the safety valve connection pipe is smooth.

4

Steam generator blue print.

Safety valve

Steam outlet

Water inlet

Water

drainage

160mm

148mm

98mm

25mm

35mm

130mm

209mm

230mm

244mm

260mm

395mm

Fuse for wire power supply

Power wire hole Controller wire

and light wirehole

304mm

Safety valve

Steam outlet

Water inlet

Water

drainage

213mm

190mm

115mm

29mm

156mm

260mm

307mm

315mm

335mm

465mm

383mm

Fuse for wire power supply

Power wire hole Controller wire

and light wirehole

Fuse for wire

power supply

User Manual

Fuse for wire

power supply

(metal conduit connector

required)

(metal conduit connector

required)

5

!

!

!

Electrical requirements:

All the connectionsmust be in accordance with national and local

electricity consumption code and be installed by professional licensed electricians.

Attention:

to facilitate maintenance, keep the steam engine clean. If the information

provided is limited, do not touch the pipeline and electric equipment.

Attention:

Caution: to avoid damage to the equipment, do not connect strong electric current

directly to the components.

510mm

435mm

Steam outlet

Safety valve

Water inlet

Water

drainage

Fuse for wire power supply

Power wire hole Controller wire

and light wirehole

300mm

340mm

350mm

385mm

205mm

265mm

215mm

142mm

28mm

User Manual

Fuse for wire

power supply

(metal conduit connector

required)

ELECTRICAL SUPPLY:

1. Test the voltage of electricity supplied to the steam generator, make sure the correct voltage is supplied

to the steam generator. Make sure ALL connections have been adequately torqued.

2. Insulated copper wire should be used with an anti-heat temperature of no less then 90 and a specified

voltage of 300V. Refer to your national or local electrical codefor specifications.

3. Intall an independant circuit breaker between the power supply and the steam generator unit in order to

provide an electricity supply with overload protection and electricity leakage protection.

4. A suitable metal conduit with connector should be used for the main power wiring connections. ALWAYS

disconnect the main power supply to the steam generator prior to attempting any service to the generator.

6

!

Ampere Meter

!

The data provided above are for 240V(1PH) and 208V(3PH). Consult the manufacturer for

three-phased electricity or electric voltage of other specifications. Within the steam generator,

install an independent circuit breaker so as to provide an electricity supply with

overflow protection and electricity leakage protection (ground fault interrupter.)

Power Supply Wire Connection

To avoid damage to the equipment, do not connect strong electric

current to the component directly.

This drawing is for explanation only. For actual installation, refer to

national and local electricity consumption codes by professional licensed electricians.

Attention:

Warning:

240V~ 1PH

240V~ 1PH

240V~ 1PH

240V~ 1PH

240V~ 1PH

208V~ 3PH

240V~ 1PH

240V~ 1PH

208V~ 3PH

12.5A

18.75A

25A x 3

Type Applicable space of

3

the room (m )

Electricity

supply

Electric

current (A)

L1 L2 L3

(240V~ 1PH) (208V~ 3PH)

L1

L1 L2 L3

Power connection terminal

User Manual

3kW

4.5kW

6kW

7.5kW

9kW

10.5kW

12kW

13.5kW

15kW

18kW

208V~ 3PH

208V~ 3PH

208V~ 3PH 18~22

15~20

14~18

12~15

12~15

10~13

8~12

8~12

6~10

5~8

4~7

3~6

25A

31.25A

37.5A

43.75A

50A

33.3A x 3

37.5A x 3

41.7A x 3

50A x 3

L2

L1 L2

The total connected load should not be more then 80% of the rating of the overcurrent devices.

European Connection

( L2 = N "Neutral")

7

J2-1

J2-2

J1-2

J1-1

J1J2

SS

Supply

Red

Black

Red

Black

Red

Red

ToControl Panal

Fill water valve

Drain water valve

Terminal Block Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Red

Black

Red

Blue

Brown Red

Light

J1-1

J1-2

J1

SS

L1

G

Supply

Red

Red

Black

To Control Panal

Fill water valve

Drain water valve

Terminal Block

Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Black

Red

Blue

Brown Red

Light

J1-1

J1-2

J1

SS

Supply

Red

Red

Black

To Control Panal

Fill water valve

Drain water valve

Terminal Block

Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Black

Red

Blue

Brown Red

Light

L2

Black

Black

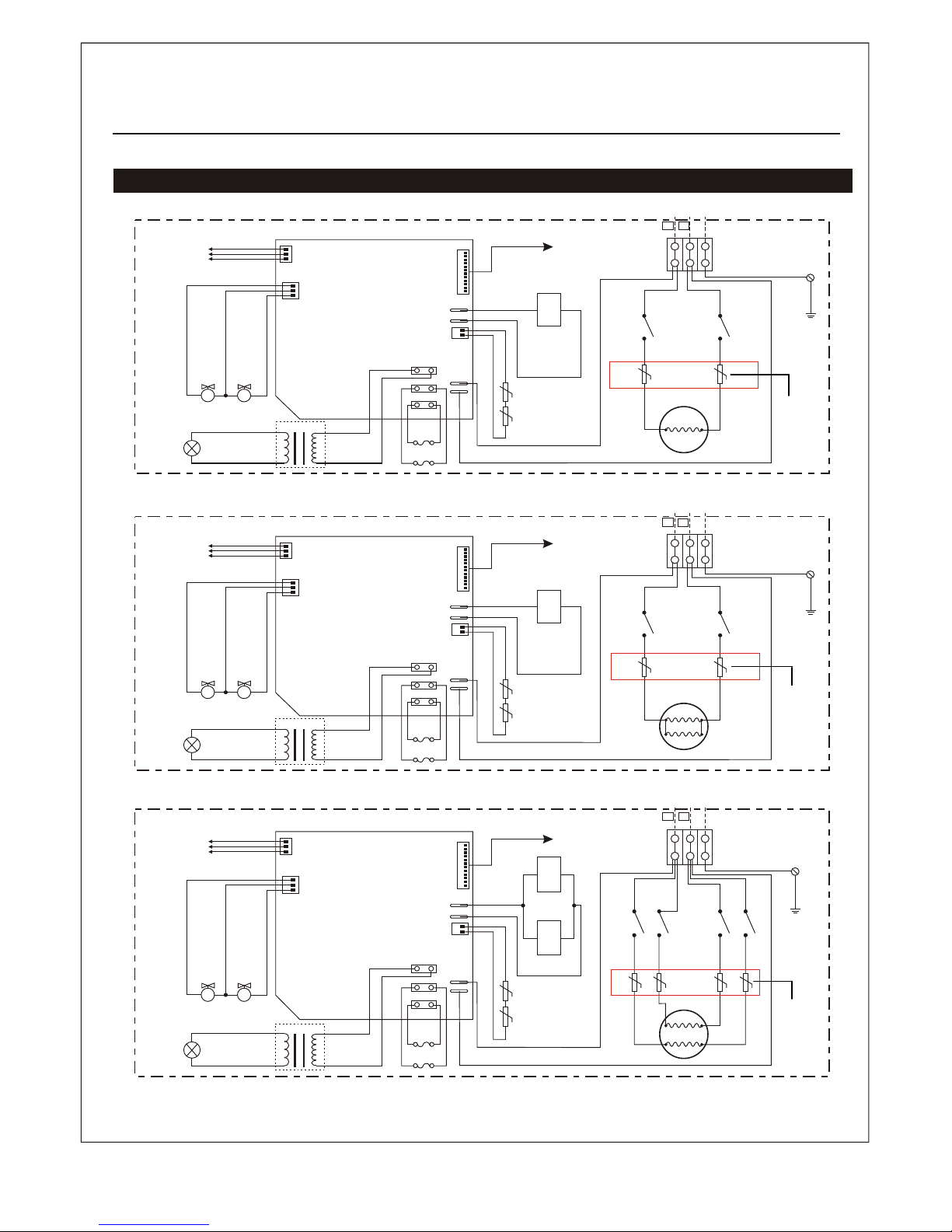

Wiring Diagram 240V(1PH)

NL

L1

G

L2

N L

L1

G

L2

N L

Optional

Optional

Optional

Steamcore Spa ** 3kW (240V - 1PH)

Steamcore Spa ** 4.5kW (240V - 1PH)

Steamcore Spa ** 6kW / 7.5kW / 9kW (240V - 1PH)

Steamcore Spa **

auto reset

hi-limit

auto reset

hi-limit

auto reset

hi-limit

manual

reset

hi-limit

manual

reset

hi-limit

manual

reset

hi-limit

European Connection

( L2 = N "Neutral")

8

J1-1

J3-2

J2-2

J1-2

J1

SS

Red

Black

Red

Black

Red

Red

To Control Panal

Fill water valve

Drain water valve

Terminal Block

Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Red

Black

Red

Blue

Brown Red

Light

Red

Red

Supply

J2J3

J2-1

Black

J3-1

Black Black

Black

L1

G

L2

N L

Optional

Steamcore Spa ** 10.5kW / 18kW (240V - 1PH)

auto reset

hi-limit

manual

reset

hi-limit

European Connection

( L2 = N "Neutral")

9

Wiring Diagram 208V (3PH)

J2-1

J1-2

J1-1

J1J2

SS

Supply

Red

Red

Black

Red

Red

ToControl Panal

Fill water valve

Drain water valve

Terminal Block

Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Red

Red

Blue

Brown Red

Light

G

L1L2L3

Red

Red

J2-2

J2-1

J3-1

J1J3

SS

Supply

Red

Red

Black

Red

Red

ToControl Panal

Fill water valve

Drain water valve

Terminal Block

Yellow/Green

Red

Black

Red

Black

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Red

Red

Blue

Brown Red

Light

G

L1L2L3

Red

Red

J1-2 Red

Red

J1-1 Red

Red

J3-2 Red

Red

J2

To Control Panal

Terminal Block

J2-2

J1-1

J1-2

J3-1

J2-1

J3-2

J1J2J3

Yellow/Green

Red

Black

Black

Red

Black

G

Supply

L1L2L3

Red

SS

Fill water valve

Drain water valve

Yellow

Red

Black

Red

Red Red

Red

Water Level Sensor

Red(Short Pin)

Black(Long Pin)

Yellow(Middle Pin)

Red

Blue

Brown Red

Light

Optional

Optional

Optional

Steamcore Spa ** 15kW / 18kW (208V - 3PH)

Steamcore Spa ** 9kW (208V - 3PH)

Steamcore Spa ** 10.5kW / 12kW / 13.5kW (208V - 3PH)

Steamcore Spa **

manual reset

hi-limit

auto reset

hi-limit

auto reset

hi-limit

manual

reset

hi-limit

manual

reset

hi-limit

auto reset

hi-limit

12 psi pressure switch (UL - USA Application 18kw & Up)

European Connection

( L2 = N "Neutral")

10

!

The calculation formula for selecting the size of steam generator is for

reference only. Due to the variability of the building, the specifications and size

illustration are used as guidelines only. If we have complete information, including

actual blueprint, project instruction and building details, we can select the type of

generator.

Important:

User Manual

Sizing steam generator

Measure the length, width and height (feet) of the current steam shower or bathtub area

Example;

L:7xW:5xH:8 = 280 Cubic Feet

You would need a 9000 watt (9KW) steam generator.

However, if your shower materials are;

x 25% for Ceramic Wall Finish = 61.25 (61.25+280) = 341 Total.

that has a ceramic wall finish.

(is multiplied by:)

Acrylic, cultured marble.

Ceramic Tile on Cement Board.

Ceramic Tile on Mortar Bed.

Glass or Glass Block

Porcelain tile on cement board

NATURAL STONE TILE (marble, granite, slate, travertine, etc)

On Cement Board.

On Mortar Bed.

Natural Stone Slabs over 1/2" thick

Each Exterior Wall(s) Insulated

0.08

1.30

1.30

1.35

1.60

1.90

2.00

2.25

1.10 for each outside wall

11

!

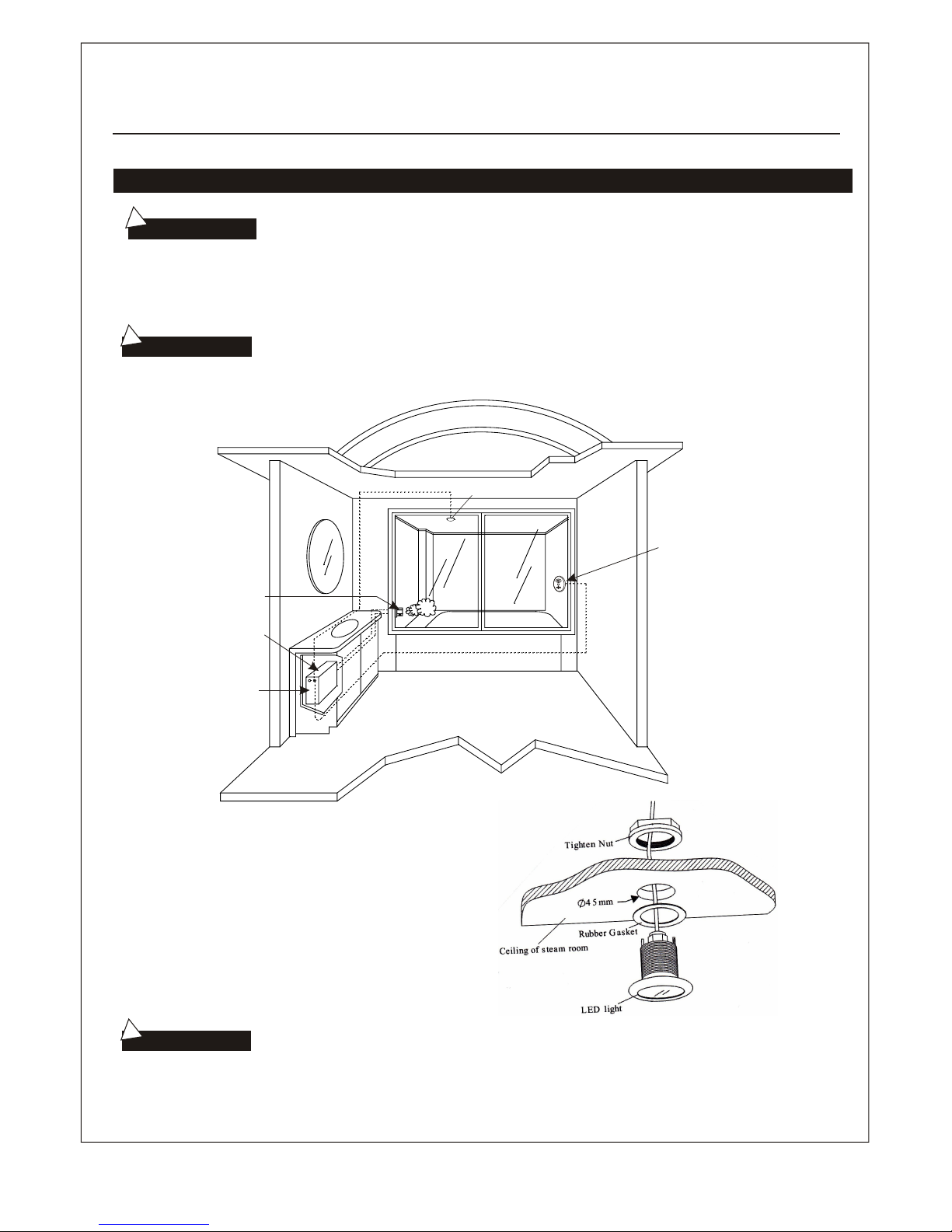

Installation of the top light

CAUTION:

The rating of the light should not surpass 3 Watts (rated power) to prevent damage to

the transformer.

!

CAUTION:

Take some moisture proof measures in the process of installation. Do

not let the electrical components be exposed to moisture or,it will cause damage or

short circuit.

The illustration is just for explaination,the practical installation must comply with

the nation's electric criteria,and performed by aprofessional licensed electrician.

!

CAUTION:

(Possible location)

The steam outlet

Under Sink

(possible location)

The steam generator

Light

The steam control panel

User Manual

The LED light should be installed on top of the steam room ceiling or in a place not accessible to children.

CAUTION: Installer must take some moisture proof

measures in the process of installation.

Electrophorus components cannot be

exposed to moisture, as it will cause damage

to the light components causing a possible

short circuit.

12

1

2

3

5

4

6

12

14

11

8

10

7

15

17

16

1Enclosure

2

3

Circuit board

4

Steam Outlet

5

6

Water fill valve

7

Water drain valve

8

Subsidiary water tank

9

Main water tank

10

Heating Element

Heat Hi-limit

Transformer

11

12

Terminal block

Fuse

Ground wire connector

16

Relay

Water level sensor

17

15

14

13

Configuration of steam generator

Fuse

13

17

9

User Manual

Pressure Safety Valve

DO NOT HEAT

DURING INSTALLATION.

(heating with torch will cause

damage to plastic solenoid valve)

Mood light transformer

18 Manual Reset Hi-Limit

18

19

19

14

!

!

!

Controller Maintenance

Safety and operation information of the controller

Warning:

If the installation and operation instruction is not read or understood, do

not install. In case there should be any dangerous installation and improper

operation.

Install the controller based on the installation instruction otherwise, the temperature in

the steam room will be too high or not heated enough.

If the controller is installed outside the steam room, the temperature sensor must be

installed in the steam room.

Caution:

Do not install the controller wire in the same conduit with high voltage electric

wire. Do not install close to hot water or steam pipe.

Important:

Before installing the controller, make sure the steam generator power is

off otherwise the controller may be damaged.

The instruction includes important safety, operation and maintenance information.

Keep the instruction in the user's hands.

If the steam generator is damaged or does not work normally, do not continue to install

or use the controller. Turn main power supply off.

User Manual

1. Use soft cloth with a mild soap/water to clean controller

2. Do NOT use harsh chemicals or cleaning products.

3. Do NOT mount controller directly over the steam nozzles.

4. If controller is readout is not stable or damaged, turn main power off and call a

service electrician to replace it.

15

User Manual

Control panel (both SSI and SSII) dimension

113mm 25mm

75mm

SSI and SSII Control panel may be switched for Spa II

SS I

SS II

160mm

120mm

23mm

70mm

16

Installation instruction of controller

!

Important:

Before installing the controller, make sure the steam generator is shut off

otherwise the controller may be damaged.

!

Important:

User Manual

!

Important:

Do not install the controller under the

water pipe or in a position where water comes into contact.

!

Do not pull tight, or clip tight the

controller wire

in case

of causing damage to it.

before repairing the controller, make

sure the steam generator is shut off otherwise the

controller may be

damaged.

Important:

Aor

Control Panel

(1ft)

(1ft)

(20ft)

SS II

Extended wire

Steam Generator

Control Panel SS I

STEP 1

STEP 2

STEP 3

STEP 4

Determine the installation location of the controller. The controller is designed

to be installed in the steam room.

1. 4 - 5 ft from the finished steam room floor.

2. Away (not above) from the steam nozzle(s) and do not expose under

the direct path of steam.

3. Installation on vertical walls only.

4. The position of the installation should facilitate easy operation and

convenience of wiring. The controller wire is 1 ft long, with a supplied

20 ft extension control cable. The max length between the generator

and the controller should not exceed 20 ft at most. If longer lengths is

of control cable is needed, additional 20 ft cables can be purchased at

an extra cost. The max length of jointable cable run should not exceed

60 ft (3 cable sets of 20 ft).

Drill a hole of 1.5 inches (35mm) diameter. No larger or smaller.

Pull the controller cable through the round hole, connect it to the controller.

Make sure when installing the 20 ft cable that it is placed in the proper direction.

Make sure that the ends are corresponding with the controller and steam

generator plugs. When attaching the controller ends, do NOT twist, aim the

ends with the marked arrows and insert horizontally wit out twisting. Take

PRECAUTION to not damage the pins on each end of the controller cables.

Do the same if unplugging is needed.

Before activiating the main power supply, make sure there are no water

leaks and that all wiring connections are adequately tightened and secure.

Operate steam generator and make sure all items on the page function well.

17

!

User Manual

Control Panel SS I

Control Panel SS I

Control Panel SS II

Temperature sensor

Locknut for temperature

sensor base

Drill

10

1cm

Ground

1.2~1.5m

(Fig.1) (Fig.2)

(Fig.3)

Temperature sensor

base (optional)

To ensure horizontal

installation of the controller, use a

level if necessary.

Important:

Control Panel SS II

Temperature sensor installation(only for SS I )Control Panel

STEP FIVE

STEP SIX

Remove the paper on the back side of the controller. To

expose the 3m adhesive tape. To achieve good adhesion

to the wall finish make sure it is clean and dry.

Locate the display screen in the direction of 12 o'clock,

and press the controller firmly to the wall finish.

1. The position of the temperature sensor for the SSI controller should be within a range of 4.5 - 5 ft (1.2M - 1.5M) from

from the steam room finish floor. Try to avoid installing in the vicinity of the steam nozzle(s) or the opening side of the

steam room door.

2. As shown Fig1, drill a small hole 3/8 inch (10mm) in the selected location.

3. Apply a bead of silicone along the edge of the back of the sensor base.

4. The sensor holder and nut is no longer supplied nor required.

5. Place sensor chrome tip within steam room and place small bead of silicone to create seal and hold sensor into place.

The temperature sensor should be installed by extending about 0.5 inch (1cm) from the front of the steam room

to make sure the speed and accuracy of temperature control.

18

Illustration ofthe controller panel (SS I )Control Panel

User Manual

Operation instruction (SS I )Control Panel

1

5

2

10

2

1

2

Steam Temperature Adjust Key--HIGH

3

4

5

6

Steam ON/OFF

Power Indicator LED

LED SCREEN

Mood Light Indicator LED

Mood Light ON/OFF

Steam Time Adjust Key--LOW

7

8

9

10

Power ON/OFF

Steam Temperature Adjust Key--LOW

Steam Time Adjust Key--HIGH

29

3

2

8

2

47

66

Power ON/OFF

When unit is powered on, power indicator LED should be lit. Press

and release button to activate system and all function buttons.

Meanwhile, power indicator LED goes out. Water input steam boil

tank automatically, and LED screens display . Shut down the

system, press button again. System drains out water in generator

water tank automatically. (NOTE: If power indicator LED flashes

when system is activated, it reports that generator water tank is lack

of water. System shuts down power supply to heater elements, and

opens water inlet valve to refill water until reaching required volume.)

IN/OUT SHOWERUSE

19

Table of contents