10 GB

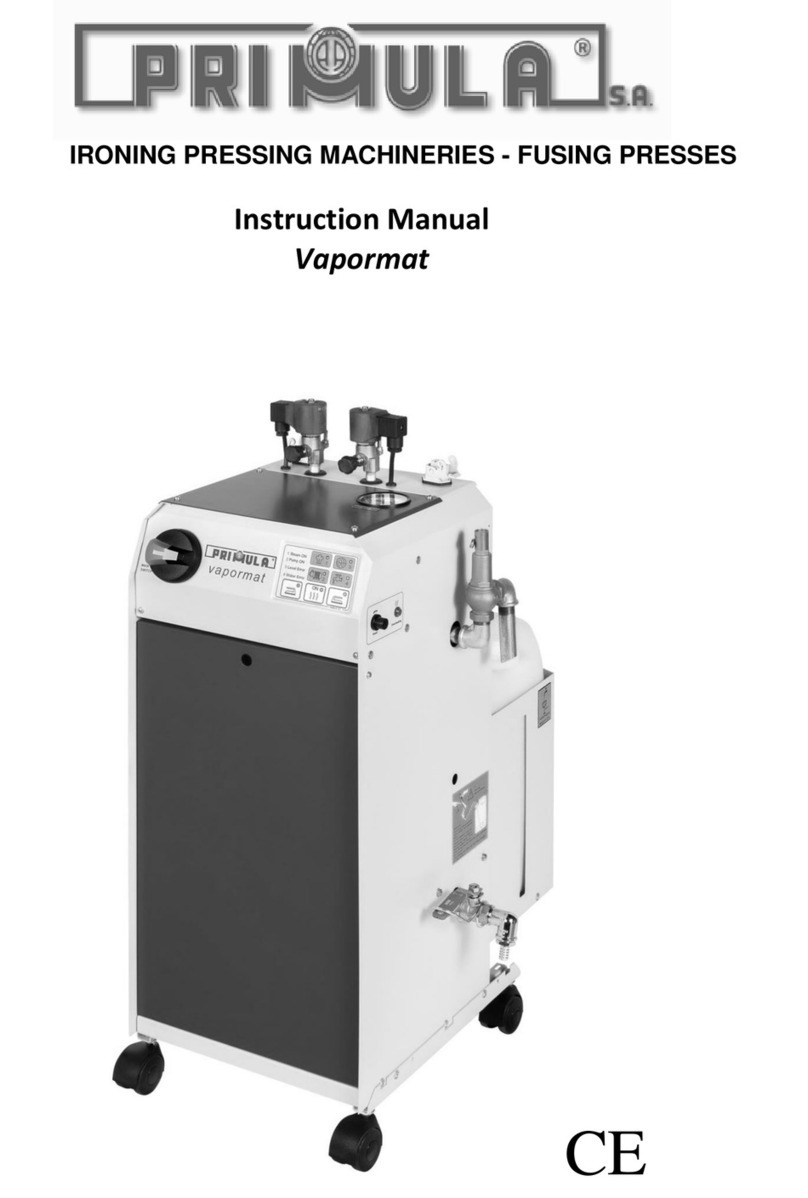

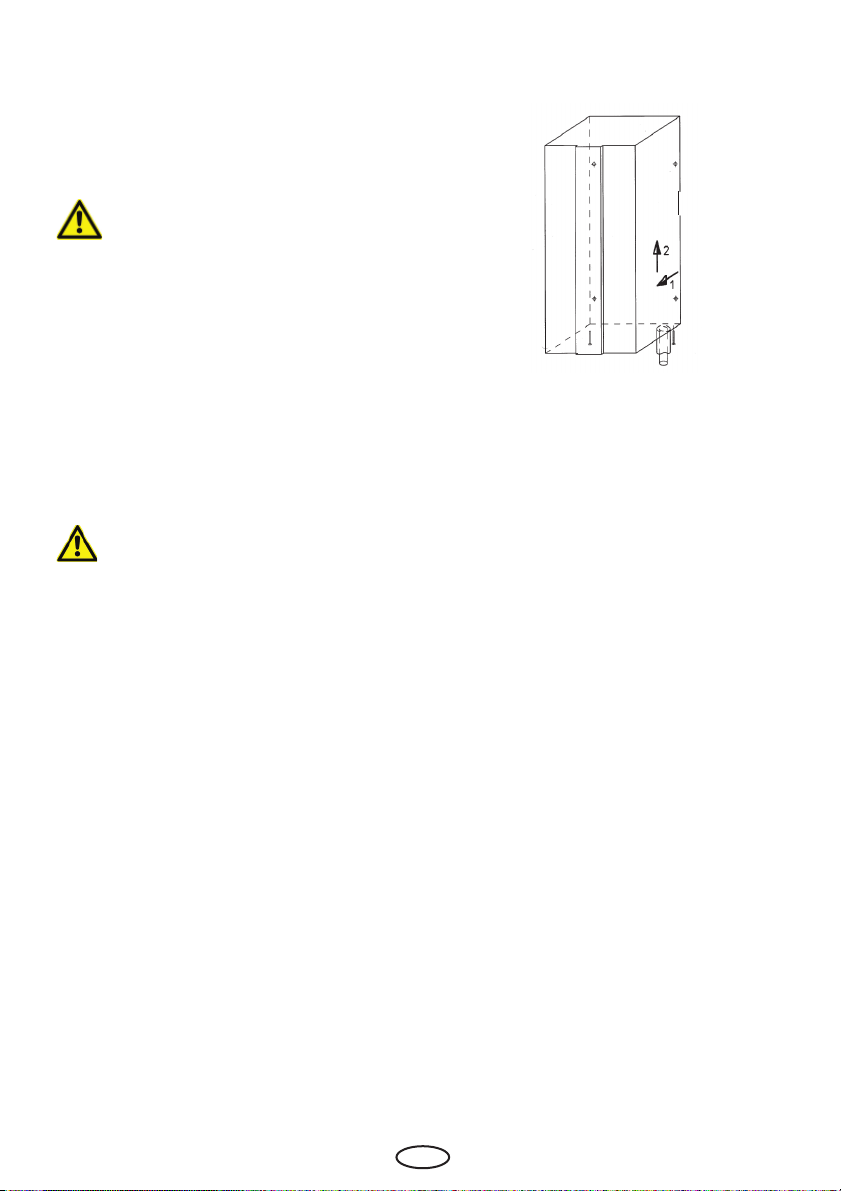

3. Flushing and decalcification

The development of lime scale deposits due to hard water in the tank and on the radia-

tors reduces quite considerably the life of the heating rods.

We recommend that you use a chemical water softener with the steam generator (as an

extra) so as to prevent lime scale from developing.

The steam generator is equipped with a fully automatic self-cleaning system (flushing

and descaling), which may be programmed at site to match the local water quality.

The flushing or decalcification process starts automatically after a delay of 30 minutes af-

ter the steam generator has been switched off. The green LED „Decalcification / flushing“

lights up on the display panel.

Whenever the decalcification programme is run, the tube pump will fill up the steam tank

with approximately 100 ml of softening agent.

This will be allowed to work for about 30 minutes and then the water with the lime scale

in it will be drained out through the electr. ball valve.

The flushing valve flushes the container a second time, the ball valve will close and the

flushing programme will come to an end.

The running time for the flushing programme is about 35 minutes.

The steam generator cannot be switched on during this time.

Check regularly if there is still enough of the cleaner / descaling liquid in the container.

When the level in the container remains unchanged over a longer time this may indicate

a failure in the cleaning system. Check the steam generator immediately to prevent da-

mages from the scale building inside water tank.

If the softening agent supply has been almost used up, the red LED „Problem with softe-

ning agent supply“ lights up on the display panel.

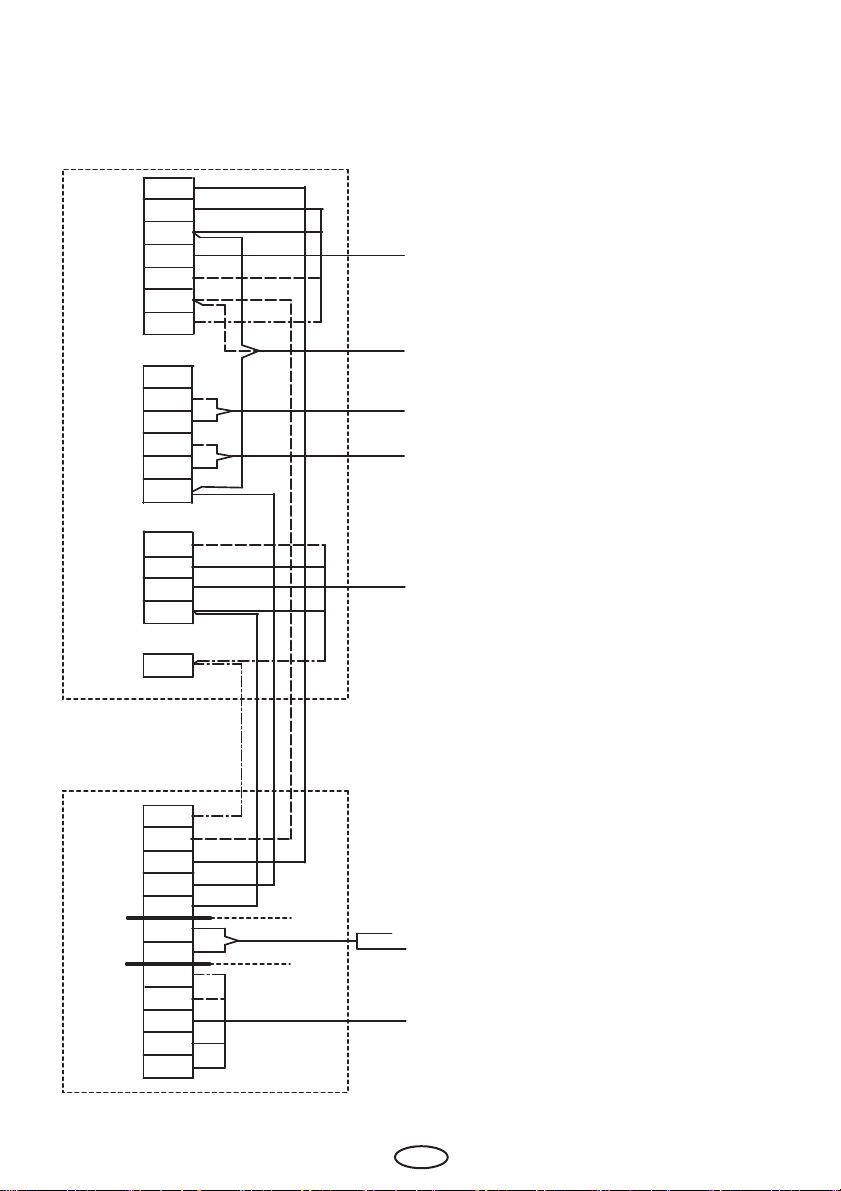

The LED „operation“ lights up when the sauna equipment is in operation, independently of

whether the steam generator is working or not.

The steam generator is equipped with an overheating protection feature (Safety Temperatu-

re Limiter (STB in German)). If this STB reacts, the steam generator switches off and the red

LED „STB problem“ lights up on the display panel.

In this case, wait briefly until the steam generator has cooled down. Disconnect the sauna

control unit from the mains for about 5 seconds (switch off fuses or FI switch). The device

now works normally again. If the fault occurs again, have the device checked by your autho-

rised EOS partner.