Steamist SMS-45 User manual

Page 2

Contents Page

Page 3 –Specification

Page 4 –Generator Dimensions

Page 5 –Controller Specification

Page 6 -8 –Plumbing

Page 9 –11 Controller Installation

Page 12 –13 Electrical Installation

Page 14 –Cleaning Process & Troubleshooting

Page 15 –Common Troubleshooting Problems

Contents Page

Page 3

Specification –Summery

4

Features

•Limited 5 year warranty

•Stainless Steel Tank Construction

•Intelligent Control Communication

•Auto Drain

•Safety Overheat Protection

•Can Link Two Generators Together

Product Number

Kw Rating

Max. Adj, Cu. M.

Range*

Volts/Phase/Max.

Amps

Dimensions

L x W x H

SMS-4.5

4.5kW

3.5m3

220-240v / 1/ 20.5A

372 x 162 x 333mm

SMS-6

6Kw

5.8m3

220-240v / 1/ 27.3A

372 x 200 x 333mm

SMS-9

9kW

10.3m3

220-240v / 1/ 41A

372 x 200 x 333mm

Installation Notes

For optimum performance, the steam generator should

be mounted as close as possible to the steam room.

Generator to control distance is 6m (Extension Cable

available upon request)

Do NOT install inside the steam room or near flammable

materials such as paints, thinners, gasoline, etc.

Steam Generators must NOT be installed outdoors, in

moist humid areas, in areas prone to freezing, or

extreme heat such as an unventilated attic. To do so will

void the warranty.

Steamhead to be mounted 300mm to 450mm from floor

150mm left side clearance for plumbing and electrical

and 150mm top access for servicing

Required Electrical Service

Dedicated circuit required. See specification chart for proper

electrical requirements

Product Information

Water Supply –½” BSP male thread

Steam Outlet –4.5kw ½” BSP male thread

6kW and bove ¾” BSP male thread

Drain Outlet –½” BSP male thread

Clean Outlet –½” BSP male thread

Generator Weight

4.5kW –11.4kg 9kW –12.9kg

6kW 12.2kg

*Refer to sizing guidelines to accurately determine the proper size generator for the installation.

Specification and Summery

Box components

Generator, SMS Control, Steamhead, lever valve, light cable.

NOTE: Cable not included for joining two generators. (Grey

cable on generator)

Page 4

4.5kW

6 / 9kW

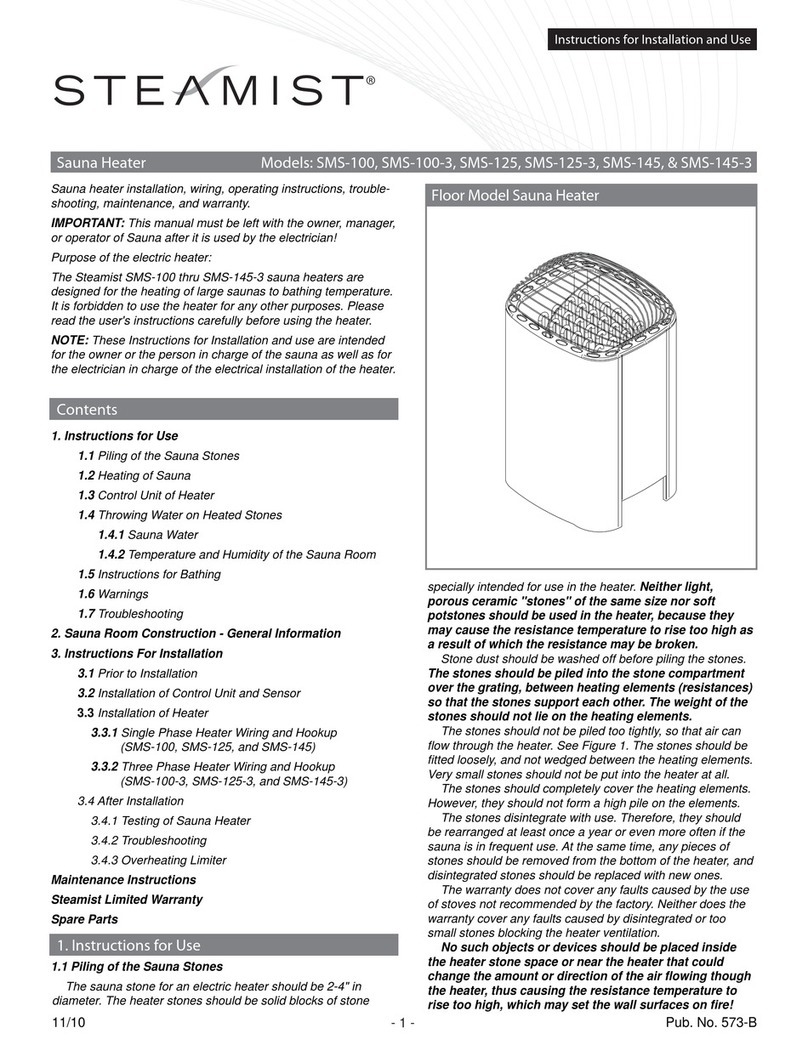

Dimensional Drawing

Page 5

141.20mm

111.20mm

Controller Information –SMS-CONTROL

Preset time and programmable temperature

Digital display of ambient, set temperature and

time remaining

Icons for temp adjustment, time adjustment,

manual drain, light and power on

Dimensions

L 141.20mm x H111.20

Package includes

Controller, control cable, Sticky pad, back box,

surface mount trim and temperature sensor

First Fix –

•Control should be installed 1.2m from floor

•If controller is inside the steam room no need to use temperature sensor

•If controller is outside the steam room or close to steam outlet, run the temperature sensor cable through

conduit pipe to the controller (Sensor connects into back of the control)

•Run black control cable through conduit pipe from generator to steam room

Note: If you are using two generators together you will need to link the grey cable from one generator to the

black control cable on the secondary generator. (Refer to Internal diagram)

Controller Specification

Notes

Page 6

The Steamist SMS Generator comes factory

assembled carefully wired and tested.

Warning: All electrical power should be turned OFF

when working with the steam generator

Important: The plumbing installation must conform

to local and national code of practice

1.Pre-Installation

a) Be sure that the proper size Steam Generator has

been selected by using the sizing page in the “The

Generator Sizing Guide”

CAUTION: An improperly sizes Steam Generator may

Not produce the amount of steam necessary to reach

selected temperature

b) For optimum performance, the Steam Generator

should be located as close as possible to the

Steamroom, Shower or tub enclosure using a ¾”

copper pipe (1/2” acceptable on 4.5kW) If the steam

pipe exceeds 3 meters, it should be insulated using

appropriate pipe insulation rated for minimum of 100

°C Maximum steam pipe distance should not exceed

a total of 15 liner meters.

CAUTION: Do NOT install near flammable material

such as paints, thinners, gasoline, etc.

CAUTION: Steam Generators must NOT be installed

outdoors, in moist humid areas, in areas prone to

freezing, or extreme heat such as an unventilated

attic. To do so will void the warranty.

2. Plumbing First-Fix

Plumbing rough-in is required for the water supply

and steam line; this should be completed before the

walls are closed. For operation, the “SMS” Steam

Generator requires a 15mm. copper tubing to the

fitting on the generator for water inlet and a 22mm

copper pipe for steam outlet.

a) Water Inlet –First fix a water line, (3 bar

max) to the hot or cold supply. An isolating

valve with a 15mm connection to the steam

generator is to be provided at the generator

location

b) Steam Outlet –First fix in the steam line

using a 22mm Copper tube with sweated or

compression brass fittings only. Do NOT use

plastic pipe or fittings. Do not use any push-

fit, snap-fit or anything else that is not

specifically rated for 100 °C steam. Do NOT

use Black Iron or Galvanized pipe to avoid

rust and discoloration to steam room. The

steam head location should be 300mm –

450mm above the steam room floor or

150mm above a rim of a bathtub and as far

from the seating area and user control as

possible

c) Drain Pipe –Rough in the drain pipe to an

open drain using 15mm copper pipe.

do NOT connect the drain pipe to the steam line

(If unable to connect to a drain, cap the outlet

with a ½” brass cap, cannot be left un-plumbed

or capped.)

d) Clean Outlet –Install supplied ball valve and

plumb into an open drain using 15mm

copper pipe. (If unable to connect to a

drain, cap the outlet with a ½” brass cap,

cannot be left un-plumbed or capped)

CAUTION: Do Not install a shutoff valve in the

steam line. Do NOT create traps or valleys in this

line which would trap condensation and block

the flow of steam. The steam pipe should be

pitched toward the Steam Generator allowing

condensation to run back toward the Steam

Generator (preferred), or toward the steamhead.

If the steam generator is equipped with a drain

valve, do NOT connect the drain pipe to the

steam line

Plumbing & Generator Location

Page 7

3. Steam Generator Installation

The Steam Generator should be mounted in a location

convenient for hook-up and service by the plumber and

electrician

CAUTION: The Steam Generator is designed to be used

ONLY in an upright and level position; to do otherwise

would damage the unit and void the warranty

a) The Steam Generator can be mounted to a

wall or set on the floor. However, the unit

must be secured. To secure the unit to a

vertical wall, remove the the four screws

removing the top cover. Then Located inside

the cabinet near the top left and right corners

are mounting holes to secure generator. Then

place top cover back and secure.

b) Connect the ½” water inlet to a shut off valve as

described in diagram below figure 1. The valve must be

kept in an open position during normal operation. In an

area where water hammer is a problem install a water

hammer arrestor in the line

c) Connect the steam line from rough-in location

described in Figure 1 to the ¾" nipple on the Steam

Generator using a union

d) We recommend installing a ¾” BSP equal tee along

with a ¾” plug on the steam outlet connection to allow

for descaling

Plumbing & Generator Diagram

Figure 1 –Plumbing Diagram

e) Connect the ½” drain outlet to an open drain.

(If unable to connect to a drain, cap the outlet with a ½”

female brass cap, this cannot be left un-plumbed or

capped.)

f) Connect the ½” clean outlet to the supplied lever

valve and plumb to an open drain (If unable to connect

to a drain, use a ½” male brass plug into the lever valve,

this cannot be left un-plumbed or capped.)

Page 8

Steam Outlet Pipe –Use 22mm copper pipe

Caution: Do NOT install a shutoff valve on the steam outlet pipe. Do NOT create traps or valleys in the line which

would prevent flow of steam. The steam outlet pipe should be pitched towards the steam generator (Preferred)

allowing condensation to run back into the Steam Generator or towards the steamhead. If the steam pipe exceeds 3

meters. Use appropriate pipe installation rater for minimum of 100 degree Celsius.

Important: Unions MUST be use on the steam line and Drain line.

Plumbing Typical Installation Diagram

CAUTION: This drawing is only for

explanation purposes. Please consult

with qualified designer, architect or

builder for steam room layout and

generator location.

Page 9

Control Installation Diagram

Page 10

Control Operation

Operation: Make sure the water and power are

turned on. Simply press the Power touch button to

begin the previously programmed cycle. Pressing the

Power touch button, a second time will cancel the

steam cycle. After a cycle is started it will take a few

minutes for the Steam Generator to heat up and begin

producing steam. During operation the display will

show the ambient room temperature.

Programming: Adjustments can be made to the

temperature control after pressing the power touch

button to start the steam cycle. To adjust the

temperature simply press the temperature + or

temperature –touch button. All changes made to the

temperature control are stored in memory until

changed again. Temperature range is 35 °C –68 °C

Additional Features

Memory: The Temperature setpoint is retained even if

there is a power failure.

Fahrenheit / Celsius: The temperature display can be

changed by pressing and holding icon 3 for 2 seconds when

control is off (Steam cycle not started) The display indicator

will then change current setting “C” to “F” and then

alternate when the change is complete.

Note: When Steam cycle has finished auto drain (if

plumbed) to drain will commence 10minutes after shut off

and remain open for 7 minutes until completion.

Error Codes –See page 12

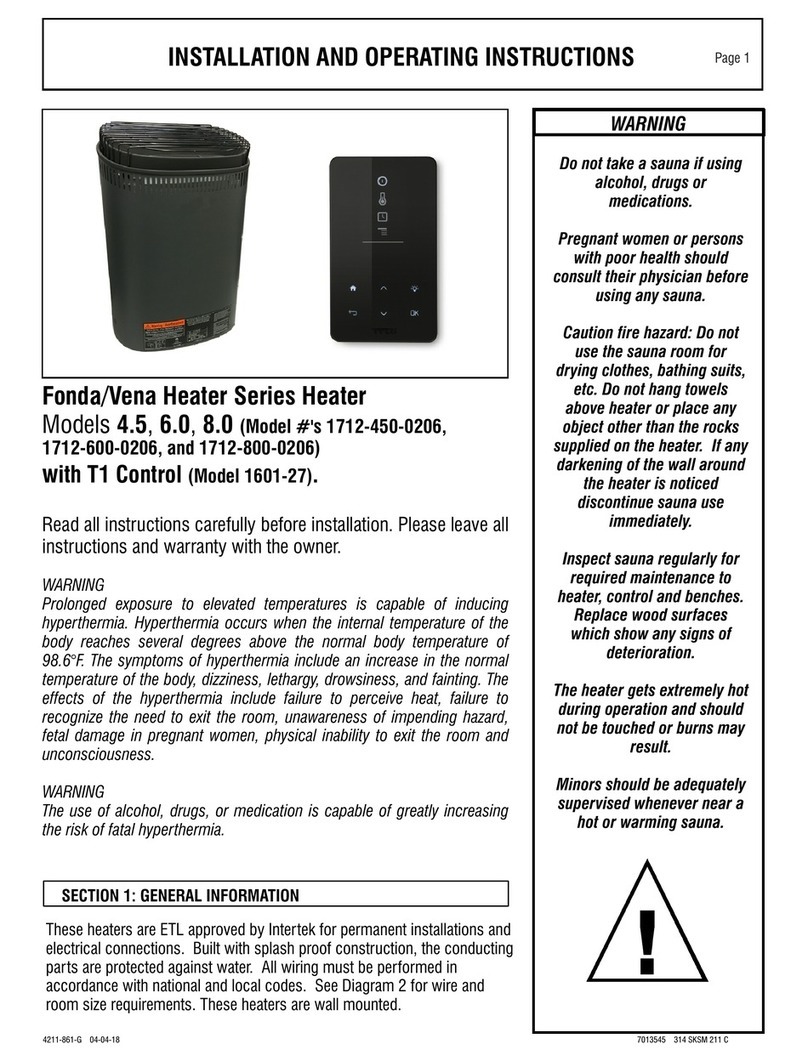

1. Power On/Off Touch Button –Press

and generator will begin producing

steam in a few minutes.

2 & 3. Up/Down Touch Button –Press

to adjust the temperature setpoint

4. Celsius / Fahrenheit Indicator

5. Temperature Display

6. Time Display

7. Time Unit

8 & 11 Time Up/Down Touch Button -

Press to adjust the remaining steam

time

9. Manual Drain

10. light –press to turn on/off steam

light

CAUTION: When joining cables check male and female connection arrows are in-line to avoid damage to internal pins.

Page 11

Steamist “SMS” Generator -Operates with one control

located inside or outside the steamroom. The Generator is

small enough in size to be tucked away using very little

space in a vanity, closes, basement, or an insulated attic,

but large enough to provide steam for more residential

steam rooms.

Steamist “SMS” Generator Steambath Generator comes

factory assembled, carefully wired and tested.

1. Pre-Installation

a) Proper electrical supply (208 or 240 Volt): See

rating label on Steam Generator and Chart on

page 13. Determine proper size of wire,

voltage, amperage, and phase for the Steam

Generator. 90°C copper wire is required for

generator connection. b) Dedicated

overcurrent protection device, such as an in-

line fuse/circuit breaker required: Fuse/circuit

breaker to be installed must be sized in

accordance with chart on back page. Do NOT

install a GFI (Ground Fault Interrupter) to this

equipment c) Route power supply

cable to the location where the Steam

Generator will be installed (before walls are

closed).

2. Electrical First Fix

a) Install appropriate power cable to the location

the Steam Generator will be installed. If

receptacle is desired, mount the box for the

isolating switch close to the Steam Generator.

NOTE: The plug and receptacle require a rating

of no less than 250V and proper amperage.

Refer to chart on page 13 for amperage rating.

3. Steam Generator Electrical Installation

WARNING: All power to the steam generator

must be turned off

d) Remove the four screws holding the top access

panel and remove

a) Strip back power cable’s outer insulation

jacket eight inches and insert into Steam

Generator. Strip back insulation ½" from

the three (3) incoming wires (one power/

live, one neutral and one ground)

b) Connect incoming ground wire to floating

green pigtail labelled “GND.

CAUTION: Be sure the ground wire does not

come in contact with a live electrical part

c) Connect incoming live to terminal block

labelled “L” and neutral to labelled

connection “N”

Electrical Installation

Page 12

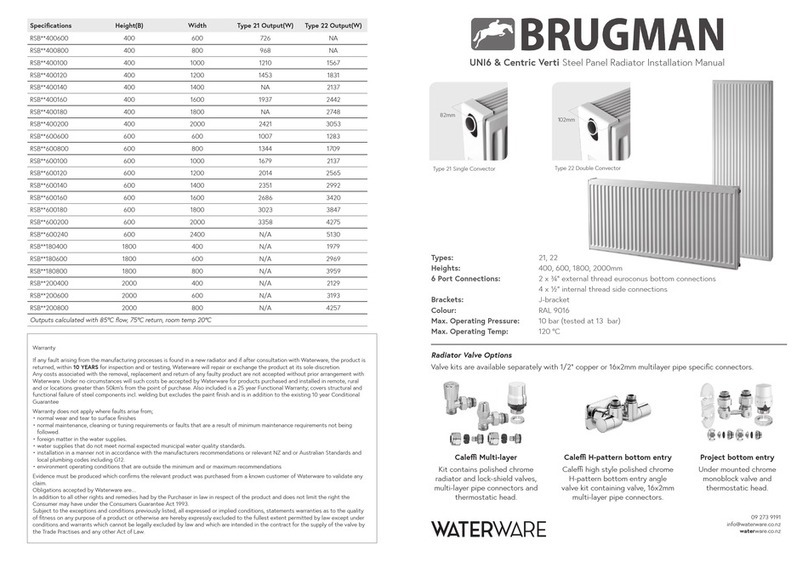

Product Number

Kw Rating

Max. Adj, Cu. M.

Range*

Volts/Phase/Max.

Amps

Dimensions

L x W x H

SMS-4.5

4.5kW

3.5m3

220-240v / 1/ 20.5A

372 x 162 x 333mm

SMS-6

6Kw

5.8m3

220-240v / 1/ 27.3A

372 x 200 x 333mm

SMS-9

9kW

10.3m3

220-240v / 1/ 41A

372 x 200 x 333mm

Electrical Data & Internal Wiring Diagram

Cleaning of the Generator

•The proper size generator has been selected by using

the generator sizing guide in the Steamist Brochure

CAUTION: An improperly sized Steam Generator will NOT

produce the amount of steam necessary to reach selected

temperature.

•The Steam Generator is installed in an upright position

•Correct electrical wire and circuit breaker has been used

•The circuit breaker is NOT a GFI (Ground Fault

Interrupter) type.

•The Steam Generator is properly grounded.

•The circuit breaker or isolator switch is on.

•Water supply to the generator is on

Checklist

N L

Internal wiring diagram of steam generator 4.5kW –6kW

(220V/1Phase

2nd Generator

*If required*

Page 13

Cleaning Process & Trouble Shooting

Make sure no water is in the generators tank

Dissolve the citric acid with hot water

Put citric acid via steam outlet

Open the cleaning mode and wait

OPL shows on the control, switch off the manual water

valve on the clean outlet

Clean Finish

Trouble Shooting & Error Codes

E0: The temperature sensor has open circuit

Water level sensor failure, check the control cable connection between the control panel to steam generator is loose

or not.

E02: The temperature sensor is short circuit

E03: Signal transfer fault between pain panel and sub-panel.

E04: Signal transfer fault between control panel and steam generator

E12. E22, E32, E42: water inlet takes over 2 minutes

E13, E23, E33, E43: water inlet tank blockage

E15, E25, 35, E45: Auto. High limit trips.

Page 14

Common Trouble Shooting Solutions

Faults

Cause of faults

Trouble-Shooting Methods

Generator not

working with power

switch on

Check green light is on, on circuit board - If

not check power connections and fuse

Green light on, check cable between

Generator and control

Change main fuse on circuit board 0.8a/250v

Tighten loose connection

Change cable if pins inside are damaged

Trip or fuse tripping

out

Check for water ingress on control and

connections

Test heating element for failure

If dampness found, dry with suitable method

Element reading ohms –replace element

No steam only hot

water through

steamhead

Water level probe faulty

Replace probe

No display on control

panel

The power connection cable between

generator and control

Check the connections are fully home at both ends

Water Escape

Water pipe develops a leak

Water solenoid valve

Water drain valve

Repair or replace and faulty pipework

Replace solenoid valve

Replace drain valve

No steam with power

and control on

No water

Temperature set below room temperature

Check water supply is on

Increase temperature above room temperature

No steam from outlet

only noise of water

boiling

Steam pipe has in-line trap

Trace steam pipe to ensure no change of direction

has been installed

Light not functioning

Fuse

Poor connection

Faulty light

Wire damage

Replace fuse

Disconnect and re-connect (poor connection)

Replace light

Check and replace wire

Calling for steam but

no steam

Heat sensor faulty

Replace sensor

Page 15

°

Generators Parts Breakdown

Generator Case

Installation Mounts

PCB Circuit Board

Steam Outlet Pipe

Pressure Relief Valve

Solenoid Valve

Water Drain Valve

Water Inlet Tank

Main Water Tank

Heating Element

105°C Hi-Temp Sensor

Transformer

L & N Terminal Block

Fuse

Earth Terminal Block

Relay

Water Level Sensor

Manual Water Drain

Page 16

Other manuals for SMS-45

1

This manual suits for next models

2

Table of contents

Other Steamist Heater manuals

Popular Heater manuals by other brands

Adax

Adax NEO user guide

Carver

Carver 3600 STC Auto Installation and servicing instructions

Viessmann

Viessmann VITOPLANAR EI2 Installation instructions for contractors

Dyna-Glo

Dyna-Glo LPC25 Series User's installation, operation and maintenance manual

Nortek

Nortek NRV24M Installation and operating manual

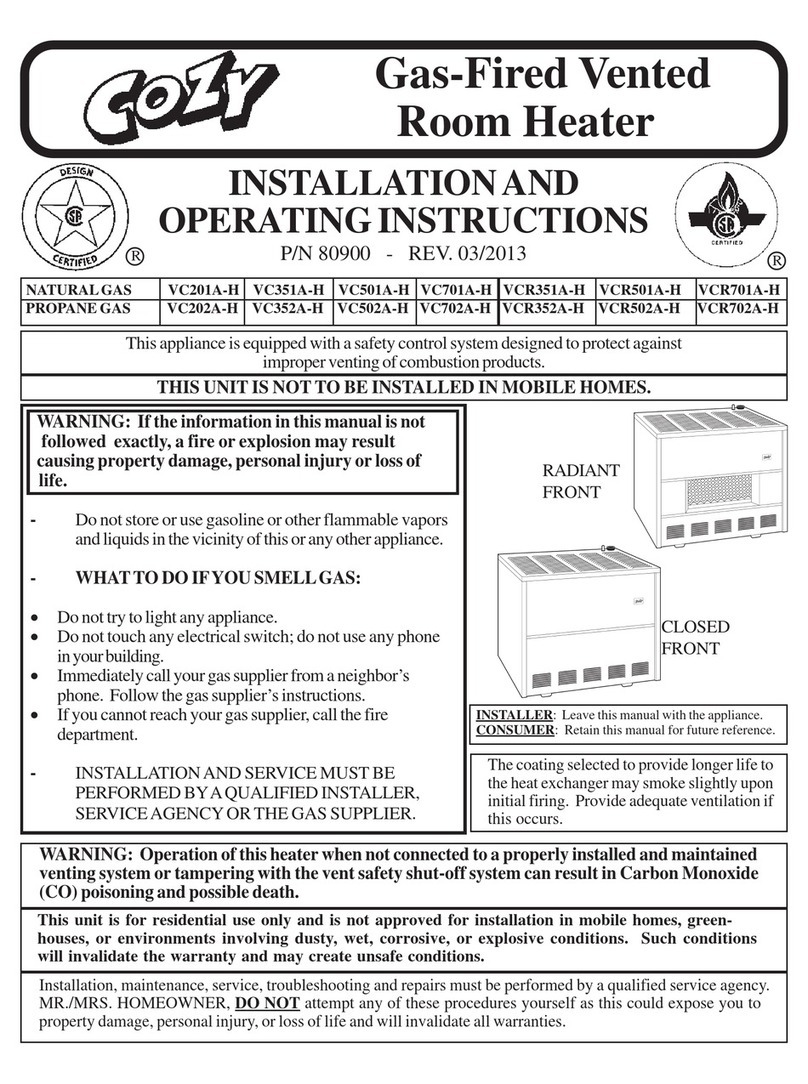

COZY

COZY VC201A-H and Installation and operating instructions