Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

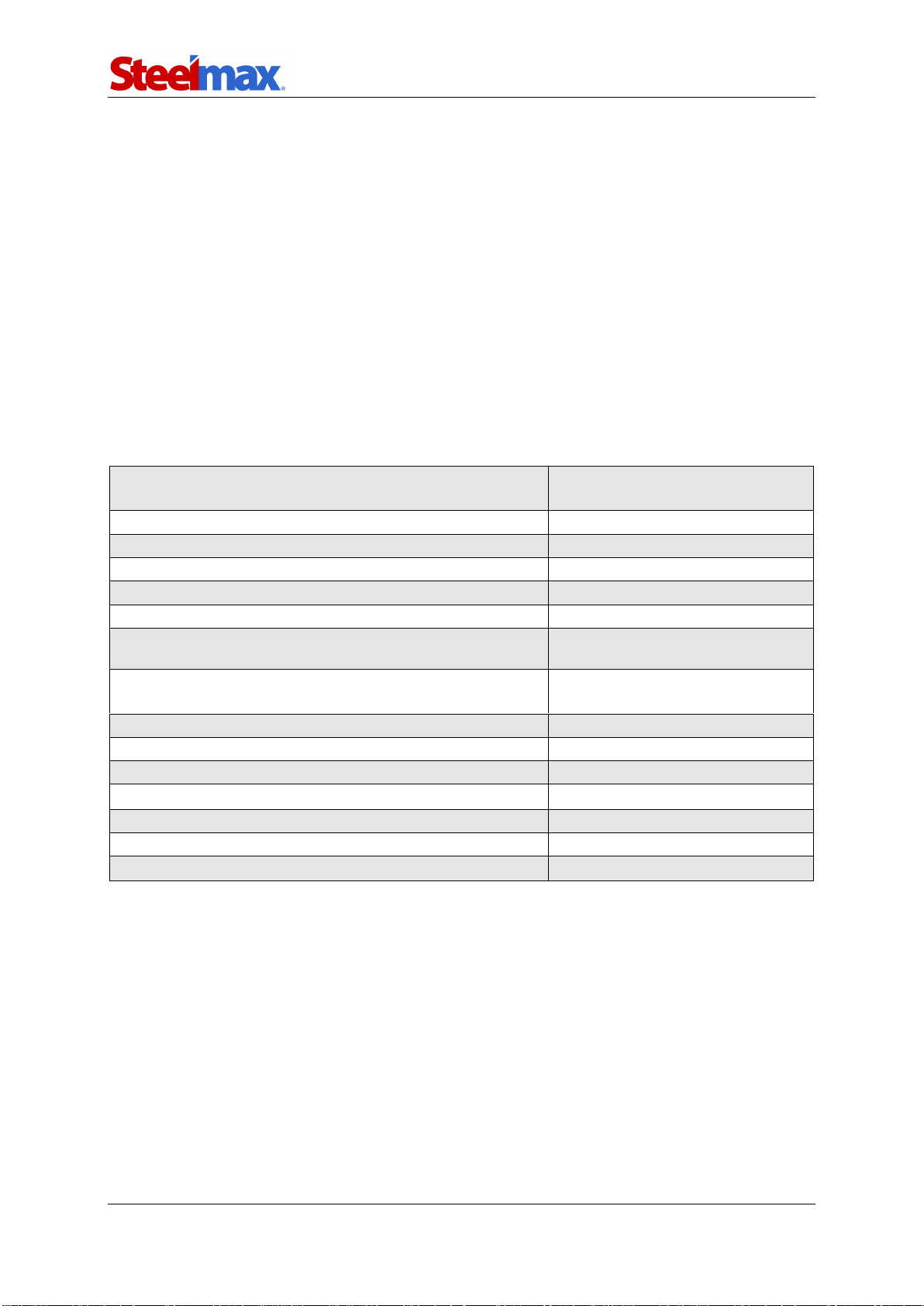

1.2. Technical data............................................................................................................ 3

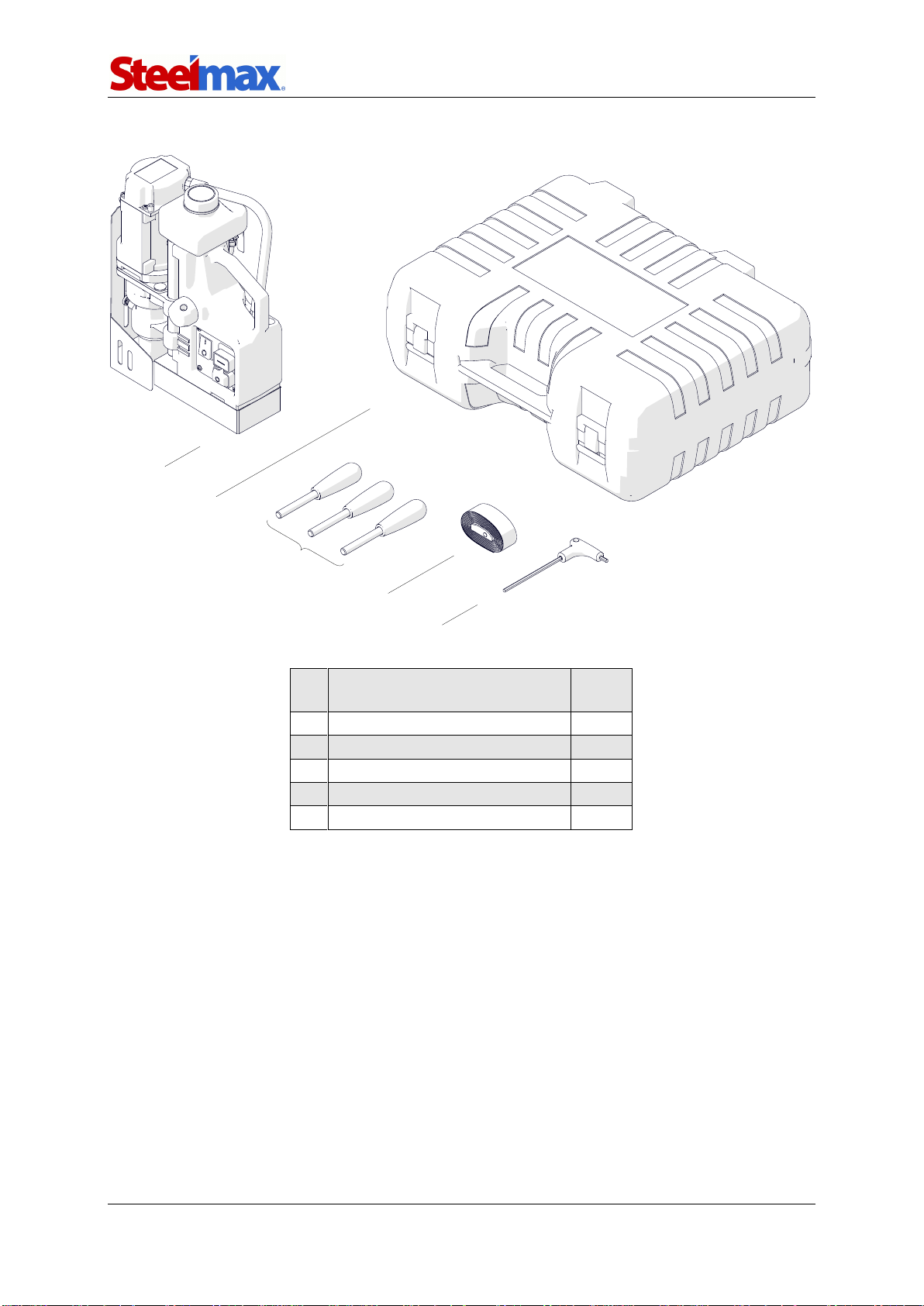

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 5

2. SAFETY PRECAUTIONS.................................................................................................. 6

3. STARTUP AND OPERATION........................................................................................... 8

3.1. Installing, removing, and operating the annular cutter................................................ 8

3.2. Installing and removing the cooling system bottle .....................................................10

3.3. Control system of the electromagnetic base holding force ........................................11

3.4. Preparing..................................................................................................................11

3.5. Drilling.......................................................................................................................13

3.6. Replacing the motor brushes ....................................................................................14

4. ACCESSORIES...............................................................................................................15

4.1. Pressure cooling system...........................................................................................15

4.2. Pipe attachment DMP 251 ........................................................................................15

5. WIRING DIAGRAM..........................................................................................................16

6. EXPLODED DRAWINGS AND PARTS LIST....................................................................17

7. DECLARATION OF CONFORMITY.................................................................................21

8. QUALITY CERTIFICATE..................................................................................................22

9. WARRANTY CARD..........................................................................................................23