SteelMax D3X R User manual

The tools of innovation.

112 Inverness Circle East Suite F Englewood, CO 80112

1–87STEELMAX, FAX 303–690–9172

www.steelmax.com sales@steelmax.com

OPERATOR’S MANUAL

D

D3

3X

X

R

R/

/L

L

/

/

D

D3

3X

XS

S

R

R/

/L

L

DRILLING MACHINE

WITH ELECTROMAGNETIC BASE

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Design ....................................................................................................................... 4

1.4. D3XS special function................................................................................................ 5

1.5. Equipment included ................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Mounting the arbor (or twist drill)................................................................................ 9

3.2. Mounting and operating the annular cutter................................................................10

3.3. Mounting the screw tap.............................................................................................11

3.4. Mounting the cooling system.....................................................................................12

3.5. Control system of the electromagnetic base holding force ........................................12

3.6. Preparing..................................................................................................................14

3.7. Drilling.......................................................................................................................15

3.8. Tapping.....................................................................................................................16

3.9. Adjusting the slider clearance ...................................................................................17

3.10. Replacing the motor brushes..................................................................................18

4. WIRING DIAGRAM..........................................................................................................19

5. D3X R-L PARTS LIST AND EXPLODED DRAWINGS.....................................................20

6. D3XS R-L PARTS LISTS AND EXPLODED DRAWINGS ................................................26

7. DECLARATION OF CONFORMITY.................................................................................32

8. QUALITY CERTIFICATE..................................................................................................33

9. WARRANTY CARD..........................................................................................................34

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The D3X(S) R/L is adrilling machine with electromagnetic base designed to drill holes

using annular cutters or twist drills. Additionally, the rotation direction switch allows

for direct tapping or tapping with the use of a holder with axial compensation.

The electromagnetic base allows the drilling machine to be fixed to ferromagnetic

surfaces with aforce that ensures user safety and proper machine operation. A safety

chain protects the machine from dropping in the case of a power loss.

1.2. Technical data

Voltage

~ 110–120 V, 50–60 Hz

~ 220–240 V, 50–60 Hz

Total power

1800 W

Motor power

1650 W

Spindle shank

MT3

Tool holder

Weldon 19 mm (0.75’’)

Maximum drilling diameter with annular cutter

12–75 mm (0.47–2.95’’)*

Maximum drilling diameter with twist drill

8–32 mm (0.31–1.26’’)

Maximum drilling depth with annular cutter

76 mm (3’’)

Maximum drilling depth with twist drill

76 mm (3’’)

Maximum tap size

M24 (G3/4’’)

Electromagnetic base holding force

(surface with the thickness of 22 mm and roughness Ra= 1.25)

19 500 N

Electromagnetic base dimensions

110 mm × 220 mm × 56 mm

4.3’’ × 8.7’’ × 2.2’’

Slider stroke

225 mm (8.9’’)

Rotational speed (under load)

80–160 rpm (gear I)

210–420 rpm (gear II)

Minimum workpiece thickness

10 mm (0.39’’)

Protection class

I

Noise level

85 dB

Required ambient temperature

0–40 °C (32–104 °F)

Weight

27 kg (60 lbs)

* Above 60 mm (2.3’’) the UCW-0191-00-00-00-0 arbor is required.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

4

1.3. Design

Figure 1. D3X R/L design

cooling system bottle

gearbox

spindle with

MT3 shank

motor

spoke handle

carrying handle

control

panel

drilling

machine

body

electromagnetic base

gear

lever

slider

chip

guard

bottle

valve

lever

safety chain lug

arbor

feed

shaft

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

5

Figure 2. Control panel design

1.4. D3XS special function

The D3XS R/L has an ability to turn the upper machine part in the range of ±15°and

to move it out up to 15 mm (0.6’’)without moving the electromagnetic base. To fix the

drilling machine in chosen position, lock the eccentric shaft using the supplied 10 mm

hex wrench.

eccentric shaft

motor START/STOP button

magnet ON/OFF switch

speed adjusting knob

rotation direction switch

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

6

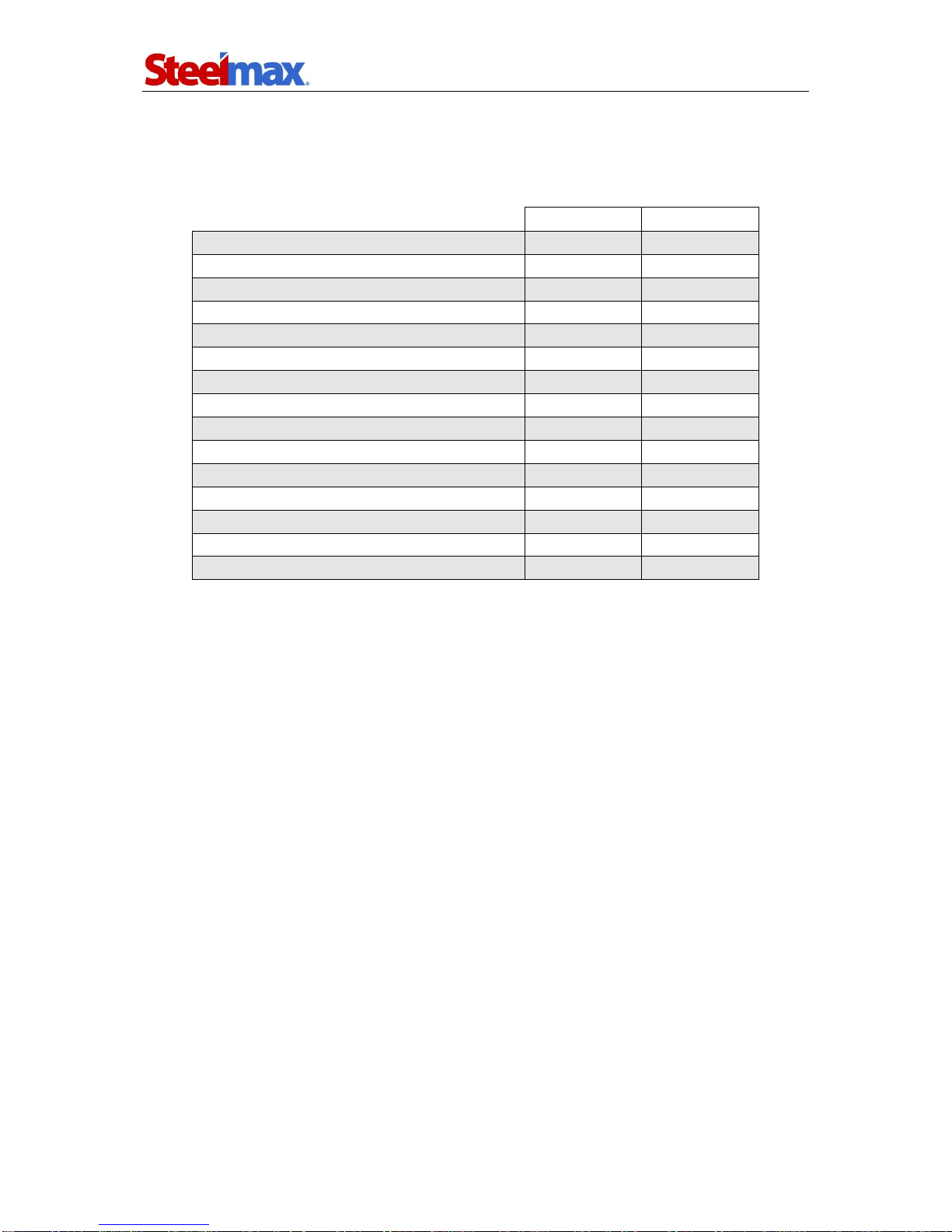

1.5. Equipment included

The D3X(S) R/L is supplied in a metal box with complete standard equipment. The

included equipment consists of:

D3X R/L

D3XS R/L

Drilling machine

1 unit

1 unit

Metal box

1 unit

1 unit

Spoke handle

3 units

3 units

Cooling system

1 unit

1 unit

Arbor with 19 mm (0.75’’) Weldon shank

1 unit

1 unit

Chip guard

1 unit

1 unit

Safety chain

1 unit

1 unit

Drill drift

1 unit

1 unit

2.5 mm hex wrench

1 unit

1 unit

4 mm hex wrench

1 unit

1 unit

5 mm hex wrench

1 unit

1 unit

6 mm hex wrench

1 unit

1 unit

10 mm hex wrench

–

1 unit

8 mm flat wrench

1 unit

1 unit

Operator’s Manual

1 unit

1 unit

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

7

2. SAFETY PRECAUTIONS

1. Before beginning, read this Operator’s Manual and complete proper occupational

safety and health training.

2. The machine must be used only in applications specified in this Operator’s Manual.

3. The machine must be complete and all parts must be genuine and fully operational.

4. Theelectricalsupplyspecificationsmustconformtothosespecifiedontheratingplate.

5. The machine must be plugged into a properly grounded (earthed) socket-outlet. The

electrical supply must be protected with a 16 A fuse for 230 V or a 32 A fuse for

115 V. When used on building sites, supply the machine through an isolation

transformer made in II protection class.

6. Never carry the machine by the cord or pull it to disconnect the plug from the

power outlet as this may damage the power cord and result in electric shock.

7. Transport and position the machine using the carrying handle, with the magnet

switch set to position ‘O’.

8. Untrained bystanders must not be present in the vicinity of the machine.

9. Before beginning, check the condition of the machine and electrical supply, including

the power cord, plug, control panel components, and milling tools.

10. Keep the machine dry. Exposure to rain, snow, or frost is prohibited.

11. Never stay below the machine placed at heights.

12. Keep the work area well lit, clean, and free of obstacles.

13. Mount the annular cutter securely using the set screws. Remove adjusting keys

and wrenches from the work area before connecting the plug to the power outlet.

14. Never use dull or damaged tools.

15. Mount and dismount tools using protective gloves and with the power cord

unplugged from the power outlet.

16. Never use annular cutters without the pilot pin except for establishing incomplete

through holes. Never use arbors without the spring.

17. Never use the machine in the vicinity of flammable liquids or gases, or in explosive

environments.

18. Using the machine on surfaces that are rusty, covered with a thick paint layer,

uneven, or not stiff is prohibited.

19. Do not start operation in the case of excessive slider clearance.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

8

20. Use the safety chain in all operating positions. The chain must not be loose and

should be fastened to a securely fixed element by catching the chain either on

the lugs or on the carrying handle. Wrap the chain around the workpiece if possible.

21. Before every use, inspect the machine to ensure it is not damaged. Check

whether any part is cracked or improperly fitted. Make sure to maintain proper

conditions that may affect the operation of the machine.

22. Always use eye and hearing protection and protective clothing during operation.

Do not wear loose clothing.

23. Operating on surfaces with thickness lower than 10 mm (0.4’’) is not recommended

as the holding force is significantly reduced.

24. The entire surface of the electromagnetic base bottom must be in full contact with

the workpiece. Before every positioning, wipe the workpiece with coarse-grained

sandpaper.

25. Do not touch moving parts or chips formed during milling. Prevent objects from

being caught in moving parts.

26. After every use, remove metal chips and coolant remainder from the machine.

Do not remove chips with bare hands.

27. Maintain the machine and tools with care. Cover steel parts with a thin grease

layer to protect them against rust when not in use for any extended period.

28. Perform maintenance only with the machine unplugged from the power outlet.

29. Perform repairs only in a service center appointed by the seller.

30. If the machine falls on a hard surface, from height, is wet, or has any other

damage that could affect the technical state of the machine, stop the operation

and immediately send the machine to the service center for inspection and repair.

31. Remove from the worksite and store in a secure and dry location when not in

use, previously removing the tool from the holder.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

9

3. STARTUP AND OPERATION

3.1. Mounting the arbor (or twist drill)

The machine allows mounting either the supplied 19 mm (0.75’’) Weldon shank arbor

for fixing an annular cutter or a twist drill into the MT3 spindle shank. Before

proceeding, unplug the power cord from power the outlet. Raise the chip guard and

rotate the spoke handles to raise the slider. Clean the arbor (twist drill) and the inside

of the spindle using a cotton cloth. Wear gloves and insert the arbor (drill) into the

spindle with the fin directed upward and rotate the arbor (drill) to match the fin with

the slot. Then, hit the arbor (drill) from the bottom to mount it into the spindle.

Figure 3. Arbor after mounting

To dismount, rotate the spindle to match the openings in the spindle and gearbox.

Insert the drill drift into the opening above the arbor (drill). Wear gloves and hold the

arbor (drill) with one hand, and hit the drift using a hammer, paying attention not to

damage the arbor (drill). Gently remove the arbor (drill) from the spindle socket and

remove the drill drift.

All safety precautions must be closely observed.

opening

arbor

spindle

gearbox

chip guard

slider

spoke

handle

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

10

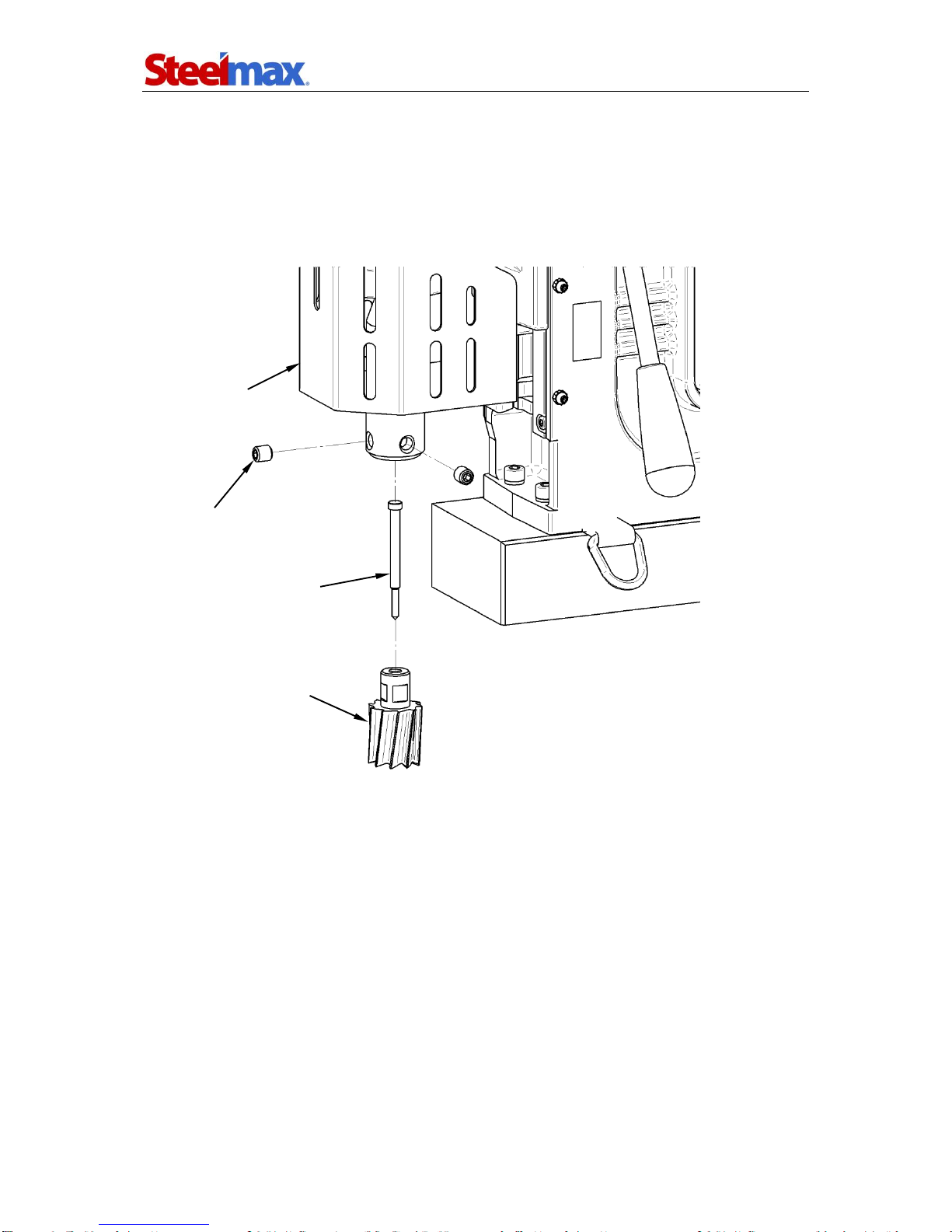

3.2. Mounting and operating the annular cutter

Mount the arbor as described before and insert the proper pilot pin into the annular

cutter (Figure 4). Then, wear gloves and mount the cutter into the arbor, aligning the

flats on the cutter shank with the set screws, and tighten the screws with the supplied

5 mm hex wrench. To dismount the cutter, proceed in reverse order.

Figure 4. Mounting the annular cutter

Figure 5 shows how annular cutters operate. As the cutter penetrates the workpiece,

the pilot pin recesses into the arbor and tightens the spring. As a result, after the cutter

goes through the entire thickness, the slug core is expelled from the cutter.

pilot pin

annular cutter

set screw

chip guard

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

11

Figure 5. Annular cutters operation

Annular cutters are designed to establish only through holes shown in Figure 6.

During establishing incomplete through holes the pilot pin must not be used.

Figure 6. Types of holes to establish with annular cutters

3.3. Mounting the screw tap

Unplug the drilling machine from the power outlet and wear gloves. Use the supplied

drill drift to knock out the arbor (drill) from the drilling machine spindle. Mount a holder

for tapping with 1- or 2-axis compensation (not included in standard equipment).

Mount the tap no. 1 into a proper adapter and then mount the adapter into the

compensation holder. Taps with a conical shank can be mounted directly in the

spindle or indirectly using a reducer sleeve with MT3 shank.

slug core

spring

pilot pin

annular cutter

arbor

incomplete through holes

complete through holes

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

12

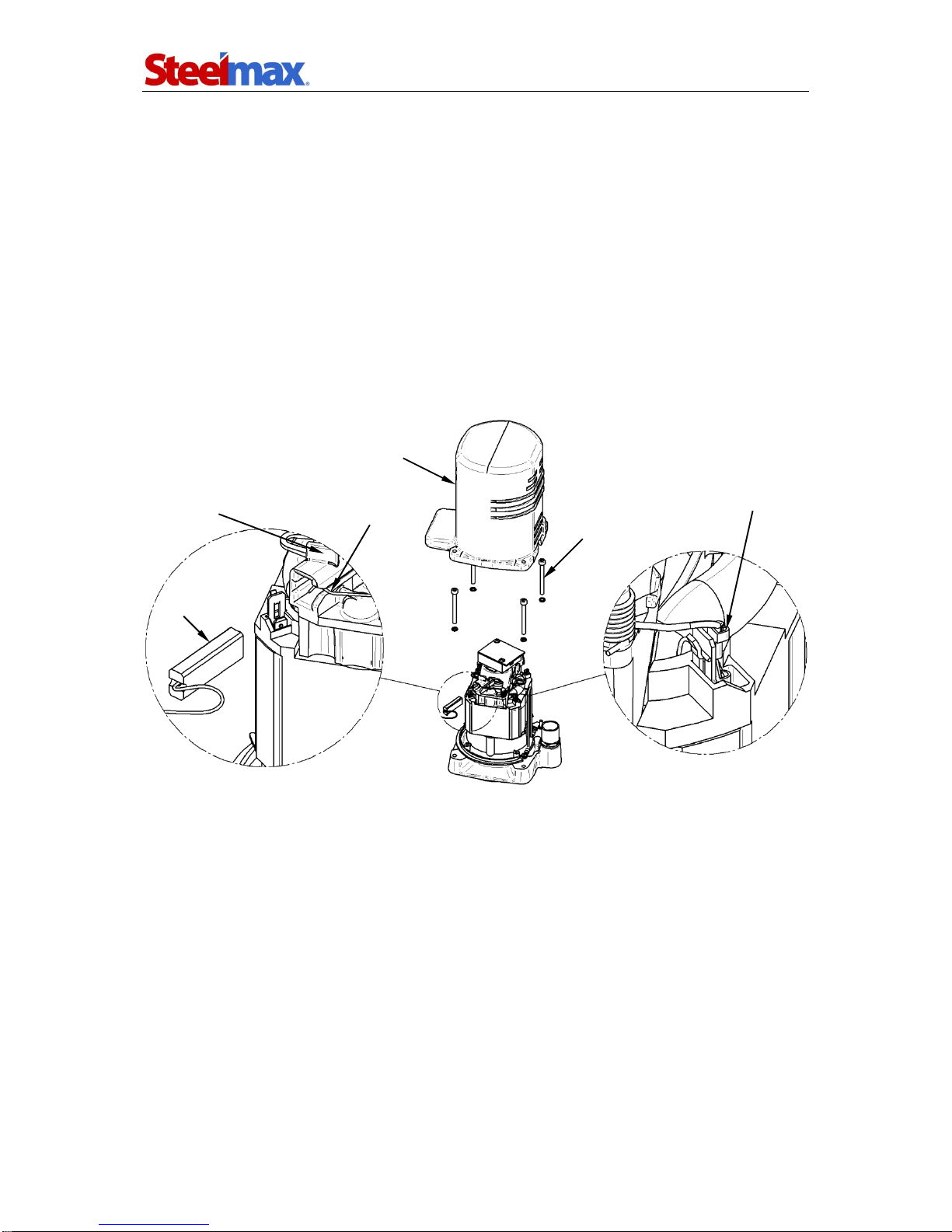

3.4. Mounting the cooling system

Hang the cooling system on the screws located on the machine side and attach the

tip of the cooling hose to the coupling, as shown in Figure 7.

Figure 7. Mounting the cooling system

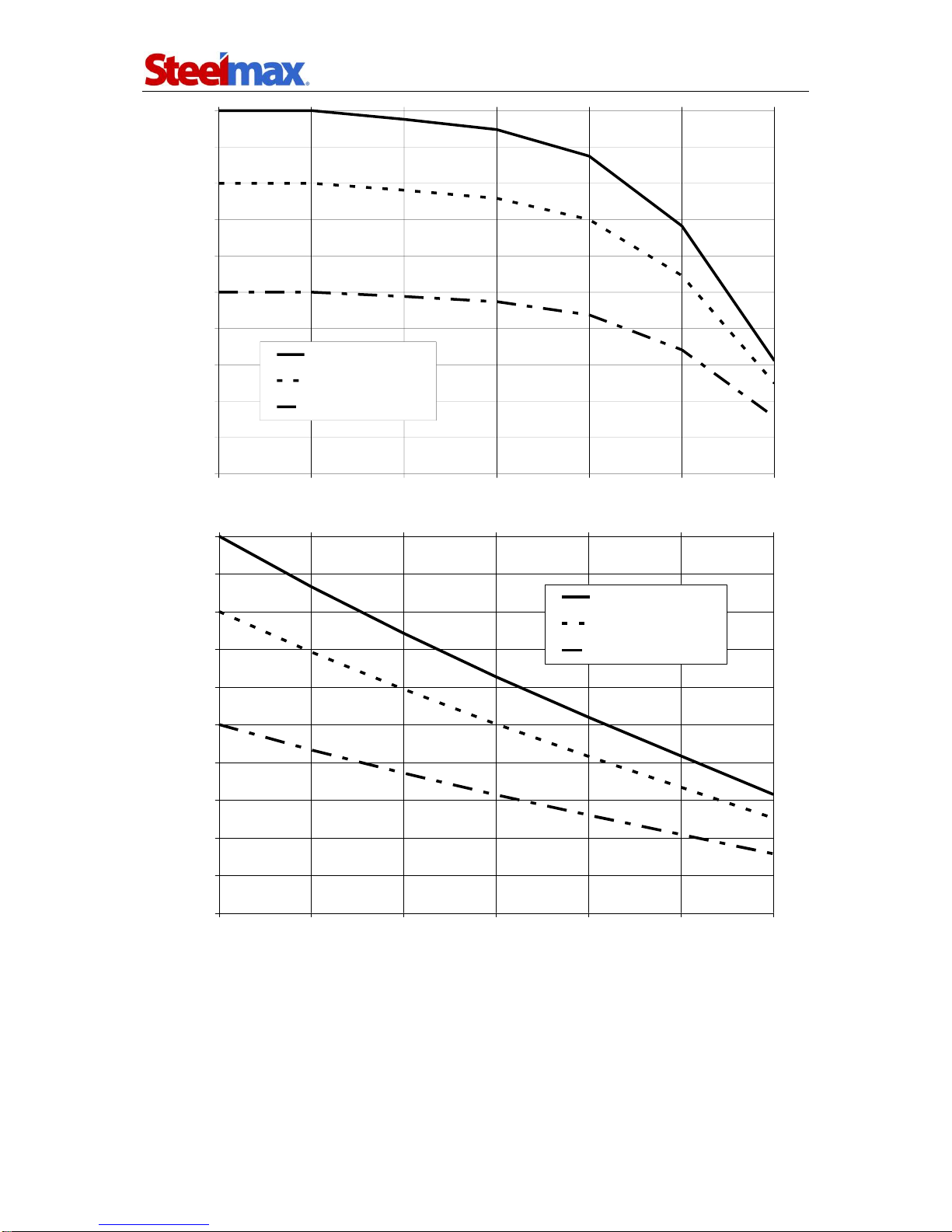

3.5. Control system of the electromagnetic base holding force

The D3X(S) drilling machine incorporates a holding force control system to monitor

the adhesion force of the electromagnetic base to the surface. The force value

depends on several factors, such as type, thickness, flatness, and roughness of the

surface, presence of paint, rust or other contaminants, supply voltage fluctuations,

and the wear of the electromagnetic base bottom.

If the holding force falls below a safe operating value (Figure 8), the control system

will not allow the machine to operate. Additionally, the system will prevent the startup

of the motor if the machine is placed on a surface thinner than 5 mm (0.2’’) as such

thickness does not provide sufficient holding force. In such a case, the adhesion force

will be only about 25 % of the force attained on a standard 22 mm (0.87’’) flat plate.

If the motor does not continue operation after the green MOTOR button is

pushed and released, it means that the control circuit is operating properly and

preventing further drilling because of too low adhesion force.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

13

0

10

20

30

40

50

60

70

80

90

100

25.4 22 19 15.8 12.7 9.5 6.3

Plate thickness [mm]

Holding force [%]

structural steel

heat-treatable steel

tool steel

0

10

20

30

40

50

60

70

80

90

100

00.1 0.2 0.3 0.4 0.5 0.6

Air gap [mm]

Holding force [%]

structural steel

heat-treatable steel

tool steel

Figure 8. Holding force for a sample base in the function of surface thickness and air gap

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

14

3.6. Preparing

Before beginning, clean steel parts, especially the MT3 socket, from grease used to

preserve the machine for storage and transport. The feed shaft can be mounted at

the opposite side of the drilling machine to allow working in places hard to reach or

using the machine by a left-handed person.

Mount a drill, the arbor with an annular cutter, or a holder with a screw tap into

the spindle in the manner described before.

Position the machine on a flat ferromagnetic surface (some types of stainless or

acid-proof steel do not conduct magnetic flux) with the thickness of least 10 mm (0.4’’).

The workpiece must be clean, without rust or paint that decrease the holding force of

the electromagnetic base.

Then, connect the drilling machine to the power outlet and enable the holding

force of the electromagnetic base by toggling the MAGNET switch to position ‘I’.

Mount the chip guard to protect yourself from swarf, and protect the machine with

the supplied safety chain by catching the chain on the carrying handle or on the lugs.

Rotate the spoke handles to place the tip of the drill, pilot pin, or tap above the drilling

(tapping) point.

When working with an annular cutter, install the cooling system. Then, fill the

cooling system bottle with a cutting fluid, slightly loosen the cap, open the valve using

the lever, and initially apply pressure on the pilot pin by rotating the spoke handles

counterclockwise. The fluid should fill the system and should begin flowing from the

inside of the cutter. Do not use pure water as the cutting fluid, however, using

emulsions formed from mixing water and drilling oil is also satisfactory.

The cooling system works by means of gravitation, therefore use

a cooling paste when working in horizontal or inverted positions.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

15

3.7. Drilling

With the tool mounted, use the gear lever to set the speed range corresponding to

the diameter of the hole to be drilled. Use the following relation among the speed,

diameter, and the type of the tool.

Tool

Hole diameter

Rotational speed

[rpm]

[mm]

[in]

Annular cutter

12–34

0.47–1.34

210–420 (gear II)

35–75

1.38–2.95

80–160 (gear I)

Twist drill

8–17

0.31–0.67

210–420 (gear II)

18–32

0.71–1.26

80–160 (gear I)

Set the rotation direction switch to position ‘R’, and start the motor using the green

MOTOR button. Slowly rotate the spoke handles to lower the cutter (or drill) to the

workpiece and gently begin drilling. Then, use the speed adjusting knob to set aspeed

suitable for given process conditions.

When drilling using annular cutters, accomplish holes in one pass. However,

drilling holes with diameters of 18–32 mm (0.71–1.26’’) using twist drills must be

performed in two passes. In such the case, drill a hole with the diameter of about 70 %

of the final diameter, and then perform the drilling again to finalize the hole to the

anticipated diameter.

When drilling holes deeper than 50 mm (2’’), retract the tool above the workpiece

as often as possible to allow the chips to be expelled from the hole. Additionally,

once the tool is retracted, clean the grooves of the tool using a small brush if they are

clogged. After exceeding 40 mm (1.6’’) of the drilling depth, introduce the cutting fluid

into the milling area manually (from the bottle).

If the operation results in an overload, caused by not sufficient cooling, using dull

tool, or too fast feed in comparison to the tool diameter, the machine will automatically

stop. In such a case, to restart the machine, press the red MOTOR button, retract the

tool from the workpiece, and then press the green MOTOR button (the electromagnetic

base must remain powered).

Once the hole is accomplished, retract the tool from the workpiece, stop the

motor using the red MOTOR button, and disable the electromagnetic base by toggling

the MAGNET switch to position ‘O’.

When the annular cutter goes through the material, the slug core

is expelled from the cutter with a significant force.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

16

To improve lubrication, after the work is finished and the motor is stopped toggle

the gear to the opposite position (for example: from gear II to I) and run the drilling

machine for awhile without load. Then, stop the motor and disable the electromagnetic

base, unplug the power cord from the power outlet, and clean metal chips and coolant

remainder from the machine. Tighten the bottle cap of the cooling system, close the

valve, and press the pilot pin to expel the coolant remaining within the system. Before

putting the drilling machine into the tool box, disassemble the cooling system and

remove the tool from the holder using gloves.

3.8. Tapping

Position the machine in such a way to place the tap no. 1 above the hole with proper

diameter. With the hole diameter being too low, tapping may be impossible because

of excessive milling resistance and insufficient motor power.

Select the first gear using the gear lever and set the rotation direction switch to

position ‘R’. Spread grease on the working part of the tap to prevent seizure and

extend durability. Then, start the motor with the green MOTOR button and slowly

rotate the spoke handles to lower the tap to the workpiece and begin tapping. Once

tapping with the tap no. 1 is finished, stop the motor using the red MOTOR button

and set the rotation direction switch to position ‘L’. Then, press and hold the green

MOTOR button to retract the tap from the hole, and release the button once the tap is

retracted.

At this stage, replace the tap no. 1 with the tap no. 3 and perform the tapping

again, proceeding as described before. To improve lubrication, after the work is

finished and the motor is stopped, switch to gear II and run the drilling machine for

a while without load. Then, stop the motor and disable the electromagnetic base, and

unplug the power cord from the power outlet.

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

17

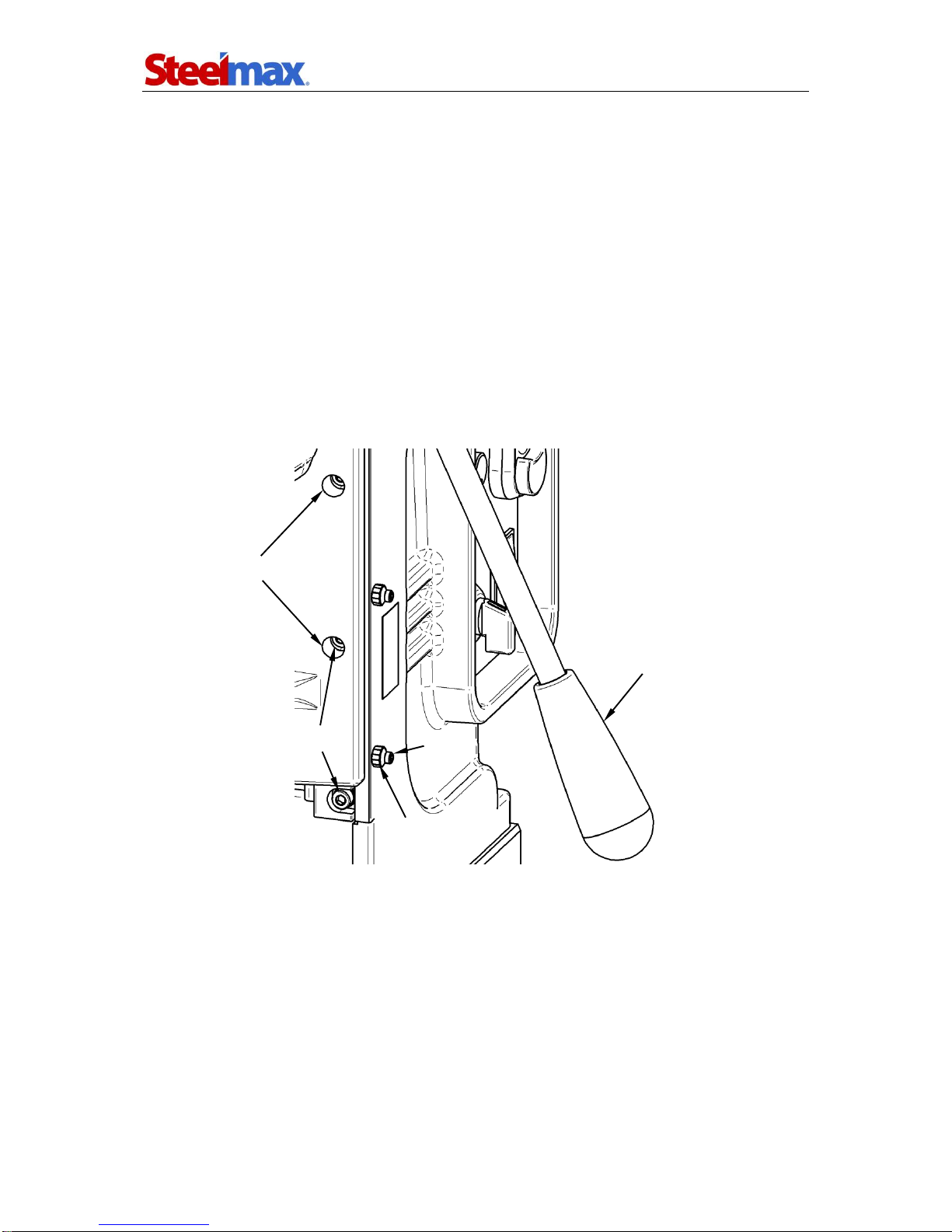

3.9. Adjusting the slider clearance

Check the slider clearance every 50 operational hours or more often as the clearance

significantly influences the quality of drilled holes. The clearance is suitable if the

slider moves smoothly and does not drop under its own weight.

To adjust the clearance, loosen the mounting screws using the supplied 4 mm

hex wrench. Access the screws through the slider holes (Figure 9) by positioning the

slider at the appropriate level using the spoke handles. With all the screws loosened,

move the slider up and down several times and tighten the central screw, then the

adjacent screws, and eventually the utmost screws. Next, tighten the set screws until

noticeable resistance, lock them using the supplied 2.5 mm hex wrench and tighten

the nuts with the 8 mm flat wrench.

Figure 9. Adjusting the slider clearance

slider openings

mounting screws

spoke handle

set

screw

nut

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

18

3.10. Replacing the motor brushes

Check the condition of the carbon brushes every 100 operational hours. If the length

of the brushes is less than 5mm (0.2’’), replace them with new ones. To do this, unplug

the power cord from the power outlet, unscrew four screws mounting the motor cover

and gently remove the cover (Figure 10). Proceed with caution paying attention to the

grounding wire connected to the cover. Then, press the center of the brush wire

connector to unlock it and remove the connector. Unbend the spring, put it on the top

of the brush holder, and gently remove the brush. Proceed as described also for the

second brush located at the opposite side of the motor. To mount brushes, proceed

in reverse order. After the replacement, run the motor without load for 20 minutes.

Figure 10. Replacing the brushes

screws

motor cover

brush wire connector

pressing spring

brush

brush holder

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

19

4. WIRING DIAGRAM

D3X R/L / D3XS R/L

D3X R/L / D3XS R/L Operator’s Manual

20

5. D3X R-L PARTS LIST AND EXPLODED DRAWINGS

13

9

3

11 12

1

8

20

15

10

19

14

16

2

6

17

4

5

18

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

KLN-0103-00-00-00-0

WEDGE MT3

1

2

UCW-0173-00-00-00-0

ARBOR ASSY AMT3-U19/3-3

1

3

LNC-0223-00-01-00-0

SAFETY CHAIN

1

4

UKL-0399-11-00-00-0

COOLING SYSTEM

1

5

DZW-0400-07-00-00-0

SPOKE HANDLE WITH KNOB

3

6

SKR-0400-12-00-00-1

METAL CASE

1

8

KLC-000003

8 MM FLAT WRENCH

1

9

KLC-000037

5 MM HEX WRENCH WITH HANDLE

1

10

OPK-000001

PLASTIC BOX

1

11

KLC-000005

2.5 MM HEX WRENCH

1

12

KLC-000007

4 MM HEX WRENCH

1

13

KLC-000009

6 MM HEX WRENCH

1

14

PDK-0139-00-04-00-0

WASHER D=18.8x10x1

1

15

USZ-0140-05-04-00-0

SEAL

1

16

WYP-0154-00-02-00-0

PLUNGER

1

17

SPR-0154-00-03-00-0

SPRING 1.6x12.4x159

1

18

KRP-0173-00-01-00-0

ARBOR BODY

1

19

PRS-000009

INTERNAL RETAINING RING 19w

1

20

WKR-000032

HEX SOCKET SET SCREW WITH FLAT POINT M10x10

2

This manual suits for next models

3

Table of contents

Other SteelMax Drill manuals

SteelMax

SteelMax D4X User manual

SteelMax

SteelMax D1PRO User manual

SteelMax

SteelMax D1 AUTO User manual

SteelMax

SteelMax D3X RS User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax D200XT User manual

SteelMax

SteelMax D1 AUTO User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax SM-D2 User manual

SteelMax

SteelMax D4X User manual

Popular Drill manuals by other brands

Central Pneumatic

Central Pneumatic 46524 Assembly and operating instructions

Worx Nitro

Worx Nitro WX130L.X manual

Toolshop

Toolshop 241-9826 Operator's manual

BLACK DECKER

BLACK DECKER BDCHD12 manual

MasterForce

MasterForce 241-0401 Operator's manual

BlackBull

BlackBull DP5UL Assembly & operating instructions