SteelMax D1 AUTO User manual

Other manuals for D1 AUTO

2

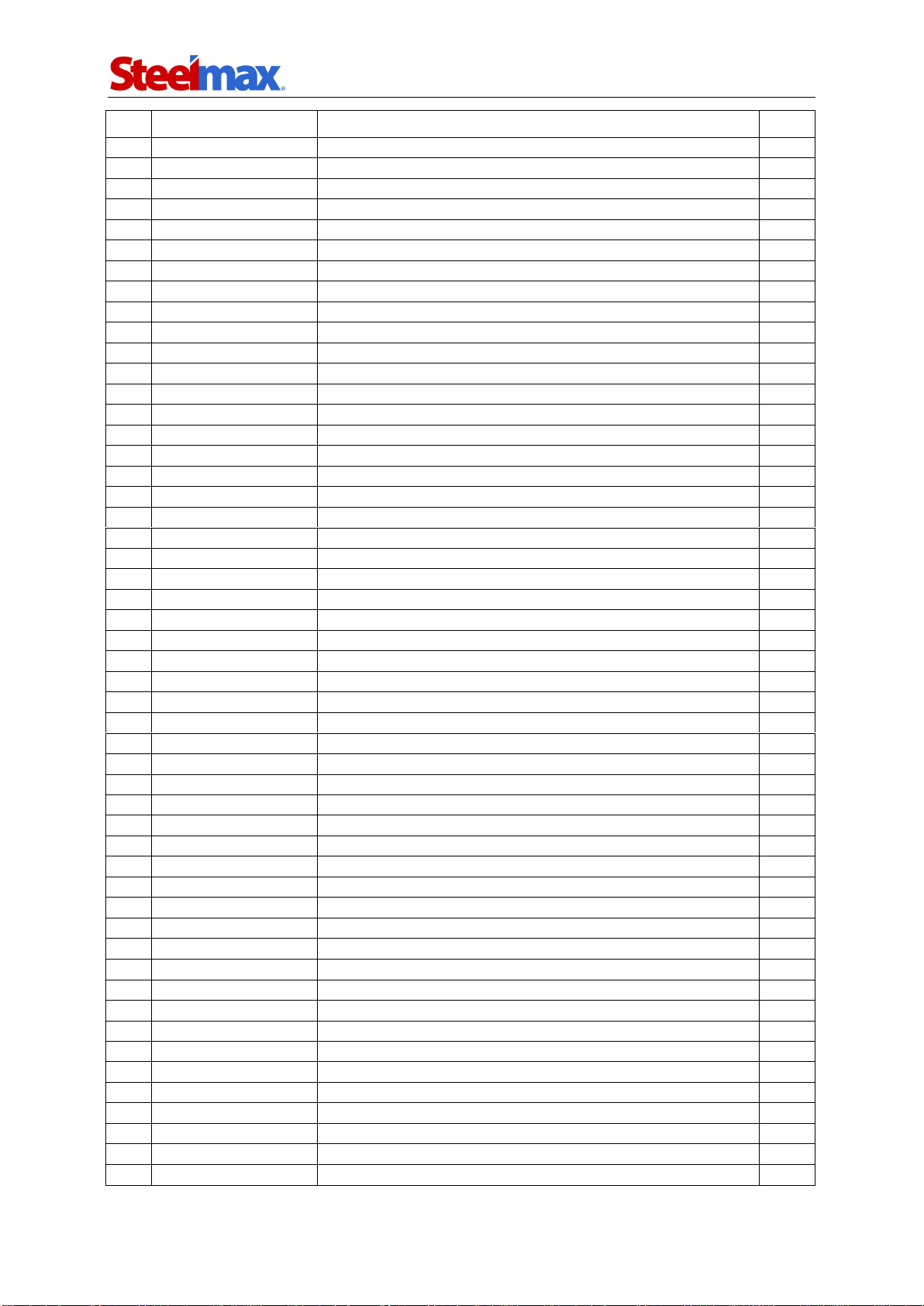

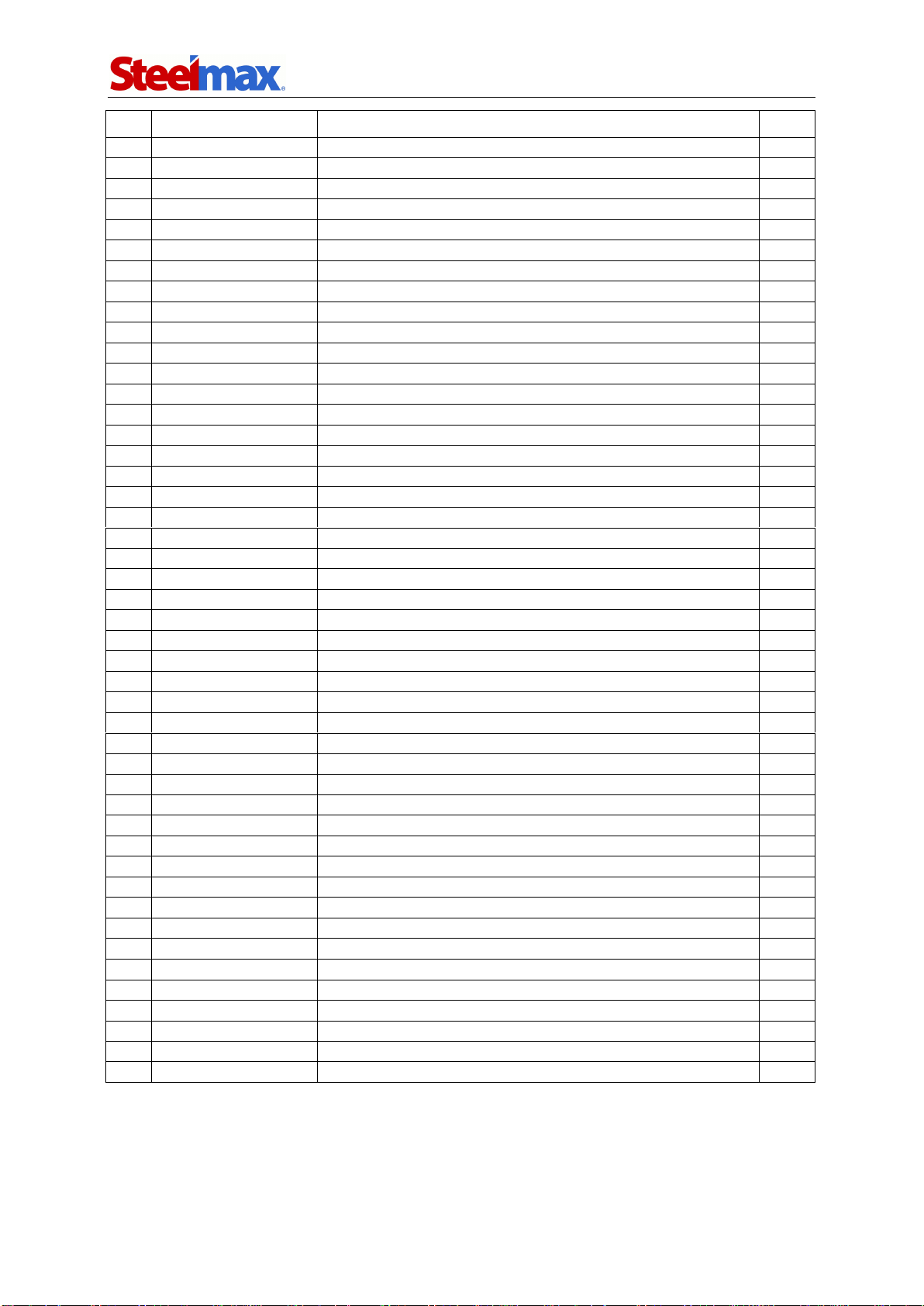

Table of contents

Other SteelMax Drill manuals

SteelMax

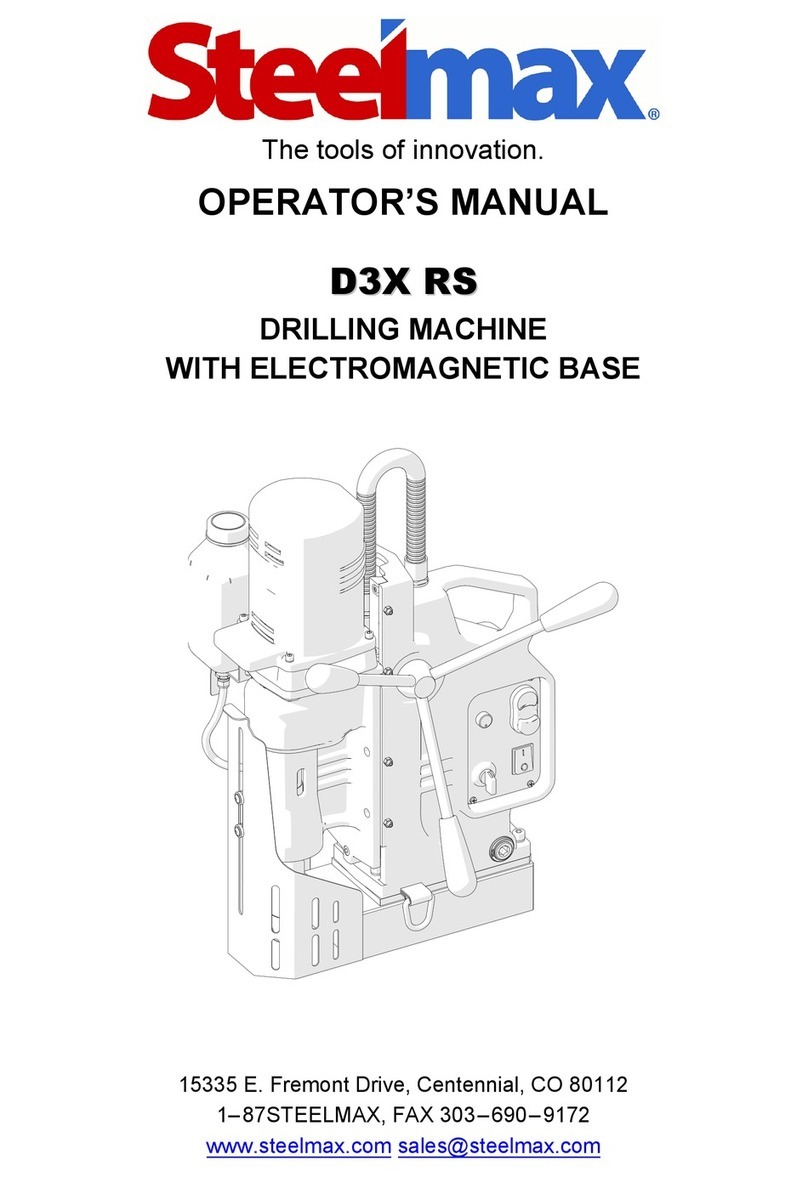

SteelMax D3X RS User manual

SteelMax

SteelMax D250X User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax D4X User manual

SteelMax

SteelMax D300XT User manual

SteelMax

SteelMax D2X User manual

SteelMax

SteelMax D1PRO User manual

SteelMax

SteelMax D1 Pro-X User manual

SteelMax

SteelMax D3X R User manual

Popular Drill manuals by other brands

Hitachi

Hitachi DV 18DSL Handling instructions

Black & Decker

Black & Decker CD182 Instruction manual and parts listing and parts listing

Ryobi

Ryobi DP121L Manual del operador

EIBENSTOCK

EIBENSTOCK BST 152/53 Original instructions

Craftsman

Craftsman CMCD720 instruction manual

Makita

Makita 6010DW instruction manual

Milwaukee

Milwaukee BS18C2 Original instructions

Makita

Makita M8100 instruction manual

Parkside Performance

Parkside Performance PABSP 20-LI A1 Operation and safety notes translation of the original instructions

Felisatti

Felisatti DHF 13/810ER2 operating instructions

Flex

Flex CHE 18.0-EC operating instructions

Zenit Powertools

Zenit Powertools ED-550 PROFI instruction manual