- 8 - - 9 -

- 8 -

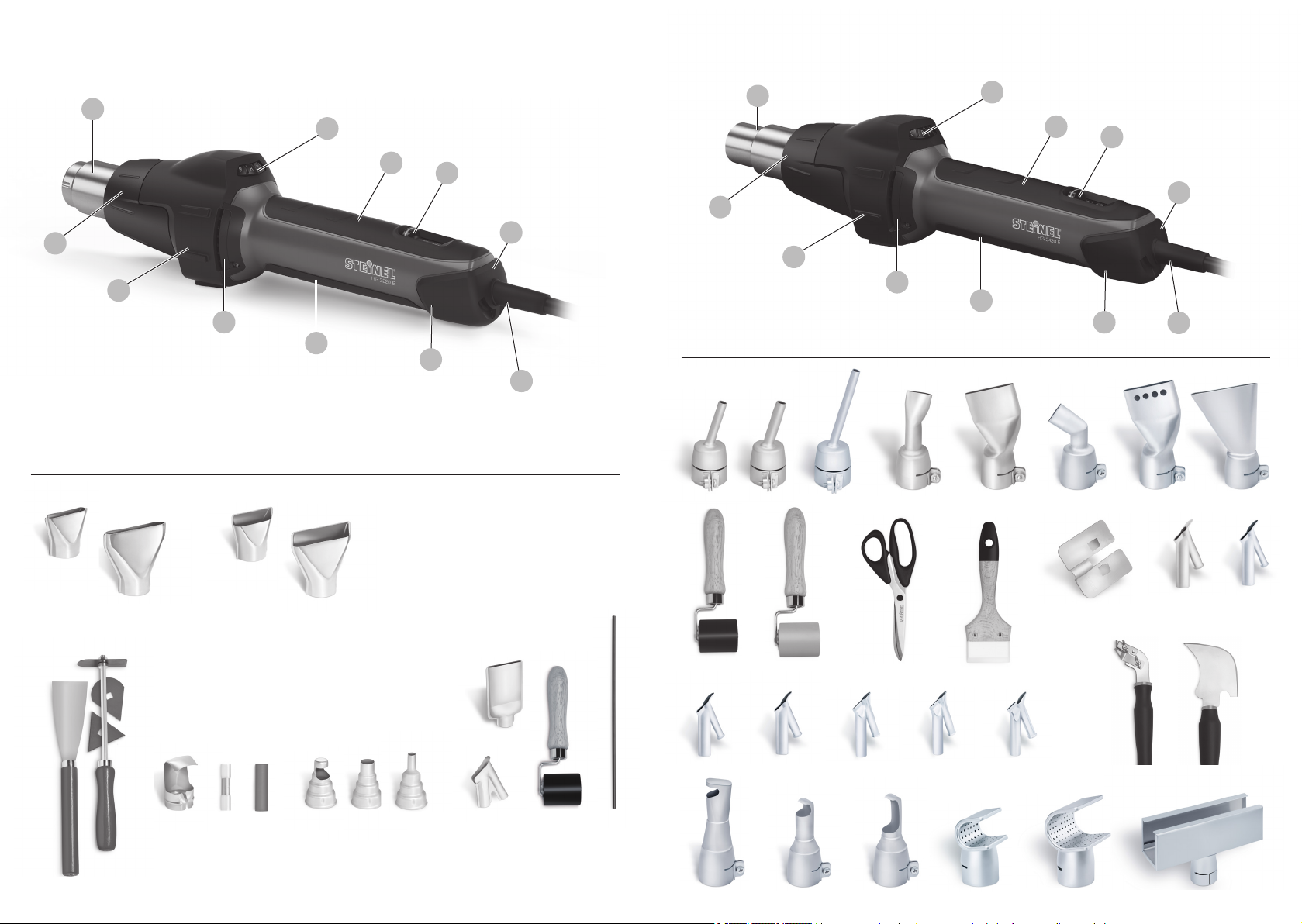

Zubehör (siehe Abb. auf dem Umschlag)

HG 2220 E

1 Breitstrahldüse 50 mm Art.-Nr. 070113

2 Breitstrahldüse 75 mm Art.-Nr. 070212

3 Abstrahldüse 50 mm Art.-Nr. 070311

4 Abstrahldüse 75 mm Art.-Nr. 070410

5 Farbschaberset Art.-Nr. 010317

6 Reektordüse Art.-Nr. 070519

7 Crimpverbinder

Ø 0,5-1,5 Art.-Nr. 006655

Ø 1,5-2,5 Art.-Nr. 006648

Ø 0,1-0,5 – Ø 4,0-6,0 Art.-Nr. 006662

8 Schrumpfschläuche

4,8-9,5 mm Art.-Nr. 071417

1,6-4,8 mm Art.-Nr. 071318

4,0-12,0 mm Art.-Nr. 072766

Schrumpfschlauchset, 3-teilig Art.-Nr. 075811

9 Lötreektordüse Art.-Nr. 074616

10 Reduzierdüse 14 mm Art.-Nr. 070717

11 Reduzierdüse 9 mm Art.-Nr. 070618

12 Breitschlitzdüse Art.-Nr. 074715

13 Andrückrolle Art.-Nr. 093211

14 Kunststoff-Schweißdraht

Hart-PVC: Art.-Nr. 073114

HDPE: Art.-Nr. 071219

PP: Art.-Nr. 073411

ABS: Art.-Nr. 074210

15 Schweißschuh Art.-Nr. 070915

Herstellergarantie

Herstellergarantie für Unternehmer, wobei Unternehmer eine

natürliche oder juristische Person oder eine rechtsfähige

Personengesellschaft ist, die bei Abschluss des Kaufes in

Ausübung ihrer gewerblichen oder selbständigen beruichen

Tätigkeit handelt.

Herstellergarantie der STEINEL Vertrieb GmbH,

Dieselstraße 80-84, 33442 Herzebrock-Clarholz

Alle STEINEL-Produkte erfüllen höchste Qualitätsansprüche.

Aus diesem Grund leisten wir als Hersteller Ihnen als Kunde

gerne eine unentgeltliche Garantie gemäß den nachstehen-

den Bedingungen:

Wir leisten Garantie durch kostenlose Behebung der Mängel

(nach unserer Wahl: Reparatur oder Austausch mangelhafter

Teile ggf. Austausch durch ein Nachfolgemodell oder Erstel-

lung einer Gutschrift), die nachweislich innerhalb der Garan-

tiezeit auf einem Material- oder Herstellungsfehler beruhen.

Die Garantiezeit für

• Heißklebepistole und Heißluftgeräte beträgt: 1 Jahr

Ausdrücklich ausgenommen von dieser Garantie sind alle

auswechselbaren Leuchtmittel. Darüber hinaus ist die

Garantie ausgeschlossen:

• bei einem gebrauchsbedingten oder sonstigen natür-

lichen Verschleiß von Produktteilen oder Mängeln am

STEINEL-Produkt, die auf gebrauchsbedingtem oder sons-

tigem natürlichem Verschleiß zurückzuführen sind,

• bei nicht bestimmungs- oder unsachgemäßem Gebrauch

des Produkts oder Missachtung der Bedienungshinweise,

• wenn An- und Umbauten bzw. sonstige Modikationen an

dem Produkt eigenmächtig vorgenommen

wurden oder Mängel auf die Verwendung von Zubehör-,

Ergänzungs- oder Ersatzteilen zurückzuführen sind, die

keine STEINEL-Originalteile sind,

• wenn Wartung und Pege der Produkte nicht entspre-

chend der Bedienungsanleitung erfolgt sind,

• wenn Anbau und Installation nicht gemäß den Installations-

vorschriften von STEINEL ausgeführt wurden,

• bei Transportschäden oder -verlusten.

Diese Herstellergarantie lässt Ihre gesetzlichen Rechte un-

berührt. Die hier beschriebenen Leistungen gelten zusätzlich

zu den gesetzlichen Rechten und beschränken oder erset-

zen diese nicht.

Die Garantie gilt für sämtliche STEINEL-Produkte, die in

Deutschland gekauft und verwendet werden. Es gilt deut-

sches Recht unter Ausschluss des Übereinkommens der

Vereinten Nationen über Verträge über den internationalen

Warenkauf (CISG).

Geltendmachung

Wenn Sie Ihr Produkt reklamieren wollen, senden Sie es

bitte vollständig und frachtfrei mit dem Original-Kaufbeleg,

der die Angabe des Kaufdatums und der Produktbezeich-

nung enthalten muss, an Ihren Händler oder direkt an uns,

die STEINEL Vertrieb GmbH – Reklamationsabteilung –,

Dieselstraße 80-84, 33442 Herzebrock-Clarholz.

Wir empfehlen Ihnen daher, Ihren Kauf-

beleg bis zum Ablauf der Garantiezeit

sorgfältig aufzubewahren. Für Transport-

kosten und -risiken im Rahmen der Rück-

sendung übernehmen wir keine Haftung.

HERSTELLER

JAHR

GARANTIE

5

HERSTELLER

GARANTIE

HERSTELLER

GARANTIE

Ihr Händler hält ein breites Sortiment an Zubehör für

Sie bereit.

HG 2420 E

1 Runddüse 5 mm Art.-Nr. 092214

2 Runddüse 10 mm Art.-Nr. 092313

3 Ründdüse 5 mm, verlängert Art.-Nr. 009076

4 Winkelachdüse 20 x 2 mm Art.-Nr. 092115

Winkelachdüse 20 x 2 mm, gerade Art. Nr. 013240

5 Winkelachdüse 40 x 2 mm Art.-Nr. 092016

6 Winkelachdüse 30 x 2 mm Art.-Nr. 011925

7 Winkelachdüse 40 x 2 mm, gelocht Art.-Nr. 009083

8 Flachdüse 60 x 2 mm für Bitumen Art.-Nr. 009090

9 Andrückrolle 50 mm Art.-Nr. 093211

10 Andrückrolle 35 mm Art.-Nr. 006785

11 Planenschere Art.-Nr. 010423

12 Kehlx Art.-Nr. 011833

13 Schweißnahtschlitten Art.-Nr. 093013

14 Schweißschuh Art.-Nr. 075316

15 Schnellschweißschuh 3 mm Art.-Nr. 010263

16 Schnellschweißschuh 4 mm Art.-Nr. 010270

17 Schnellschweißschuh 5 mm Art.-Nr. 010287

18 Schnellschweißschuh 3 mm,

mit schmalem Luftschlitz Art.-Nr. 009106

19 Schnellschweißschuh 4 mm,

mit schmalem Luftschlitz Art.-Nr. 011765

20 Schnellschweißschuh 5 mm,

mit schmalem Luftschlitz Art.-Nr. 011840

21 Fugenhobel Art.-Nr. 093112

22 Viertelmondmesser Art.-Nr. 092917

23 Lötreektordüse Art.-Nr. 011871

24 Reektordüse 20 mm Art.-Nr. 011857

25 Reektordüse 35 mm Art.-Nr. 011864

26 Siebreektordüse 35 x 20 mm Art.-Nr. 010416

27 Siebreektordüse 50 x 35 mm Art.-Nr. 010409

28 Schalenreektordüse Art.-Nr. 011888

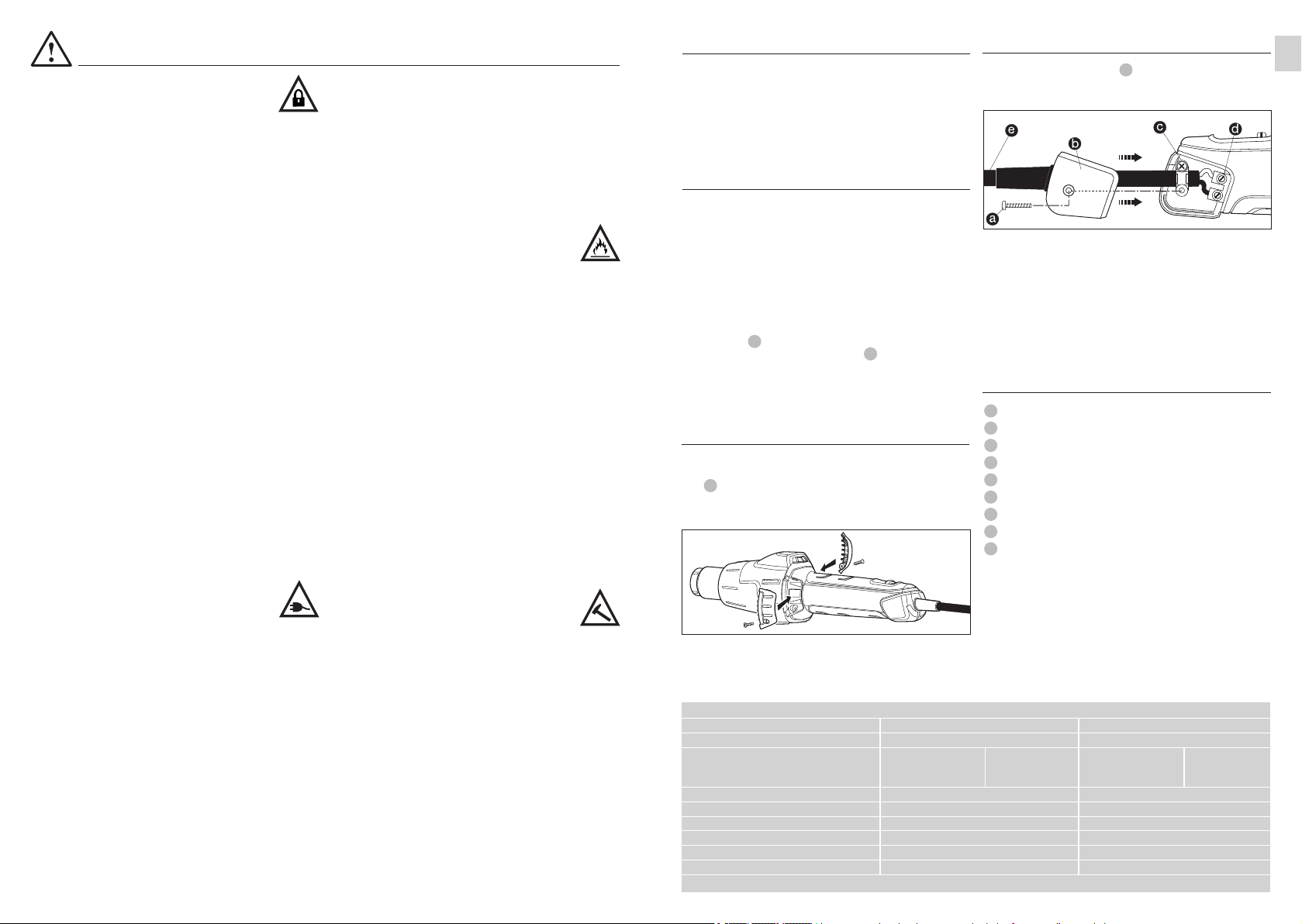

Please familiarise yourself with these operating instructions

before using this product because prolonged reliable and

trouble-free operation will only be ensured if it is handled

properly.

We hope your new hot air tool will give you lasting

satisfaction.

GB Translation of the original

operating instructions About this document

Read and observe this information

before using the tool. Failure to

observe the operating instructions

may result in the tool

becoming a source of danger.

When using electric power tools,

observe the following basic safety

precautions to avoid electric shock

as well as the risk of injury and re.

Used carelessly, the tool can start an

unintentional re or injure persons.

Check the tool for any damage

(mains connection lead, housing etc.)

before putting it into operation and

do not use the tool if it is damaged.

Do not leave the tool switched on

unattended.

Children should be supervised to

make sure they do not play with

the tool.

First time of use

A small quantity of smoke may de-

velop when the tool is used for the

rst time. This smoke is caused by

binding agents released from the

heater's insulating lm during the rst

time of use.

To let the smoke escape quickly,

the tool should be set down on its

standing surface. The area you are

working in should be well ventilated

when using the tool for the rst time.

Any smoke coming out of the tool is

not harmful!

Take the ambient conditions

into account.

Do not expose electric power tools

to rain. Do not use electric power

tools when they are damp or in a

damp or wet environment. Exercise

care when using the tool in the

proximity of ammable materials.

Do not direct the tool at one and

the same place for a prolonged

period. Do not use in the presence

of an explosive atmosphere. Heat

emitted may be conducted to am-

mable materials that are hidden from

direct sight.

Protect yourself from

electric shock.

Avoid coming in contact with

grounded objects, such as pipes,

radiators, cookers or refrigerators.

Do not leave the tool unattended

while in operation.

Please read carefully and keep in a safe place.

- Under copyright. Reproduction either in whole or in part

only with our consent.

- Subject to change in the interest of technical progress.

Safety warnings

GB

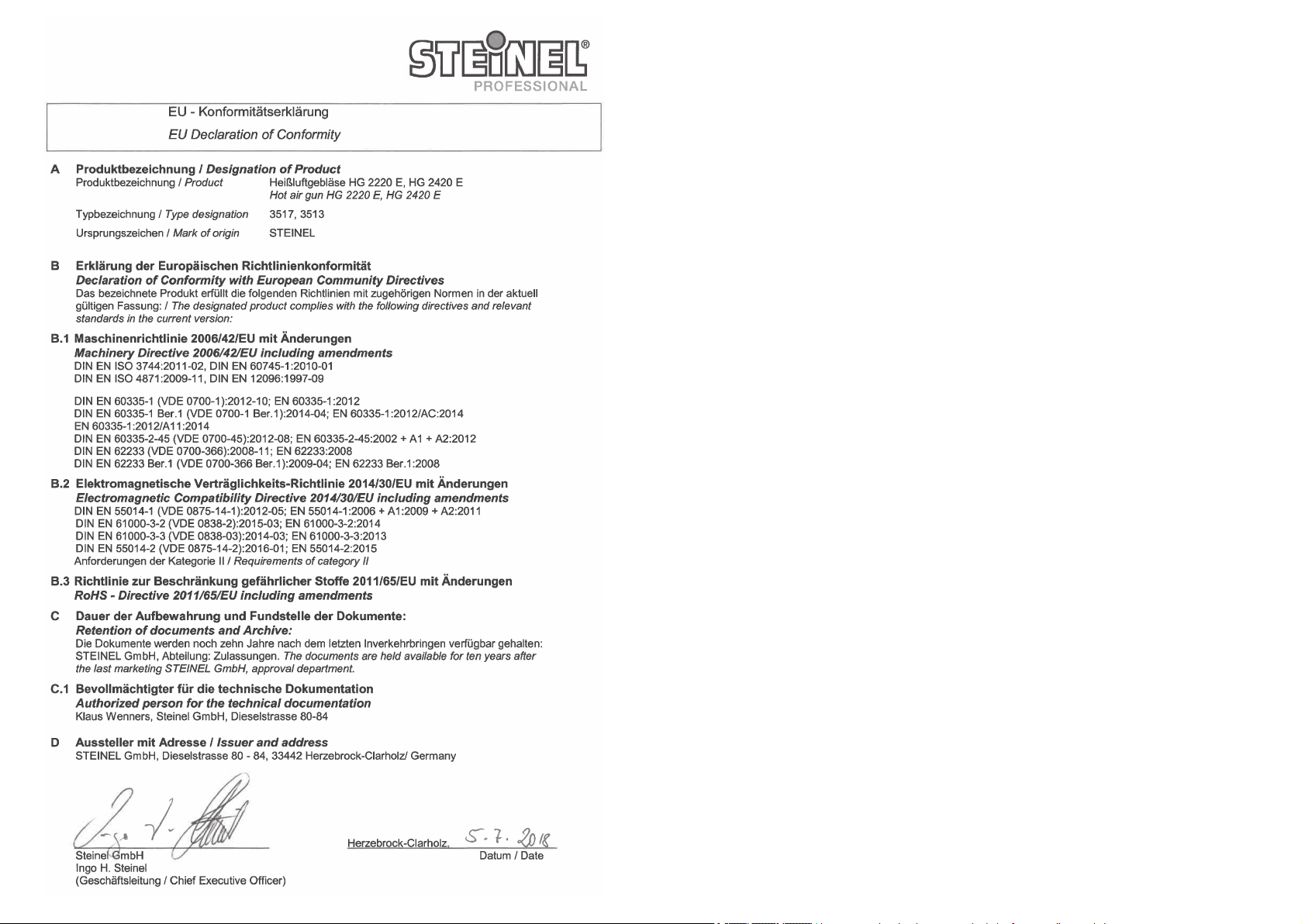

Konformitätserklärung

(siehe Seite 134)