Steiner TR270 TERRA Programming manual

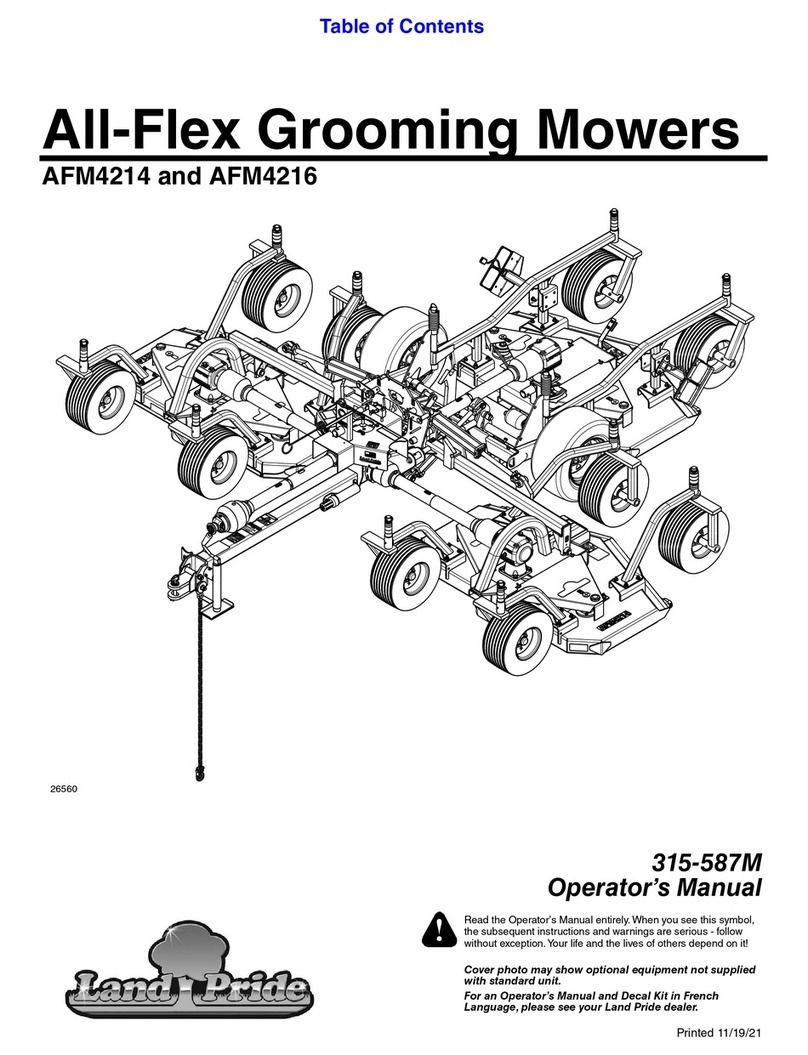

OPERATOR’S & PARTS MANUAL

MAN 4177521

Rev. A 04-2019

75-70681

TR270 TERRA RAKE

(S/N 0000 and higher)

2

TERRA

RAKE

IMPORTANT MESSAGE

Thank you for purchasing this Schiller Grounds Care, Inc. product. You have purchased a world class product,

one of the best designed and built anywhere.

This product comes with an Operator's/Parts Manual. The useful life and good service you receive from this

product depends to a large extent on how well you read and understand this manual. Treat this product

properly and adjust it as instructed, and it will give you many years of reliable service.

See a Schiller Grounds Care, Inc. dealer for any service or parts needed. Schiller Grounds Care, Inc. service

ensures that you continue to receive the best results possible from Schiller Grounds Care, Inc. products. You

can trust Schiller Grounds Care, Inc. replacement parts because they are manufactured with the same high

precision and quality as the original parts.

Schiller Grounds Care, Inc. designs and builds its equipment to serve many years in a safe and productive

manner. For longest life, use this product only as directed in the manual, keep it in good repair and follow

safety warnings and instructions. You'll always be glad you did.

Schiller Grounds Care, Inc.

One Bob Cat Lane

Johnson Creek, WI 53038-0469

CALIFORNIA PROPOSITION 65

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

ADVERTENCIA: Cáncer y Dãno Reproductivo - www.65Warnings.ca.gov.

TABLE OF CONTENTS .................................................FIGURES ......................................................... PAGE

TABLE OF CONTENTS.................................................. ................................................................................ 2

DESCRIPTION / SPECIFICATIONS ................................................................................................................ 3

SAFETY ........................................................................................................................................................4-6

ASSEMBLY / OPERATION............................................................................................................................... 7

OPERATION..................................................................................................................................................... 8

TINE DEPTH / TINE ANGLE ADJUSTMENT ................................................................................................... 9

ROTATION ADJUSTMENT / CASTER ARM PLACEMENT ........................................................................... 10

OPTIONAL 3-POINT HITCH MOUNTING ............................................................................................... 11, 12

MAINTENANCE / STORAGE......................................................................................................................... 13

PARTS SECTION........................................................... .............................................................................. 15

HITCH ASSEMBLY.........................................................FIGURE 1......................................................... 16, 17

MAIN FRAME ASSEMBLY .............................................FIGURE 2......................................................... 18, 19

CASTER WHEEL ASSEMBLY .......................................FIGURE 3......................................................... 20, 21

TINE ASSEMBLY ...........................................................FIGURE 4......................................................... 22, 23

TABLE OF CONTENTS

3

TERRA

RAKE

04-2019

DESCRIPTION / SPECIFICATIONS

DESCRIPTION

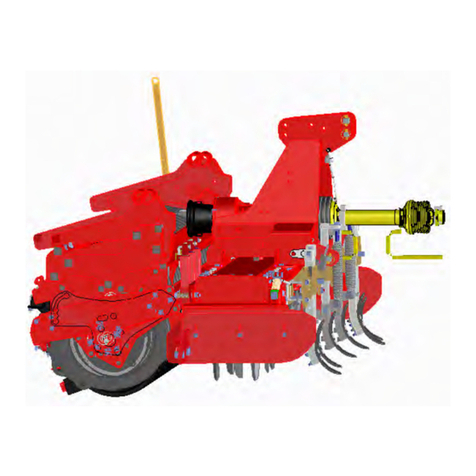

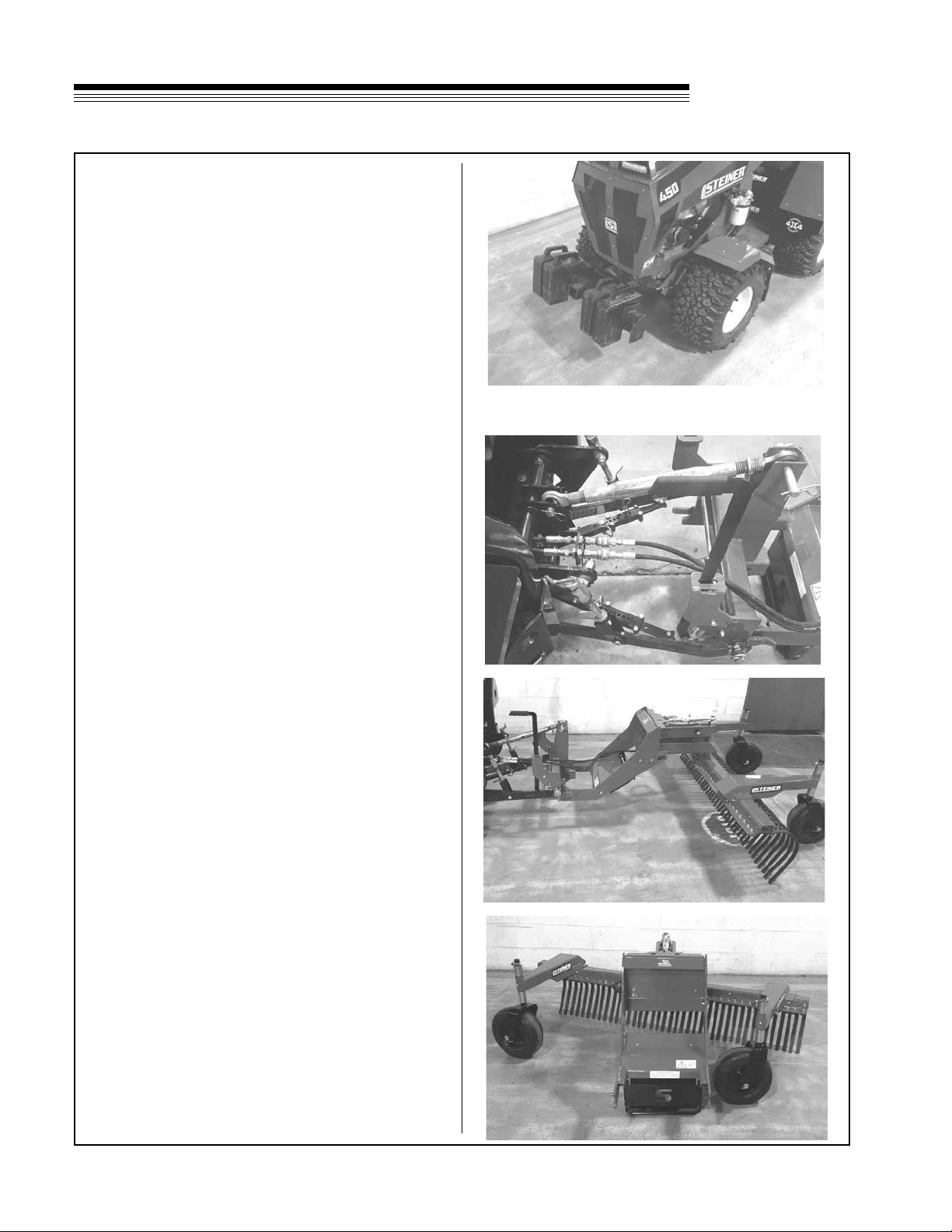

The front mounted Steiner landscape rake, the TR270 Terra Rake, effectively rakes soil, landscape debris,

aggregate and other materials. Applications include seed bed preparation, or landscape work such as leveling

dirt or gravel in driveways and parking areas.

From the operator's seat, the accessory controls on the Steiner tractor are used to hydraulically angle the

70" wide rake left or right to direct raked material. A spring-tensioned leveling system in combination with the

independently height adjustable caster wheels provides material leveling independent of the tractor. The Terra

Rake tine angle and tine depth can be easily adjusted from aggressive, to move large amounts of material,

to light, to nely nish the surface with a reduced potential of unwanted throwing of debris. The caster wheels

can be mounted inward to the front when working near structures, outward for greater leveling control, or to

the rear of the rake, giving operators maximum exibility.

The TR270 Terra Rake comes with the Steiner Quick Hitch attachment system for easy installation or removal

in minutes without any tools. The Terra Rake can also be mounted to the rear 3-point hitch with a Steiner

3-Point Quick Hitch.

SPECIFICATIONS

Specications are subject to change without notice.

Overall Length with Wheels in front................................. 65"

Overall Length with Wheels in rear.................................. 48"

Overall Height.................................................................. 30"

Maximum working width .................................................. 70"

Minimum working width (angled)..................................... 65"

Right and left maximum angle......................................... 20°

Number of tines ............................................................... 40

Tine adjustment range..................................................... 4.25" below grade

......................................................................................... 4.50" above grade

Rake angle adjustment.................................................... ±5°

Caster wheel height adjustment ...................................... 4.75"

Weight ............................................................................. 382 lbs.

4

TERRA

RAKE

SAFETY

NOTICE !!!

Unauthorized modications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Schiller Grounds Care, Inc., strongly warns against,

rejects and disclaims any modications, add-on

accessories or product alterations that are not

designed, developed, tested and approved by Schiller

Grounds Care, Inc. Engineering Department. Any

Schiller Grounds Care, Inc. product that is altered,

modied or changed in any manner not specically

authorized after original manufacture–including the

addition of “aftermarket” accessories or component

parts not specically approved by Schiller Grounds

Care, Inc.–will result in the Schiller Grounds Care,

Inc. Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modications,

add-on accessories or products not approved by

Schiller Grounds Care, Inc. will be considered

the responsibility of the individual(s) or company

designing and/or making such changes. Schiller

Grounds Care, Inc. will vigorously pursue full

indemnication and costs from any party responsible

for such unauthorized post-manufacture modications

and/or accessories should personal injury and/or

property damage result.

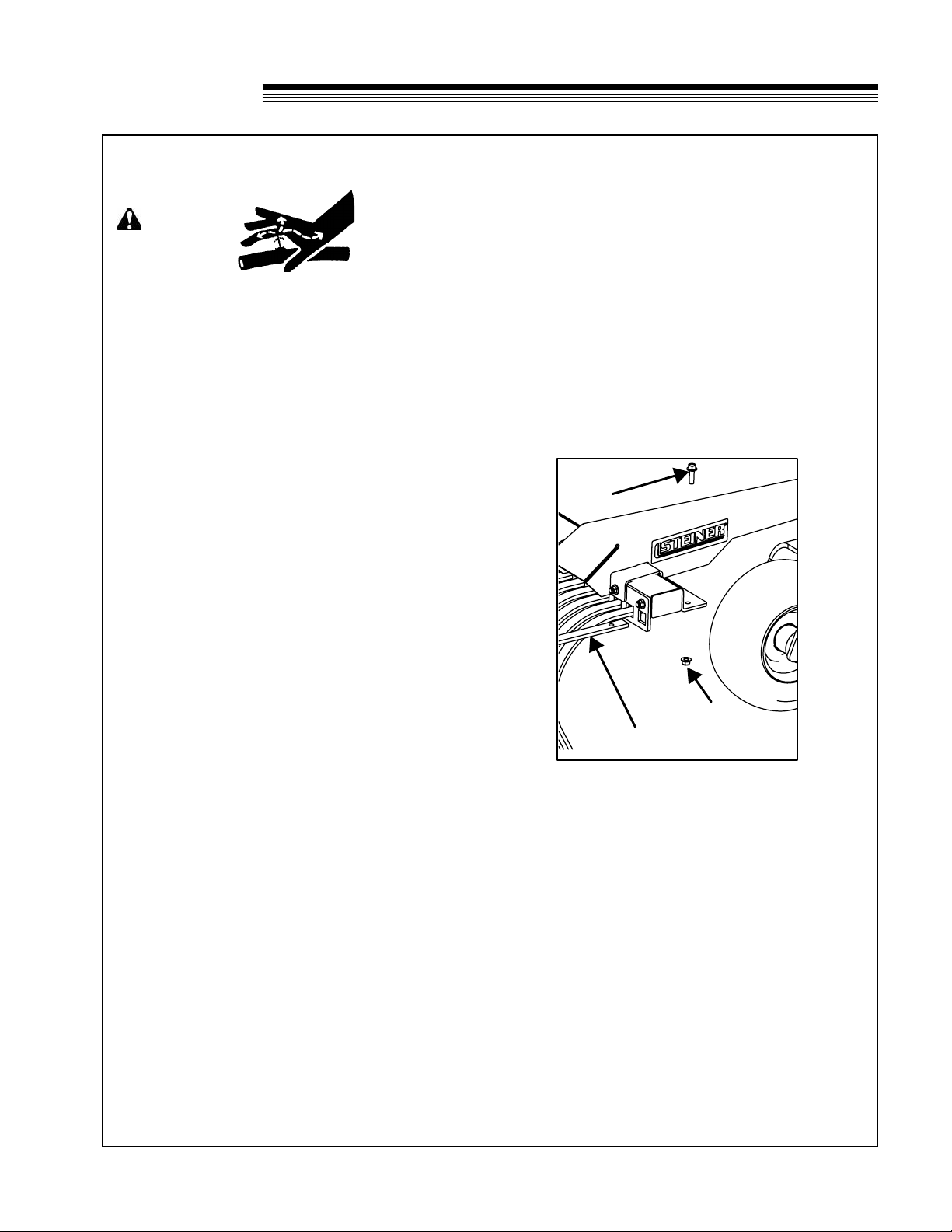

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your tractor. It contains the model number

followed consecutively by the serial number.

Use this number when ordering parts or seeking

warranty information.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word denitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manual and on the safety labels attached to Schiller

Grounds Care, Inc. machines. For your safety and

the safety of others, read and follow the information

given with these signal words and/or the symbol

shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

5

TERRA

RAKE

SAFETY

GENERAL SAFETY

Read the Operation & Safety Manual

• The owner of this machine is solely responsible for properly training the operators.

• The owner/operator is solely responsible for the operation of this machine and prevention of accidents or

injuries occurring to him/herself, other people, or property.

• Read and understand the operator’s manual, before attempting to operate this machine.

• Operate all controls from the operator’s seat.

• If the operator of the machine cannot understand this manual, then it is the responsibility of this machine’s

owner to fully explain the material within this manual to the operator.

• Learn and understand the use of all controls.

• Know how to stop the power unit and all attachments quickly in the event of an emergency.

• Do not leave machine unattended while it is running. STOP the engine and remove the key, set parking

brake and lower attachment.

• Always park the machine on level ground.

• Do not allow minors, untrained personnel or the inexperienced to operate this machine.

• Children are attracted to machine activity. Be aware of children and do not allow them in the working area.

Turn off the machine if a child enters the work area.

• Do not operate or repair machine if you are not in good physical and mental health, if you will be

distracted by personal devices, or are under the inuence of any substance which might impair deci sion,

dexterity, or judgment.

• Keep people and pets a safe distance away while using this machine. Injury could result from ying

debris. Stop machine if someone enters the work area.

• Wear protective clothing and personal safety devices to protect your head, eyes, ears, hands, and feet.

• Always be alert to what is happening around you, but do not lose focus on the task you are performing.

• Always look in the direction the machine is moving.

• Stop operation immediately at any sign of equipment failure. An unusual noise or vibration can be a

warning of equipment failure or a sign that maintenance is required. Make all necessary repairs before

operating machine again.

• Only operate in well-lit conditions.

6

TERRA

RAKE

SAFETY / SAFETY DECALS

OPERATION SAFETY

• Do not attempt to work on the Terra Rake while the power unit engine is running.

• Inspect machine before operation. Repair or replace any damaged, worn, or missing parts. Be sure

guards and shields are in proper working condition and are secured in place. Make all necessary

adjustments before operating machine.

• Alterations or modications to this machine can reduce safety and could cause damage to the machine.

• Before each use, verify that all controls function properly and inspect all safety devices. Do not operate if

controls or safety devices are not in proper working condition.

• Make sure all hydraulic connections are tight and all hydraulic hoses and tubes are in good condition.

Repair any leaks and replace any damaged or deteriorated hoses or tubes before starting the machine.

• Hydraulic leaks can occur under high pressure. Hydraulic leaks require special care and attention. Use

a piece of cardboard and a magnifying glass to locate suspected hydraulic leaks. Keep body and hands

away from pinhole leaks or nozzles that eject high pressure hydraulic uid. Hydraulic uid escaping

under high pressure can penetrate the skin causing serious injury, leading to severe complications and/

or secondary infections if left untreated. If hydraulic uid is injected into the skin, seek immediate medical

attention

• The Terra Rake hydraulic system may contain stored energy. Before performing maintenance or repairs

on the attachment, lower attachment to the ground, shut off power unit engine, put hydraulic accessory

lever in oat to relieve hydraulic pressure, and disconnect hydraulic hoses from the auxiliary quick

connectors.

• Ensure the Terra Rake is fastened securely to the power unit before operating.

• Never leave the operator’s seat without lowering the attachment to the ground, setting the parking

brake, shutting off the engine, and removing the ignition key. Make sure all moving parts have come to a

complete stop before dismounting.

• Do not attempt to straighten bent tines. Bending a tine may cause it to break.

• Do not use the TR270 for digging or moving large amounts of material. The TR270 is designed for

nishing work. Overly aggressive contact with the ground, aggregate, rocks, and other debris can cause

damage to the Terra Rank including bent or broken tines.

• Know the work area well before operation. Do not operate where traction or stability is questionable.

7

TERRA

RAKE

ASSEMBLY

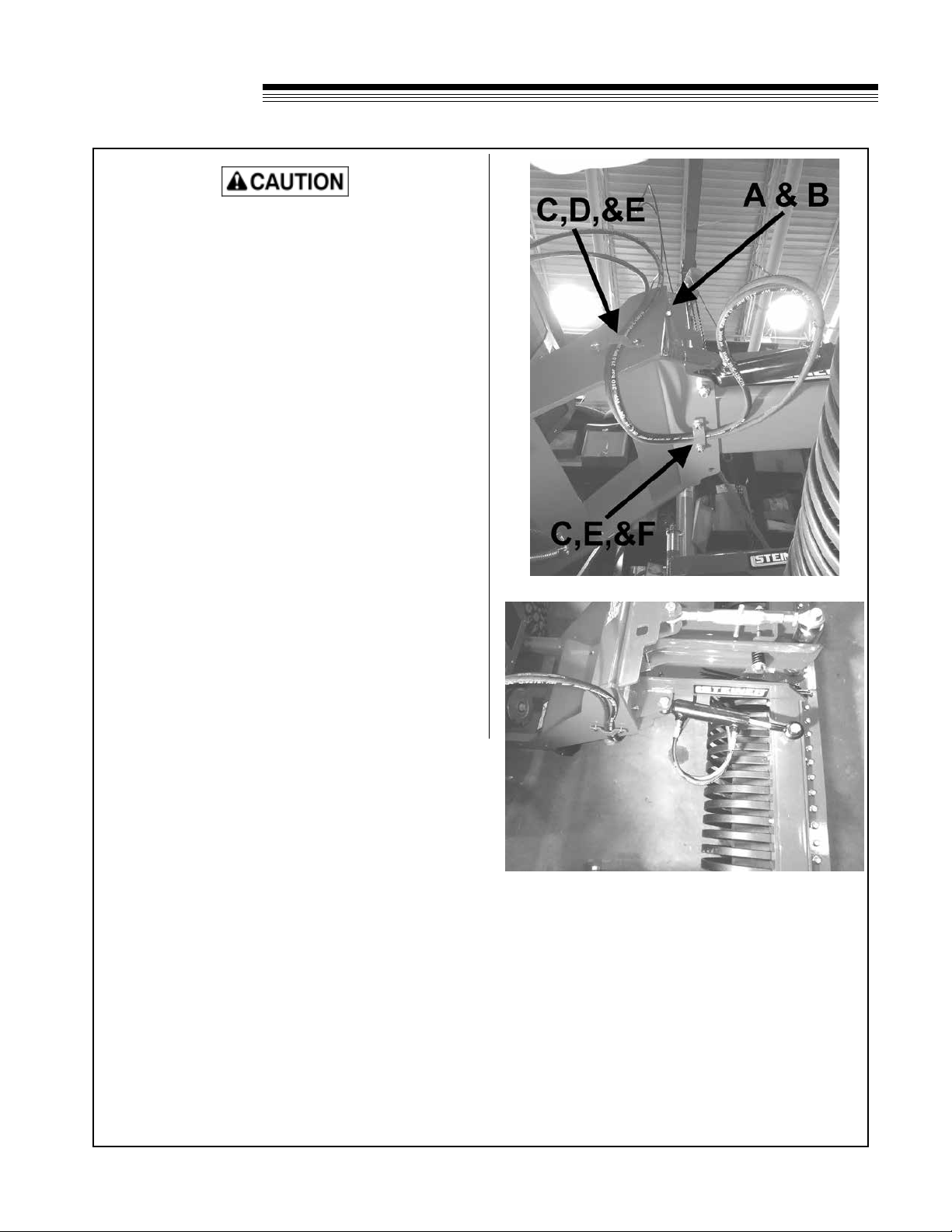

ASSEMBLY

1. On level ground, remove rake and attaching

parts from shipping crate.

2. Attach Hitch Frame to Main Frame with eight 3/8-

16 X 1 bolts Aand eight 3/8-16 nuts Bas shown.

3. Lower kickstand. Adjust to desired height.

4. Attach caster arms to desired location. See

Caster Arm Placement Section for information

regarding caster arm location.

5. Route hoses and install hose clamp Cto main

frame using two 5/16-18x1-1/4 bolts F and two

5/16-18 nuts E. Install hose clamp Cto hitch

frame using two 5/16-18 x 1 bolts Dand two

5/16-18 nuts E.Be sure to provide enough slack

to allow full motion of hitch arms while not pulling

hoses too tight.

6. Grease center ball joint and caster wheels.

Attaching to Tractor

7. Operate latch control lever on tractor to open

hitch latches.

8. Drive tractor into position aligning the quick hitch.

9. Engage both latches and conrm they are in the

locked position.

10. Lower, set parking brake, turn off tractor.

11. Wipe hose ends clean and attach hydraulic

hoses to auxiliary quick connect ports on power

unit.

12. Raise kickstand.

13. Check and tighten all bolts. Grease center ball

joints and caster wheels.

Rear Weight Requirements

• The Steiner 450 tractors requires two 50#

rear weights based upon average raking

conditions and operator’s weight of 150 lbs. The

recommendations may vary with the weight of

the operator, other accessories, and operating

conditions. It is the operator’s responsibility to

determine the correct amount of weight needed

to improve stability. All weights must be removed

when the rake is removed.

• If equipped with a cab, no weights are required.

NOTE: Optional 3-point hitch installation is covered

under it own section. See 3-Point Hitch Installation

Section.

8

TERRA

RAKE

OPERATION

1. Set tine depth and angle for desired surface nish. See Angle Adjustment and Tine Depth Adjustment

Sections.

2. Use hydraulic angle adjustment to rotate rake left or right.

3. Transport with the rake raised to prevent tines from catching on high spots, rocks, debris, or other

obstacles.

4. Operate in "FLOAT" to allow the rake to follow terrain and level independently of tractor.

5. Remove large rocks before raking. DO NOT use the Terra Rake as a bulldozer. If large amounts of

material needs to be leveled, start with a Steiner Slip Scoop or Steiner Power Angle Blade and smooth

out rst. Finish with the Terra Rake.

Detaching from Tractor

1. Park power unit on level surface and set the parking brake.

2. Lower kickstand and lower rake to the ground. Shut off the tractor.

3. Disconnect the hydraulic hoses from the tractor and store with the hose ends on rake. Do not allow hose

ends to lay on the ground.

4. Disengage the front hitch latches.

5. Restart unit, release the parking brake and slowly back away from the rake.

OPERATION

9

TERRA

RAKE

TINE DEPTH AND TINE ANGLE ADJUSTMENT

The TR270 tine depth and tine angle can be set to desired depths and angles by adjusting the caster spacer

positions and the top link length. See typical congurations below.

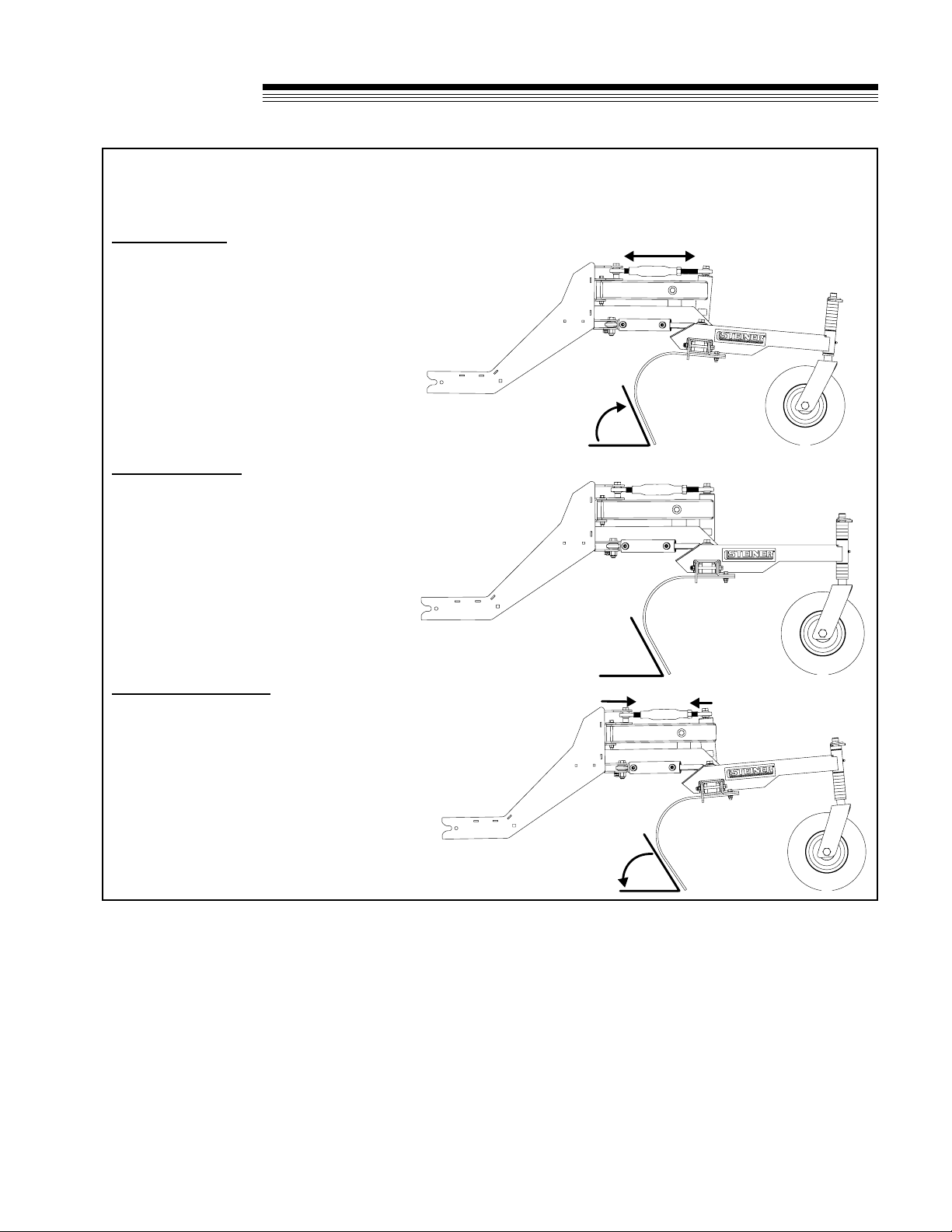

Light Tine Angle

• Light tine angles are useful for lightly

combing loose material to nish, clean or

prep a work site.

• Increasing the length of the top link will

lighten the effectiveness of the tine angle

and also decreases the tine depth.

• To maintain desired tine depth, caster

spacers need to be repositioned from

below the caster arm to above the caster

arm.

Neutral Tine Angle

• Neutral tine angle produces the most

satisfactory results across most working

conditions.

• Neutral tine angle position is achieved by

adjusting the top link until the top of the

caster arms are running parallel with the

ground.

• Caster spacer positions may also need

to be adjusted to achieve a neutral tine

angle at desired depth.

Aggressive Tine Angle

• Aggressive tine angles are useful for

moving large amounts of material and

working heavily compacted materials.

• Decreasing the length of the top link will

increase the aggressiveness of the tine

angle and also increase the tine depth.

• To maintain desired tine depth, caster

spacers need to be repositioned from

above the caster arm to below the caster

arm.

ADJUSTMENTS

10

TERRA

RAKE

CASTER ARM PLACEMENT

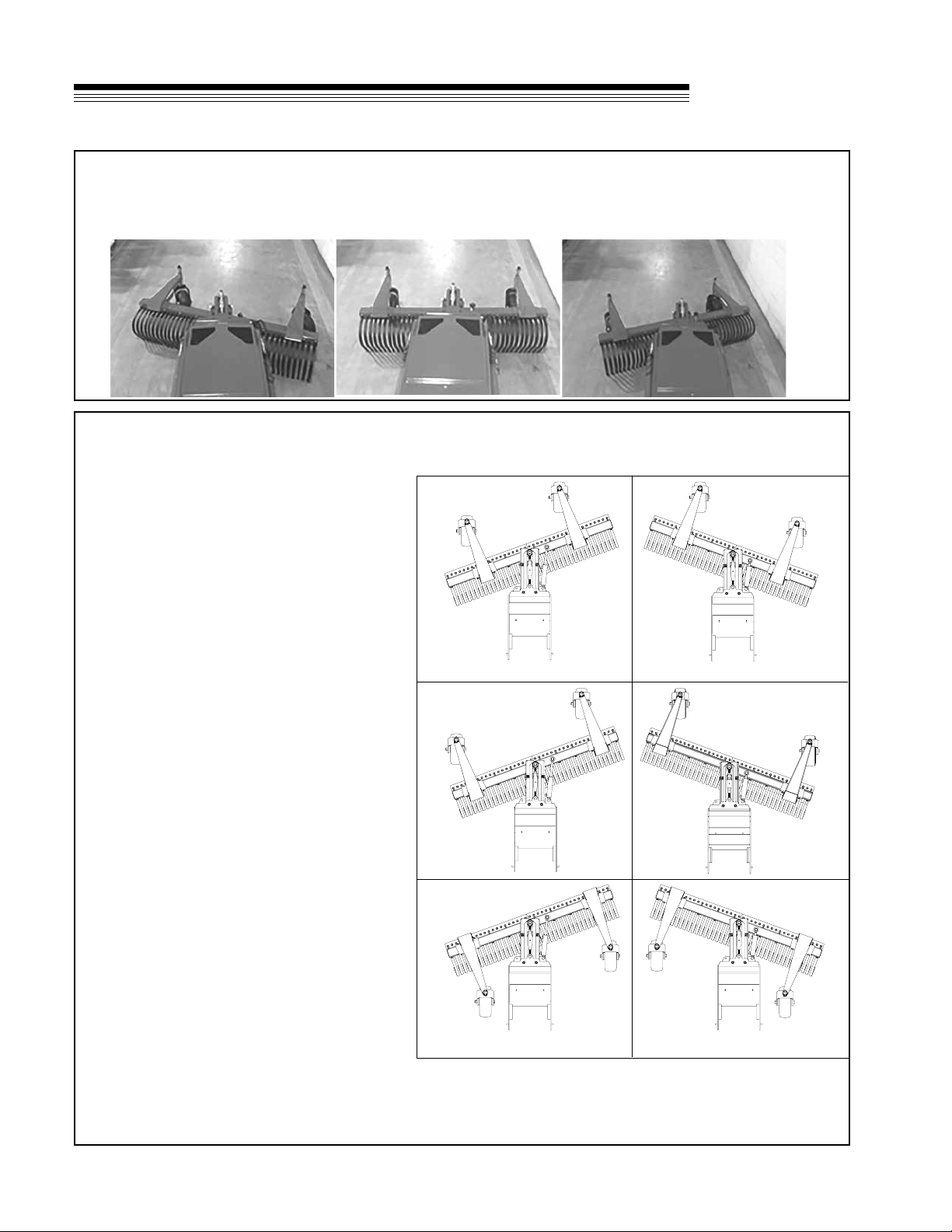

• Mounting the caster arms to the inside will

make maneuvering next to barriers easier.

in this position, the footprint is narrower and

the ends may dig in harder when operating

around a mound or ridge.

• Mounting the caster arms to the outside will

assist in creating a more level surface.

• Mounting the caster arms to the rear will

allow the rake to set the grade and follow

the raked surface. The rake will dig in as it

approaches inclines. The caster arms must

be mounted to the outside to prevent hitch

frame contact.

• Removing the caster arms requires tine

depth to be set using the auxiliary controls.

Removing the caster arms may produce a

more uneven surface. Removing caster

arms may be useful for clearing large loose

debris and working in rough areas where

caster arms may be unsuitable.

ROTATION ADJUSTMENT

• Rotate the rake to the right or left to direct material and create windrows of debris.

• If desired, reverse auxiliary hydraulic hoses to reverse control operation.

ADJUSTMENTS

11

TERRA

RAKE

OPTIONAL 3-POINT HITCH MOUNTING

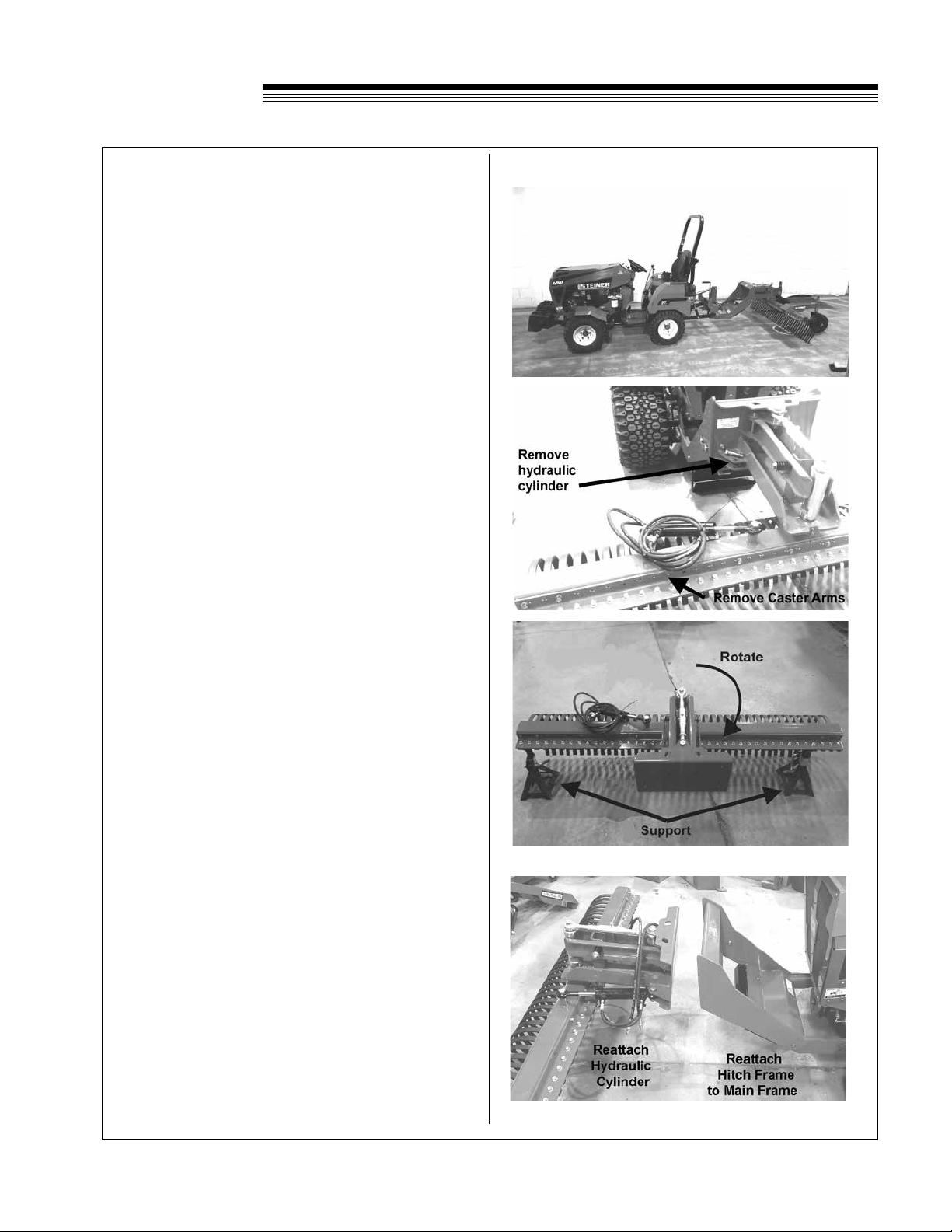

OPTIONAL REAR MOUNT 3-POINT HITCH

1. To setup the TR270 Terra Rake for use on the

3-Point Quick Hitch QH202, it is recommended to

rst attach the rake to the front of the tractor for

setup.

2. Remove hose clamps on the side of the quick hitch

frame and main frame of the rake.

3. Remove the caster arms.

4. Remove hydraulic cylinder from the main frame,and

secure the hydraulic hoses out of the way.

5. Support the rake so that it will not fall once

unbolted. Unbolt the main frame from the quick

hitch frame.

6. Rotate the main frame 180°.

7. Reattach hydraulic cylinder.

8. With the hitch frame still on tractor, reattach to the

main frame.

9. Place kickstand down and unhook the hitch frame

from the tractor.

12

TERRA

RAKE

OPTIONAL 3-POINT HITCH MOUNTING

10. For stability, the 75-71203 WB200 Front Weight Bar

Kit and 75-71204 WB201 Weight Kit must be used

if the TR270 is mounted to the 3-point hitch.

11. Attach the terra rake to the 3-point quick hitch.

Reattach hose clamps to main frame and hitch

frame. Ensure hoses are not pinched or pulled too

tight.

12. Plug in hydraulic hoses to rear accessory ports.

13. Reinstall caster arms.

14. When mounted to the 3-point Quick Hitch adapter

and caster arms are mounted towards the tractor,

the caster arms must be mounted to the outside to

prevent contact.

13

TERRA

RAKE

MAINTENANCE / STORAGE

MAINTENANCE

DAILY INSPECTION AND MAINTENANCE

• Visual inspection for loose, missing or worn

components and replace if needed.

• Inspect for bent rake tines and replace as

needed.

• Check tire pressure.

• Inspect and grease pivot ball and caster

bushings as needed.

• Inspect hydraulic hoses and ttings for leaks,

deterioration, or damage.

• Inspect and lightly lube top link as needed.

ANNUAL INSPECTION AND MAINTENANCE

• Visual inspection for loose, missing or worn

components and replace if needed.

• Inspect for bent rake tines and replace as

needed.

• Check tire pressure.

• Inspect and grease pivot ball and caster

bushings as needed.

• Inspect and lubricate rod ends on top link.

• Inspect and lubricate rod ends on hydraulic

cylinder.

• Inspect caster wheel axles and bearings.

• Inspect hydraulic hoses and ttings for leaks,

deterioration, or damage.

TIRE PRESSURE

Tire pressure should be maintained at 40 psi.

WARNING

LUBRICATION LOCATIONS

3 points-Centerlink and wheel casters

RAKE TINE REPLACEMENT

1. Park power unit on level surface and set the

parking brake.

2. Lower kickstand and lower rake to the ground.

Shut off the tractor.

3. Adjust top link so tines are off the ground.

4. Remove bolt Xand nut Y. Slide out old tine.

5. Insert new rake tine and attach to rake with bolt

Xand nut Y.

X

Y

Z

STORAGE

PLACING RAKE IN STORAGE

1. Clean the rake.

2. Inspect for loose or missing hardware, damaged

or worn parts. Repair or replace any damaged or

worn parts.

3. Apply grease to grease points. Wipe off excess

grease. Inspect and lightly lube top link as

needed.

REMOVING RAKE FROM STORAGE

1. Clean and inspect rake for use.

15

TERRA

RAKE

PARTS

SECTION

16

TERRA

RAKE

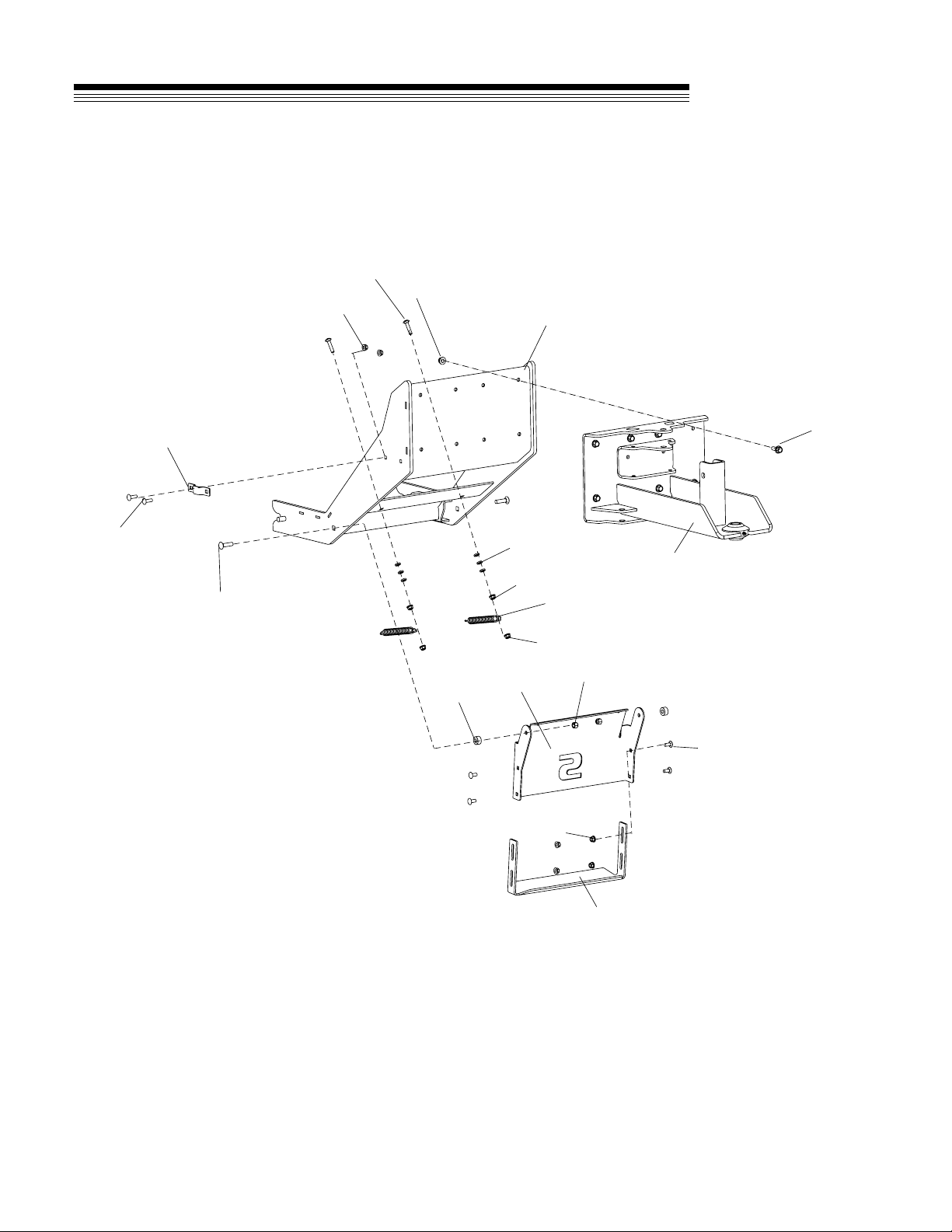

FIGURE 1

HITCH ASSEMBLY

15

11

7

81

6

3

5

2

4

9

19

10

12

14

13

11

11

11

17

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

TERRA

RAKE FIGURE 1

HITCH ASSEMBLY

1 4177225.17 WLDMT-FRAME, MAIN 1

2 64268-03 NUT-FL NYLON LOCK 3/8-16 8

3 64262-011 BLT-FLG HD 3/8-16 X 1 8

4 64018-51 BLT-CRG 5/16-18 X 3/4 SN 4

5 64018-49 BLT-CRG 3/8-16 X 1-1/2 2

6 64018-34 BLT-CRG 5/16-18 X 1-1/2 2

7 4177754.7 BRKT-KICKSTAND LOWER 1

8 64163-02 WSHR .321X.593X11GA 6

9 64229-03 NUT-NYLON LOCK 3/8-16 2

10 4176763.17 CLAMP-HOSE 1

11 64268-02 NUT-FL NYLON LOCK 5/16-18 10

12 4177196.17 WLDMT-HITCH FRAME 1

13 64018-15 BLT-CRG 5/16-18X1 SN 2

14 4174797 SPRING, BBC 2

15 33030-07 IDLER BUSHING 2

16 4177753.7 BRKT-KICKSTAND UPPER 1

18

TERRA

RAKE

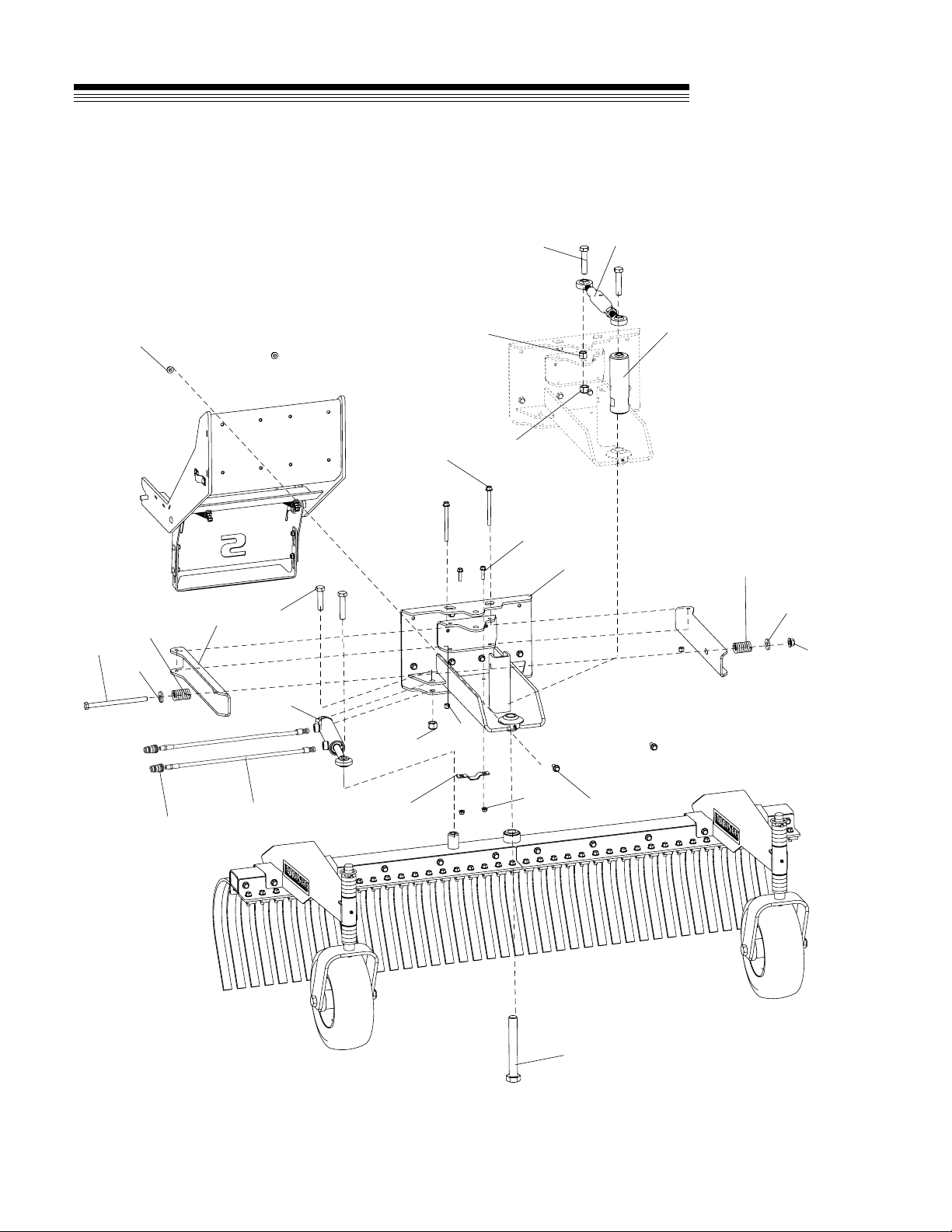

FIGURE 2

MAIN FRAME ASSEMBLY

10

16 9

14

21

12

13

7

1

8

64

3

5

2

18 20

15

19

17

11

13

10

16

22

23

19

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

TERRA

RAKE FIGURE 2

MAIN FRAME ASSEMBLY

1 4177225.17 WLDMT-MAIN FRAME 1

2 4177210 TOP LINK 1

3 23-058 CYLINDER 1-1/2 X 5 DUMP 1

4 4176748 BAR-TINE FRAME CENTERING 1

5 64262-011 BLT-FLG HD 3/8-16 X 1 8

6 64268-03 NUT-FL NYLON LOCK 3/8-16 8

7 64123-342 BLT-HEX 1-14X7-1/2 1

8 64262-040 BLT-FLG HD 3/8-16 X 4-1/2 GR 8 2

9 4176753.17 ARM-CENTERING 2

10 64163-99 WSHR-.510X1.31X.179 2

11 64123-210 BLT-HEX 1/2-13X7-1/2 1

12 64123-325 BLT-HEX,5/8-11 X 3 3

13 64229-06 NUT-NYLON LOCK 5/8-11 2

14 64268-03 NUT-FL NYLON LOCK 3/8-16 2

15 64123-168 BLT-HEX 5/8-11X2-1/2 1

16 4177744 SPRING-COMPRESSION 1.25"X2" 2

17 4130974-01 SPACER-.625/.635x.88x.688 1

18 4176763 CLAMP-HOSE 1

19 64262-008 BLT-FLG HD 5/16-18 X 1-1/4 2

20 64268-02 NUT-FL NYLON LOCK 5/16-18 2

21 64268-05 NUT-FL NYLON LOCK 1/2-13 1

22 4177755-01 HOSE-M 1/4NPFT - M 1/4 NPFT X 75 2

23 23-004 MALE QUICK COUPLER 2

20

TERRA

RAKE

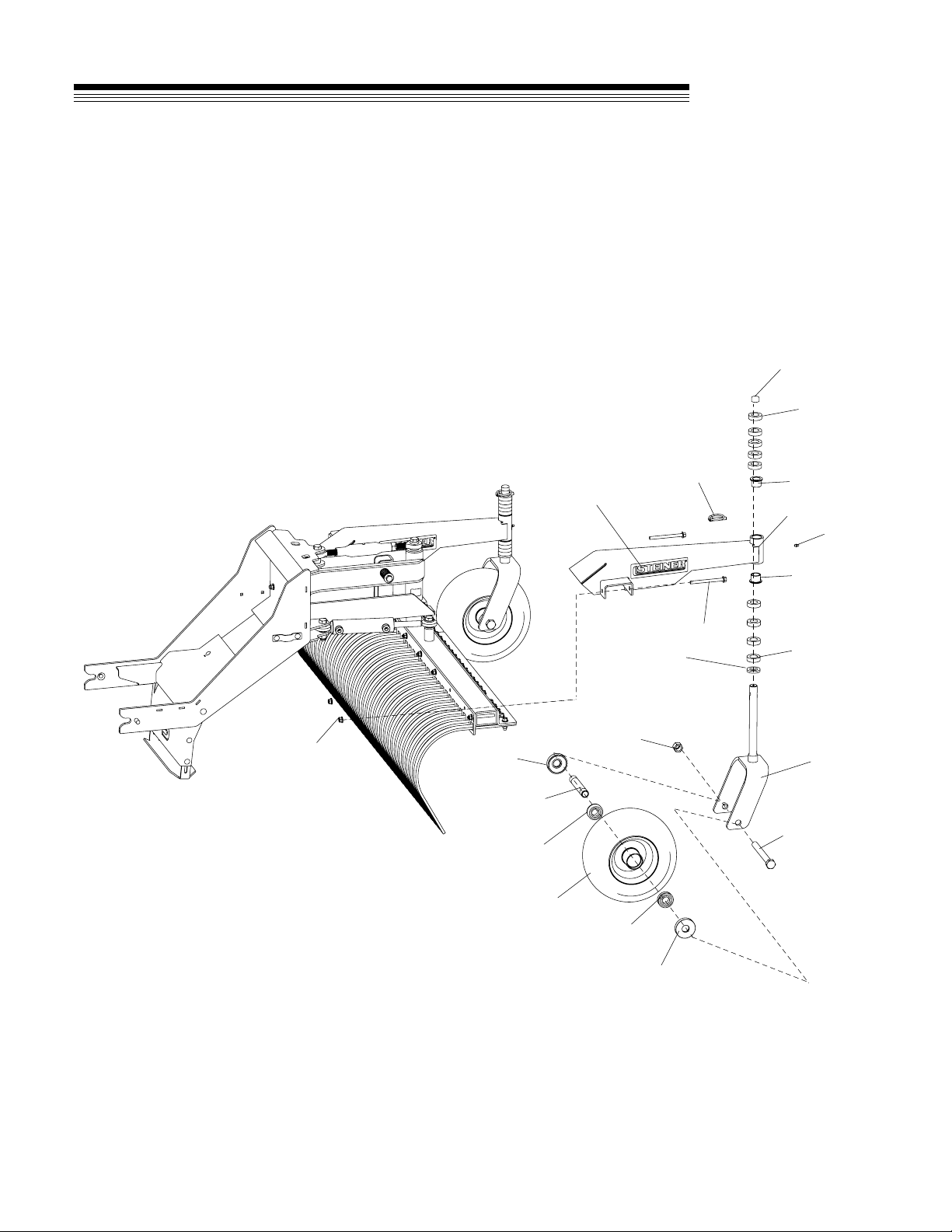

FIGURE 3

CASTER WHEEL ASSEMBLY

8

4

13

6

7

9

3

10

1

2

11

12

16

17

15

14

5

7

10

12

16

Table of contents

Other Steiner Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Oregon

Oregon 480RC Original instruction manual

Wintex Agro

Wintex Agro WINTEX 1000 Workshop manual

Reese

Reese Aitchison Seedmatic 40 D Series manual

Yetter

Yetter 5000-025B owner's manual

FPM Agromehanika

FPM Agromehanika 627 152 ASSEMBLY / OPERATION/ MAINTENANCE, SPARE PARTS LIST

LELY

LELY HIBISCUS 1525 Master Operator's manual