Steiner SS244 Setup guide

OP/PARTS MANUAL

MAN 4174944

Rev. A 4-2017

MODELS:

75-70625A

SLIP SCOOP 44”SS244

75-70630A

SLIP SCOOP 48”SS248

CALIFORNIA PROPOSITION 65

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

ADVERTENCIA: Cáncer y Dãno Reproductivo - www.65Warnings.ca.gov.

3

SLIP

SCOOP

IMPORTANT MESSAGE

Thank you for purchasing this Schiller Grounds Care. Inc. product. You have purchased a world class product,

one of the best designed and built anywhere.

This product comes with an Owner/Operator's Manual / Illustrated Parts List. The useful life and good service

you receive from this product depends to a large extent on how well you read and understand this manual. Treat

this product properly and adjust it as instructed, and it will give you many years of reliable service.

See a Schiller Grounds Care. Inc. dealer for any service or parts needed. Schiller Grounds Care. Inc. service

ensures that you continue to receive the best results possible from Schiller Grounds Care. Inc. products. You

can trust Schiller Grounds Care. Inc. replacement parts because they are manufactured with the same high

precision and quality as the original parts.

Schiller Grounds Care. Inc. designs and builds its equipment to serve many years in a safe and productive man-

ner. For longest life, use this product only as directed in the manual, keep it in good repair and follow safety

warnings and instructions. You'll always be glad you did.

Schiller Grounds Care. Inc.

One Bob Cat Lane

Johnson Creek, WI 53038-0469

4-2007

TABLE OF CONTENTS FIGURES PAGE

DESCRIPTION/SPECIFICATIONS .................................................................................................................. 4

SAFETY........................................................................................................................................................5, 6

ASSEMBLY INSTRUCTIONS .......................................................................................................................... 7

INSTALLATION/OPERATION...........................................................................................................................8

PARTS SECTION.............................................................................................................................................9

44" HYDRAULIC SLIP SCOOP PARTS .............. FIGURE 1 ................................................................... 10, 11

48" HYDRAULIC SLIP SCOOP PARTS .............. FIGURE 2 ................................................................... 12, 13

4

SLIP

SCOOP

DESCRIPTION/SPECIFICATIONS

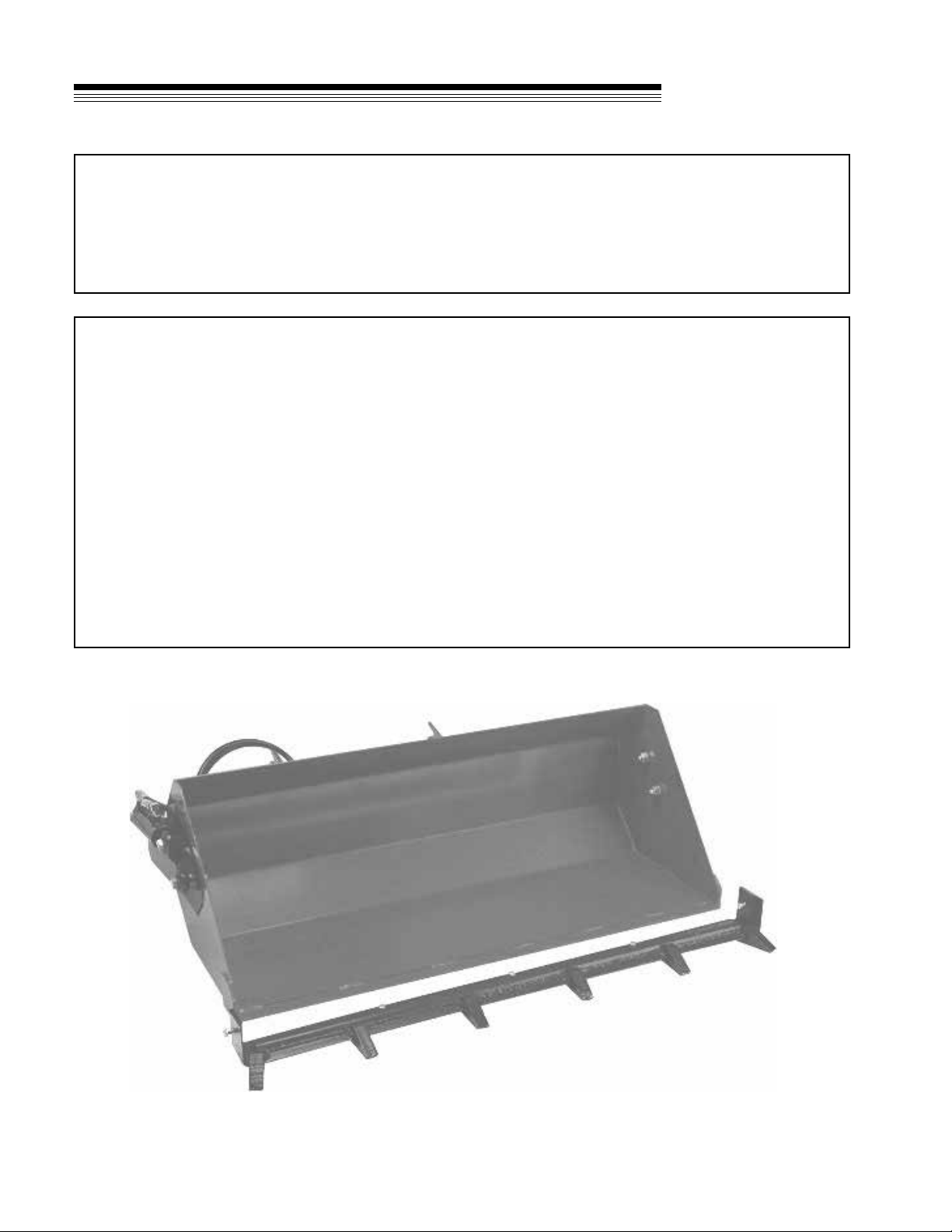

SPECIFICATIONS

Model 75-70625 75-70630

Overall width:............................. 48" ............................................. 52"

Overall height: ........................... 16" ............................................. 16"

Overall length: ........................... 33" ............................................. 33"

Width of bucket:......................... 44" ............................................. 48"

Bucket Capacity:........................ 3.25 cubic ft. .............................. 3.5 cubic ft.

Dumping: ................................... Hydraulic.................................... Hydraulic

Weight ....................................... 135 lbs. ...................................... 170 lbs.

NOTE: Specications are subject to change without notice.

DESCRIPTION

The Slip Scoop attachment mounts on the quick hitch front lift of the power unit. On or off in a

minute or less, it is a quick, inexpensive way to relocate loose materials. Use it for landscaping, light

excavating and many tasks where you would normally use a wheelbarrow. Twin hydraulic cylinders control

the bucket position on hydraulic operated slip scoops.

5

SLIP

SCOOP

SAFETY

NOTICE !!!

Unauthorized modications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Schiller Grounds Care. Inc. strongly warns against,

rejects and disclaims any modications, add-on

accessories or product alterations that are not

designed, developed, tested and approved by Schiller

Grounds Care. Inc. Engineering Department. Any

Schiller Grounds Care. Inc. product that is altered,

modied or changed in any manner not specically

authorized after original manufacture–including the

addition of “after-market” accessories or component

parts not specically approved by Schiller Grounds

Care. Inc.–will result in the Schiller Grounds Care.

Inc. Warranty being voided.

Any and all liability for personal injury and/or

property damage caused by any unauthorized

modications, add-on accessories or products not

approved by Schiller Grounds Care. Inc. will be

considered the responsibility of the individual(s) or

company designing and/or making such changes.

Schiller Grounds Care. Inc. will vigorously pursue

full indemnification and costs from any party

responsible for such unauthorized post-manufacture

modications and/or accessories should personal

injury and/or property damage result.

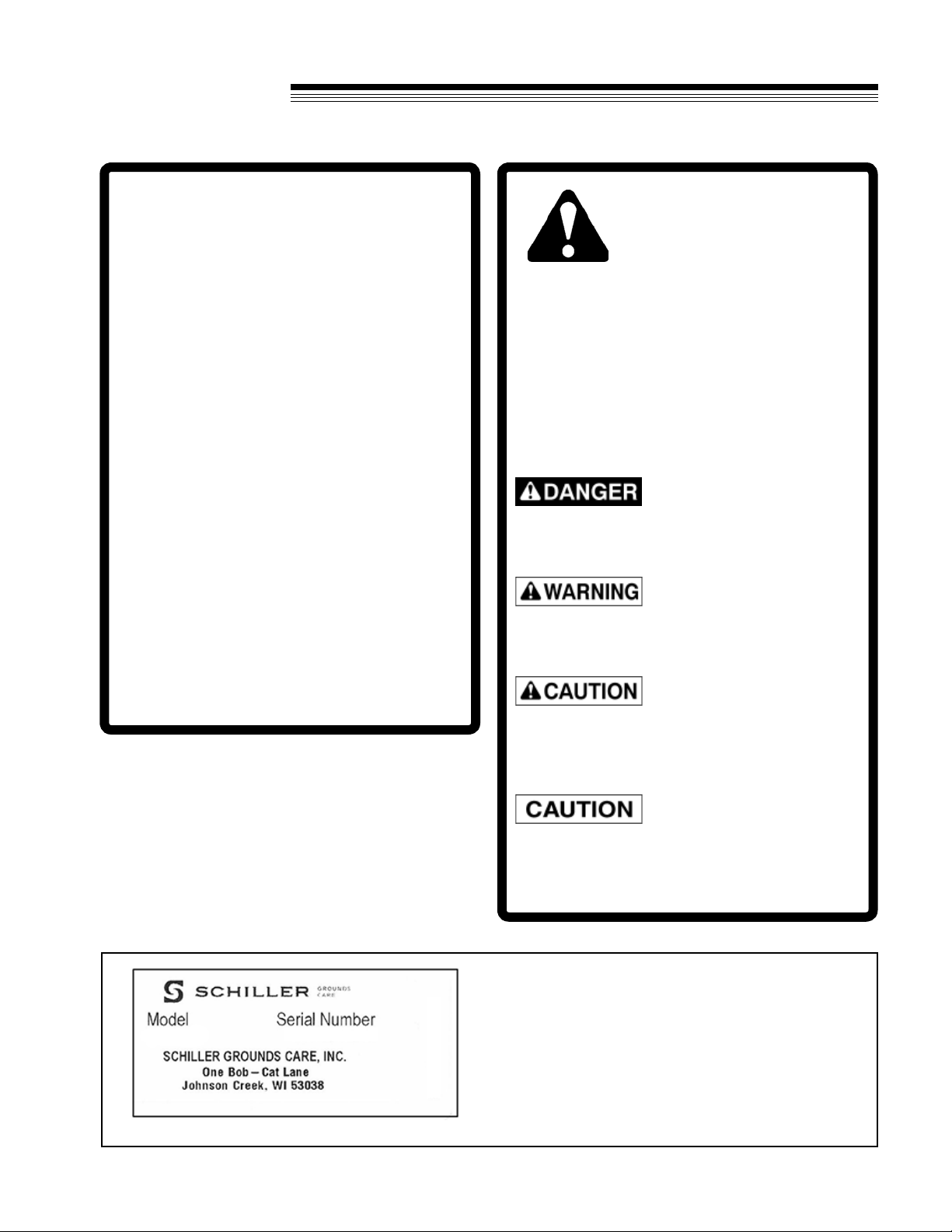

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word denitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manual and on the safety labels attached to Schiller

Grounds Care. Inc. machines. For your safety and

the safety of others, read and follow the information

given with these signal words and/or the symbol

shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your unit. It contains the model number fol-

lowed consecutively by the serial number. Use

this number when ordering parts or seeking war-

ranty information.

6

SLIP

SCOOP

SAFETY

1. Read and understand the Owner’s Manual before attempting to operate this machine.

2. Operate all controls from the operator’s seat. NO RIDERS.

3. Keep all shields in place and safety switches adjusted properly.

4. Do not leave equipment unattended. STOP the engine and remove the key.

5. Do not allow minors or the inexperienced to operate this machine.

6. Keep people and pets a safe distance away from machine using power driven attachments. Injury could

result from ying debris.

GENERAL SAFETY

OPERATING SAFETY

1. Do not attempt to work on unit or any

attachments with engine running. STOP

ENGINE!

2. WARNING! The tractor may coast when the

engine stops.

3. Before leaving the tractor seat:

• Set Parking brake.

• Stop Engine.

CARRY LOADS LOW AND AVOID HIGH SPEEDS

OR QUICK, SHARP TURNS. A REAR WEIGHT

BAR SHOULD BE ADDED WITH WEIGHT EQUAL

TO THE SCOOP LOAD.

7

SLIP

SCOOP

ASSEMBLY INSTRUCTIONS

Refer to Pages 10 - 13 for Parts

Identication

Assembly Instructions 75-70625A

(Figure 1)

1. Unfasten the bucket (Fig. 1, Item 16) and the

sub-frame (Fig. 1, Item 15) from the sides of the

crate and remove.

2. Remove the hardware package from the crate

and open.

3. Loosen all ball joints prior to connecting them to

the bucket.

4. Place the bucket between the frame arms so that

the holes at the ends of the arms line up with the

lower set of holes on each side of the bucket.

5. Insert a 5/8 X 2-1/2 bolt (Fig. 1, Item 19) through

the rear end of each arm and place one 5/8 at

washer (Fig. 1, Item 12) and one spacer (Fig. 1

Item 5) on each bolt. Insert the bolts through the

lower holes on each side of the bucket. Place a

5/8 stover locknut (Fig. 1, Item 18) on each bolt

and tighten.

6. Insert a 5/8 X 2-3/4 bolt (Fig. 1, Item 3) through

the rod end of each cylinder (Fig. 1, Item 4) Place

a washer (Fig. 1, Item 12), and two spacers (Fig.

1, Item 5) on each bolt. Insert the bolts through

the upper holes on each side of the bucket.

Place a 5/8 stover locknut (Fig. 1, Item 18) on

each bolt and tighten.

7. If installing on a 430/440 or earlier tractor,

please locate the two loose couple hoses (Fig.

1, Item 7) and ttings (Fig. 1, Item 8) provided.

Remove ttings (Fig. 1, Item 21 & 22) and

existing hoses (Fig. 1, Item 20 & 23) from slip

scoop. Install hoses (Fig. 1, Item 7) and ttings

(Fig. 1, Item 8) the per illustration on page 10.

Insure hoses are clear from the wheels when

the scoop is raised and lowered. Adjust as

necessary.

Assembly Instructions 75-70630A

(Figure 2)

1. Unfasten the bucket (Fig. 2, Item 16) and the

sub-frame (Fig. 2, Item 15) from the sides of the

crate and remove.

2. Remove the hardware package from the crate

and open.

3. Loosen all ball joints prior to connecting them to

the bucket.

4. Place the bucket between the frame arms so that

the holes at the ends of the arms line up with the

lower set of holes on each side of the bucket.

5. Insert a 5/8 X 2-3/4 bolt (Fig. 2, Item 3) through

the lower hole on each side of the bucket.

(Through the outer bracket only.) Insert bolts

through the end of each arm and place one

washer (Fig. 2, Item 12) and two spacers (Fig. 2,

Item 5) on each bolt. Push the bolts through the

bucket. Place a 5/8 stover locknut (Fig. 2, Item

18) on each bolt and tighten.

6. Insert a 5/8 X 2-3/4 bolt (Fig. 2, Item 3) through

the upper hole on each side of the bucket.

(Through the outer bracket only.) Insert bolts

through the rod end of each cylinder

(Fig. 2, Item 4) and place one wahser (Fig. 2,

Item 12) and two spacers (Fig. 2, Item 5) on each

bolt. Push the bolts through the bucket. Place a

5/8 stover locknut (Fig. 2, Item 18) on each bolt

and tighten.

7. If installing on a 430/440 or earlier tractor,

please locate the two loose couple hoses (Fig.

2, Item 7) and ttings (Fig. 2, Item 8) provided.

Remove ttings (Fig. 2, Item 17 & 24) and hoses

( Fig. 2, Item 19 & 25) from slip scoop. Install

hoses (Fig. 1, Item 7) and ttings (Fig. 2, Item 8)

the per illustration on page 12. Insure hoses are

clear from the wheels when the scoop is raised

and lowered. Adjust as necessary.

8

SLIP

SCOOP

INSTALLATION/OPERATION

HYDRAULIC SLIP SCOOP OPERATION

1. Use “Low” (1) range for operating scoop.

2. Level the scoop, for loading materials, by moving the auxiliary hydraulic lever. To dig into the surface, the

front edge of the scoop must be lower than the rear.

3. When the scoop is loaded, move the auxiliary hydraulic lever to roll back the scoop to contain the load.

4. To dump the load, move the auxiliary hydraulic lever.

NOTE: A rear weight bar is recommended to use with the Slip Scoop. Add weights equal to the load carried

in the scoop. Remove weights when the Slip Scoop is removed.

HINTS FOR OPERATION OF HYDRAULIC SLIP SCOOP

A. Use “FLOAT” position for loading loose materials on a rm surface.

B. Use DOWN PRESSURE to dig into rm surfaces.

C. To level loose materials, roll the bucket to the extreme dump position. Lower the scoop and move

backward to get a back blade leveling effect. Use a little down pressure.

HYDRAULIC SLIP SCOOP INSTALLATION

1. Attach the slip scoop to the front lift.

2. Attach the hydraulic hoses to the auxillary couplers. Route the hoses in a place where they will not be

damaged. If the hydraulic lever movement seems backward, reverse the hoses at the quick couplers..

9

SLIP

SCOOP

PARTS SECTION

PARTS

SECTION

10

SLIP

SCOOP

44" HYDRAULIC SLIP SCOOP PARTS

FIGURE 1

430/440

SET UP

450

SET UP

20

23

21

22

21

25

24

11

SLIP

SCOOP

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

44" HYDRAULIC SLIP SCOOP PARTS

FIGURE 1

1 25-2103-4-6 90-M/M 9/16 JIC x 1/8 NPTF 4

2 20-217 HOSE-1/4 X 20 2

3 90-1022 BOLT-5/8 X 2-3/4 4

4 23-058 CYLINDER-1-1/2 X 5 2

21-0A009066 SEAL KIT-CYLINDER 1

5 64163-12 .635/.640X1.0X.25 WASH 10

6 25-033T-6-6 FITTING-TEE 2

7 20-074 HOSE-1/4 X 31 2

(430/440 MODEL ONLY)

8 25-0103-4-6 FITTING 2

(430/440 MODEL ONLY)

9 23-004 QUICK COUPLER-MALE 2

10 20-029 HOSE-1/4 2

11 64229-01 NUT-NYON LOCK 1/4-20 3

12 64163-93 WASHER 6

13 4165751 CLAMP-HOSE 1/2 3

14 64123-07 BLT-HEX 1/4-20 X 1-1/2 3

15 4177009 S-FRAME 1

16 62-735.17 BUCKET 1

17 64-999.7 KICKSTAND 1

18 99-A10 NUT-STOVER LOCK 5/8-11 6

19 90-1020 BOLT-5/8 X 2-1/2 2

20 20-027 HOSE (1/4 X 22) 1

(450 MODEL ONLY)

21 25-3903-6-6 FTG 90 -6 MJIC X -6 F.JIC 2

(450 MODEL ONLY)

22 25-2103-4-6 90-M/M 9/16 JIC x 1/8 NPTF 2

(450 MODEL ONLY)

23 20-006 HOSE 1/4 X 24 100R1 #6 JIC 1

(450 MODEL ONLY)

* 4116761 DECAL-MADE IN THE USA 1

* 4158620 DECAL-STEINER 1

24 43067A COLLAR, SET, PLATE 1

25 02-PP0313 PRESTO PIN-3/32 X 1-5/8 1

*NOT ILLUSTRATED

12

SLIP

SCOOP

430/440

SET UP

450

SET UP

19

25

24

17

24

48" HYDRAULIC SLIP SCOOP PARTS

FIGURE 2

13

SLIP

SCOOP

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

1 25-2103-4-6 90-M/M 9/16 JIC x 1/8 NPTF 4

2 20-027 HOSE (1/4 X 22) 2

3 90-1022 BOLT-5/8 X 2-3/4 6

4 23-058 CYLINDER-1-1/2 X 5 2

21-0A009066 SEAL KIT-CYLINDER 1

5 64163-12 .635/.640X1.0X.25 WASH 12

6 25-033T-6-6 FITTING-TEE 2

7 20-074 HOSE-1/4 X 31 2

(430 / 440 MODELS ONLY)

8 25-0103-4-6 FITTING 2

(430 / 440 MODELS ONLY)

9 23-004 QUICK COUPLER-MALE 2

10 20-022 HOSE-1/4 2

11 64229-01 NUT-NYON LOCK 1/4-20 4

12 64163-93 WASHER 6

13 4165751 CLAMP-HOSE 1/2 4

14 64123-07 BLT-HEX 1/4-20 X 1-1/2 4

15 4177008 S-FRAME 1

16 64-984.17 BUCKET 1

17 25-2103-4-6 90-M/M 9/16 JIC x 1/8 NPTF 2

(450 MODEL ONLY)

18 99-A10 LOCKNUT-5/8 STOVER 6

19 20-027 HOSE (1/4 X 22) 1

(450 MODEL ONLY)

20 43067A COLLAR, SET, PLATE 1

21 02-PP0313 PRESTO PIN-3/32 X 1-5/8 1

22 64-999.7 KICKSTAND 1

23 85010N GREASE FITTING 2

24 25-3903-6-6 FTG 90 -6 MJIC X -6 F.JIC 2

(450 MODEL ONLY)

25 20-006 HOSE 1/4 X 24 100R1 #6 JIC 1

(450 MODEL ONLY)

* 4116761 DECAL-MADE IN THE USA 1

* 4158620 DECAL-STEINER 1

*NOT ILLUSTRATED

48" HYDRAULIC SLIP SCOOP PARTS

FIGURE 2

SCHILLER GROUNDS CARE, INC.

ONE BOB-CAT LANE

P.O. BOX 469

JOHNSON CREEK, WI 53038

920-699-2000

www.schillergc.com ©Schiller Grounds Care, Inc. 2010

Other manuals for SS244

1

This manual suits for next models

3

Table of contents

Other Steiner Farm Equipment manuals