Steiss 8 Series User manual

Grade

* This ‘Grade’ is a guide only. Each individual must be assessed

by a tissue viability specialist, the correct product chosen and set

to operate according to the patient’s needs. Regular repositioning

schedules need to be in place as this product does not replace

good nursing care.

Digital Auto Sensor

Alternating Air- Pressure

Mattress System

USER MANUAL

SERIES

8

DX860

Grade*4

Contents Page

1.The

Purpose of this

Manual

2.lmportant

Safeguar

d

3.Quick

Start-up

guide

Arrival of

Product

Preparation of

area

Inflation of

mattress

Mattress

CPR

Check

Mattress Comfort

Check

Hand

Check

4.Emergency

Air Release

-

CPR Valve Function

5.Alarms

Power ON/OFF

Low

Pressure

Power Failure

Al

arm

Movement

Al

arm

Deactivation of Audible

Al

arm

6.Product Description

Intended

Use

Features of Master Control

Unit/pump

Pump

Features

7

.

Instructions

for Proper

use

8.

Maintenance and Troubleshooting

9.Cleaning

& Disinfection Protocol

Cleaning of Mattress

Cover

Cleaning of

Mattress Cells

Cleaning of Master Control

Unit

Cleaning of

Ai

r Filter

10.

H o w t o r eplace Air

Filter

11.Storage

&

Care

12. Specifica

tio

n

I Technical Data

13.

EMC (Electro Magnetic Compatibility) Guide

14.

Waste

Disposal

15.

Symbols

Used

16.

Expected Service Life

17.

Warranty

18.

Legal Disclaimer.

19.Service

Guidelines &

Equipment

Notes

Steiss Service

Record

page

1

page2

page

3

-4

page

3

page

3

page

4-5

page6

page6

page6

page7

page

7-8

page

7

page

7

page

7

page

8

page

8

page 9-11

page

9

page9

page

10

page

11

page

12

page

13-14

page

13

page

14

page

14

page

14

page

14

page

15

page

16

page

17-20

page

21

page

21

page

21

page

22

page

22

page

23-25

page

23

page

24

page

25

Contents

Page

1

1.The

Purpose

of this

Manual

This operation manual mainly focused on the setup, cleaning and routine maintenance of

the Steiss

DX860

Alternating

Pressure Mattress Replacement System. The

Steiss

DX860

is a

high

-s

pecification alternating

Air-

pressure mattress replacement system designed to prevent and

treat pressure ulcer up

to grade

4

We recommend

you keeping this manual handy to answer most of the questions

related to

the

system.

NOTE: This

manual

is just a guide and we advise all Nurses &Cares to take responsibility for the care of their

patients,including the responsibility for questioning any matters in the manual should they be in any doubt

1. The Purpose of this Manual

2. Important Safeguards

2

2

2. Important Safeguards

PLEASE READ ALL INSTRUCTIONS BEFORE USING THIS ELECTRICAL APPLIANCE

Warning & Cautions

Only connect the Steiss 8 pump to a M60 mattress.

Only connect the master control unit of the

DX860

to a220-240V power source.

Place power cable and pump away from head end to reduce risk of strangulation or entanglement with

any cord, cable or pipe.

Keep the tubes free of kinks.

Disconnect the control unit power plug before moving the bed.

Do not unplug the control unit by pulling the cord.

Only use the DX860 products indoors.

Only use this product if it has an un-damaged cord or plug.

Keep the cord away from heated surfaces.

Do not use this product, if it has been dropped or damaged, or it has been submerged into water.

(Do return the product to a service centre to be examined and/or repaired).

Do not expose the control unit to humidity or direct moisture.

Operation Temp: 15 to 35 degree, 30% to 75% non-condensing

Never blocktheair openingsor insert anyobjectinto them.

Never place mattress on acouchor sofa where the air openingscouldbe blocked.

Do not sprayany aerosolsonto the mattress.

Note cleaning/washing instructions laterin manual.

Thisdeviceis not registered as AP/APG protected.

Do contact your service centre if this product is not working properly.

Use only manufacturer-approved parts when maintaining or repairing the Steiss DX860. Use

only manufacturer-approved accessories with this device.

control unit.

Use of other parts and accessories in conjunction with this device is not recommended.

The control unit can only be repaired by an authorized technician.

Re-positioning of the patient is always recommended when using an alternating pressure air mattress.

It is advisable to monitor product when used by, on or near children and physically/mentally challenged

individuals

If any pain, redness, irritation, numbness or swelling occurs while using cushion, please inform healthcare

professional for them to assess and evaluate the situation.

Should the carer decide to insert extra foam or place this mattress on top of another mattress, it is at all

times the carer’s responsibility to ensure that there is adequate/legal clearance from top of this mattress to

the top of the siderails.

In the event of an extended power failure, it is advisable to disconnect the air hose from the pump and

attach the transport clip.

Do remember to reconnect the mattress to the pump once the power has been re-established.

DX860

3.Quick Start-up guide DX860

ARRIVAL OF

PRODUCT

BOX1: Air-Alternating

mattress

,

pump

,

manual

PREPARATION OF

AREA

a

.

Place the Steiss

DX860

Alternating

Pressure Mattress directly on top of the bed frame

and ensure that the air hose is at the foot of the bed. Secure the mattress using the straps at the

base.

CAUTION: When securing the mattress to the bed, please ensure that you are securing on the

movable parts of the bed and NOT the actual bed

fram

e

this will

obstruct

the

mechanical

movement and could cause damage to both mattress and bed. The warranty for both

the

mattress and the bed may well be

invalidated

if damage is caused by this

means.

NOTE: When the mattress is opened for the first time, please write today’s date (with a non-

Phenol based pen) in the top white box on the PU cover and add in the 'same date' for

the

following

three years in the bottom white box. This will remind the care team when the

annual

service is

due.

b. Hang the Steiss

DX860

pump at the foot of the bed. Connect the push-fit hose

connector

from the foot of the mattress to the air outlet of the pump.

c. Plug the pump power cable into the mains

outle

t.

Ensure that

electrical

cables are safe and tidy, are not

caught in the bed frame and are free from

obstruction.

Turn the power on at the mains outlet and turn the

power switch on the pump to the 'ON' position.

CAUTION:It is important to

routinely

inspect power cables to ensure they are not

obstructed

or

causing a

tripping

hazard. Check the power cable is not under strain or is

damaged.

The light will now

iII

uminate

next to

'STANDBY'

on the front panel.

3

3. Quick Start-up Guide DX860

4

INFLATION OF

MATTRESS

1. Ensure that the Cardio Pulmonary Resuscitation (CPR) valve of side mattress is closed.

CAUTION:

It

is

important

to

ensure

that no

person/object

is

Iying/sitting

on the

mattress

when

it

is

initially being inflated

2. Press the front ON/OFF button to put the pump into 'OPERATION'

The light will illuminate next to OPERATE' on the front

pane

l.

During this inflation period:

The 'ALARM' button will automatically iIIuminate as there is 'Iow

pressure.'

The audible alarm is set with a delay function to take into consideration the inflation time.

The Pump will automatically be set into

‘

ACTIVE' mode

The light will illuminate next to

'ACTIVE'

3

.

Press th

e

'MAX' button fo

r

a

fast

inflatio

n of themattress

.

The pump will begin to inflate the air cells in

‘

STATIC' mode with maximum pressure for approximately

30

-4

0

minutes. The low-pressure LED will be displayed until the mattress is properly

inflated.

The light will illuminate next to ‘STATIC’.

NOTE:

‘

MAX' and

‘

STATIC'

modes

are

designed

to

return

to

‘

dynamic mode'

after 30

minutes

activation.

5

4

.

Whe

n the

mattress is

fully

inflate

d

,

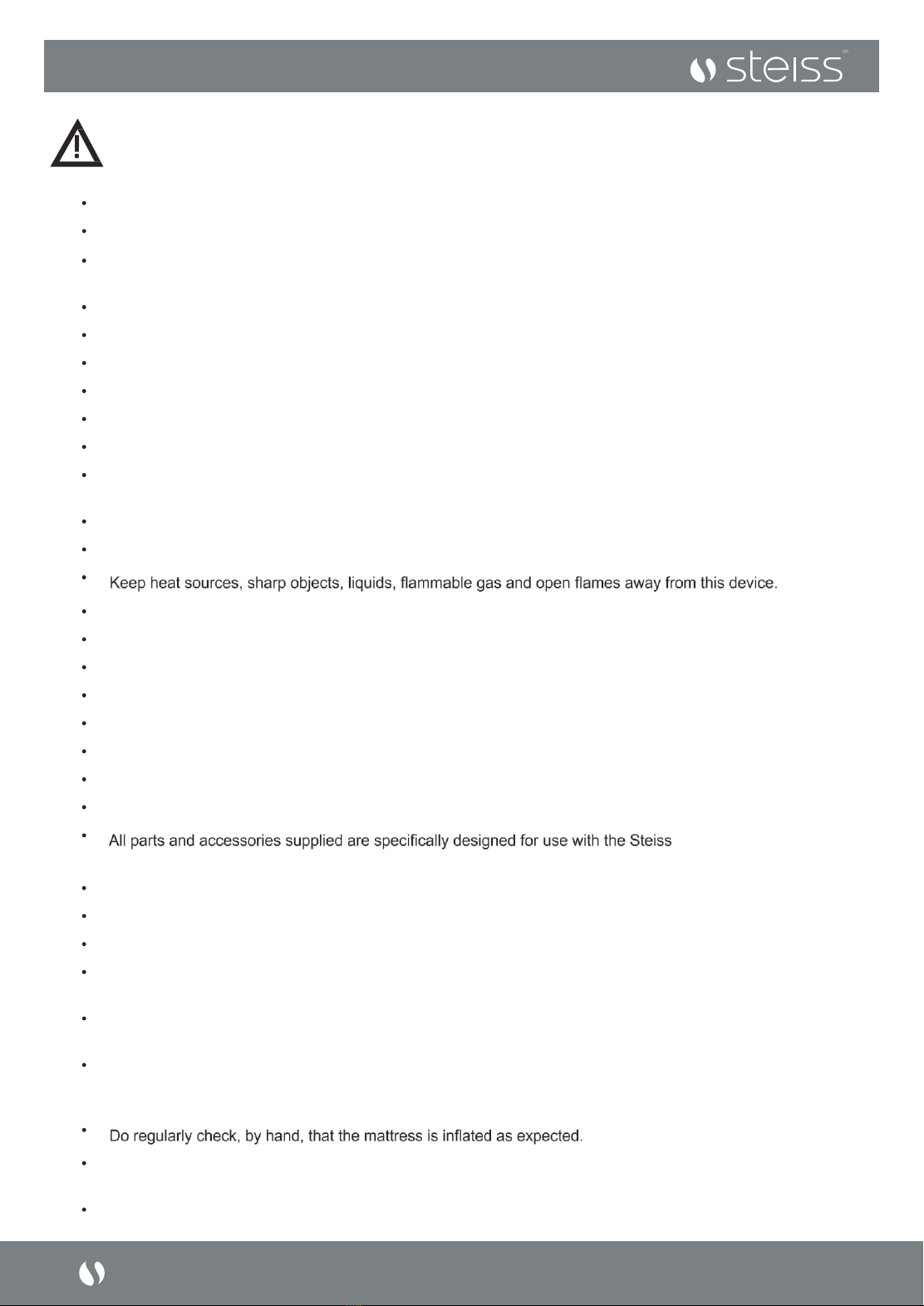

set the correct weight on the

comfort control

.

This control enables you

to

adjust the

firmness of the mattress

. The mattress is ready to be used.

The pump and mattress will then run continuously in 'dynamic mode'

.

Th

e

alternating function will inflate and

deflate the

mattress

cells over a 10 minute cycle (default setting).

5.

The carer can press

the

‘

MODE'

button

to put the

mattress

into

‘

STATIC'

mode for ease when performing

nursing tasks.

6. The 'alternating

function' can be

adjusted to the needs of the

patient

using the ratio

setting'

by pressing

the central of the button.

The choices being

10

,

20

or 30 minutes cycles.

The LOCK

facility

can be

de-activated

by

deliberately holding

own the 'LOCK' button for

3

seconds.

The light will

iII

uminate

next to 'ALARM'

button

when active

The LOCK

facility

can be

de-activated

by

deliberately holding

own the 'LOCK' button for

3

seconds.

7

,

The

mattress

is now ready to be used.

NOTE: When the

patient's

position

changes

,

the

mattress pressure will drop from the set

pressure

and the audible alarm will

switch

to a

five-minute

delay to avoid the alarm being

activated.

6

CAUTION:

During a power cut, pump will stop functioning and

power failure

LED indicator

may be flashing as well as the power failure alarm may be triggered if equipped, these are

normal.

The pump will return to its normal operation when power is resumed.

7

6. Instructions for Proper Use

The

DX860

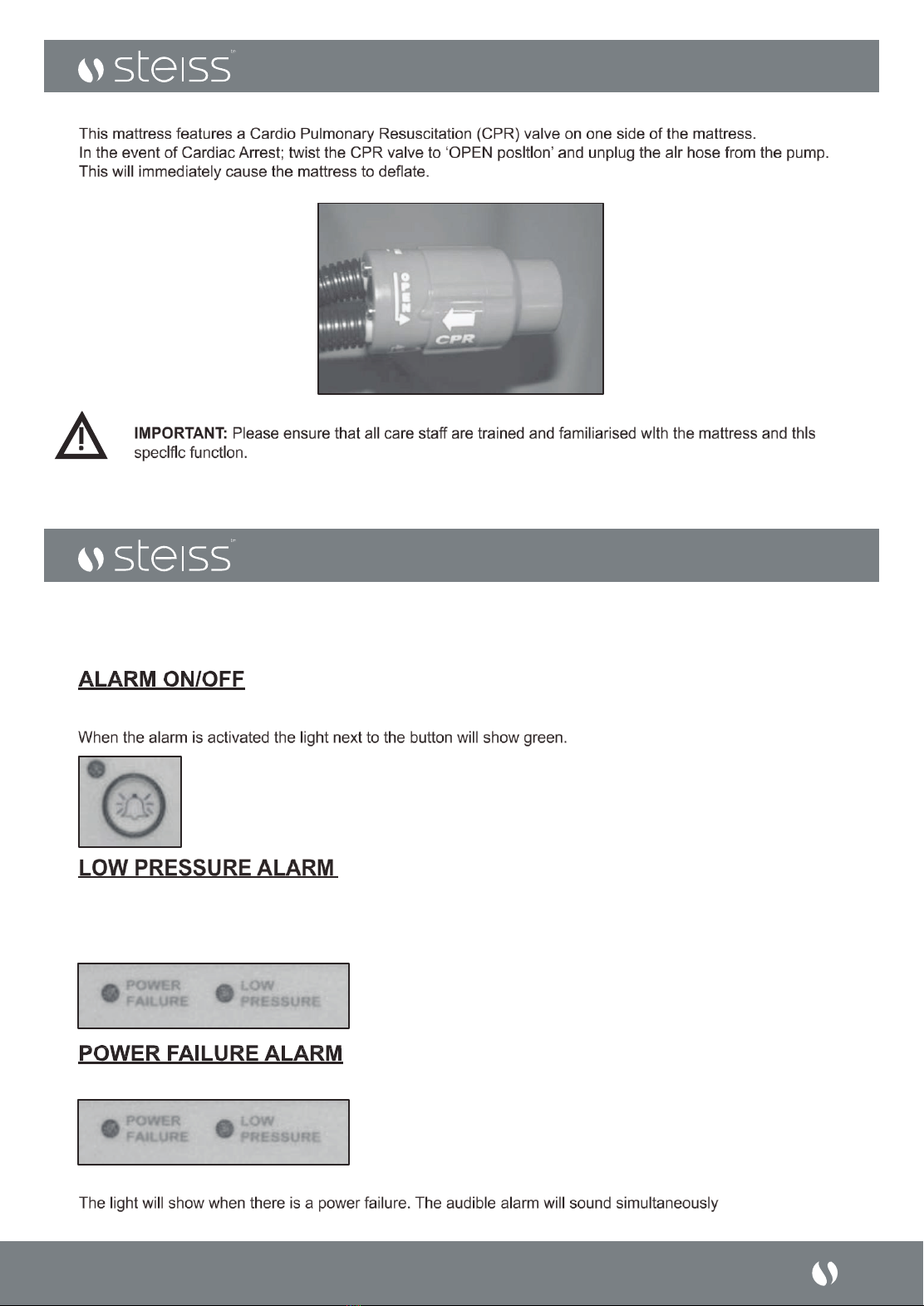

Alternating Air-Pressure Mattress System is equipped with visual and audible alarms in the event of low pressure or power

failure.

Push the Alarm button to turn on or off.

While the system is operating, if the pressure in the mattress is insufficient over 45 minutes, the audio alarm will be

activated and the ‘Low Pressure’ light will be illuminated on the panel.

4. Emergency Air Release – CPR Valve Function

5. Alarms

The

DX860

Alternating Air-Pressure Mattress System is equipped with visual and audible alarms in the event of low pressure or power

failure.

Push the Alarm button to turn on or off.

While the system is operating, if the pressure in the mattress is insufficient over 45 minutes, the audio alarm will be

activated and the ‘Low Pressure’ light will be illuminated on the panel.

5. Alarms

8

To deactivate the audible alarm by press the audible alarm button.

6. Product Description

9

6. Product Description

9

INTENDED USE

The Steiss

DX860

is a high specification Alternating

Air-Pressure Full Mattress Replacement System and is

designed to prevent and treat pressure ulcers up to grade 4.

The system uses the latest technology in alternating mattress therapy to provide accurate pressure settings for

individual patients’ needs. The 20 cells of the mattress are arranged in a transverse manner to provide extra

protection and comfort for the patient.

Through the use of alternating therapy Steiss

DX860

system works on the principle of actively

the selectable cycles 10,20 and 30 minute. This results in the reduction of surface pressures helping to prevent

tissue breakdown and encourage healing.

For added durability, and longer working life, your Steiss

DX860

mattress has been constructed using high

strength components and premium grade materials. The mattress features a heavy duty base layer and a

100% waterproof, multi-stretch vapor permeable PU cover to reduce risks of friction and shear.

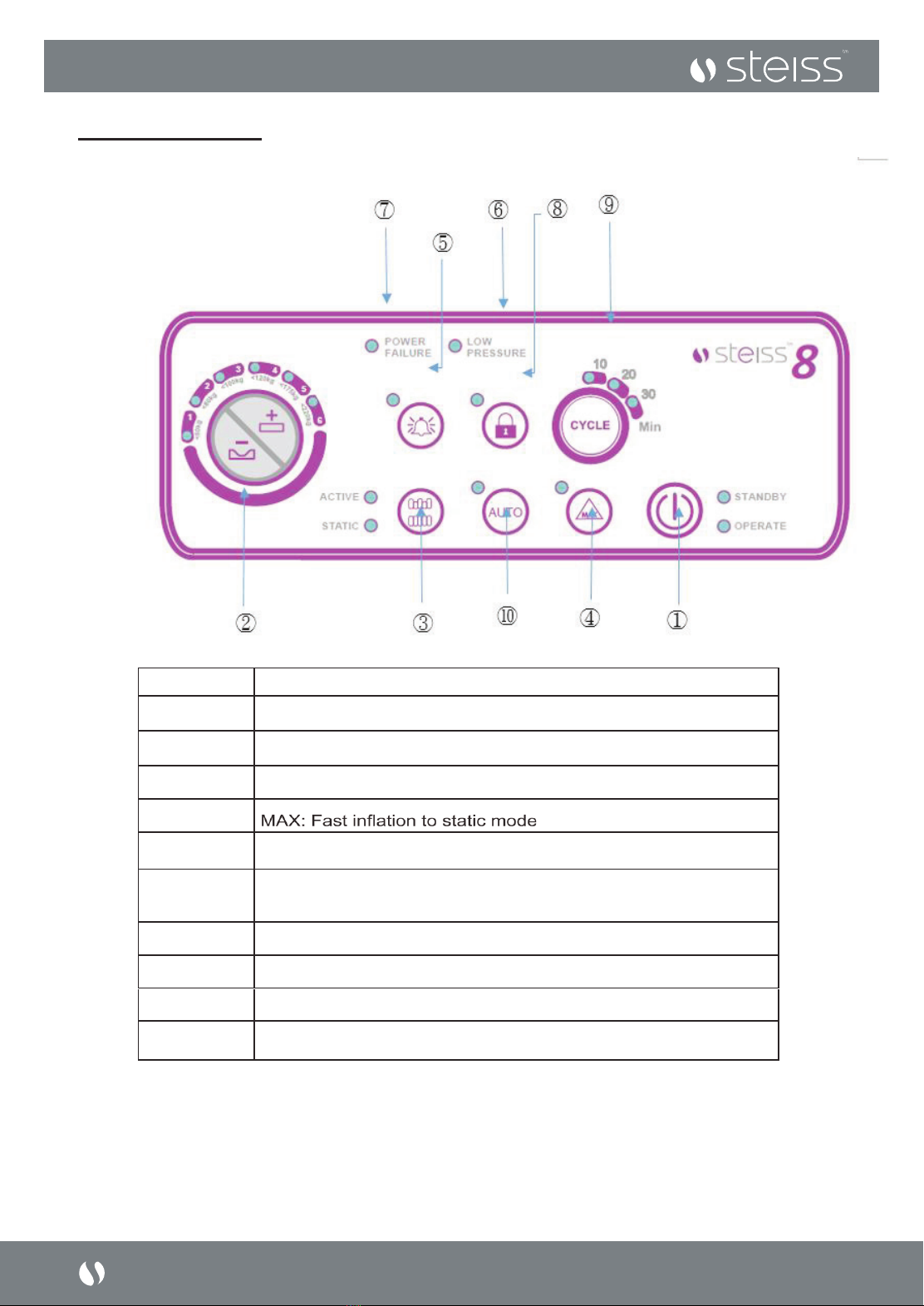

FEATURES OF MASTER CONTROL UNIT/PUMP

Advanced Digital Full Mattress Replacement System, suitable for hospital, home and care units

Adjustable digital control unit with 10, 20 or 30 min cycles for various patient scenarios.

Grade 4 risk / management

1:2 alternation therapy providing a very low interface pressure.

Intelligent Touch Pad Panel with Pictograms for simple control

Alternating & Static settings

Static mode with 30 min auto-return for backup protection

Unique ‘reverse-pressure’ sensing.

Intuitive LED indicator for function status

6 adjustable comfort settings

Visual and audible alarms for low pressure and power failure

Auto lock-out (one minute) function to protect from unauthorised changes

Transport security device

NOTE: The audio alarm will resume normal operation after the initial 45 minutes

of

10

PUMP FEATURES

Item

Description

1 Power Switch

2

Comfort Setting

3 Therapy mode selection

4

5 Alarm mute

6

Low Pressure: instant low pressure alarm. Audio alarm will be

triggered after 5 minutes if alow pressure is not resolved

7 Power Failure: Instant power failure alarm

8

Control Panel Lock

9

Dynamic alternating cycle time setting in minute

10

Auto Sensing: Detect the patient weight automatically

10

11

7. Instructions for Proper Use

11

FEATURES-MATTRESS

•

Advanced Digital Full Mattress Replacement

System

suitable for

hospital,

home and care

units

•

Grade 4 risk I management

•

1:2 alternation therapy for superior

pressure care

•

20 full depth alternating cells for superior pressure

management

•

Separate pocket for optional foam

insert

underneat

h

air

cells

•

7 specialist narrow heel cells for

targeted pressure care

•3 static

head cell section for greater patient

comfort

•

Fi gure -of-8 air

circulation

•

Multi-stretch,

highly

vapour-permeable

PU top cover providing low

shear, friction

and moisture

protection

•

Static mode with 30 minute auto-return for safer patient transfers and nursing

tasks

•

External CPR design for fast emergency

deflation

•

Anti-kink tubing for added safety and r e l

iability

•

Integrated

power cable management assists in safety and organization of power cables

•

Premium quality all-round zip with large waterfall cover for improved infection control

•

Modularized design allows for easy cleaning and replacement of air

cells

•

Strong base-mount straps holding the

mattress

when insitu and when in the rolled-form during storage

•

Transport Facility with stopper ensuring mattress remains inflated even though disconnected from pump

•

Recom

mended

minimum safe working capacity of 40kg/6.3

stone

•

Reco

mmended

maximum safe working capacity of 220kg/34.64

stone

7. Instructions for Proper Use

It is important to read this information before using the Steiss

DX860

Alternating Air Pressure Mattress

System.Please follow the

guideline

below for your safety and to

maintain

the system's performance.

•

Minimum patient weight :40kg/6,3

stone

•

Maximum patient

weigh

t:

220kg/34.64

stone.

•

Avoid exposing the pump to

liquids

•

Use a Steiss

DX860

pump with a Steiss

DX860

mattress only.

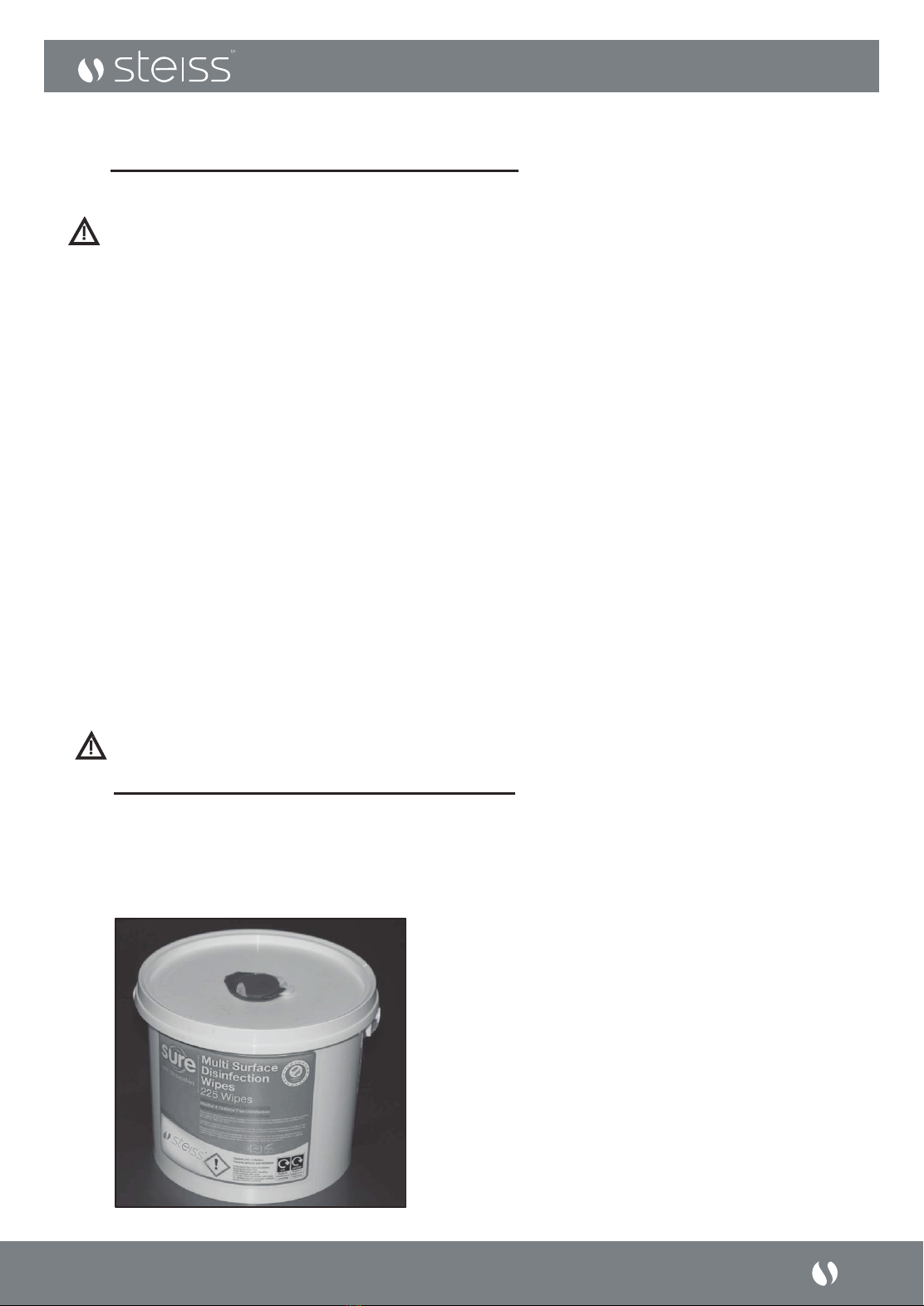

When cleaning do not use Phenol based

substances. Steiss offer Multi-surface disinfection wipes which

are ideal for cleaning both pump housing and mattress.

11

FEATURES-MATTRESS

•

Advanced Digital Full Mattress Replacement

System

suitable for

hospital,

home and care

units

•

Grade 4 risk I management

•

1:2 alternation therapy for superior

pressure care

•

20 full depth alternating cells for superior pressure

management

•

Separate pocket for optional foam

insert

underneat

h

air

cells

•

7 specialist narrow heel cells for

targeted pressure care

•3 static

head cell section for greater patient

comfort

•

Fi gure -of-8 air

circulation

•

Multi-stretch,

highly

vapour-permeable

PU top cover providing low

shear, friction

and moisture

protection

•

Static mode with 30 minute auto-return for safer patient transfers and nursing

tasks

•

External CPR design for fast emergency

deflation

•

Anti-kink tubing for added safety and r e l

iability

•

Integrated

power cable management assists in safety and organization of power cables

•

Premium quality all-round zip with large waterfall cover for improved infection control

•

Modularized design allows for easy cleaning and replacement of air

cells

•

Strong base-mount straps holding the

mattress

when insitu and when in the rolled-form during storage

•

Transport Facility with stopper ensuring mattress remains inflated even though disconnected from pump

•

Recom

mended

minimum safe working capacity of 40kg/6.3

stone

•

Reco

mmended

maximum safe working capacity of 220kg/34.64

stone

7. Instructions for Proper Use

It is important to read this information before using the Steiss

DX860

Alternating Air Pressure Mattress

System.Please follow the

guideline

below for your safety and to

maintain

the system's performance.

•

Minimum patient weight :40kg/6,3

stone

•

Maximum patient

weigh

t:

220kg/34.64

stone.

•

Avoid exposing the pump to

liquids

•

Use a Steiss

DX860

pump with a Steiss

DX860

mattress only.

When cleaning do not use Phenol based

substances. Steiss offer Multi-surface disinfection wipes which

are ideal for cleaning both pump housing and mattress.

8. Maintenance and Troubleshooting

12

12

If

issue not resolved,

please

contact your

Steiss Supplier.

8. Maintenance and Troubleshooting

Fault/Problem Description

Troubleshooting

Solution

No

indication

that the

pump

is on Check

pump unit

is

connected

to the

mains power

supply.

Ensure mains plug

is connected

and on.

Check the

pump

is

switched

on

Ensure mains plug

is connected

and on.

Check the

pump

is

switched

on.

Check

mains plug

fuse. Replace fuse if blown.

Check if

mains socket

is faulty. Try

another socket.

If

still

not working;

consult

the

Steiss

technician.

The

pump

is noisy. Make sure the

pump

is

hanging

freely Check there is

nothing rubbing

against

the pump.

Reposition.

If

still

noisy;

consult

the

Steiss

technician

Low

Pressure

in mattress/mattress

not

inflating.

Check the

pump unit

is

connected

to

the

mains power

supply.

Check the

pump

is

switched

on and

fuse in

plug

is ok.

Check

pump/mattress

air

connections

are

fitted

securely.

Ensure

air is

coming from

pump.

Ensure connectors

are fastened

securely

and

reconnect pump

air

hoses

if loose.

Check CPR is

connected correctly

and is

not

leaking.

Reconnect

CPR if

not

secure.

Check the

connector tubes for

kinks,

obstructions

or damage.

Untwist

any

kinks,

or move any

obstructions.

Check the

setting

on the

comfort

control pressure

range dial.

Turn up dial to

increase pressure,

wait

for pressure

to

stabilize

(a few

minutes

before

making another

adjustment.

Remove

filter

on back of the

pump

to

check

if it is dirty.

Replace

with

new filter.

Pump

controls

‘freeze

’

Turn off. and

unplug

the pump. Wait a few

seconds,

then

plug

the

pump

back in. Turn on the pump.

Low

pressure light

is

constantly

illuminated

or

mattress

does

not inflate

when

pump

is operating.

Check

for loose

hose

connections.

Check the CPR valve.

Check air

cells for holes/tears

(other

than where part of the design)

Make sure

connectors

are secured.

Make sure CPR valve is closed.

Replace any damaged air cells.

Consult

a

qualified service technician

if the

problem

persists.

9. Cleaning & Disinfection Protocol of all parts

13

13

Mattresscells

can be

wiped down with

a

solution

of

sodium hypochlorite

1,000ppmor any

other

non-phenol-

based

germicidal cleaning

solution.

Steiss

have

developed

a

dedicated

wipe to ease the

cleaning process for their

clients.

Please ask

your mattress supplier for

Multi-surface disinfection wipes.

CLEANING OF THE MATTRESS CELLS

10

minutes

2

minutes

5minutes

10

minutes

6

minutes

10

minutes

2

minutes

Cold

60°C

(140°F)

70°C

(158°F)

Break wash

Main wash

Main wash

Extraction

Cold Rinse

Extraction

Industrial

The

mattressshould

be cleanedon the bed

weeklyusing

a damp,

soft cloth

and

mild

detergent.

NOTE: Do not use a phenol-based cleaning solution as this may reduce the life of the

mattress.

Steiss

has

developed

a

dedicated

wipe to ease the

process for their

clients.

If the

top

PU

coverbecomes dirty, unziptopcover from bottom section

and wash.

If the PU

cover

on the

base-foambecomes dirty, unzip top cover from bottom section

andwash.

If the

top cover

or base

coverbecomesexcessivelysoiled,put

on

protective

wear and remove the

covers

from

the air

cells

and

tubing.

Place the

soiled covers

in an

appropriate plastic

bag and

consult your supplier

for

advice

on

specialistcleaning.

Then replace

with

clean covers.

If the

covers

are

minimally soiled,

then these canbe washed and

thermally disinfected

in a

washing

machine

by

following

the

procedures

below:

CLEANING OF THE MATTRESS COVER

9.

Cleaning

&

Disinfection Protocol

of all parts

Domestic

Pre-wash

Main

wash

Extraction

Cold

rinse

Extraction

Cold

70°C

(158°F)

5minutes

Note:

T

umble Drying or Tunnel Drying is not

recommended.

14

14

CLEANING OF THE MASTER CONTROL UNIT

Caution: Always switch the electrical supply to the pump and disconnect the power cord from

the

main supply before cleaningor

inspection.

Thepumpunitshouldbe cleanedweeklyusing a damp,softcloth and a milddetergent.

If the casingis especiallydirty, the pumpcanbe wipeddownwith a sodiumhypochlorite solutionto adilutionof

1,000ppm,or any EPA-approvedhospital-gradedisinfectant.

The pump casing is manufactured from ABS plastic - therefore:

NOTE: Do not use a phenol-based cleaning solution. Steiss has designed cleaning wipes called Multi-

surface disinfection wipes. Please contact your supplier for this

product.

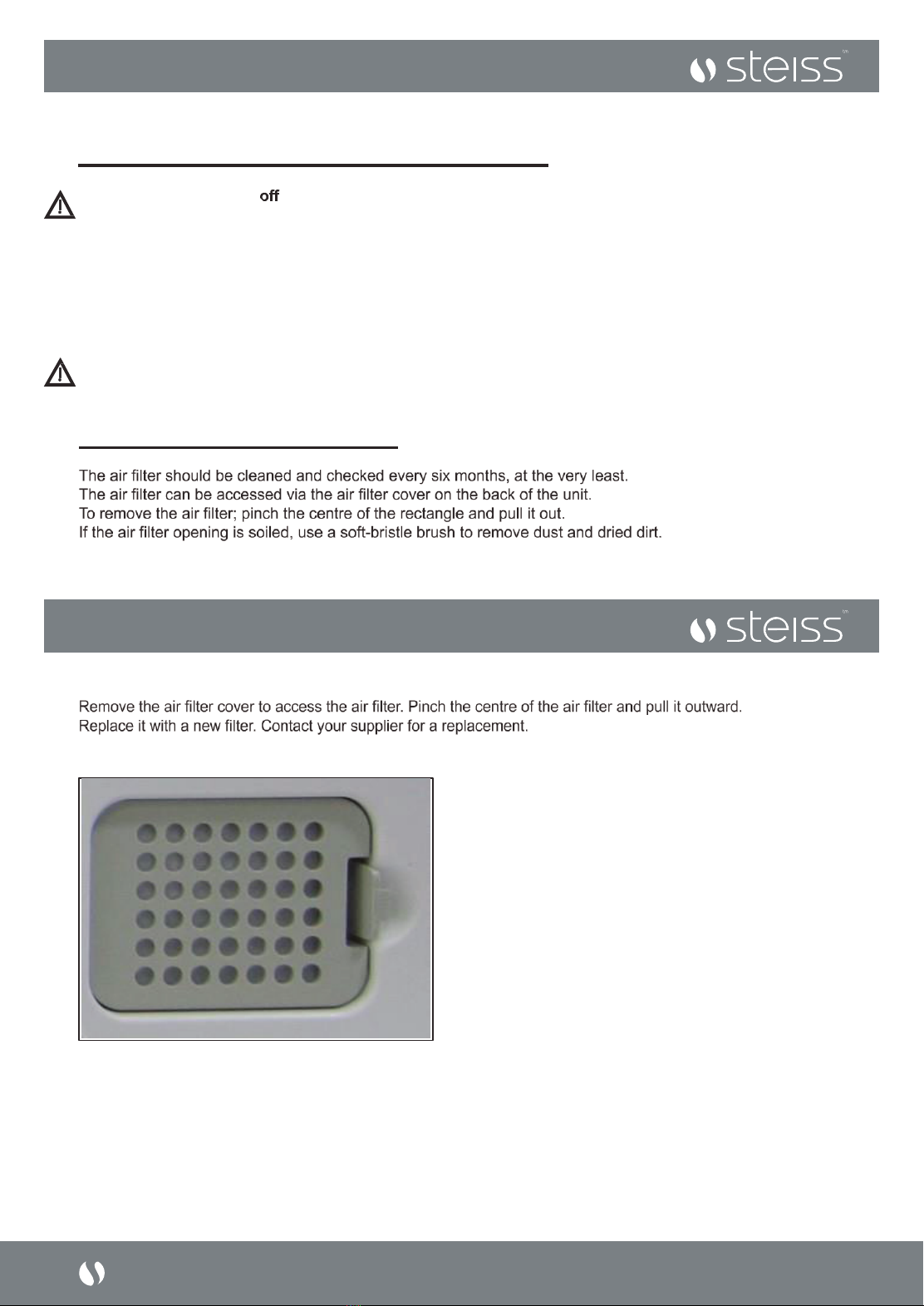

CLEANING OF THE AIR FILTER

10. How to replace the Air Filter

14

10. How to replace the Air Filter

14

14

CLEANING OF THE MASTER CONTROL UNIT

Caution: Always switch the electrical supply to the pump and disconnect the power cord from

the

main supply before cleaningor

inspection.

Thepumpunitshouldbe cleanedweeklyusing a damp,softcloth and a milddetergent.

If the casingis especiallydirty, the pumpcanbe wipeddownwith a sodiumhypochlorite solutionto adilutionof

1,000ppm,or any EPA-approvedhospital-gradedisinfectant.

The pump casing is manufactured from ABS plastic - therefore:

NOTE: Do not use a phenol-based cleaning solution. Steiss has designed cleaning wipes called Multi-

surface disinfection wipes. Please contact your supplier for this

product.

CLEANING OF THE AIR FILTER

10. How to replace the Air Filter

14

15

MATTRESS

•

•

•

•

•

Check the air

manifold for kinks

or

breaks

and replace it if necessary.

Disconnect

the CPR valve and

disconnect

the air

tubes from

the

control unit

to

allow

the

mattress

to

deflate

quickly.

Starting

at the head of the

mattress, roll

the

unit

up and use the base

mount straps

to

secure

it.

Place the

mattress

in

carry

bag

provided for this

purpose.

MASTER CONTROL UNIT/PUMP

•

•

•

Check the

power cord

and

plug for abrasions

or

excessive

wear.

Plug in the

control unit

and

verify

air

flow from

the hose

connection

ports.

Place the

control unit

in a

plastic

bag to

store

it.

Note: Please follow the recommended guidelines when

storing.

It is

recommended

the

following guidelines

are used

whenever this system

is

being stored

or

transported

to

another

location:

Temperature limitations:

Relative Humidity:

5°C (41°F) ~ 60°C

(140°F)

30% to

90%

10.

Storage

and Care of all parts

15

11. Storage and Care of all parts

16

12. Specifi cation/Technical Data

Steiss DX860 Master Control Unit / Pump

Model Name Steiss

DX860

Master Control

Unit

Size L x W x H 34.5 x 14.5 x 21cm (13.58 x 5.71 x 8.26 inches)

Weight 3.3kg (7.27lbs)

Cycle Time 10, 20, 30 minutes

Min Operating pressure 14 +/- 6mmHg

Max Operating pressure 60 +/- 6mmHg

Max Flow Rate 5 L/min

Rated Voltage AC 220-240V/50Hz

Max Current 0.1Amp

Fuse rating T1AH 250V

Class II Type BF (Not AP/APG type) / Ingress of Water Protection IP21

Mode of Operation Continuous

Environment (temperature) Operation: 15°C to 35°C (59°F to 95°F)

Storage: 5°C to 60°C (41°F to 140°F)

Environment (humidity) Operation: 30% to 75% non-condensing

Storage: 30% to 90% non-condensing

Test Standard: IEC60601-1 & IEC60601-1-2 & IEC60601-1-11

Safety Standard: CE

Steiss DX860 Mattress

Model Name

Size L x W x H (mattress)

Weight

Cells Number

Cells Material

Cover Material

Base Material

Transport Facility

Maximum Weight Capacity

Steiss

DX860

Mattress

200.66 x 90.17 x 24.13cm (79” x35.5” x9.5”)

8kg (17.64lbs)

20 cells (2 types. 13 large for body and 7 smaller for heals)

PU coated nylon

PU laminated nylon cover w/ premium quality all-round zip

PVC laminated polyester

Yes & secure

220kg

16

13. EMC-Related Notifi cations

17

Warning: Medical electrical equipment needs special precautions regarding EMC and needs to

be

installed according to the EMC (Electro Magnetic Compatibility) information provided.

Careful

consideration of this information is essential when stacking or collocating equipment and when

routing

cables and

accessories.

Warning: RF mobile communications equipment can medical electrical

equipment.

Recommended separation distances between portable and mobile RF communications equipment and

the

Steiss

DX860

The Steiss

DX860

is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the Steiss

DX860

can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and

the Steiss

DX860

as recommended below, according to the maximum output power of the communications

equipment.

Rated Maximum

output

power of transmitter

W

Separation distance according to frequency of

transmitter

(metres)

150 kHz to 80

MHz

d= 1,2 p

80 MHz to 800

MHz

d= 1,2 p

800 MHz to 2.5

GHz

d= 2,3 p

0,01 0,12 0,12 0,23

0,1 0,38 0,38 0,73

11,2 1,2 2,3

10 3,8 3,8 7,3

100 12 12 23

For transmitters rated at amaximum output power not listed above, the recommended separation distance din metres

(m) can be estimated using the equation applicable to the frequency of the transmitter, where Pis the maximum output

power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2:

17

Guidance and manufacturer’s declaration –electromagnetic

emissions

The Steiss

DX860

.

The customer or the user of the Steiss

DX860

should ensure that it is used in such an environment.

Emissions

Test Compliance

Electromagnetic environment –

guidance

RF Emissions

CISPR 11

Group 1

The Steiss

DX860

uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to cause

any interference in nearby electronic equipment.

RF Emissions

CISPR 11

Class B

The Steiss

DX860

is suitable for use in all establishments, including

domestic establishments and those directly connected to the public

low-voltage power supply network that supplies buildings used for

domestic purposes.

Harmonic Emissions

IEC 61000-3-2

Class A

Voltage Fluctuations

IEC 61000-3-3

complies

18

.

18

This manual suits for next models

1

Table of contents

Popular Accessories manuals by other brands

Daintree

Daintree GE Current WOS2-RM installation guide

USC

USC Tube Series 3500 Operator's manual

Lafferty

Lafferty Sentinel 976936 Installation & operation instructions

Yamaha

Yamaha MLA-200 owner's manual

Nexen

Nexen PH20 Installation, operation and maintenance guide

Serene House

Serene House Oracle 101205001 Instruction manual & warranty