Installation

Chapter 2 - Installation

General Installation

This chapter is designed to serve as a

general guide for the installation of a Stellar

10628 Telescopic Crane on a Stellar Service

Body. Each installation is considered unique

so certain portions of this chapter may or

may not apply to your direct application. f

a question should arise during the installation

process, please contact Stellar Customer

Service at (800) 321 3741.

This crane is designed for use with a Stellar

Service Body installed on a vehicle that

meets the minimum chassis requirements of

the crane. t is the installer’s responsibility to

assure that the crane is mounted on a

platform that will support the maximum

crane rating of this crane.

Notice:

PTO and Pump installation instructions are

provided by the corresponding

manufacturers. For more information on

which PTO and Pump fit your application,

please contact your local Stellar Distributor

or Stellar Customer Service.

Installation Notice

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall

complete the vehicle in such a manner that

it conforms to the standards in effect on the

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This

requirement shall, however, be superseded

by any conflicting provisions of a standard

that applies by its terms to vehicles

manufactured in two or more stages.

Therefore, the installer of Stellar cranes and

bodies is considered one of the

manufacturers of the vehicle. As such a

manufacturer, the installer is responsible for

compliance with all applicable federal and

state regulations. They are required to

certify that the vehicle is in compliance with

the Federal Motor Vehicle Safety Standards

and other regulations issued under the

National Traffic and Motor Vehicle Safety

Act.

Please reference the Code of Federal

Regulations, title 49 - Transportation, Volume

5 (400-999), for further information, or visit

http://www.gpoaccess.gov/nara/index.html

for the full text of Code of Federal

Regulations.

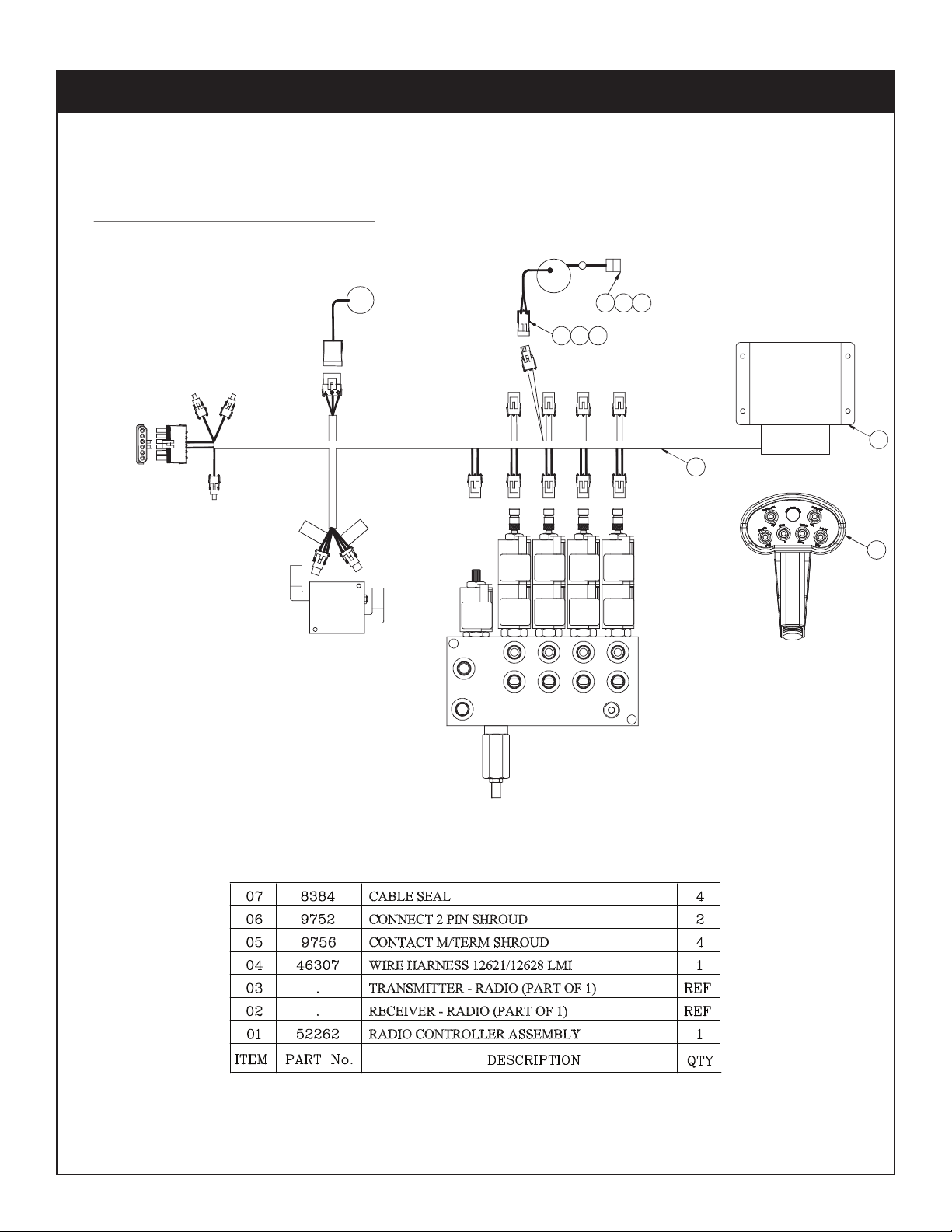

Notice: Read this age Before Installation of the Crane

Important: When installing welder units to the service

bodies, it is highly recommended that a surge

protector is installed on the chassis batteries to protect

the crane radio receiver, wiring and other electronic

devices from an unexpected electrical spike or surge.

Failure to do so could result in extensive damage to

the service body and crane electrical circuit.