Introduction

........................................................2

Precautions

........................................................2

Preparations...................................:...................3

Required Items..............................................................3

Suggested Building Supplies

......................................3

Optional Building Supplies

..........................................4

Building

Notes

....................................................4

Adhesives

......................................................................5

Glossary ofTerms Usedin

This

Manual

&

Plans

..........................................5

Die-Cut

Pattern

..................................................7

Build

the

Stabilizer

&

Elevator

..........................8

Build the Formers

........................................................8

Build

the

Fin

and Rudder

....................................9

Bevel the

Fin

&

Rudder

................................................9

Cutting

the

Hinge

Slots

..............................................10

Build

the

Fuselage

............................................10

Fuse

Side Construction

..............................................10

Fuse

Structure

Assembly............................................

11

Preparing the Canopy

................................................13

Build

the

Wing

..................................................14

Joining

the

Wing

Panels....................................17

Align

the

Stab

to

the

Wing

..............................18

Install

the

Forward Wing

Fillet..........................18

Balance

the

Model

Laterally

............................19

Finishing............................................................19

Final

Assembly

..................................................19

Radio

Installation..............................................20

Pushrod

Installation..........................................21

Final

Hookups

&

Checks

..................................22

Radio Settings

............................................................22

Balance

the

Model

............................................22

Checking

for

Warps

..........................................23

Preflight............................................................

24

Charge

the

Batteries

........................................24

Find

a

Safe

Place

to

Fly

....................................24

Range Check

the

Radio

....................................24

AMA

Safety

Code (excerpt)

..............................24

Flying................................................................25

Trim

Flights

......................................................25

Your First Hi-start Launch

................................25

First

Flights

......................................................26

Thermal

Flying

..................................................26

Facts

About

Thermals........................................27

Thermal Soaring................................................27

Pointers

for

Contest

Flying

..............................28

Slope

Soaring....................................................29

Flying

..........................................................................29

Slope Landings

..........................................................29

Ballasting..........................................................30

Flight

Log

............................................Back

Cover

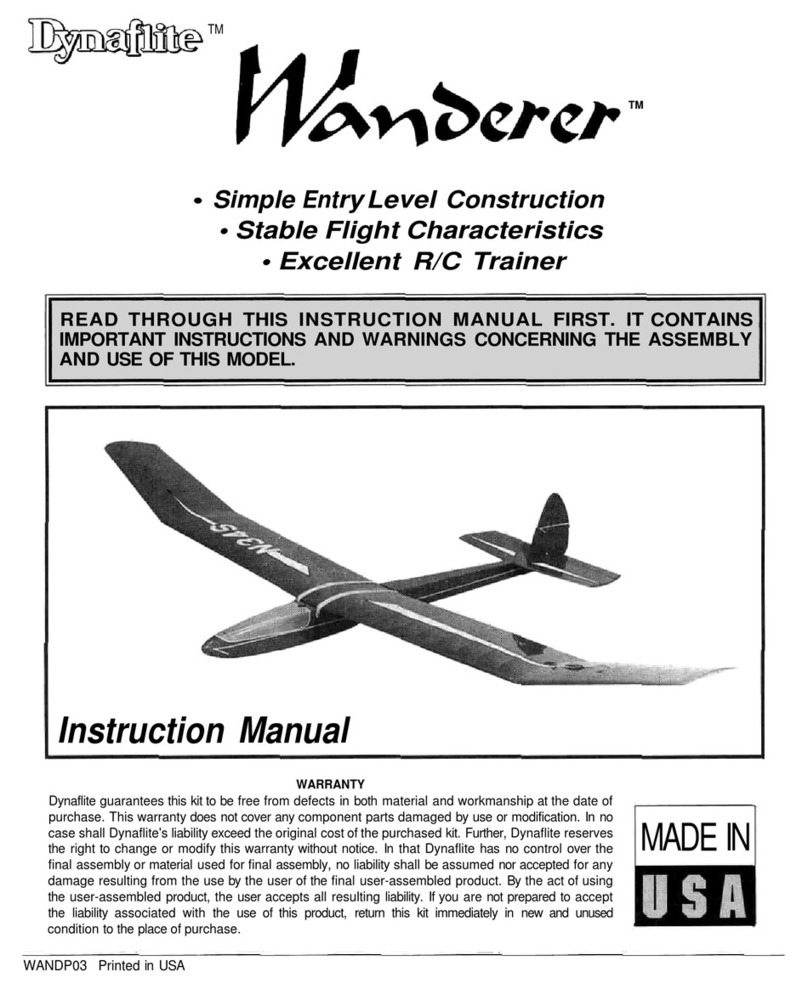

Congratulations on your choice of this kitfor

yourproject. Ifyou arenew to Radio Control

Modeling, we would like to take a minuteto

give you some information on the Daydream.

The Daydream was designed to use a modern

airfoilspecificallydesigned forthermalgliders.

The constructionof the Daydream uses the

minimum amount ofmaterialsto keep the

overall weight down. The combination of these

provides you with a model that will beable to

catch and ride out the slightest thermal.

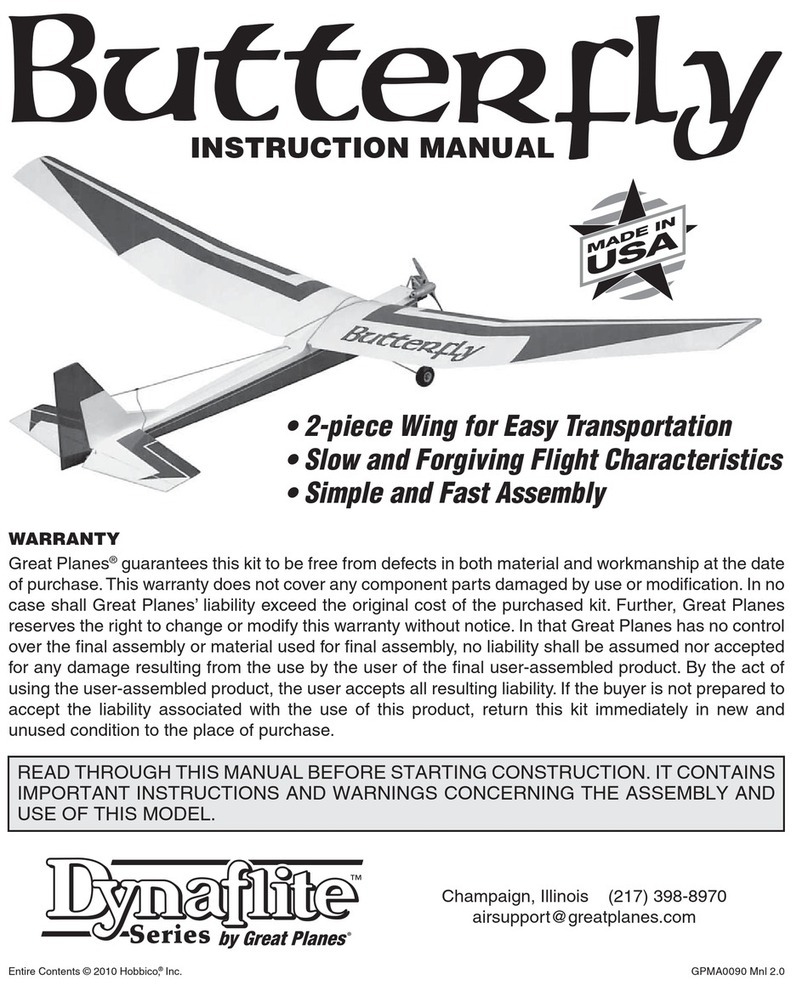

At Dynaflite we take pride inoffering kitsthat

are simple and straightforwardto build and

provide value for your modeling dollar.

Tomake your R/Cmodeling experience totally

enjoyable,we recommendthat you get

assistancewith yourfirstflightsfroman

experienced,knowledgeablemodeler.You'll

learnfasterand avoidrisk to your model before

you're trulyreadyto solo.Your localhobby

shop has informationabout flyingclubs inyour

areawhosemembership includes qualified

instructors.

You canalsocontactthe nationalAcademy of

ModelAeronautics(AMA),whichhasmorethan

2,500 charteredclubs acrossthe country. We

recommendyou jointhe AMA, which will

provide you with insurancecoverageat AMA

club sites and events. AMA Membership is

required at chartered club fields wherequalified

2