Stem NCUM 20 User manual

OPERATION

The safety unit NCUM20 integrates the unit for uncontrolled movement and a

leveling control unit. It can be used in different way

Mode with independent leveling (Fig.1): in some application is needed to

separate the elevator levelling from the UCM detector to avoid, in case of exit

from leveling zone, that the controller put the elevator out of order.

In this case, the system needs to add to the NCUM20, also a control unit for the

leveling (NC80,NC96LIFT) with an additional 2 contacts sensor.

The leveling unit output, in parallel with the safety door contact, make the

optoisolated input C11 The magnet used to activate the double contacts sensor

wired on the inputs S11-S12, S21-S22 must be positioned so that its activation

will be longer then the activation of the leveling control unit sensors

If the input PS2 is connected before the car door contact, the NCUM will

automatic restart closing its outputs (13-14/ 23-24) in case a safety contact before

the door has been opened ( it's not an unintended car movement) . If the power

supply sense (PS2) is not used, the door contact has to be wired at the

beginning of the elevator safety circuit.

Mode with or without leveling on the elevator safety circuit (Fig.2):the control

unit NCUM20 integrated as well the leveling function as the uncontrolled

movement function.

The safety door contact is wired in parallel with the outputs 53-54 in case it is

needed the leveling with open doors, and it is connected to the optoisolated input

C11 If the leveling is not necessary the outputs 43-44 must be wired on the input

S41.

If the input PS2 is connected before the car door contact, the NCUM will

automatic restart closing its outputs (13-14/ 23-24) in case a safety contact before

the door has been opened ( it's not an unintended car movement) . If the power

supply sense (PS2) is not used, the door contact has to be wired at the

beginning of the elevator safety circuit.

Mode independent inputs (Fig.3): in this case the system is completely

independent from the elevator safety circuit, in fact it is used the input S42

provided by a second safety door contact(mechanical or provided from the Stem

IP67 Unit) while at the input S41 is connected the output 43-44 of the leveling unit.

The 53-54 can be used as standard leveling output

The unit NCUM20 monitors the signal status of the inputs (C11-C12, S41-S41)

and if a dangerous event happen, it will open the safety outputs 13-14/ 23-24

The unit NCUM20 allows the leveling operation with open doors. Monitoring inputs

S11-S12 and S21-S22it will open the safety contacts 43-44/53-54 if the car

moving out the doors zone(detail on the leveling operation in fig.7 and fig.8)

Hazardous event

Is consider an Hazardous event a car movement with the doors open out of the

door zone. Therefore the positioning of the magnet for the leveling must be due to

guarantee the car stop within one meter in case of uncontroled movement

as indicated in the normative.

Start

As required by law, if a hazardous event occurs, the output will remain open until

the safe operation by a competent person will bring the system in safety

conditions and send a signal to start contacts (S31-S32). If a temporary lack of

power supply happen, the module will continue to work if it is connected to the

battery.

SAFETY PRECAUTIONS

The inputs of the unit(C11-C12-S41-S42) must be safety contacts comply

with paragraph 5.11.2 of the standards EN 81-20:2014 and perform a

function of personal protection; they should not be bypassed (by shorting the

contacts), moved, removed or rendered ineffective by other means. Incorrect

installation or manipulation can cause serious personal injury. The

manufacturer or installer of the machine is responsible for the proper and

safe operation.

The auxiliary output 31-32-33/61-62-63 provides a indication on the status of

the device, so it must not be used in any way as a safety output.

The NCUM20 is not suitable for operation in the presence of ionizing and non

ionizing radiation (X-rays, microwaves, lasers, ultraviolet rays).

The NCUM20 control unit must be assembled in a suitable operating area

(switch cabinet, protective housing).

In the following cases you must use a IP54 cabinet:

- If the safety UCM outputs (13-14,23-24) have a voltage difference between

them greater than 160V

- if outputs of the leveling safety output (43-44, 53-54) have a difference of

voltage between them exceeding 160V

Operating instructions for safety control unit mod. NCUM 20 - Original instructions -

!

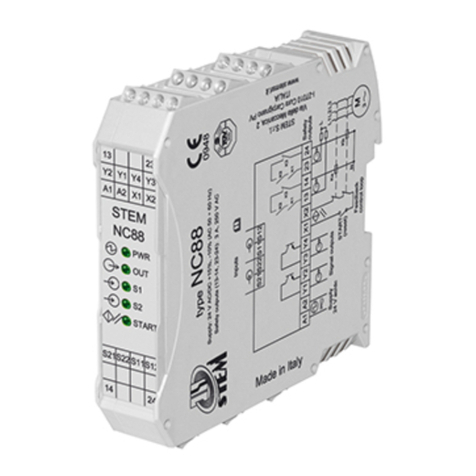

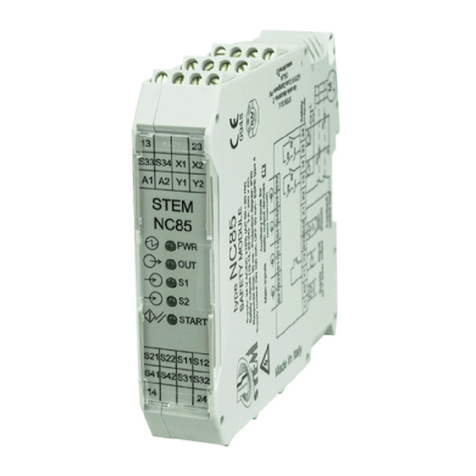

DESCRIPTION

The unit NCUM20 is a safety device used to detect the uncontrolled movement

of elevators in accordance with EN 81-20:2014, EN 81-50:2014.The operation

of this module is based on the use of guided safety relay contacts.

ELECTRICAL CONNECTION

Electrical connection must be performed by authorized personnel only.

All the electrical inputs must either be isolated from the mains supply by

a separate coils safety transformer in accordance with EN IEC 61558-2-6

with limited output voltage in the event of a defect or by another

equivalent movable mechanism.

Each safety relay output (13-14/23-24/43-44/5354) has a maximum

current of 3 A; the supply connected to the outputs must be protected

from overcurrents by devices adequate to the loads that have to be

protected.

All the output contacts must have an adequate protective circuit for

capacitive and inductive loads. A fast-blow 500mA fuse must be

connected to input A3 of the battery (+12 V).

If a common power supply is used, all the inductive and capacitive loads

(e.g. relay contactors) connected to the power supply must be connected

to appropriate interference suppressors.

ASSEMBLY

Installation must be performed by authorized personnel only.

The unit is installed by clipping it to a standard 35 mm top-hat rail.

SERVICE AND INSPECTION

The correct functioning of the NCUM20 safety unit must be controlled by the

operator and/or by the control circuit of the elevator periodically by checking:

- correct switching function

- secure mounting of components

- correct connection fixing.

The monitoring function of the unit is done at every switching.

In the event of damage or wear and tear, the damaged system component

must be replaced.

Liability coverage is void under the following circumstances:

- if instructions are not followed

- non-compliance with safety regulations

- installation and electrical connection not performed by authorized personnel

- non-implementation of functional checks.

SETUP

If the control unit does not appear to function when operating voltage is

applied (green "Power" LED does not light up), the unit must be returned

unopened to the manufacturer.

Check whether the safety outputs are being switched (see LED display) by

activating the two inputs and START.

LED

Second door contact*: CLOSED

Power supply

Function

State

Color

Green

Output 13-14 e 23-24: CLOSED

LED Table

on

CP

Green on

PWR

Green on

OUT

* Second contact of a double door contacts or second output of the

STEM IP67 safety door system.

If the contacts S41 and S42 are bothclosed (+12 V),

the CP LED remains off.

!

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMANCUM20 rev.4 15/02/2017

Levelling Sensor S1 S1 Green on

Levelling Sensor S2 S2 Green on

Output 43-44 e 53-54: CLOSED OUTL Green on

STOPPING DEVICES

The stopping elements usable with our device are: electrical brakes,

solenoid lock to activate the overspeed governor, solenoid valves.

The stopping elements have to comply the EN 81-20:2014. If the

switching current to energize the braking element is greater than 3A (6A

in case of outputs 13-14/23-24 connected in parallel) appropriate

contactors in accordance to the point 5.11.2 of the EN 81-20:2014, have

to be installed between NCUM and the coil of the braking elements. The

response time of the contactors have to be considered in the global

system response time calculation.

- 1 -

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

If the elevator car is at the floor, the safety output (13-14, 23-24) remain

closed instead, if the cabin is out the floor, the level unit is open and in

cosequence also the safety outputs (13-14, 23-24) will be open.

The unit sense the presence of power supply, thanks the inputs PS1,PS2

and it will send an automatic start to close the outputs contact.

Operating instructions for safety control unit mod. NCUM 20 - Original instructions -

signal Output

Power supply

24 V ac/dc

~~ +

-

V+

3233 31

14

Doors

contact

SAFETY

CHAIN

voltage

Safety chain

IN Safety chain

OUT

FIG. 1 Indipendent levelling mode

24

K21

K11

Safety

outputs

UCM

K22

K12

+

4454

K51

K41

K52

K42

~~ +

-

Start

(Leveling)

Feedback

control loop

6263 61

+

L

Signal output

Power supply

24 V ac/dc

~~ +

-

V+

3233 31

14

Feedback

control loop

Start

(UCM)

Ka

Kb

NDoors

Contact

SAFETY

CHAIN

Voltage

Safety Chain

IN Safety Chain

OUT

24

S42 43C11

C12

A2 A1

13 23 S32 S22

leveling

unit

K21

K11

Safety

outputs

K22

K12

S12

+53

4454

K51

K41

K52

K42

Safety

levelling

output

PS2PS1

~~ +

-

C11

S41

Start

(Leveling)

S33

S11S31

Feedback control

loop

6263 61

A3

A4 +

+

Signal output

Power supply

24 V ac/dc

~~ +

-

V+

3233 31

14

SAFETY

CHAIN

voltage

24

K21

K11

Safety

output

UCM

K22

K12

+

4454

K51

K41

K52

K42

Levelling

safety output

~~ +

-

Start

(Leveling)

Feedback control

loop

6263 61

+

+

IP67

SAFETY

CHAIN

IZ

N.O.

IZ

N.O.

IS

N.O.

ID

ID IS

SUM

2 NO separated

MZ

MD

MS

IUM

N.O.

N.O.

N.O.

IZ

N.O.

IS

N.O.

ID

MZ

MD

MS

N.O.

IZ

N.O.

IS

N.O.

ID

MZ

MD

MS

L

Feedback control

loop

Start

(UCM)

Ka

Kb

N

L

Feedback

control loop

Start

(UCM)

Ka

Kb

STOP

DEVICE 1

N

FIG. 2 with or without levelling on safety chain mode

FIG. 3 Indipendent safety chain mode

43 - 44

C12

S42

S41

A1

A2

A4

PS1

PS2

31

32

33

53 - 54

C11

S11 - S12

S21 - S22

S12 - S33

S31 - S32

V+

61

62

63

A3

13 - 14

23 - 24

Safety circuit input AC/DC (voltage according to ordering code)

Safety circuit voltage reference AC/DC

Second door conctact input

Second levelling unit contact input

Leveling unit first sensor input

Leveling unit second sensor input

Start / feedback leveling contact

Start / feedback UCM contact

Power supply module 24VDC positive / 24VAC

Power supply module 24VDC negative / 24VAC

Positive 12V battery power supply (connect 500 mA fast blow fuse)

Negative 12V DC battery voltage

UCM internal suppy positive supply volatge

Sense power supply pin1 AC/DC(Vmax Voltage safety circuit)

Sense power supply pin2 AC/DC(Vmax Voltage safety circuit)

UCM safety output1

UCM safety output2

Auxiliary output UCM: Comon

Auxiliary output UCM: NC

Auxiliary output UCM: NO

Levelling unit safety output1

Levelling unit safety output2

Levelling auxiliary output: Common

Levelling auxiliary output: NC

Levelling auxiliary output: NO

S21

-

-

S42 43C11

C12

A2 A1

13 23 S32 S22

S12 53

PS2

PS1

C11

S41

S33S11

S31 S21

S42 43C11C12A2 A1

13 23 S32 S22

S12 53

PS2

PS1

C11

S41

S33

S11S31 S21

A3

A4

A3

A4

-

-

-

-

Safety circuit

reference

STOP

DEVICE 2

STOP

DEVICE 1

STOP

DEVICE 2

STOP

DEVICE 1

STOP

DEVICE 2

Signal output

Signal output

signal Output

- 2 -

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Safety circuit

reference

Safety circuit

reference Safety circuit

reference

Safety circuit

reference Safety circuit

reference

Battery

12 V dc

Battery

12 V dc

Battery

12 V dc

CONNECTORS PINS FUNCTIONALITY

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMA NCUM20 rev.4 15/02/2017

Operating instructions for safety control unit mod. NCUM 20 - Original instructions -

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

ts1

43-44 / 53-54

S1

S2

Manual restart timing diagram

START

Automatic restart timing diagram

t2

2) Automatic leveling start

External contactor feedback loop

(shortcut if unused)

LEVELING UNIT FUNCTIONALITY

The safety module NCUM20 has integrated a leveling unit and it is able to check the status of the contacts (S11-S12/S21-S22): the leveling

output (43-44 /53-54) are activated if the sensors are in the correct position and if the start button S41 has been activated. The opening of

even only one input contact (S11-S12/S21-S22) , leads to a safety situation, by putting the safety outputs (43-44 /53-54) in open state and by

preventing the closing even after the re-closing of the contact and the pressure of the START button.

For the automatic start, please check the following scheme.

The responsibility to choose the adequate components for safety applications, for example guided contacts safety relays, falls to the user.

1) Manual leveling start

S1

External contactor feedback loop

S2

Avvio

S1 S2

ts1

43-44 / 53-54

S1

S2

t2

FIG. 4 Conections and timing diagram for manual restart FIG. 5 Conections and timing diagram for automatic restart

S42 43C11

C12

A2 A1

13 23 S32 S22

S12 53

PS2PS1

C11

S41

S33S11

S31 S21 S42 43C11

C12

A2 A1

13 23 S32 S22

S12 53

PS2PS1

C11

S41

S33S11

S31 S21

Leveling unit sensors positioning

Sensors and leveling unit have to comply EN81-20:2014. The sensor targets (typically a magnet) have to be positioned in the door zone and their legth

have to be appropriate in order to guarantee the car stopping within 1m from the landing sill as required by EN81-20:2014. The trimming of the target

length (i.e. magnet) is in charge of the user in accordance to the response time of the stopping element and the elevator speed.

-3-

N.O.

IZ

N.O.

IS

N.O.

ID

MZ

MD

MS

L

Ka

Kb

N

~~ +

-

V+

3233 31

14 24

S42S41 43C11

C12

A2 A1

13 23 S32 S22

K21

K11

K22

K12

S12

+53

44

54

K51

K41

K52

K42

PS2PS1

~~ +

-

C11

S21

S33S11S31

6263 61

A3

A4

+

-

-

-

STOP

DEVICE 2

STOP

DEVICE 1 DOOR

CONTACT

Feedback

control loop

Start

(UCM)

Feedback control

loop

Start

(Leveling)

Safety

Circuit

Safety

Circuit

in

Safety

Circuit

out

Safety

output

UCM Signal output

Power supply

24 V ac/dc Levell ing

safety output

FIG. 6 Uncontrolled mouvement test

Safety circuit

reference Safety circuit

reference

+

Battery

12 V dc

TESTING PROCEDURE ACCORDING TO EN81-50:2014

Testing procedure according to § 5.8.3.2.4

1) Install all the appropriate out of service signaling at each floor

2) Check that nobody is in the car

3) Deactivate the landing call

4) Change the electrical connection as indicated in fig.1 (AnnexA)

5) Using the maintenance panel send a landing call

6) The NCUM will open the outputs 13-14, 23-24

7) The stopping element will be activated

8) Measure the braking trip distance

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMA NCUM20 rev.4 15/02/2017

Operating instructions for safety control unit mod. NCUM 20 - Original instructions -

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Relative humidity: 5% ... 95%

Temperature: -25 ... +70

Relative humidity: 4% ... 100%

max: 0,5A @ 24 Vdc

IEC 60068-2-6:2007, IEC 60068-2-27:2008

EN 12015: 2004, EN 12016: 2004 + A1: 2008

IP20

750 mA PTC fuse

EMC compliance

Approval

Housing conditions

Auxiliary outputs terminals

Weight

Internal fuse on the suply

External fuse on outputs 13-14, 23-24, 43-44, 53-54

Safety output swiching power

Minimum switching current @ 10 V

Safety outputs switching voltage

Pollution Degree (see note1)

Degree of protection (IEC 60529)

Vibration resistance

Current consuption

Usage category / Electrical life

(SAFETY outputs)

A3 uncontroled movement safety outputt contacts

Supply voltage

Operating conditions

Parameter

Dimensions

Housing material

Mechanical life 7

10 cycles

4 A gG (according to IEC EN 60269-1)

10

13 -14 / 23-24

24 -15% / +10% (AC 50 ÷ 60 Hz)

@24Vdc: 80 min, 210 max; @24Vac: 190 min, 480 max

3

Temperature: -5 ... +55

160,5 x 96,8 x 62,5 (height)

Value

335

PA

VA

V ac

mA

V dc

°C

mA

kPa

g

mm

°C

Unit

20OFF state response time

31 - 32 NC 31 - 33 NOAuxiliary uncontroled movement safety output contacts

Switching current AC-1 / Electrical life

240 (max) (Safety output)

720 (max)

3 A (Ssfety output) / >10 cycles

5

In accordance with EN 81-20:2014, EN 81-50:2014

ms

Assembly 35 mm DIN standard rail

Connection type Screw terminals

AC-15: 1,4 A / 240 V (inductive load, cosΦ=0,3)/10 cycles

DC-13: 1A / 24 V / 10 cycles

5

200Max input sensor resistence ohm

Battery supply voltage 12 -15% / +10%

V ac/dc

Pressure: 86 ... 106

Pressure: 86 ... 106

kPa

EN 81-50:2014

Safety leveling output contacts 43 -44 / 53-54

61 - 62 NC 61 - 63 NO

Auxiliary levelling output contacts

SAFETY CIRCUIT

VOLTAGE

24V

48V

110V

ORDERING CODE

220V

NCUM20000024

NCUM20000048

NCUM20000110

NCUM20000220

TüV SUD EDES010

- 4 -

A

60V NCUM20000060

TECHNICAL DATA

500 mA fast blow fuse

External fuse on battery supply (A3, +12V)

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMA NCUM20 rev.4 15/02/2017

5

Overvoltage category 3

NOTE 1

Condition met if:

-The UCM safety outputs (13-14,23-24) in the final application have a voltage differencebetween them of less than 160V

- The leveling of safety outputs (43-44, 53-54) have a voltage difference between them of less than 160V

Other Stem Control Unit manuals