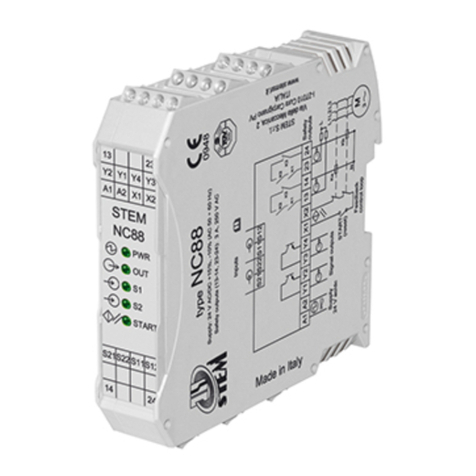

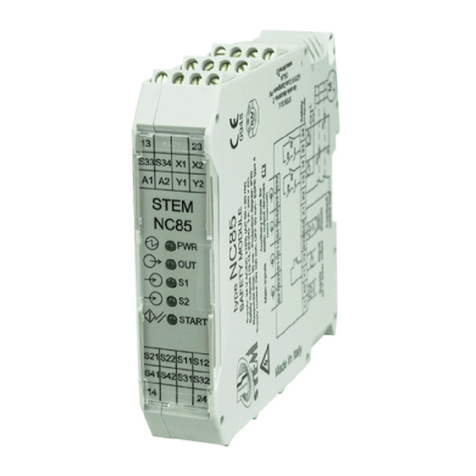

Stem NC86 User manual

! !

Y2

Signal

Output

Supply

24 V ac/dc

A1 A2 Y1

Ka

Start

button

(reset)

Feedback loop of the

external contactor

(bridged if not used)

NM

3

K1

23X1S33S34

K1

X2 13 14

L3L1L2

24

Main inputs

S22S21

K2

K3

K2

S11S12

K3K3

Safety

outputs

Kb

L

Operating instructions for safety control unit mod. NC86 - original instructions -

Description

The NC86 safety relay is created for use in safety circuit intended by

EN 81-20, EN 81-50, EN 60204-1, EN ISO 13849-1.

This module is based upon the use of guided-contact safety relays.

Safety Precautions

The manufacturer or the technician that install the machinery is responsible for

correct and safe overall function.

Auxiliary output Y1/Y2 is optoinsulated and gives informations about the state of the

device; it must not be used as a safety output.

The NC86 is not proper for the operation in presence of ionizing and not ionizing

radiations (rays X, microwaves, laser, ultraviolet rays)

(EN 60204-1:2018, §4.4.7).

Functioning

The NC86 Module can control the state of two contacts (Reed sensors,

emergency stop button, mechanical safety switches, interlocks for mobile guards):

the output is activated by pressing the START button only if the contacts of two

sensors are closed. The opening of even only one input contact (S1 and/or S2),

leads to a safety situation, by putting the safety outputs in open state and by

preventing the closing even after the re-closing of the contact and the pressure of the

START button.

WARNING: the start command does not fulfill the requirements of §5.2.2 of

EN ISO 13849:2015 standard because it works on the rising edge of the signal.

If the NC86 is used to control emergency stop button, after the intervention of the

device, the reset of the command shall not restart the machinery but only permit

restarting

(EN 60204-1:2018, §9.2.3.4.2, EN ISO 13850:2015, §4.1.4).

If the NC86 is used to control interlocks for mobile guards, the reclosing or

resetting of an interlock safeguard shall not initiate hazardous machine operation

(EN 60204-1:2006, §9.3.1).

If START button is not used (automatic rearmament), see the connection diagram in

the following page; the behavior of the machinery to the restart of the device - or the

not automatic restart of the dangerous elements of the machinery - depends on the

realization of the command circuit of the machinery according to the risk evaluation

effected by the user.

Input channels work on opposite potentials (S11,S31 →- ; S21,S41 → +).

It's available an input (X1-X2) for feedback with contactors or external relays

(see Ka and Kb on the connection diagram); if not used, X1-X2 have to be bridged.

Safety category 4 is granted only if (see connection diagram):

-to interrupt the load are used two relays, each connected to an input of the

safety unit;

-the contacts of the relays controlled by the safety unit are inserted into the

feedback loop.

The safety is ensured by using guided contacts, by the redundance and by the

interconnection schematic of the contacts.

The responsibility to choose the adequate components for safety applications, for

example guided contacts safety relays, falls to the user.

Assembly

Installation must be performed by authorized personnel only.

The NC86 control unit must be assembled in a suitable operating area

(switch cabinet, protective housing).

The unit is installed by clipping it to a standard 35 mm top-hat rail.

Electrical Connection

Electrical connection must be performed by authorized personnel only following the

indications of EN ISO 13849-1 and EN ISO 13849-2.

All the electrical inputs must either be isolated from the mains supply by a separate

coils safety transformer in accordance with EN IEC 61558-2-6 with limited output

voltage in the event of a defect or by another equivalent movable mechanism.

The outputs of the relays have a maximum current of 3 A; the supply connected to

the outputs must be protected from overcurrents by devices adequate to the loads

that have to be protected. All the output contacts must have an adequate protective

circuit for capacitive and inductive loads.

If a common power supply is used, all the inductive and capacitive loads (e.g. relay

contactors) connected to the power supply must be connected to appropriate

interference suppressors.

Service and Inspection

The correct functioning of the NC86 safety unit must be controlled by the operator

and/or by the control circuit of the machine in which it is used periodically (at the

beginning of every shift), by checking:

- Correct switching function of each sensor by checking:

a) that the opening of the single sensor / safety guard will cause the opening of the

safety outputs (13-14 / 23-24)

b) that the closure of the same sensor / safety guard will cause the closing of the

safety outputs (13-14 / 23-24) as a result of a startup command

- secure mounting of components

- correct connection fixing.

The monitoring function of the unit is done at every switching cycle.

If with all safety guards closed and following the eventual start command, the safety

device does not activate its safety outputs, do not turn off and turn on the device ,

then proceed to the checking of the possible safety guard open and perform the

above tests in point a) and b). In the event of damage or wear and tear, the

damaged system component must be replaced.

Liability coverage is void under the following circumstances:

- if instructions are not followed

- non-compliance with safety regulations

- installation and electrical connection not performed by authorized personnel

- non-implementation of functional checks.

Setup

If the control unit does not appear to function when operating voltage is applied

(PWR LED does not light up), the unit must be returned unopened to the

manufacturer.

Check whether the safety outputs are being switched (see LED display) by

activating the two inputs S1, S2 and START.

Operation according to EN 81-20:2014

The safety module ensures the opening of contacts within 15 ms from the opening

of the sensors S1 or S2.

It can be used as a detector, according to 5.6.7.7 EN 81-20:2014,to be integrated in

a A3 system.

Connections

-

+

1) Lift applications

(EN 81-20, EN 81-50:2014):

Reed contact sensors S1 e S2

S11S22S21 S12

S2 S1

2) Machine safety applications

(cat.4 EN ISO 13849-1):

sensor (S1) with 2 normally open

(N.O.) contacts

S11S22S21 S12

S1

3) Mobile guard interlock sensors

with normally closed (N.C. contacts)

(EN ISO 14119;

cat.4 EN ISO 13849-1;

EN 60204-1:2018, §9.3)

S11S22S21 S12

S2 S1

4) Emergency stop button in

accordance with EN ISO13850

(stop category 0, EN ISO 13850)

with 2 N.C. contacts (S1)

(cat 4 EN ISO 13849-1)

S21

S1

S12S22 S11

5) Emergency stop button with 1 N.C. contacts (S1) in accordance with

EN ISO13850 (stop category 0, EN ISO 13850;

EN 60204-1:2018, §9.2.3.4; cat 4 EN ISO 13849-1 if one or no*

sensor is connected to the unit)

S21

S1

S12S22 S11

*Short the inputs if not used for

2 NO contacts sensor

Alimentazione

24 V ac/dc

A1 A2

L1 +

L2 -

-

+ -

+

-

+ -

+

Automatic start connections

-1- Automatic start ONLY FOR use as lift safety unit

(EN 81-20, EN 81-50)

Reed switch sensors ID, IS and IZ.

In this configuration the inputs synchronization time among the closing

of IZ and one between IS and ID, it is endless, but a correct closing

sequence has to be respected: the first contact to be closed is IZ, then

IS or ID.

-2- Short-circuit of S33 and S34; in this case there will be a

synchronism time between inputs of 600 ms. S33S34

S12S11 S22S21 S33S34

GND + +

NOT CONNECTED

IZ

IS ID

Feedback loop of the

external contactor

(short-circuit if not used)

MD

N.O.

N.O.

MZ

N.O.

MS

ID

IZ

IS

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMA NC86 0000 rev.18_03/2022

Operating instructions for safety control unit mod. NC86 - original instructions -

S1, S2

START

Power

S1, S2

START

LED DISPLAYS

Inputs S1, S2, START: CLOSE

Inputs S1, S2, START: OPEN

Outputs 13/14, 23/24 and Y1/Y2: CLOSE

Outputs 13/14, 23/24 and Y1/Y2: OPEN

Function

Supply Voltage

on

off

on

green

green

-

OUT

off

State

on

Color

(ON)

-

green

OUT

LED

Dimensions

S21

A1

S11S22 S12

Y2Y1A2

S33

13 23

X2X1S34

START

PWR

NC86

OUT

STEM

S2

S1

14 24

STEM S.r.l.

via della Meccanica, 2

I-27010 Cura Carpignano

Pavia Italia

Tel. +39 0382 583011 Fax +39 0382 583058

www.stemsrl.it st[email protected]t

600

13-14 e 23-24 (normally open)

PA 6.6

DC: OUT=off: 50 OUT=on: 100; AC: OUT=off: 50 OUT=on: 100

in accordance with EN 81-50,EN 60947-5-3

0,15 (MAX)

60 (MAX)

55 (MAX)

Y1-Y2 (collector-emitter optoinsulated)

750

10

2,5 x 10 (250 Vac, 3 A cosφ=1)

5

7

250

1

24 +15%, - 15% (AC 50 ÷ 60 Hz)

Technical data

Parameter

115 x 105 x 22,5 / 180

IP20

3

Value

W

mA

Vdc

VA

V AC

V ac/dc

Hz

mA

ms

ms

mm / g

Unit

Usage category: safety outputs parameters AC-1: 3A @ 250V; AC-15: 0,9A @ 250V

DC-13: 1,8A @ 24V / 0,13A @ 120V / 0,06A @ 240V

0 according to EN 60204-1 e la EN ISO 13850

kPa

°C

kPa

°C

EN 81-20,EN 81-50,EN 60204-1, EN ISO 13849-1,

EN ISO 14119, EN ISO 13850

cycles

cycles

15

Input cables maximum length (lmax)

lmax= Rlmax / (Rl/ km)

Rlmax = total max resistance of the input cables

Rl/ km= cable resistance / km

km

Safety outputs minimum load 10 mA / 5V

Current (A)

Lifetime

(cycles@ Im ax)

Voltage (V)

MIN

AC-1

5

0,01

DC-13AC-15

MAX

250

3

MIN

5

0,01

MAX

250

0,9

MAX

240

0,06

MIN

5

0,01

2,5x10 3x107x10

54 6

Usage category paremeters

3 (MAX) A

Connection type

Supply voltage

Degree of contamination

Degree of protection (IEC 60529)

Housing conditions

Operating conditions

Current consuption

Housing Material

Dimensions / Weight

Assembly

Internal fuse on the supply

Max. switching frequency

OFF state response time (t2)

Input synch. time ts (automatic start -2-)

Safety Output switching voltage

Safety output switching current

Safety output switching power

Safety outputs terminals

Auxiliary outputs terminals

Auxiliary Output voltage

Auxiliary output current

Auxiliary output power

Mechanical operation life

Stop Category

Safety Category and PL

(EN ISO 13849-1)

Approvals

EMC compliance

Vibration resistance

Electrical operation life

In accordance with

TÜV IT 0948 10 MAC 0015 B, TÜV EDES 004

Pressure: 86 ... 106

Relative humidity: 5% ... 95%

Temperature: -25 ... +70

Pressure: 86 ... 106

Relative humidity: 4% ... 100%

Temperature: 0 ... +55

DIN standard 35 mm guide

Screw terminals

750 mA resettable PTC

13-14 / 23-24

S1

S2

Timing diagram for manual start

START

S1

S2

13-14 / 23-24

Timing diagram automatic start - 2 -

(S33-S34 bridged)

t1

t2

IZ

IS o ID

13-14 / 23-24

t1 t2

ts ts ts ts

Timing diagram automatic start - 1 -

(ONLY for lift applications)

EN 61000-6-2, EN 61000-6-3, EN 60947-5-3,

IEC 61326-3-1, EN 12015, EN 12016

Cat. 4

PL - e

nop (numero operazioni / anno)

N°

cycles/

year

61320 17520

years

years

MTTFd

TM

PFHd

20

30

2,47x10- 8

100

9,54x10- 8

Output response time (t1) Typical 120, max 160 ms

Subject to technical modifications without notice, no liability will be assumed for any detail. © STEM S.r.l. 1SMA NC86 0000 rev.18_03/2022

Overvoltage Category

Other Stem Control Unit manuals

Popular Control Unit manuals by other brands

Hayward

Hayward SelectaFlo SP0425 owner's manual

Bailey

Bailey Infi 90 IMRIO02 Instruction

fimotec-fischer

fimotec-fischer FS-26E operating instructions

Goetze

Goetze 455 Assembly instructions

schmersal

schmersal AES 1266 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley 1718 Series user manual

Hubner

Hubner U-ONE-LWL operating instructions

Osram

Osram DALI PRO 2 IoT manual

Eaton

Eaton Char-Lynn VersaSteer 10 Series Parts and Repair Information

Victron energy

Victron energy BlueSolar Pro manual

GAPOSA

GAPOSA QC100 Operation instructions

New England Arbors

New England Arbors NEBNext Ultra E7442L instruction manual