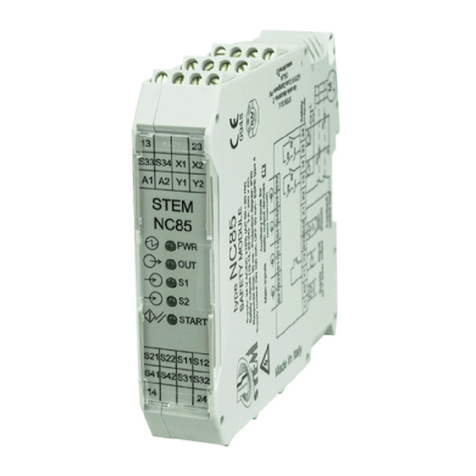

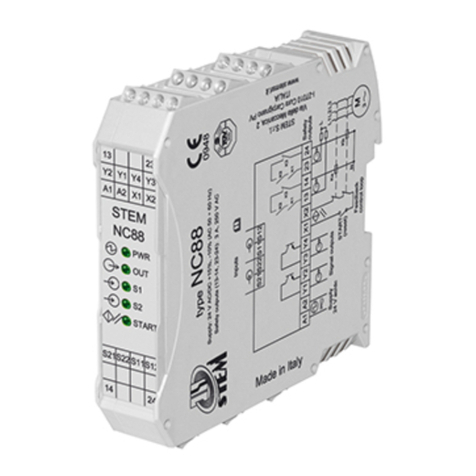

Stem NCBM 01 User manual

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

NCBM 01

1 Introduction

The control unit NCBM 01 can be used to realize the automatic monitoring

systems of a built in redundancy devices , as requested by EN81-20 against

uncontrolled movement.

For the hydraulic elevators:

NCBM01 allows to periodically monitor the functioning of the two down

direction valves, connected in series and controlled in sync.

It also permits the control the activation ad deactivation phase of the single

additional valves.

For traction lift with brakes:

NCBM01 allows to monitor the brakes of gearless/geared machine controlling at

each lift travel the safety micro switches mounted on the brake.

For traction lifts with uncontrolled movement device on the OSG(over speed

governor):

NCBM01 allows to monitor the proper functioning of the blocking element

(electromagnet) installed on the OSG

All the stopping element : down direction valves, electrical brakes and the OSG

must be certified.

Main features:

•activation of an output relay, in case of failure of the test.

•Reset button to manually restore the normal operation of the device

after alarm activation

•HW redundant circuitry of the micro-controller section that will activate the alarm relay in the case

where the test has not been performed within 38 hours.

•internal clock to the time configuration of the test (e.g. during the night).

•Hour configuration using a button

•6 LEDs to signalize alarms and operating status

•USB port and software application for configuring the unit allowing maximum flexibility to insert test

and operational parameters.

During electrical cabinet assembly a fast parameter download is possible selecting the appropriate file

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

2 Operation for hydraulic lift

The hydraulic lift can use 3 different uncontrolled movement systems:

•With Single blocking additional valve

•With double valves monitored.

•Bucher I-VALVE signal control

2.1 Electrical connection scheme for hydraulic lift

BTAMP 12V

D2

A4

A3

D1

NCBM 01

Voltage reference / N (AC)

+24VDC / L1(AC)

Car Door

VARISTOR

V2

PO1

PO2

V1

Speed

VARISTOR

JP3

Voltage reference

N (AC)

DOWN

+24VDC / L1(AC)

TEST

JP2

A2

T2

T1

A1

JP1

VARISTOR

FNO

Voltage reference / N (AC)

VARISTOR

VARISTOR

J3

PT1

PT2

S2

S1

Floor

+24VDC / L1(AC)

Up

End of the

safety chain

Solenoid valve V1

Solenoid valve V2

J2

FNC

CF

J1

K1

K2

Fault Relay

Door contact

Door Bypass

CO

TW

O1

O2

Test warning

FIG. 1 Electrical scheme connection for hydraulic lift

2.2 System with single additional valve

Some manufacturers of valves, provide the possibility of using an additional valve block which must be opened first

and closed after the main valve of descent. In this case, the valve does not work under pressure and not being

considered in parallel to the main valve of descent does not require monitoring.

The NCBM01 allows to select the activation sequence valve by setting the parameter "valve sequence" in the

configuration window. Using the parameter "down valve opening delay" the advance opening time of the additional

valve is configured, while the parameter "down valve closing delay" determines the delayed additional valve closing

time.

The periodic test, in this configuration, is disabled. To activate the valves the doors have to be closed (presence of

voltage on P01,P02, LED4 off). Needed connections: down, up, speed, power supply, outputs (CO1, O1,O2)

2.3 System with double valves monitored

In the case of double valve system monitored and controlled in parallel, the manufacturers prescribe the obligation to

perform a test for periodic monitoring through the concept of "built in redundancy" introduced by the regulations EN81-

20

In this case, the device NCBM01 performs test at the hour set in the parameter "test time" written during the

configuration of the device. The test is repeated daily or hourly according to the parameter "test frequency" set

The conditions that must occur to begin the test are:

• Scheduled time

• Contactors up, down, speed must be turned off, doors closed (voltage between P01-P02, LED4 off) for at

least 30 seconds and lowest floor signal present (voltage present between PT1,PT2 LED 5 ON).

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

If the above conditions are met the test will start by opening the output O1 (valve V1 closed in testing) and maintaining

the output O2 closed so that the valve V2 will remain open. The duration of the test valve is set via the parameter “test

duration” in the configuration user interface, after the test of the first valve, after 5 seconds it will proceed to the tests

of the second valve in a similar manner (activate O1, O2 deactivated). In case a leveling command is activated (up

command active without speed signal within 5 second), the test is repeated. If during the second attempt a leveling

command is activated again the test failed. The alarm is signaled by the fault relay and the lighting of the LED

indicators. After a switch on/off of the NCBM01 the alarm remain activated until the reset button is pusher for at least

5 seconds. If, during the test one of the following commands: door open or down or up followed by the speed within

5s, the test is suspended.

If a frequency daily tests is set, the device has a time-out for the execution of the test of one hour. If the test is not

performed within 1 hour an alarm is generated. If it is set the tests frequency of one hour, there is no time-out

The parameters for the handling of activation delay of the valves, during normal elevator operation, are configured

using the masks "Valve sequence", "down valve closing delay", "down valve opening delay", as described in the

previous paragraph.

Thirty seconds before the execution of the test and for the whole duration of the same, the output TW (test warning)

will remain active to signal the imminent execution of the test. This function is useful to signal to the control cabinet the

test coming and to perform the commands necessary for the preparation of the test : door closing, lowest floor...

2.4 Bucher I-VALVE signal control

FIG. 2 Electrical scheme connection for hydraulic lift

The configuration Bucher I-VALVE allows to control the timing of the SMA signal when the travel signal is changing

the state. As indicated in the valve manual, the system detects the error1 and error2:

Error 1 : when travel command goes from high level to low level, the SMA signal should change the state from 0.1s to

1s after the travel signal change, if the timing is not respected error1 has to be detected

Error 2 : when travel command goes from low to high level, the SMA signal should change the state within 0.1s after

the travel signal change, if the timing is not respected error2 has to be detected

If the error is detected the Fault relay will change state according to the relay polarity selected in the SW configuration

•FNO, in case of alarm FNO, CF is closed

•FNC, in case of alarm FNC,CF is closed

Led 3, Led4 and led5 continues to signal the state of the SMA and TRAVEL commands even if NCBM is in alarm

The alarm will be maintained until a manual reset will be performed.

JP1

T2

D2

D1

JP3

V1

PO2

JP2

T1

A2

A1

PO1

V2

J1

FNC

J2

CF

S1

S2

J3

FNO

K2

Fault Relay

K1

PT2

PT1

A3

A4

NCBM 01

+24VDC / L1(AC)

TRAVEL

COMAND

SMA

SIGNAL

CO

TW

O1

O2

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

FIG. 3 Bucher I-valve signals

2.5 Signalling Hydraulic mode

Using the function LED functionality of the user interface SW is possible select the led options.

NORMAL FUNCTIONALITY HYDRO

MONITOR / NOMONITOR

BUCHER I-VALVE

LED

(OPZ1)

(OPZ2)

LED1(GREEN)

Up(On/Off)

Valve V1

OFF

LED2 (GREEN)

Down (On/Off)

Valve V2

OFF

LED3 ((GREEN)

High speed (On/Off)

POWER OK

Blink if travel low / On if travel high

LED4 (GREEN)

Doors (On/Off)

Doors (On/Off)

SMA signal, on if high

LED5 (GREEN)

Lower floor (On/Off)

Lower floor (On/Off)

Time verification pending, On until SMA signal change

the state

ALL (RED)

Alarm (Off)

Alarm (Off)

Alarm (Off)

TAB. 1 Led Meaning in normal functionality monitor / nomonitor / I-Valve configuration

TEST PENDING

TEST IN PROGRESS

LED

(OPZ1)

(OPZ2)

(OPZ1)

(OPZ2)

LED1

(Green)

Up (On/Off)

Valve V1 (O1 out

On/Off)

Off

Valve V1 (O1 out On/Off)

LED2

(Green)

Down (On/Off)

Valve V2(O2 out

On/Off)

Off

Valve V2(O2 out On/Off)

LED3

(Green)

Test pending (Led blink)

Test pending (Led

blink)

Test pending (Led blink)

Test pending (Led blink)

LED4

(Green)

Doors (On= open

Off=closed)

Doors (On= open

Off=closed)

Doors (On= open

Off=closed)

Doors (On= open

Off=closed)

LED5

(Green)

Lower floor (On=at floor

/Off =not at floor)

Lower floor (On=at

floor /Off =not at

floor)

Test in progress (led blink)

Test in progress (led blink)

ALL (Red)

Alarm (Off)

Alarm (Off)

Alarm(Off)

Alarm (Off)

TAB. 2 Led Meaning during test monitoring pending or in execution

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

ALARM

Severity

Restore

LED1

LED2

LED3

LED4

LED5

ALL

Relay

fault

Monitoring fault valve1

Unit

blocked

RESET

Button

ON

OFF

OFF

OFF

OFF

ON

ON

Monitoring fault valve12

Unit

blocked

RESET

Button

OFF

ON

OFF

OFF

OFF

ON

ON

Time out test, test not done in

time

Unit

blocked

RESET

Button

ON

ON

OFF

OFF

OFF

ON

ON

Bucker-Ivalve (error 1)

Unit

blocked

RESET

Button

ON

OFF

Blink/ON

x

x

ON

ON

Bucker-Ivalve (error 2)

Unit

blocked

RESET

Button

OFF

ON

Blink/ON

x

x

ON

ON

TAB. 3 Led Meaning in case of alarm

2.6 Activation of the valves during an upward travel (monitor / no monitor config.)

Using the configuration window "Opening Up Valve Timing", you can configure the opening of a single or both valves

during upward elevator travel. The maximum opening time is configurable to 4s.

Checking the box "always on", you can configure the continuous opening of the valves during an upward travel. If in

the configuration menu the box V1,V2 and “always on” are selected together, the opening and closing of the valves are

handled according to the parameter set in the menus “Valve sequence”, “down Opening Valve Delay” e “Down

Closing Valve Delay”.

3 Working principle for traction lift

In the case of traction lift, as elements to stop the elevator car can be used the electrical machine brake or the safety

gear driven by the speed limiter by means of a coil.

3.1 Electrical connection scheme for traction lift

FIG. 4 Scheme for electrical lift

BRAKE

VARISTOR

D1

D2

A4

A3

NCBM 01

MICROSWITCH 1

MICROSWITCH 2 PO2

V1

JP3

V2

PO1

+24VDC / L1(AC) A1

JP1

A2

T2

JP2

T1

Fault Relay

J3

S2

S1

PT1

FNO

CF

PT2

+24VDC / L1(AC)

MICROSWITCH 3

MICROSWITCH 4

J1

K1

J2

FNC

K2 O2

O1

TW

CO

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

3.2 Operation as a monitoring system for electric brakes

If the elevator is equipped with electric certified brakes, it’s possible monitoring them checking the safety microswitch

on the brakes at each change of state (open / close). The NCBM controls at each lift travel the status of the microswitch

and if an anomaly is detected triggers the alarm resettable via the manual button.

it s possible to monitor 2,3 or 4 safety switches, the configuration is selectable using the user interface SW.

The device receives the brake command and after a configurable time (default 5 seconds) checks the status of the

microswitch. If the status is not correct the fault signal will be generated and the LED will indicate the possible fault on

the brake.

The microswitch can be:

•Normally closed (NC) check the opening of the contact when the brake is activated (coil not energized).

•Normally open (NO) check the opening of the contact when the brake is activated (coil not energized).

In this configuration (electric lift) it’s possible to select the polarity of the fault output using configuration SW trough

the parameter “fault relay polarity”:

•FNO, in case of alarm FNO, CF is closed

•FNC, in case of alarm FNC,CF is closed

3.3 Signalling traction lift

LED

Brakes deactivated

No Alarm

Brakes activated

Brakes deactivated

with alarm

Brakes activated with

alarm

LED1(GREEN)

OFF (Contact1)

OFF (Contact 1)

ON if contact 1 faulty

ON if contact 1 faulty

LED2 (GREEN)

OFF (Contact 2)

OFF (Contact 2)

ON if contact 2 faulty

ON if contact 2 faulty

LED3 (GREEN)

ON (POWER OK)

ON blink (brake

activated)

ON blink (brake

activated)

ON blink (brake

activated)

LED4 (GREEN)

OFF (Contact 3)

OFF (Contact 3)

ON if contact 3 faulty

ON if contact 3 faulty

LED5 (GREEN)

OFF (Contact 4)

OFF (Contact 4)

ON if contact 4 faulty

ON if contact 4 faulty

ALL (RED)

Alarm (Off)

Alarm (Off)

ON

ON

Unit blocked, relay fault ON, restore using the reset

button

TAB. 4 Signaling for traction lift

4 Monitoring system for OSG blocking coils

4.1 Working principle as OSG monitoring

Where it is used the certified speed limiter as an element able to activate the overspeed governor in the event of

uncontrolled movement, it involves the use of an electromagnet which pushes a pivot to lock the wheel of the

mechanical limiter.

The OSG is equipped with a sensor (usually mechanical microswitch or inductive) that allows to detect the position of

the locking pivot activated by the electromagnet coil. This contact can be monitored by NCBM01.

Currently, there are two types of certified overspeed governor:

1. With coil released and activated and each arrival / departure from the floor

2. With coil always activated and released only in the event of uncontrolled movement

The type 1) can be monitored as an electric brake so please refer to section 3.1

The type 2) is described below.

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

4.2 Wiring diagrams for overspeed governors

FIG. 5 Connections scheme for monitoring OSG type1

FIG. 6 Connections scheme for monitoring OSG type2

VARISTOR

Electromagnet

driver

D1

A3

D2

A4

BTAMP 12V

JP3

JP1

JP2

+24V

Electromagnet

OSG

Microswitch

TEST

A1

A2

T1

_

V1

T2

PO1

V2

PO2

J1

K1

Fault Relay

NCBM 01

K2

-

J3

FNO

S2

CF

J2

FNC

PT1

PT2

S1

CO

TW

O1

O2

VARISTOR

Down

BTAMP 12V

D1

D2

A4

A3

+24VDC / L1(AC)

TEST

Voltage reference / N (AC)

VARISTOR PO2

V2

PO1

V1

R=1Kohm

not needed with

NCUM Module JP3

Voltage reference

N (AC)

+24VDC / L1(AC)

T2

JP2

A2

T1

A1

JP1

Fault Relay

K2

K1

NCBM 01

J2

J1

FNC

FNO

PT2

PT1

S1

S2

J3

CF

+24VDC / L1(AC)

Floor

VARISTOR

Voltage reference / N (AC)

Test is coming

Control panel

A3 Safety

circuit

OSG

Microswitch

ELETTROMAGNET

Voltage reference / N (AC)

CO

TW

O1

O2

Test warning

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

4.3 Working principle in case of OSG actuated only in the event of uncontrolled

movement

The NCBM01 unit allows to configure, using the SW interface, the time at which you want to run the test and its

frequency (eg once a day). If the following conditions are true:

•elevator stopped for at least 30s

•elevator to the lowest floor

•closed doors

•test time

•Led configuration to start the test: LED2,5 on, LED3 flashing

one of the following tests will start

Test option1:

1. the power supply contact of the electromagnet (O1) will be open

2. In a maximum time of 3 seconds the NCBM checks the microswitch status installed on the OSG (NC closed

when OSG free to move, LED2 off)

3. if the contact remain closed the alarms will be activated.

4. If there were no alarms, the electromagnet is power supplied again (LED2 ON)

5. The contact will close again, if it remains open the alarm will be activated.

Test option2 (to be used for example in conjunction with the product Stem NCUMxx):

1. A test impulse of 300ms is sent on the O1 output

2. After a set time (default 3s) the status of the microswitch installed on the OSG is checked (NC closed

when OSG free to move, LED2 OFF then ON)

3. If the test fails, the alarms will be activated

In both cases the signaling outputs activated are:

• TW (test warning), thirty seconds before the execution of the test and for the duration of the whole test, to signal

to the control cabinet the test coming and to perform the commands necessary for the preparation of the test : door

closing, lowest floor, stop of the elevator

• O2 about 10 seconds before the test is performed, to signal the imminent execution of the test to the control

panel. This information is useful to prevent a up/down command given at the same time of the O1opening, that

may cause the operation of the safety gear.

During the waiting phase of the test (30s), the commands UP, down, door opening and lowest floor if activated will

delay the test execution.

4.4 Signaling

LED

Normal working

Test pending

Alarme activated

LED1(Green)

UP/down (On if active)

UP/down (On if active)

On

LED2

(Green)

OSG contact (On if closed)

OSG contact (On if closed)

On

LED3

(Green)

ON

Test pending (blink.)

Off

LED4

(Green)

Doors (On if open/Off

closed)

Doors (On if open/Off

closed)

Off

LED5

(Green)

Lowest floor (On at floor)

Lowest floor (On at floor)

Off

ALL (RED)

Alarm (Off)

Alarm (Off)

Alarm (On)

Unit blocked, relay fault ON, restore using the reset

button

TAB. 5 Signaling for OSG application

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

5 Generic alarm valid for all configurations

ALARM

Severity

Restore

LED1

LED2

LED3

LED4

LED5

ALL

Relay fault

Battery

No Block

Automatic

OFF

OFF

OFF

OFF

ON

ON

OFF

RTCC Alarme

No Block

Automatic

OFF

OFF

ON

OFF

OFF

ON

OFF

Alarme memory write

No Block

Automatic

OFF

OFF

OFF

ON

OFF

ON

OFF

Allrm time out HW

Block

RESET Button

OFF

OFF

ON

OFF

OFF

ON

ON

TAB. 6 Generic alarm valid for all configurations

6 HW redundancy circuitry

The NCBM is equipped with a redundancy HW circuit that in case the test is not performed within a 38-hour generates

an alarm. The reset is possible only by pressing the reset button.

Each time the monitoring test is performed, the internal counter is reset by the change of status of the outputs O1-O2

and subsequent activation of the V1-V2 (to be connected in any application hydraulic, electrical and OSG)

7 Internal clock management

The device has an internal clock that thanks to the battery, continues to operate even in the absence of main power

supply. Clock adjustment can be accomplished using the SW interface or by using the buttons on the NCBM unit.

Pressing the TIME button for 5 seconds, the current time is displayed by blinks of the led3: every flash corresponds to

one hour.

Pressing the time and reset button for about 3 seconds allows to enter in configuration mode: the LED1 will light and

every time you press the button “time” you will add 1 hour (example: if I need to set the 10 o clock, we must press

“TIME”10 times ). LED4 will flash each time you press the button.

8 Battery and operation in case of power failure

In case of power failure the NCBM01 keeps in operation only internal clock. After the return of the supply voltage, the

control unit restores its normal operation within 1 minute.

The customer can select to use external 12V battery connected to the inputs A3-A4 or to use an internal battery inserted

on the front side. The internal battery should be type CR2032 220mAh the “+” polarity toward the upper part of the

device (tampo-print side). To avoid unexpected behavior when replacing the battery, it is suggested to insert it when the

control unit is on. The battery is used only to keep the clock updated, in case of traction lift configuration or hydraulic

without monitor it can be not used

9 START UP AND E PERIODIC INSPECTION

9.1 HYDRAULIC LIFT WITH MONITORING

1. Set through the user interface SW related parameters

2. Do some test runs up and down checking through the LEDs 1 to Led5 (Option 1 and Option 2) that the

received signals from the system are correct and the LED FAULT is not activated.

3. Simulate the operation of re-leveling and checks by means of the LEDs1 to Led5 (Option 1 and Option 2) that

the received signals from the system are correct and the LED FAULT is not activated.

4. PERIODIC TEST SIMULATION SUCCESSFULLY PERFORMED: With the system stopped at the

bottom floor and with closed doors, turn on the test input (T1 to GND, T2 to 24VAC/DC) by means of an

external pushbuttons. The test monitoring will start opening one valve at a time. If the LED fault remain off,

the test is considered passed

5. PERIODIC TEST SIMULATION WITH NEGATIVE RESULT AT VALVE V1:With the system

stopped at the bottom floor and with closed doors, turn on the test input (T1 to GND, T2 to 24VAC/DC) by

means of an external pushbuttons. During the valve V1 test (V2 open) simulate a re-leveling, once the car

position is OK wait for the restart of the test (Led3/led5 flashing) and simulate again a re-leveling. The test is

considered passed if the control unit will activate the alarm LED and the fault relay will change state.

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

6. PERIODIC TEST SIMULATION WITH NEGATIVE RESULT AT THE POWER ON:

after the alarm generated at the step 5) remove and reconnect the power supply make sure that the alarm

remains active, then press the reset button for approximately 5 seconds to reset the faulty condition.

7. PERIODIC TEST SIMULATION WITH NEGATIVE RESULT AT VALVE V2:with the system

stopped at the bottom floor and with closed doors, turn on the test input (T1 to GND, T2 to 24VAC/DC) by

means of an external pushbuttons. During the valve V2 test (V1 open) simulate a re-leveling. Once the car

position is OK, wait for the restart of the test (Led3/led5 flashing) and simulate again a re-leveling. The test is

considered passed if the control unit will activate the alarm LED and the fault relay will change state.

8. Do again the point 6

9. Checks the time and eventually set it to the correct value.

9.2 HYDRAULIC LIFT WITH BUCHER I-VALVE

1. Set through the user interface SW related parameters

2. Do some test runs up and down checking through the LEDs that received signals from the system are correct

and the LED ALL and the relay FAULT are not activated.

3. I-VALVE ERROR 1 DETECTED: disconnect the SMA signal, travel command high (run elevator) than

travel command low (stop the elevator), checks activation of the relay alarm and the correct led status

4. I-VALVE ERROR 2 DETECTED: connect the P01 to 24V, travel command high (run elevator), checks

activation of the relay alarm and the correct led status

9.3 TRACTION LIFT USING BRAKES

1. Set through the user interface SW related parameters

2. Do some test runs up and down checking through the LEDs 1 to Led5 (Option 1 and Option 2) that the

received signals from the system are correct and the LED FAULT is not activated.

3. TEST SIMULATION WITH NEGATIVE RESULT: simulate a non opening and a non-closing of the

microswitch per each of them which is used.

4. TEST SIMULATION WITH NEGATIVE RESULT AT THE POWER ON:

after the alarm generated at the step 3) switch on and off the power supply make sure that the alarm remains

active, then press the reset button for approximately 5 seconds to reset the faulty condition.

5. Checks the time and eventually set it to the correct value.

9.4 TRACTION LIFT USING OSG

1. Set through the user interface SW related parameters

2. Do some test runs up and down checking through the LEDs 1 to Led5 (Option 1 and Option 2) that the

received signals from the system are correct and the LED FAULT is not activated.

Type 1 OSG with electromagnet released each time the elevator stops at floor:

Perform the test 8.2 from points 3 to 5

Type 2 OSG with electromagnet released only in case of undeteced movement

Option 1:

1. TEST SIMULATION SUCCESSFULLY PERFORMED: With the system stopped at the bottom

floor and with closed doors, turn on the test input (T1 to GND, T2 to 24VAC/DC) by means of an

external pushbuttons. After the pending time (30s), the test sequence will start, with the opening and

subsequent closing output O1 in series with the electromagnet. If there is proper switching sequence

on the OSG contact: opens when O1 opens, closes when O1 closes, the test ends successfully

2. TEST SIMULATION WITH NEGATIVE RESULT (contact failure to open):

a. Jumper output O1 so that the electromagnet remains always powered

b. With the system stopped at the bottom floor and with closed doors, turn on the test input (T1

to GND, T2 to 24VAC/DC) by means of an external pushbuttons. After the pending time

(30s), the test sequence will start opening the output O1, but the microswitch will not change

state because the electromagnet remain energized. The monitoring alarm will be activated

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

3. TEST SIMULATION WITH NEGATIVE RESULT AT THE POWER ON:

after the alarm generated at the step 2) switch on and off the power supply make sure that the alarm

remains active, then press the reset button for approximately 5 seconds to reset the faulty condition.

4. TEST SIMULATION WITH NEGATIVE RESULT (contact failure to close):

a. Disconnect the electromagnet from the output O1

b. With the system stopped at the bottom floor and with closed doors, turn on the test input (T1

to GND, T2 to 24VAC/DC) by means of an external pushbuttons. After the pending time

(30s), the test sequence will start opening the output O1. The NCBM will check the opening

of the contact, but since there will be no its closure an alarm will be generated.

5. Repeat test 3

6. Checks the time and eventually set it to the correct value.

Option 2:

1. TEST SIMULATION SUCCESSFULLY PERFORMED: With the system stopped at the bottom

floor and with closed doors, turn on the test input (T1 to GND, T2 to 24VAC/DC) by means of an

external pushbuttons. After the pending time (30s), an impulse will be sent to the output O1. If the

contact of the microswitch connected to the OSG will perform the correct sequence: opens when O1

opens, closes when O1 recloses, the test will end with positive result.

2. TEST SIMULATION WITH NEGATIVE RESULT (contact failure to open):

a. Jumper output O1 so that the electromagnet remains always powered

b. With the system stopped at the bottom floor and with closed doors, turn on the test input (T1

to GND, T2 to 24VAC/DC) by means of an external pushbuttons. After the pending time

(30s), the test sequence will start sensing an impulse to the output O1. The microswitch will

not change the state and an alarm will be generated.

3. TEST SIMULATION WITH NEGATIVE RESULT AT THE POWER ON after the alarm

generated at the step 2) switch on and off the power supply make sure that the alarm remains active,

then press the reset button for approximately 5 seconds to reset the faulty condition.

4. TEST SIMULATION WITH NEGATIVE RESULT (contact failure to close):

a. Disconnect the electromagnet from the output O1

b.

c. With the system stopped at the bottom floor and with closed doors, turn on the test input (T1

to GND, T2 to 24VAC/DC) by means of an external pushbuttons. After the pending time

(30s), the test sequence will start opening the output O1. The NCBM will check the opening

of the contact, but since there will be no its closure an alarm will be generated.

5. Repeat test 3

6. Checks the time and eventually set it to the correct value.

9.5 PERIODICAL CHECKS

The tests described above are to be repeated during the maintenance visits and / or according to the indication provided

by the manufacturers of the stopping elements (valves, brakes or limiter)

The frequency of the monitoring tests with regard to the valves and limiters type 2 are to be set in agreement with the

indications prescribed by the valves or OSG manufacturer

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

10 Connectors

TAB. 7 Connectors

11 Push buttons

Buttons combination

Functions

Reset

Alarm reset if pushed for at least 5 seconds

Time

If pushed for at least 5 seconds, the current time is visualized

Reset +Time

If pushed for at least 3 seconds, the clock configuration will start

Time (in configuration)

Each press of the button one hour is incremented

TAB. 8 Push buttons

12 General technical data

General technical data

Power supply

15-30V AC/DC 3W

Voltage inputs at the connectors: : PO, PT,V,D,S

24 ÷220VAC/DC if the inputs are connected in parallel

with coils (eg. contactor coils or solenoid valves), we

recommend the use varistors or tranzorb diodes to protect

the inputs

Maximum switching capability at alarm fault output

220VAC, 60W

Maximum switching capability outputs O1-O2

400 VAC, 500W

Working temperature

0 –70 °C

USB port

MINI USB typeB 5 contacts.

Internal Battery type

3V -220mAh 2032 type (diameter 20mm)

Battery life in stand-by

20 days

External Battery (Input A3-A4)

12V-7Ah Acid lead

Mechanical Dimension

Box ME MAX22, IP 20, thickness 22,5mm Height

125mm, width 105mm

Mechanical fixing system

DIN Type

Storage temperature

-40°C + 120°C

EMC compliance

EN12015:2005 –EN12016:2005

In accordance with

EN81-1:1998+A3:2009, EN81-2:1998+A3:2009, EN81-

20:2014, EN81-50:2014

Approvals

IMQ certificate N°847

Name

Type

Functions Hydro

Monitor/nomonitor

Functions Hydro

I-VALVE

Functions

Electric

Functions OSG

Range

[V]

AC/DC

Max I

[A]

Max

Power

[W]

A1-A2

Power supply

Power supply

Power supply

Power supply

Power supply

15 ÷30

0.1

T1-T2

Optoisolated input

Immediate test

Immediate test

15÷30

0.01

D1-D2

Optoisolated input

Down contactor

TRAVEL

Brake coil

Down contactor

24÷220

0.01

A3-A4

Battery supply

Battery supply

Battery supply

Battery supply

Battery supply

12V

0.1

V1-V2

Optoisolated input

Speed contactor

Not used

Microswitch1

OSG microswitch contact

24 ÷220

0.01

P01-P02

Optoisolated input

Door contactor

SMA

Microswitch2

Door contactor

24 ÷220

0.01

S01-S02

Optoisolated input

Up contactor

Not used

Microswitch3

Up contactor

24÷220

0.01

PT1-PT2

Optoisolated input

Lowest floor contactor

Not used

Microswitch4

Lowest floor contactor

24÷220

0.01

TW

Transistor Output

OC NPN

Test is coming

Not used

Not used

Test is coming

0-24VDC

0.1

0.24

O1

Relay out 1

V1 valve activation

Not used

Not used

Impulse test / Command

power supply of the

electromagnet

400VAC

Switching

10

500

O2

Relay out 2

V2 valve activation

Not used

Not used

Not used

400VAC

Switching

10

500

CO

Common relay

output

Common relay output

Not used

Not used

Common relay output

400VAC

Switching

10

500

CF

Common relay fault

Common relay fault

Common relay fault

Common relay

fault

Common relay fault

220VDC

Switching

2

60

FNC

Relay fault normal

closed

Relay fault normal

closed

Relay fault normal

closed

Relay fault

normal closed

Relay fault normal closed

220VDC

Switching

2

60

FNO

Relay fault normal

open

Relay fault normal

closed

Relay fault normal

closed

Relay fault

normal closed

Relay fault normal closed

220VDC

Switching

2

60

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

TAB. 9 General technical data

13 Order code

CODICE

DESCRIZIONE

NCBM01

A3 monitoring unit

1SBATTCR2032

Battery CR2032 (1 battery is included in the NCBM01)

1PUSB2TAMB2M

Cable USB 2.0 Type A / Mini-B, length 2m

Connector: USB Type A Male / Type Mini-B Male

High/Full/Low Speed USB compatible

TAB. 10 Order codes

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

14 User interface Configuration

14.1 Driver USB installation

•Copy a folder on the C disk of your computer the directory

STEM_NCBM_APP

•Before connecting the NCBM, check which communication

ports are available on the PC

•Connect the NCBM to the PC via a USB cable, and turn it on. Windows will detect the new device

•Install the driver present in the

folder C:\STEM_NCBM_APP\inf\

•Check the presence of the new communication device

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

14.2 NCBM_COM_APP User interface

•Run the executable program NCBM_COM_APP in the folder STEM_NCBM_APP

•Select the correct communication port

•Perform a read cycle to check the current settings

•The mask will be configured according to the data read

14.2.1 Hydraulic user interface Monitor/ no Monitor mask

Lift type= elevator type , Hydraulic

Options=with monitoring /without monitoring

Date and Time= date and time configuration

Test Time= test hour configuration

Test Frequency= test frequency: once a day or once per hour

Test Duration= test time duration

Valve sequence= setting phase shift valves, V1 open before and close after V2 or viceversa

Down closing valve delay= Advance opening time of the additional valve (to be set 0, in case of

simultaneous opening)

Down closing valve delay= dalayed closing time of the additional (to be set 0, in case of simultaneous

closing)

Up Opening Valve delay= valves opening time during the upward travel, if you select "always on" valves

shall be open continually during the upward travel

Led Functionality=led option according to table 2

Active Error= errors active

Firmware version= firmware version

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

14.2.2 Hydraulic user interface Bucher i-VALVE

Lift type= elevator type , Hydraulic

Date and Time= date and time configuration

Active Error= errors active

Firmware version= firmware version

Fault Relay Polarity=set the fault relay polarity

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

14.2.3 Elettric /OSG1 user interface mask

Lift type= elevator type , electric

Option= type and number of contact to be checked

Date and Time= date and time configuration

Test Duration= maximum time out to check the change state of the microswitch (max 5s)

Active Error= errors active

Firmware version= firmware version

Fault Relay Polarity=set the fault relay polarity

MANUAL NCBM 01 Revision 14 11/06/2021

STEM S.r.l. via della Meccanica, 2 I-27010 Cura Carpignano- Pavia Italia Tel. +39 0382 583011 Fax +39 0382 583058 www.stemsrl.it stem@stemsrl.it

Subject to change without notice, no responsibility will be taken for every detail. © STEM S.r.l.

14.2.4 OSG2 user interface mask

Lift type= elevator type , OSG type2

Option= option as indicated at the point 4.3 (option 2 to be used with the NCUM devices

Date and Time= date and time configuration

Test Time= test hour configuration

Test Frequency= test frequency: once a day or once per hour

Test Time Duration= maximum time out to check the change state of the microswitch (max 5s)

Active Error= errors active

Firmware version= firmware version

14.3 Global Configuration

Save = save a specific configuration in the written path

Select File = load a previously saved configuration

Download = configures the NCBM depending on the file loaded with the load command configuration

Table of contents

Other Stem Control Unit manuals