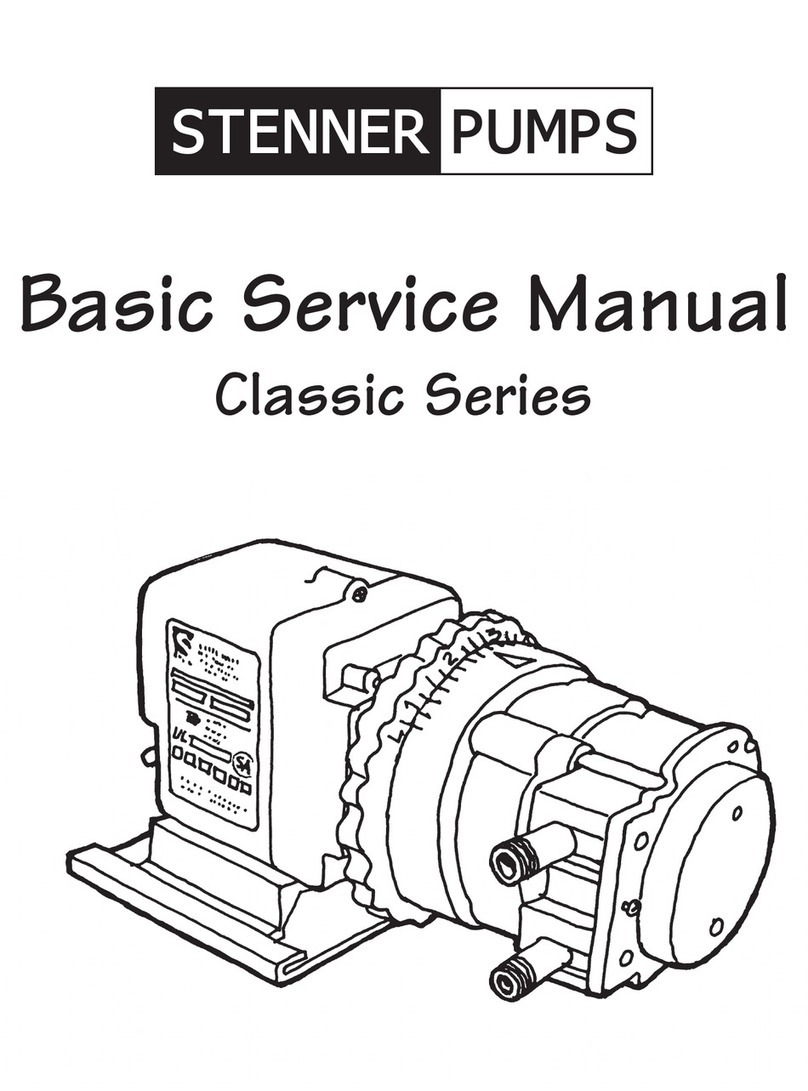

US and Canada 800.683.2378, International 904.641.1666 Classic Series

TROUB ESHOOTING PUMP HEAD

PROB EM POSSIB E CAUSE SO UTION

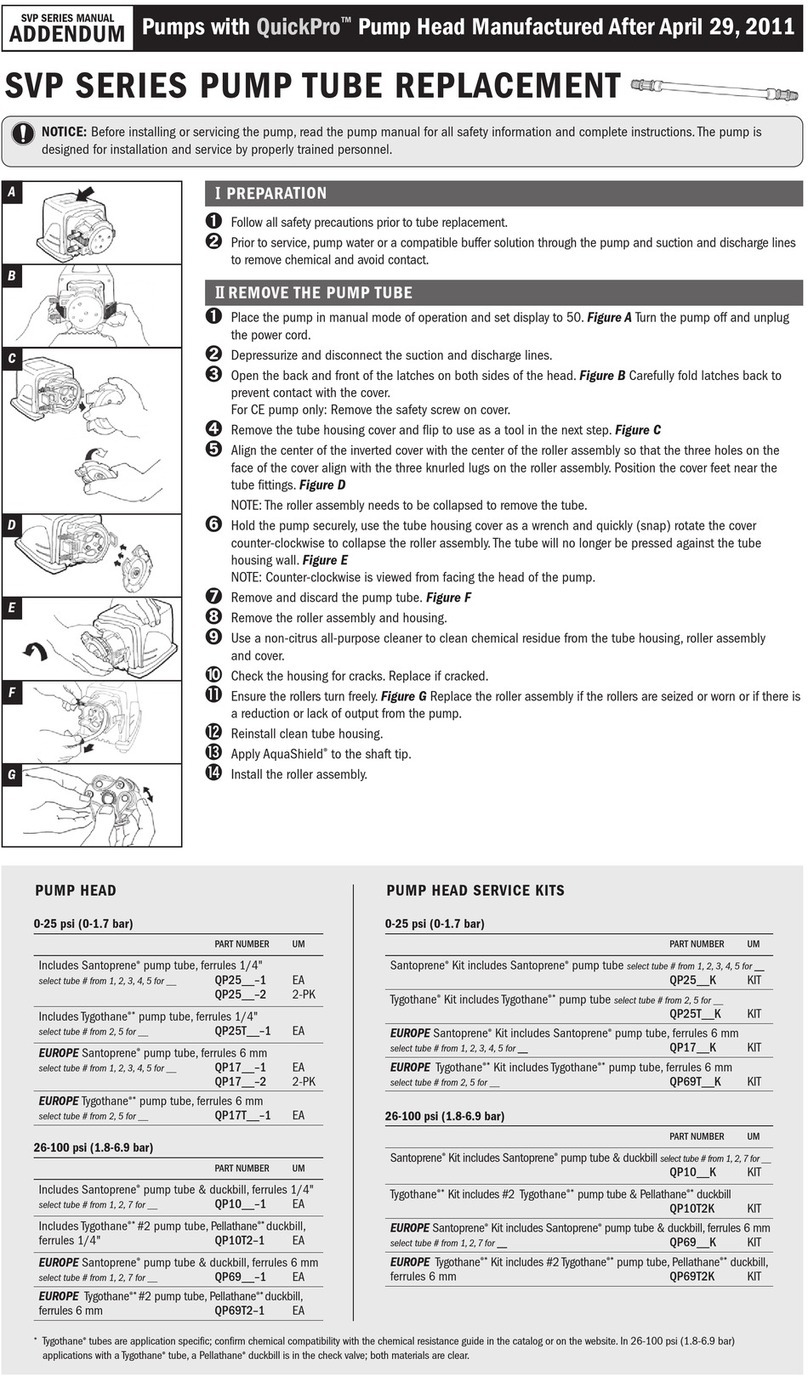

Roller Assembly Motor not locked ixed Rate Pumps: Place tube housing latch

will not expand or into motor slot; Adjustable Rate Pumps:

collapse with Set feed rate control to 10

tube housing cover Stripped or cracked Replace roller assembly

roller assembly hub

Components cracking Chemical attack Check chemical compatibility

Chemical intrusion from tube failure Identify and correct cause, clean components of

chemical & replace tube according to manual

Pump head leaking Pump tube rupture Identify and correct cause, clean components of

chemical & replace tube according to manual

No pump output, Roller assembly not fully expanded Expand roller assembly using pump head cover

pump head rotates as a tool, according to manual

Depleted or weighted strainer is above Replenish solution and position suction line 3"

solution tank above bottom of tank

Leak in the suction line or Inspect or replace suction line and/or connections

at connections

errules installed incorrectly, Replace ferrules, beveled end faces pump

missing or damaged

Sleeve and/or plastic gripper inside Replace if damaged or missing. Reorient if

3/8" connecting nut is missing incorrectly assembled; gripper beveled end

damaged, or incorrectly assembled faces nut; sleeve wide end faces gripper

Injection point is clogged Inspect and clean injection point

Clogged suction and/or discharge Clean and/or replace as needed

line and/or check valve

Life of pump tube exhausted Replace tube according to manual, schedule

tube replacement based on application

Suction line is flush with the nose of the Pull suction line approximately 1" from bottom of

weighted strainer strainer, cut bottom of suction at an angle

Low pump output, Life of pump tube exhausted Replace tube according to manual, schedule

pump head rotates tube replacement based on application

Rollers worn or broken Replace roller assembly

Injection point is restricted Inspect and clean injection point regularly

Incorrect tube size or setting Refer to pump output chart and determine dial

ring setting or replace tube & ferrules

High system back pressure Verify system pressure against tube psi,

replace tube and ferrules

No pump output, Stripped or cracked Replace roller assembly

pump head roller assembly hub

doesn’t rotate eed rate control problem Refer to feed rate control troubleshooting

Motor problem Refer to motor troubleshooting

Pump output high Incorrect tube size or setting Refer to pump output chart and determine dial

ring setting or replace tube and ferrules

Roller assembly broken Replace roller assembly

Malfunctioning feed rate control Refer to feed rate control troubleshooting

Incorrect motor rpm Replace with motor that matches pump model