STEPCRAFT 420 User manual

EasyBuild-

Assembly

Manual

Enclosure for

Desktop CNC /3D Systems

STEPCRAFT 300/ 420

Original assembly manual

date of 01.07.2017

Dear customer,

thank you very much for purchasing our high-quality kit of an enclosure of your Stepcraft

Desktop CNC /3D System. This manual will take you through every step of the assembly.

Please read the entire manual carefully before starting assembly. This way, you obtain an overview of the steps

required which will help you avoid unneccessary mistakes. Please take care to use the the correct parts in the correct

orientation as some parts differ only minimally. Please let a second person assist you in the assembly.

Before beginning the assembly process, please verify that you have all of the required parts in your kit using the list

below. Stepcraft provides video support with certain assembly steps. Simply scan the related QR code with your

smartphone. If you do not have a smartphone, please enter the following URL in your web browser:

www.stepcraft-systems.com/enclosure/xx-xx (replace xx-xx with the number under the QR code).

STEPCRAFT has taken extreme care to ensure the correctness of the information contained in this manual. We accept

no liability for damage in materials or injury to persons caused by assembling the enclosure. You are responsible for the

safe operation of your Stepcraft Desktop CNC /3D System and its accessories.

23

46

8

1

enclosure

front panel

1x

Content of the construction kit (illustrations are not true to scale)

1x

enclosure

rear panel

2x

upper prole

lower prole lateral pane prole

vertical without

handle

lateral pane prole

horizontal

lateral pane prole

horizontal

9

front pane prole

vertical without

handle

front pane prole

vertical without

handle

5

front door prole

bottom/ top

7

lateral pane prole

vertical with

handle

2x 2x 12x

4x 16x 3x

300: 343 mm

420: 413 mm

300: 105 mm

420: 135 mm

300: 341 mm

420: 411 mm 300: 304 mm

420: 374 mm

13

16

15

14

17 18

23 24

1110

front pane prole

vertical with

handle

front pane prole

horizontal

12

rubber seal

(silicone)

connection

prole

(silicone) side pane front pane

8x 2x

1x

base plate base plate partition

25 26

slot nut,

lockable

slot nut, loose slot nut, loose

external

6x 6x

machine

table

pivot pin

front pane

2x

19 20 21

1x

top plate plastic corner

45x

circular brush

1x 4x

1x

1x

22

strip brush

cable outlet

1x 4x 20x

300: 120 mm

420: 165 mm

300: 302 mm

420: 372 mm

300: 4,50 m

420: 5,50 m

300: 0x

420: 2x

300: 311 x 127 mm

420: 381 x 172 mm

300: 225 x 563 mm

420: 315 x 683 mm

300: 244 x 563 mm

420: 334 x 683 mm

300: 373 x 563 mm

420: 463 x 683 mm

300: 350 x 112 mm

420: 420 x 142 mm

(silicone)

black

300: 1,9 m

420: 2 m

orange

300: 0,8 m

420: 0,9 m

37

32 33 34 35 36

ange screw,

M5 x 12 mm

2x 2x6x6x20x

spacer,

M5 x 50 mm

1x

42 43 44 45 46

47 48 49 50 51

38 39 40 41

cam lock screwwooden dowel cam screw

end switch with

cable supply

locking nut,

M5

set screw,

M4 x 5 mm

ange screw,

M6 x 20 mm

emergency switch emergency switch

cable

cable conduit

6/4 mm

hole plug

8 mm

hole plug

36 mm

15 pin Sub-D

cable

grounding cable

set incl. serrated

lock washer

4x

3x 1x

1x

1x

27 28 29 30 31

door handle

spacer

M3 x 10 mm

4x 4x 6x

socket head screw,

M6 x 30 mm

pressure pin

10x

plastic foot

1x

1x 1x

controller board

button head

cap screw,

M3 x 6 mm

wood screw

3,5 x 15 mm

3x

10x

300: 0x

420: 4x

300: 0x

420: 4x

300: 0x

420: 4x

2,60 m

socket head screw,

M5 x 30 mm

300: 0,75 m

420: 0,88 m

Explanation of symbols and details:

Required tools and materials:

- Needle le (supplied)

- Spanner 5,5 mm

- Allen wrench 2,0 mm - Spanner 8 mm

- Allen wrench 3,0 mm - Rubber mallet

- Allen wrench 4,0 mm - Crosstip screwdriver

- Allen wrench 5,0 mm - Superglue

1A1

= assembly phase = assembly group = work step

= view of assembly

phase

= required parts for this

work step

= larger detailed view/

pre-assembly of parts

= Tighten the screw.

= Engage the screw, but do not tighten.

= Caution! Work particularly careful.

= Tighten clockwise.

= Remove protection lm and afx self-adhesive part.

= Fasten part with superglue, use sparingly, must not get on bearing or running surface.

= Deburring.

= Apply dish liquid as shown in picture.

!

Differences in the assembly of size 300 and 420:

The illustrations in this assembly manual are exemplary and are based on the enclosure

for size 420.

The assembly group A as well as the work steps 1.1 and 1.2 do not apply with

size 300!

Please pay attention to the different dimensions of the individual parts!

!

1

41

2x

39

2x

1.1

4016

17

1x

A

4x1x

! Please produce 2x !

Base frame

Assembly group A and work steps 1.1 and 1.2 only

apply for size 420!

1.2

1.3

4

1.4

2930

A

2x

4x 4x

2x

1.5

18

37

322

B

22

32

B1

1x 1x

1x1x

1x

1x

1.6

33

B

Preparatory steps for all doors:

6x1x

B

Before attaching the plastic corners it is especially

important that the leading edges of all proles are

deburred with the supplied needle le in order to

avoid blocking due to plastic chips.

!

12

20

C

C1

C2

8 20

300: 105 mm

420: 135 mm

Please pay attention

to the correct length!

105/ 135 mm !

!

!

For an easier assembly of

the plastic corners, please

turn the prole and use the

rubber mallet to x it to

the corner!

! Please produce 16x !

1x

1x

300: 107 mm

420: 137 mm

1x

27

14

D

D1

D2

6

!

Please pay attention

to the correct length!

343/ 413 mm !

Please pay attention

to the correct length!

341/ 411 mm !

!

7

C

! Please produce 2x !

1x

1x

1x

1x

1x

300: 343 mm

420: 413 mm

300: 341 mm

420: 411 mm

14

E

E1

E2

6

!

Please pay attention

to the correct length!

343/ 413 mm !

Please pay attention

to the correct length!

343/ 413 mm !

!

6

C

! Please produce 2x !

1x

1x

1x

1x

300: 343 mm

420: 413 mm

300: 343 mm

420: 413 mm

6

14

F

F1

F2

6

!

Please pay attention

to the correct length!

343/ 413 mm !

Please pay attention

to the correct length!

343/ 413 mm !

!

C

! Please produce 2x !

1x

1x

1x

1x

300: 343 mm

420: 413 mm

300: 343 mm

420: 413 mm

14

G

G1

G2

6

!

Please pay attention

to the correct length!

343/ 413 mm !

Please pay attention

to the correct length!

341/ 411 mm !

!

C

277

! Please produce 2x !

1x

1x

1x

1x

1x 300: 343 mm

420: 413 mm

300: 341 mm

420: 411 mm

2

12

2.2 13

2.1

D

1x

Side doors

(produce 2x)

300: 345 mm

420: 415 mm

300: 343 mm

420: 413 mm

D

E

F

G

13

C

2.3

2.4

2.5

27

E

1x1x

1x

300: 345 mm

420: 415 mm

C

2.6

2.7

2.8

F

13

1x

1x

300: 345 mm

420: 415 mm

12

C

2.9

2.10

2.11

G

1x

1x

300: 345 mm

420: 415 mm

2.13

2.14

C27

2826

2826

2.12

1x 1x

4x 2x

4x 2x

! Please produce 2x !

3

34

3.2

1x

3.1

1x

2423

1x

25

1x

1x

1x

2

Upper frame

1

This manual suits for next models

1

Table of contents

Popular Enclosure manuals by other brands

Thermaltake

Thermaltake Vi-ON ST0008U user manual

AZZA

AZZA OVERDRIVE manual

Safety Technology International

Safety Technology International STI-1229HTR-HAZ manual

Rockford Fosgate

Rockford Fosgate R1-1X10 Installation & operation

Thermaltake

Thermaltake Urban S71 WOT Edition manual

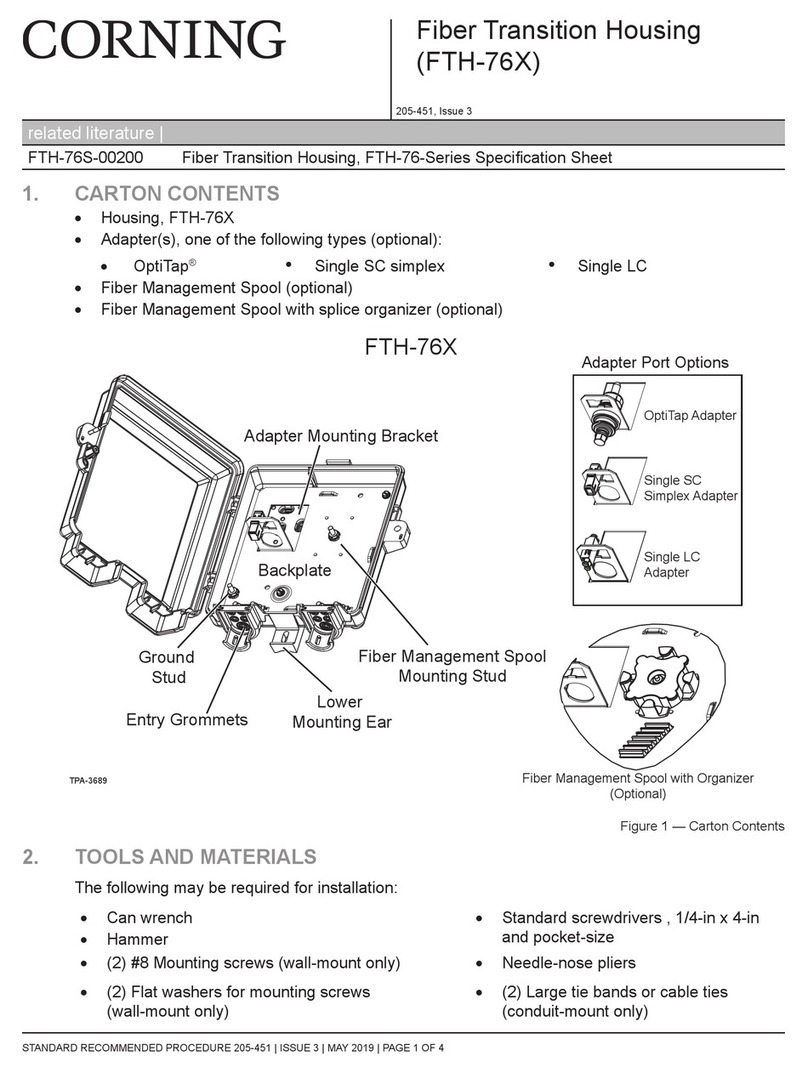

CORNING

CORNING FTH-76 Series quick start guide