Stepp OJK-V series User manual

OPERATIONS/MAINTENANCE/PARTS

MANUAL

Diesel or LP Burner Systems

12325 River Road North Branch MN 55056 ~ Phone: 651-674-4491 ~ Fax: 651-674-4221

www.steppmfg.com

Rev. 12/2014

2

Warranty

Stepp Manufacturing Company Inc. hereby warrants to the original purchaser that products

manufactured by Stepp Mfg. will be free from defects in material and workmanship for a

period of one (1) year from the date of purchase.

Stepp Mfg., at its discretion, will provide for the repair or replacement of any part found

upon examination by Stepp Mfg. to be defective, except as noted below. Such repair or re-

placement will be free of charge to the original purchaser for a period of one (1) year from

the date of purchase, except as noted below.

No warranty is extended to cover:

•Product pump wear or damage caused by foreign objects.

•Routine maintenance, cleaning, and adjustments.

•Parts/components that have been altered, misused, or improperly adjusted or maintained.

•Transportation to and from the place of warranty repair.

•Removal of material from equipment.

The following items are covered solely by their manufactures warranty:

•Engines

•Hydraulic components

•Burners

•Pumps

•Tires

•Other component parts

The following items are covered by a pro-rata warranty:

•Hoses that carry heated materials.

•Heating elements for hoses and wands.

Disclaimer of further warranty:

Stepp Mfg. makes no warranty, expressed or implied, other than this warranty. The implied

warranties of merchantability and fitness for particular purpose are hereby disclaimed. Re-

pair or replacement of products or parts proving to be defective in material or workmanship

shall be the exclusive remedy for breach of this warranty.

Stepp Mfg. shall not be liable for incidental or consequential damages including but not

limited to: damages for inconvenience, rental or purchase of replacement equipment, for

loss of profits, loss of material, or other loss resulting from breach of this warranty.

Stepp Mfg. reserves the right to incorporate any changes in design into its products without

obligation to make such changes on products previously manufactured.

Please see Warranty section for more details.

Stepp Manufacturing Co., Inc.

12325 River Road

North Branch, MN 55056

P: 651-674-4491 F: 651-674-4221

www.steppmfg.com

3

INTRODUCTION

OJK Stepp Oil Jacketed Kettle

Thank you for selecting Stepp highway maintenance equipment. We are confi-

dent you will be satisfied with the Stepp Oil Jacketed Kettle. Stepp Manufactur-

ing is backed by over 70 years of experience in the design and manufacture of

highway maintenance equipment. This experience along with our innovative de-

sign and unique features make the Stepp Oil Jacketed Kettle the fastest and

most efficient kettle available.

In order to assure safe operation of this equipment, the operator must read and

understand all operating procedures and safety notices contained in this manu-

al. In addition, the operator must receive instruction on how to safely operate the

Stepp Oil Jacketed Kettle. Contact the manufacturer if any questions arise or if

you desire training for additional staff members.

Operating instructions, adjustments and periodic maintenance procedures are

given so you, the operator, can keep your unit working like new and expect

many years of dependable service from it. Remember, any machine, regardless

of design or type, will perform only in relation to the way it is operated and the

maintenance it receives.

Read this manual carefully and observe all warnings and cautions. If you have

any recommendations or comments regarding this manual, please send them

attention to: Stepp Manufacturing Co., Inc., 12325 River Road, North Branch

MN 55056-6225 or call 651-674-4491. All comments we receive are reviewed

and may be incorporated into future manuals.

When ordering parts or making any inquiry about the Stepp Oil Jacketed Kettle,

be sure to include the model number and serial number found on the data plate

attached to the frame.

4

TABLE OF CONTENTS

Introduction 3

Contents 4

Warnings, Cautions, Notes 5

Description 7

Operations 15

Maintenance 25

Troubleshooting 45

Replacement Parts 57

NHTSA Reporting Safety Defects 74

Warranty Guide 75

Watlow Programming 81

Schematics 91

Heat Transfer Oil MSDS 99

Hydraulic Oil MSDS 109

Tire Information/ Engine Manual Inserts

IMPORTANT NOTICE!

This manual contains cautions and warnings that alert you to potential safety issues.

WARNING is used to inform you of conditions or operations that could cause serious injury or death.

CAUTION is used to inform you of conditions or operations that could cause damage to the equipment

NOTE is used to provide you with additional information that may be helpful or useful for a particular situation.

This manual explains the basic operations, maintenance and use of the Stepp OJK Oil

Jacketed Kettle. The main objective of this equipment is to melt rubberized crack seal-

ing and water proofing compound and apply them to road surfaces.

5

Before Starting or Operating this Machine

Understand and observe all the following Warnings, Cautions, and Notes.

WARNINGS

This equipment contains mechanical and heating components that may cause serious injury or death if not

handled or maintained properly. All personnel must be properly trained in the operation and maintenance of

this equipment.

Before refueling, shut off the burners and allow all flames in the burner and pilot light to extinguish. Shut off

the engine.

Check fuel lines, fuel line connections, and all other components for leaks. If any leaks are found, they must

be repaired before using the unit.

Know the temperature required for the material being used, and do not exceed this temperature. Avoid over

heating, as this may cause equipment damage, personal injury, and/or death.

Never load a tank with heated oil when moisture is present in the tank. Depending on the temperature of the

hot oil, the moisture may instantly boil causing hot oil to foam up and out of the tank causing severe burns.

Do not operate the tack tank burner when the amount of material in the tank is less than 4" above the flues.

Allow 10 minutes cool-down time after the burner has been shut off before exposing the flues. Exposed flues

will over-heat and cause an explosion and/or fire.

The tack tank cover must be unlatched when operating the tack tank burner. This is to provide for emergen-

cy venting, in the event of a flash, to prevent the tank from exploding.

CAUTIONS

Know the materials being used and know the proper handling, heating, application, clean-up, and storage

procedures. Not all materials are compatible with each other. Many materials have a very limited shelf life.

Most materials require special handling procedures to prevent personal injury and/or equipment damage.

Contact your material supplier and/or manufacturer for proper handling instructions. Equipment malfunction

or damage due to improper handling or use of the materials is not covered by warranty.

Do not exceed the maximum heating temperature or storage time as recommended by the material manu-

facturer. This may cause emulsion type materials to separate and become difficult or impossible to remove

from the machine. Consult with the material manufacturer for recommendations.

Over-agitation or circulation may cause emulsion type materials to separate and become difficult or impossi-

ble to remove from the machine. Consult with the material manufacturer for recommendations.

Do not mix Anionic and Cationic materials together, as the materials attach to each other and will become

difficult or impossible to remove from the machine. If you are not sure consult your material supplier.

NOTES

Become familiar with the Material Safety Data Sheet (MSDS) for the material being used in the machine and

take appropriate safety precautions. Wear the proper clothing and protective gear as recommended by the

MSDS and your safety director.

DO NOT use the equipment unless it is in good condition.

In case of skin contact with hot materials, dip into cool, clean water immediately. Do not wipe the product,

as this will spread the burn.

Consult the MSDS and contact your safety director for proper extinguishing of petroleum based fires.

Carry a fire extinguisher(s) as recommended by your safety director.

Notify your supervisor or the manufacturer if any questions arise concerning the operation of this equipment.

6

7

DESCRIPTION

8

The OJK uses a tank surrounded by an oil jacket filled with heat transfer oil. The heat transfer

oil is heated by a diesel fired burner and is circulated in the oil jacket by a pump. In addition to

the oil jacket there is a coil surrounding the agitating auger in the tank. Heat transfer oil is

pumped through this coil to facilitate heating of the asphalt material. The temperature of the

product and the heat transfer oil is automatically maintained by electronic temperature con-

trols.

The heated asphalt is applied to the crack by an electrically heated hose and wand. The heat-

ing element in the hose and wand keep the product at working temperature thus eliminating

wand "freeze up". No clean-up or flushing of the wand & hose is required.

Power is supplied by a diesel engine. The engine drives a 24 volt alternator for the heated

hose and wand. It also drives a hydraulic pump that powers the heat transfer oil circulation

pump, product pump, and the agitating auger.

Heat from Burner Heat Transfer Oil Insulation

DESCRIPTION

9

DESCRIPTION Component Location

1. Safety loading chute — Provides a "splash free" way of loading product into a "hot" tank.

2. Hood — Provides easy access to the inside of the tank for cleaning or "cold" loading.

3. Product pump motor — Powers the pump that pumps the product from the tank to the

wand.

4. Expansion tank — Provides room for the heat transfer oil to expand and allows the oil to

cool. This creates a "cold seal" effect allowing safer operation at elevated oil tempera-

tures.

5. Hydraulic pump — Provides hydraulic power to the heat transfer oil circulation pump, au-

ger, and the product pump.

6. 24 volt alternator — Provides electrical power to the wand and hose heating elements.

7. Engine control panel — Provides a means of controlling engine functions.

8. Engine fuel filter — Provides clean fuel to engine.

9. Hydraulic filter — Removes contaminates from the hydraulic system.

10.Hydraulic reservoir — Provides a 15 gallon capacity for the hydraulic system.

11.Fuel tank — Stores 30 gallons of diesel fuel to operate the burner and the engine.

12.Heat exchanger chamber — Exchanges heat from the burner to the heat transfer oil.

13.Wand & Hose — Provides a means of applying the product to the road surface.

14. Product pump control — Allows the operator to start, stop, or reverse the rotation and con-

trol the speed of the product pump.

3214567

8

9

10

13 12 11

14

10

1. Thermometer — Indicates the temperature of the material as it is pumped from the tank.

2. Wand Pressure Control (WPC) valve — Controls the amount of pressure being applied to

the hose & wand when the Pump Saver System is not used. Also allows the operator to

divert the flow of material back to tank for circulation, or to the wand for application to

the road surface.

3. Drive Motor — Hydraulic drive motor powers the product pump.

4. Circulating Flange — The wand is placed into this port allowing circulation through the

wand and back to tank.

5. Wand Rest — Holds the wand in position when circulating through the wand back to tank.

6. Draw off cock — Provides a means of draining tank or filling dispensing equipment.

7. Thermal Well — Contains temperature sensor for product temperature.

8. Heat Transfer Oil Level Plug — Allows easy check of oil level only when unit is cold.

9. Thermostats — Digital display thermostats control the temperature of the heat transfer oil

and the product temperature

10.Wand Heat Switch — Supplies power to the electric heated wand & hose.

11.Boom Power Cable — Supplies power for the heating elements in the boom, hose, and

wand.

DESCRIPTION Component Location

1

234

7

11

5

6

8

9

10

11

DESCRIPTION Heating System

Burner System:

The heating system is designed to burn diesel fuel and efficiently heat the transfer oil. The

heating system is equipped with constant ignition (flame-out protection) and automatic con-

trols to monitor the temperature of the heat transfer oil and the product temperature. Heat

transfer oil must be circulated through the heat exchanger when ever the burner is on. This

prevents the heat exchanger from over heating and causing damage to the equipment. Oper-

ation of the engine is required during the heating cycle to supply hydraulic pressure to the

heat transfer oil pump. The pump then circulates the heat transfer oil through the heat ex-

changer and the hot oil coil in the product tank.

WARNING: Operation of the burner without the engine running and oil circulating will cause

an overheat situation resulting in severe damage to the heat exchanger. Whenever the en-

gine is shutdown, the burner will also shutdown.

Temperature Control:

The Stepp OJK is equipped with automatic temperature controls. Two thermostats are used

to monitor the temperature of the heat transfer oil and the asphalt product. Both thermostats

have the capability of shutting off the burner when their respective settings are reached. Con-

tinuous observation of the temperature is recommended. If temperatures exceed the thermo-

stat settings, a possible problem with the thermostatic controls may exist. Shut the burner

OFF and contact qualified service personnel.

Agitator:

This unit is equipped with a hydraulically operated agitator with forward/reverse control. Oper-

ating the agitator during the heating cycle will decrease the amount of time and energy neces-

sary to bring the product up to working temperature. The agitator should be turned on as soon

as the material melts sufficiently to allow the agitator to rotate. Observe the drive motor for

rotation as you engage the lever, if no rotation is observed, allow more heating time to melt

the material. The agitator may be run in either direction and left on while applying crack filler.

This will give superior performance through even heating of the product.

Product Pump:

The Stepp OJK is equipped with a hydraulically operated product pump with "Pump & Re-

verse" control. In the "Pump" position, the pump delivers product from the tank, through the

hose, and to the wand for application to the road surface. In the "Reverse" position the pump

draws the product out of the product pump, plumbing, and WPC (wand pressure control)

valve to prevent freeze-up when the unit is shut down. The product pump is mounted in the

tank allowing it to heat to the proper temperature along with the product, thus it is not neces-

sary to preheat the pump. The product pump should only be engaged when the product has

reached a temperature that will allow the product to flow thorough the pump and plumbing.

12

DESCRIPTION Wand Pressure Control Valve

CAUTION: Operators must understand the proper operation of the WPC valve located on the

top rear of the unit.

The purpose of this valve is to direct the flow of product either back to the tank (during start-

up to assist melting) or to the wand (during crack filling operations).

Because of the properties of rubberized asphalt, no automatic relief valve is installed in the

system. Therefore, the operator must adjust the WPC valve to a position midway between

the valve stops. This will allow product to flow to the wand and also back to the tank at the

same time, preventing excessive pressure from building up in the hose and wand.

During normal operation the WPC valve will be in the “Wand” position and the flow of crack

sealant will be adjusted by the “Pump Speed” control located in the operators control box.

NOTE: Positioning of the WPC valve towards "Recirculate" will cause less flow and less pres-

sure to the wand. Positioning of the WPC valve towards "Wand" will cause more flow and

more pressure to the wand.

CAUTION: The WPC valve should never be positioned fully to the “Wand” position unless the

wand control valve located on the wand is fully open, or the optional "Pump Saver" feature is

installed and in operation. Excess flow and pressure to the wand may cause damage to the

hose and system resulting in personal injury.

Observing unusual flexing in the wand hose should alert the operator that excess pressure is

being applied to the wand hose. Considering factors such as temperature of product, desired

amount of flow and varied operating conditions will assist the operator in selecting the proper

position of the WPC valve.

When finished for the day, the WPC valve will be returned to the “Recirculate” position and

the pump reversed to evacuate the plumbing.

13

DESCRIPTION Misc.

Heated Hose & Wand:

The application wand and hose are equipped with an internal heating element. The element is

powered by the 24 volt alternator run by the engine. This heating element prevents the prod-

uct from "freezing" in the hose and wand.

The electric wand heat control should be turned on 20 to 30 minutes before trying to pump

material through the hose and wand. This will allow time for the material to reliquefy in the

hose.

NOTE: It is recommended that you circulate the product back to the tank through the wand

circulating flange provided in the hood. This is to assure proper flow and temperature of the

material going though the wand.

Depending upon the volume of the material going through the wand and the outside tempera-

ture, it may not be necessary to run the heated wand all the time. Once flow is established

through the wand and circulating back to the tank, it is recommended that the electric heating

element be used only as required to maintain flow. This will help to extend the service life of

the components. If the flow is not adequate to maintain temperature in the hose and wand,

freeze up may occur. If this happens, simply turn the electric heating element on and allow

time for the material to remelt.

No cleanup is required with the electric wand, just shut the machine off as the product can be

remelted by activating the wand heat control. No additional flushing is required.

Overnight Heater (optional):

This feature will maintain the product from 150° to 200° F., saving startup time. The system

consists of two heating elements submerged in the heat transfer oil.

The heaters require 110V, 15 amp service each. The extension cords used must be the out-

door heavy duty type, grounded, and each rated for 1500 watt service.

CAUTION: Make sure to plug each heater into separate circuits or it may cause the breaker

to trip on your outlet.

Digital Engine Management Controls:

The engine controls consist of a starter / glow plug button, an unloader switch to relieve the

hydraulic pressure for starting purposes (the deep sea control will also stop the engine in

case of low oil pressure or high coolant temperatures), and indicator lights for oil pressure,

coolant temperature, hour meter and volt meter. Optional equipment includes engine gauges.

14

15

OPERATIONS

16

OPERATIONS Basic Operations

Pre-start Checks:

The burner system is equipped with a safety interlock system that prevents the burner from

igniting unless the engine is running.

WARNING: This safety interlock must be tested each time before the engine is started. Fol-

low the steps below prior to engine start.

1. With engine OFF, turn the burner power switch ON, the burner and blower motor should

NOT operate. If the burner or blower motor runs there is a fault in the system, shut OFF

burner switch immediately. Contact a qualified service technician and correct the problem

before continuing.

2. Be sure the burner switch is in the OFF position.

3. Check the overall appearance of the unit inspecting for any obvious damage.

4. Check all fluid levels, the condition of the hot asphalt hose, and the 24 volt alternator belt

(refer to the daily maintenance schedule).

17

OPERATIONS Basic Operations

Transporting:

1. Shut off the burner and the engine.

2. Securely latch the loading chute and recirculating flange.

3. Secure the wand and hose assembly in the hanger.

4. Attach the unit to the towing vehicle being certain hitch is fully engaged, connect safety

chains, electrical connector, and breakaway switch (if equipped), retract the landing gear

and secure in the up position.

5. Check the condition and operation of the lights, tires, brakes, hitch, and safety chains.

Loading:

It is very important that the operator know the operating temperature and flash point of the

product being used. This information is available from the product manufacturer. Be sure the

thermostat is set at the recommended temperature.

Prior to adding product to the tank, ensure the compatibility of the product in the tank to that

being loaded. If products are not compatible the tank must be thoroughly drained and cleaned

before switching products.

Loading When Cold

1. Release the hood latch.

2. Each side of the hood is equipped with a Lid Breaker to break open the hood if it is stuck.

3. Extend the telescopic handle, tighten the lock, and push down to open the hood.

4. Use the ring to secure in the open position.

5. Load product to the desired level.

6. Close and secure hood.

Loading When Hot:

1. Open loading chute and place block of product in chute, close loading chute and product

will drop into tank. Open chute and repeat until product is at the desired level. Agitator will

automatically shut off when cover is open. Make sure to close the cover to start the agita-

tor and ensure that the material stays mixing.

2. Close loading chute but DO NOT latch, this will allow for emergency venting in case of a

“flash”.

18

Engine Starting:

NOTE: Be sure all pre-start checks are complete prior to starting engine.

1. Fill fuel tank.

2. Set the WPC valve to the "re-circulate" position.

3. Set wand heat control to OFF.

4. Set product pump control to neutral (center) position.

5. Set agitator control to neutral (center) position.

6. Turn key counter clockwise to the preheat position until the glow plug indicator light goes

out.

7. Hold the unloader button and the Murphy switch in, then turn the key to the start position,

release key when engine starts, then release the Murphy switch.

8. Continue to hold the unloader button for about 10 seconds to allow the engine to come up

to speed, then release the un-loader button.

9. Check to see that the heat transfer oil pump is rotating. If not, investigate problem before

proceeding to heating operations.

OPERATIONS Engine

19

OPERATIONS Burner and Pump

Burner & Pump Operations:

1. Start engine (see engine operations).

2. Open burner exhaust rain cap.

3. Unlatch loading chute, this will allow for

emergency venting in case of a "flash".

4. Set heating oil thermostat 25 to 50° F above the asphalt product manufacturers recom-

mended temperature. Thermostat will display the set point and the actual temperature of

the product.

5. Set product thermostat to the product manufacturers recommended temperature. Thermo-

stat will display the set point and the actual temperature of the product.

6. Turn ON burner power switch and the burner will ignite.

7. When product begins to melt, slowly engage agitator and observe drive motor for rotation,

if it does not rotate, allow additional heating time before engaging.

8. Set pump saver switch to the "Recirculate" position.

9. As the product reaches application temperature, place the WPC valve in the "Recirculate"

position and slowly engage product pump hydraulic valve to the "Pump" position and ob-

serve pump motor for rotation, if no rotation is observed, allow additional heating time.

(This will circulate the product with-in the pump and tank.)

10.Place wand into the recirculating flange and fully open the wand flow control valve located

on the wand handle.

11.Set the electric wand heat control to the ON position and allow 20 to 30 minutes for the

elements to heat.

12.Continue to recirculate the product until the recommended temperature is reached as indi-

cated on the thermometer next to the WPC valve.

13.Slowly move the WPC valve towards the "Wand" position to allow the product to flow

through the wand and back to the tank. If no product flows out the wand, allow additional

time for the electric heating elements to melt the product in the hose and wand.

NOTE: The pump will not operate unless the trigger is pulled on the wand.

14.When the product is flowing freely and temperatures are stabilized, the product is ready to

20

OPERATIONS Application

Standard Application Operations:

NOTE: For units equipped with pump saver option installed, the pump will only function when

the trigger is pulled on the wand.

Application Operations with "Pump Saver”:

1. Position the WPC valve fully to the "Wand" position.

2. Close the wand flow control valve (located on the wand handle) and remove wand from

the recirculating flange.

3. Open the wand flow control valve and pull trigger to apply product to the road surface.

4. Adjust the pump speed as necessary for the desired flow.

6. Monitor the level in the tank and add product as necessary.

CAUTION: Do not engage wand heat unless there is product in the hose.

CAUTION: Positioning of the pump speed all the way to the "max flow" position may cause

excess pressure in the wand which may cause damage to the wand hose or system. The

pump speed should not be positioned fully to the "max flow” unless the wand flow control

valve located on the wand is open and product is flowing freely, or the pump saver is in op-

eration. Observing unusual flexing in the wand hose should signal to the operator that excess

pressure is being applied to the wand hose and the pump speed should be adjusted accord-

ingly.

Table of contents

Other Stepp Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

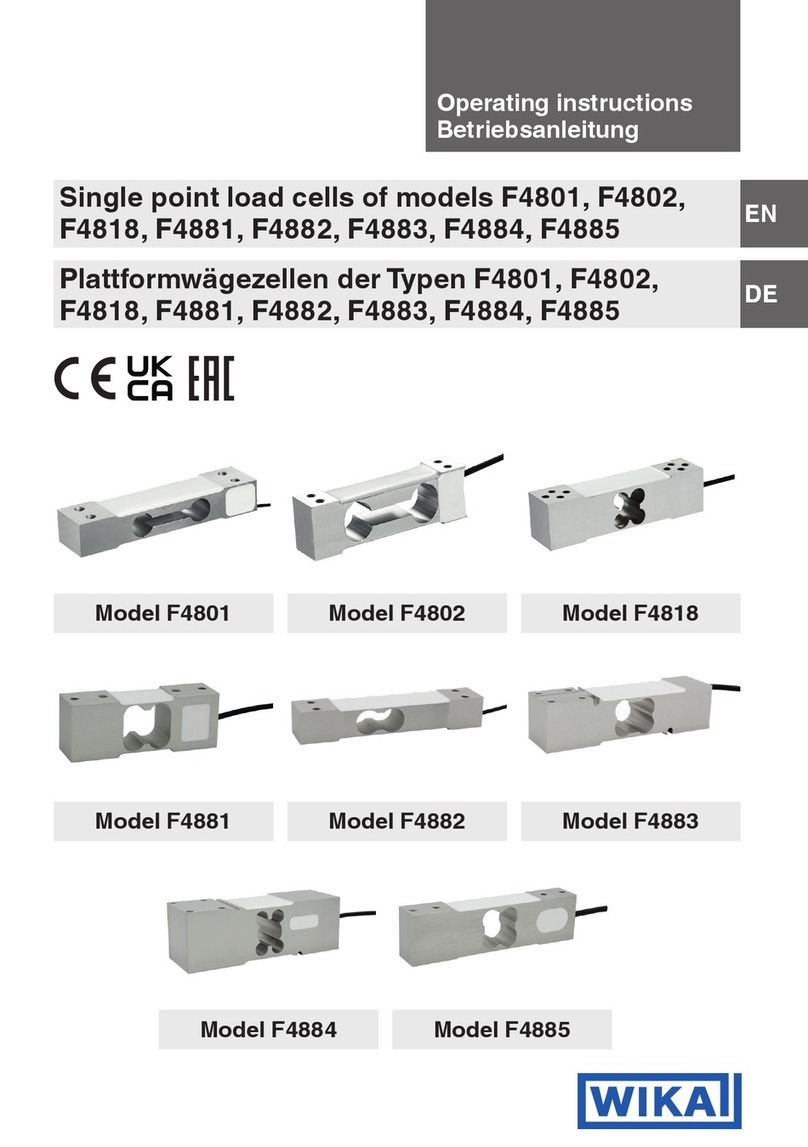

WIKA

WIKA F4801 operating instructions

Clarke

Clarke CSBCT Operation & maintenance instructions

Chicago Pneumatic

Chicago Pneumatic M2501-5500-TL Safety information

Charmhigh

Charmhigh CHM-T48VB manual

IEMCA

IEMCA MASTER 880 MP E-volution Manual for use and maintenance

WALTHER PILOT

WALTHER PILOT PILOT Signier 20 357 operating instructions