WP440L-Series Reverse Osmosis System

Installation Instructions and User Manual

I/O Expander .................................................................................................................................................................. 24

Auxiliary Output.............................................................................................................................................................. 24

Tank Low........................................................................................................................................................................ 24

Boost Pump Output........................................................................................................................................................ 24

Divert Output .................................................................................................................................................................. 24

Alarm Output.................................................................................................................................................................. 24

ADJUSTMENTS ................................................................................................................................................................ 24

TDS / Conductivity Calibration....................................................................................................................................... 24

Display Adjustment ........................................................................................................................................................ 24

Initial System Start-Up....................................................................................................................................................... 25

Operating DO’s & DON’Ts................................................................................................................................................. 26

System Automation ........................................................................................................................................................... 26

System Shut-Down............................................................................................................................................................ 27

System Monitoring and Record Keeping ........................................................................................................................... 27

Data Log ............................................................................................................................................................................ 28

Troubleshooting .................................................................................................................................................................... 30

General Troubleshooting ................................................................................................................................................... 30

System Controller Troubleshooting – I-ROC150S ............................................................................................................ 31

Pump Troubleshooting (for Systems with Procon Pumps) ............................................................................................ 32

System Maintenance............................................................................................................................................................. 34

Sediment Pre-Filter Cartridge............................................................................................................................................ 34

When to Change Sediment Prefilter Cartridge .............................................................................................................. 34

Changing Cartridge Filters ............................................................................................................................................. 34

Membrane Cleaning .......................................................................................................................................................... 34

When to Clean Membranes ........................................................................................................................................... 34

Common Foulants and Their Associated Symptoms .................................................................................................... 35

Cleaning Sequence........................................................................................................................................................ 35

Cleaning Procedure Using Membrane Cleaning Cartridges.......................................................................................... 35

Membrane Replacement ................................................................................................................................................... 35

Low Pressure Switch Adjustment ...................................................................................................................................... 36

Pump Maintenance (for systems with Sta-Rite Pump)...................................................................................................... 37

Shut Down and Storage ........................................................................................................................................................ 38

Membrane Storage (outside of RO system)...................................................................................................................... 38

RO System Storage and Biocidal Protection..................................................................................................................... 38

Disinfection and Sterilization of RO Elements................................................................................................................... 39

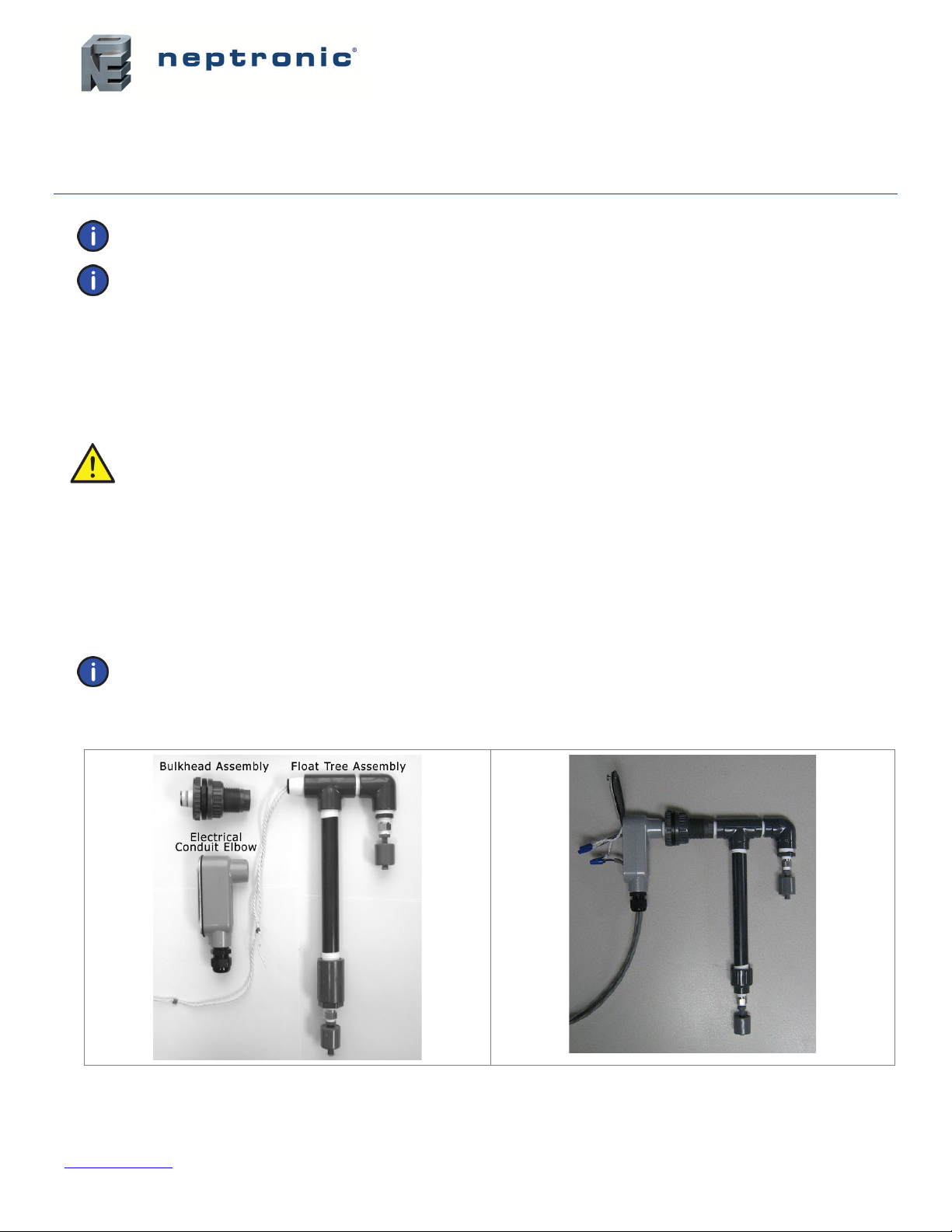

Component Identification- Standard Features up to WP4406L........................................................................................ 39

Component Identification- Standard Features for WP440XL ............................................................................................ 43

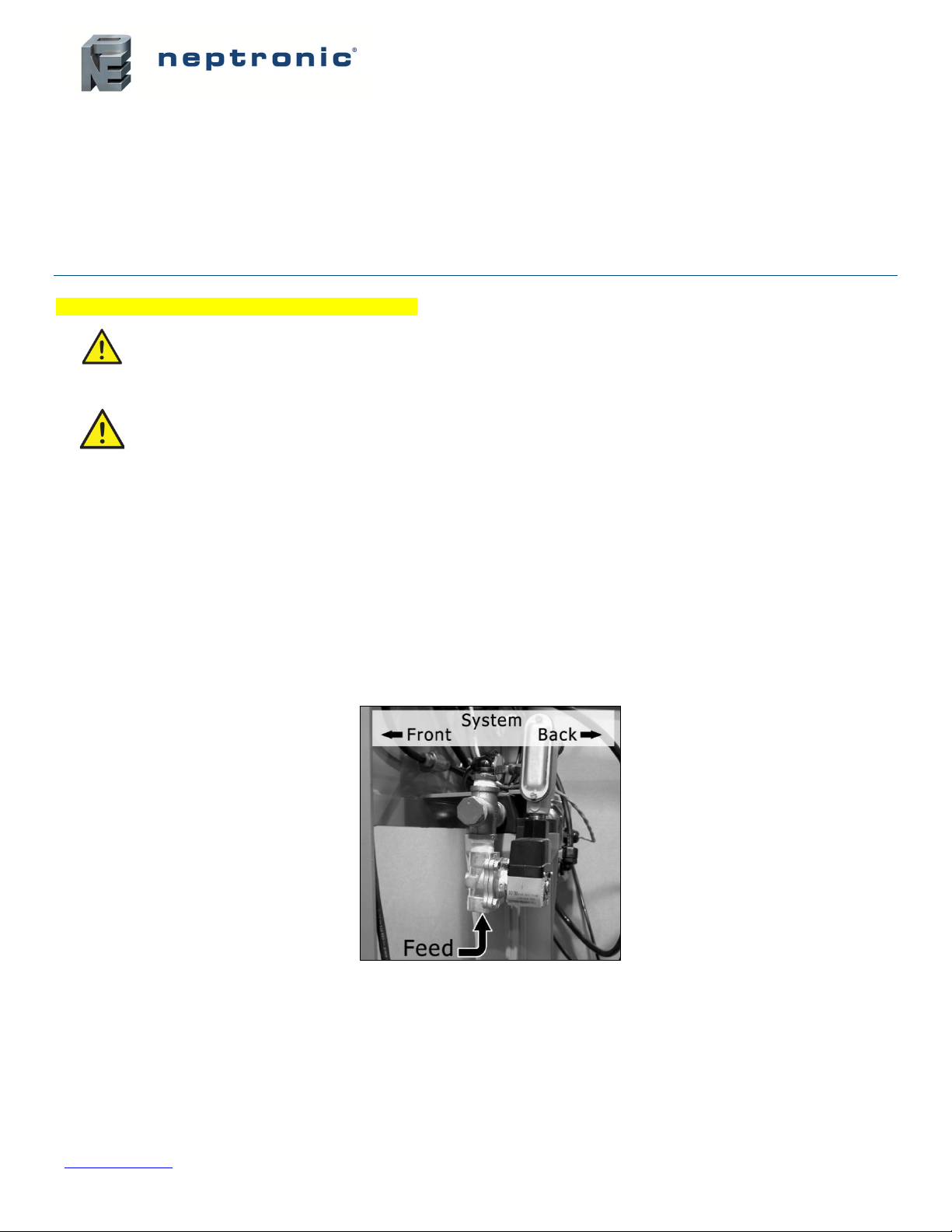

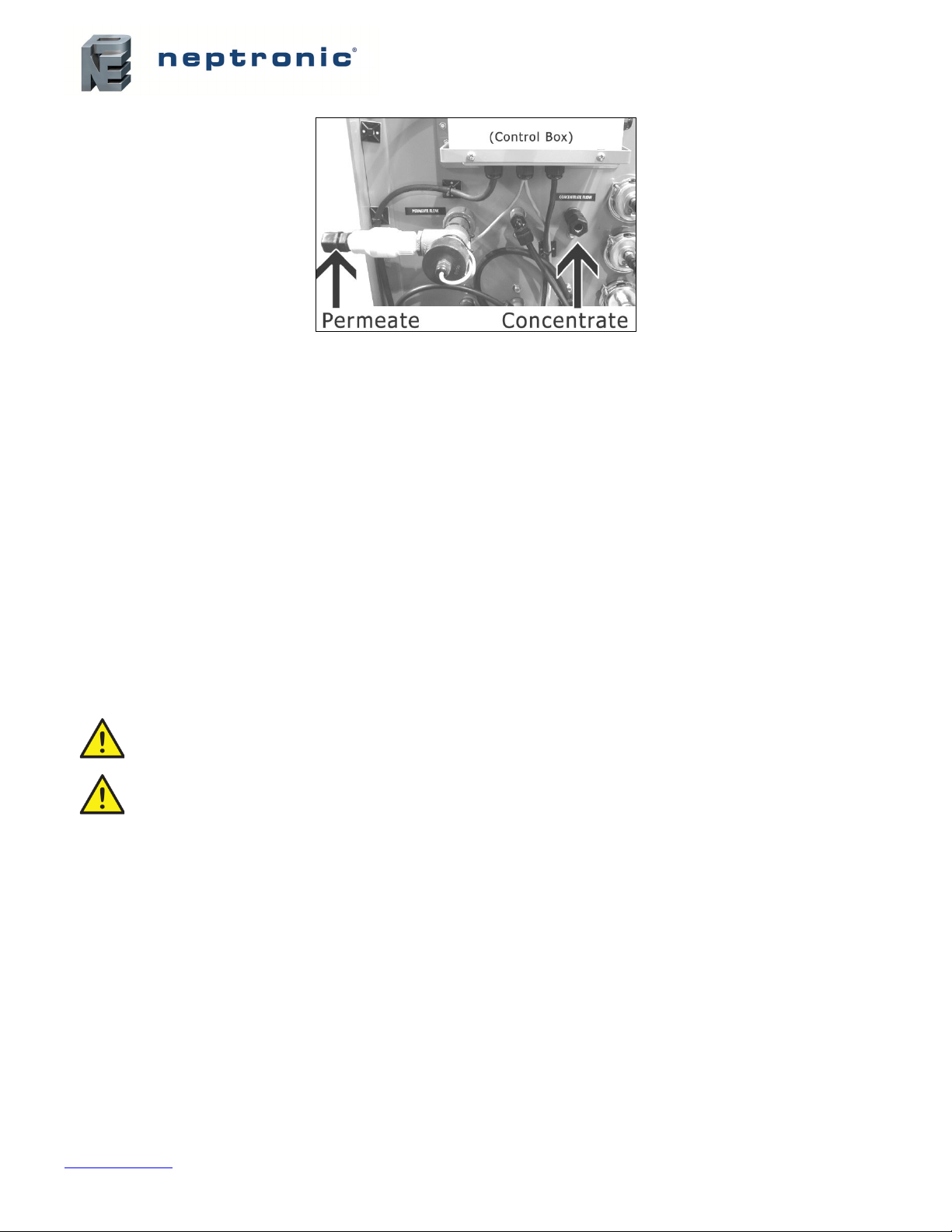

General Arrangement of Systems with Procon Pump....................................................................................................... 44

General Arrangement of Systems with Sta-Rite Pump ..................................................................................................... 44

Parts & Instrumentation Drawing (P&ID) ........................................................................................................................... 45