Z_ISE20C-TF2Z061EN

Page 2 of 3

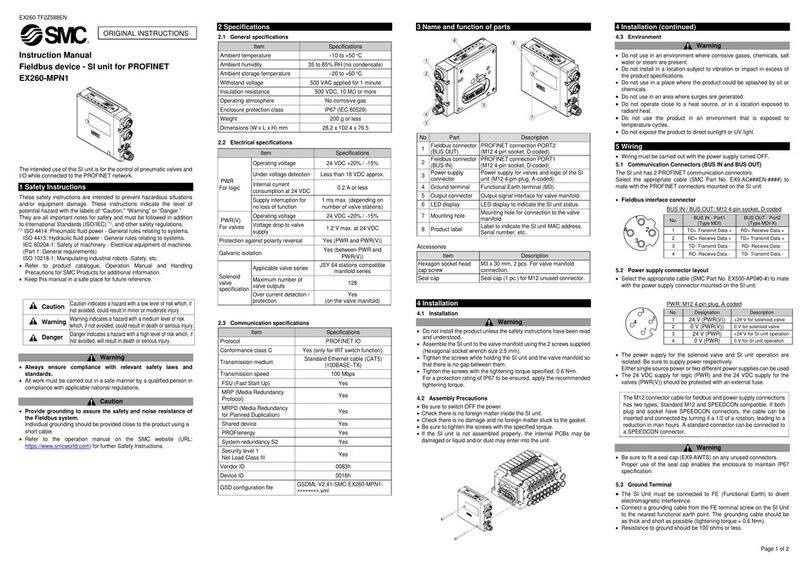

4 Installation (continued)

•Bottom Piping

•Hold a panel between panel mount adapter A and B.

•Then insert pressure switch and mounting bracket into the panel in

that order.

•Panel mount adapter (Part No.: ZS-35-B)

Panel mount adapter + Front protective cover (Part No.: ZS-35-E)

4.2 Environment

Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact. Check the

product specifications.

•Do not mount in a location exposed to radiant heat.

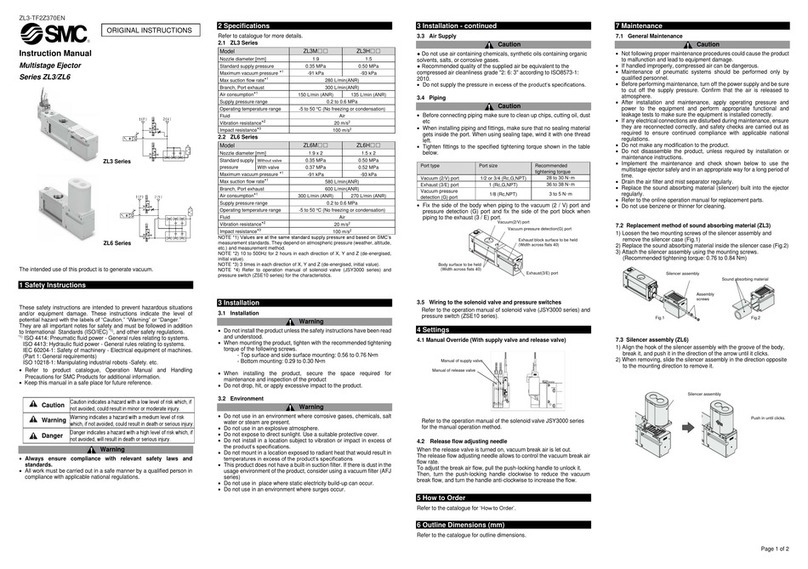

4.3 Piping

Caution

•Before piping make sure to clean up chips, cutting oil, dust etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

•Connection using screw type fitting

•Connect suitable piping to the port.

•To connect the hexagon socket head plug or fitting to the pressure

port, hold the hexagon part of the pressure port with a suitable

spanner. Apply a tightening torque of 8 to 12 N•m.

When tightening, do not hold the pressure switch body with a spanner.

4 Installation (continued)

4.3.1 Tube attachment

•When the pressure switch is used in a place where water and dust

splashes may occur, insert a tube in the atmospheric vent port, and

position the other end of the tube at safe position to protect the vent

port from water and dust (see the figure bottom).

∗: The tube should be inserted to the end of the atmospheric vent port.

∗: SMC TU0425 (polyurethane, O.D φ4, I.D φ2.5) is a suitable tubing.

4.3.2 Wiring connections

•Connections should be made with the power supply turned off.

•Use a separate route for the product wiring and any power or high

voltage wiring. Otherwise, malfunction may result due to noise.

•If a commercially available switching power supply is used, be sure to

ground the frame ground (FG) terminal. If the switching power supply is

connected for use, switching noise will be superimposed and it will not

be able to meet the product specifications. In that case, insert a noise

filter such as a line noise filter/ferrite between the switching power

supplies or change the switching power supply to a series power

supply.

4.3.3 How to use connector

Connector attachment / detachment

•When connecting the connector, insert it straight onto the pins, holding

the lever and connector body, and lock the connector by pushing the

lever hook into the concave groove on the housing.

•To detach the connector, remove the hook from the groove by pressing

the lever downward, and pull the connector straight out.

Connector pin numbers

4.4 Lubrication

Caution

•SMC products have been lubricated for life at manufacture, and do

not require lubrication in service.

•If a lubricant is used in the system, use turbine oil Class 1 (no

additive), ISO VG32. Once lubricant is used in the system, lubrication

must be continued because the original lubricant applied during

manufacturing will be washed away.

5 Settings

Power is supplied.

The product code is displayed

for approximately 3 sec. after supplying power.

∗

: Within approximately 0.2 second after power-on, the switch starts.

5.1 Default Pressure setting

When the pressure exceeds the set value, the switch will turn on. When

the pressure falls below the set value by the amount of hysteresis or

more, the switch will turn off. The default setting is to turn on the

pressure switch when the pressure reaches the center of the

atmospheric pressure and upper limit of the rated pressure range. If this

condition, shown to the below, is acceptable, then keep these settings.

6 3 step Setting mode

[3 step setting mode (hysteresis mode)]

In the 3 step setting mode, the set value (P_1 or n_1, P_2 or n_2) and

hysteresis (H_1 or H_2) can be changed. Set the items on the sub

display (set value or hysteresis) with or button. When changing

the set value, follow the operation below. The hysteresis setting can be

changed in the same way.

(1) Press the button once when the item to be changed is displayed

on the sub display.

The set value on the sub display (right) will start flashing.

(2) Press the or button to change the set value.

The set value can be increased with button and can be reduced

with button. When the and buttons are pressed and held

simultaneously for 1 second or longer, the set value is displayed as [- - -],

and the set value will be the same as the current pressure value

automatically (snap shot function). Afterwards, it is possible to adjust

the value by pressing the or button.

(3) Press the button to complete the setting.

The Pressure switch turns on within a set pressure range (from P1L to

P1H) during window comparator mode.

Set P1L, the lower limit of the switch operation, and P1H, the upper limit

of the switch operation and WH1 (hysteresis) following the instructions

given above. (When reversed output is selected, the sub display (left)

shows [n1L] and [n1H].)

∗: Set OUT2 in the same way. (ex. P_2, H_2)

Setting of the normal/reverse output switching and hysteresis/window comparator

mode switching are performed with the function selection mode [F 1] Setting of

OUT1 or [F 2] Setting of OUT2.

7 Simple Setting mode

[Simple setting mode (hysteresis mode)]

(1) Press and hold the button between 1 and 3 seconds in

measurement mode. [SEt] is displayed on the main display. When the

button is released while in the [SEt] display, the current pressure value

is displayed on the main display, [P_1] or [n_1] is displayed on the sub

display (left), and the set value is displayed on the sub display (right)

(Flashing).

(2) Change the set value with or button and press the

button to set the value. Then, the setting moves to hysteresis setting.

(The snap shot function can be used).

(3) Change the set value with or button and press the

button to set the value. Then, the setting moves to the delay time of the

switch output. (The snap shot function can be used).

(4) The delay time of the switch output can be selected by pressing the

or button at the ON and OFF point of the switch output.

Delay time setting can prevent the output from chattering.

The delay time can be set in the range 0.00 to 60.00 sec. in 0.01 sec.

increments.

(5) Press the button for 2 seconds or longer to complete the setting.

(If the button is pressed for less than 2 seconds, the setting will move to

the OUT2 setting).

In the window comparator mode, set P1L, the lower limit of the switch

operation, and P1H, the upper limit of the switch operation, WH1

(hysteresis) and dt1 (delay time) following the instructions above.

(When reversed output is selected, the sub display (left) shows [n1L]

and [n1H]). ∗: Set OUT2 in the same way.

[Measurement mode]

Detects the pressure after power is supplied and indicates the

display and switch operating status. This is the basic mode; other

modes should be selected for set-point changes and other

function settings.

Measurement mode screen

Sub display

In measurement mode, the display of the sub display can be

temporarily changed by pressing the or buttons.

∗: One arbitrary display mode can be added to the sub display by setting

the [F10] sub display setting.

If the sub display is switched during the arbitrary display setting, the display

will be returned to the arbitrary display 30 seconds later. (The default

setting does not include arbitrary display.)

Direct the tube to a safe position to protect from water and dust.

button

once.

button

and 3 sec.

button

between 3

and 5 sec.

Set either of

set value or

hysteresis

(3 step setting

mode)

value,

hysteresis

and delay

time

Change the

function

settings

(Function

selection

mode)

Settings

•Zero-

clear

function

•Key-lock

∗: The outputs will continue to operate during setting.

∗: If a button operation is not performed for 3 seconds during the setting, the

display will flash.

(This is to prevent the setting from remaining incomplete if, for instance, an

operator were to leave during setting.)

∗: 3 step setting mode, simple setting mode and function selection mode

settings are reflected each other.