14599906 05/2023 EN/DE

EN

WIKA operating instructions, models F4801, F4802, F4818, F4881, F4882, F4883, F4884, F4885 3

Contents

Contents

1. General information 4

2. Design and function 5

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Description . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . .5

3. Safety 6

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . .6

3.2 Intended Use . . . . . . . . . . . . . . . . . . . . . .6

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . .7

3.4 Responsibility of the operator . . . . . . . . . . . . . . . . .7

3.5 Personnel qualification . . . . . . . . . . . . . . . . . . .8

3.6 Personal protective equipment . . . . . . . . . . . . . . . .8

3.7 Labelling, safety marks . . . . . . . . . . . . . . . . . . .9

4. Transport, packaging and storage 10

4.1 Transport. . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Packaging and storage . . . . . . . . . . . . . . . . . . 10

5. Commissioning, operation 11

5.1 Mounting preparation . . . . . . . . . . . . . . . . . . 11

5.2 Mounting instructions . . . . . . . . . . . . . . . . . . 11

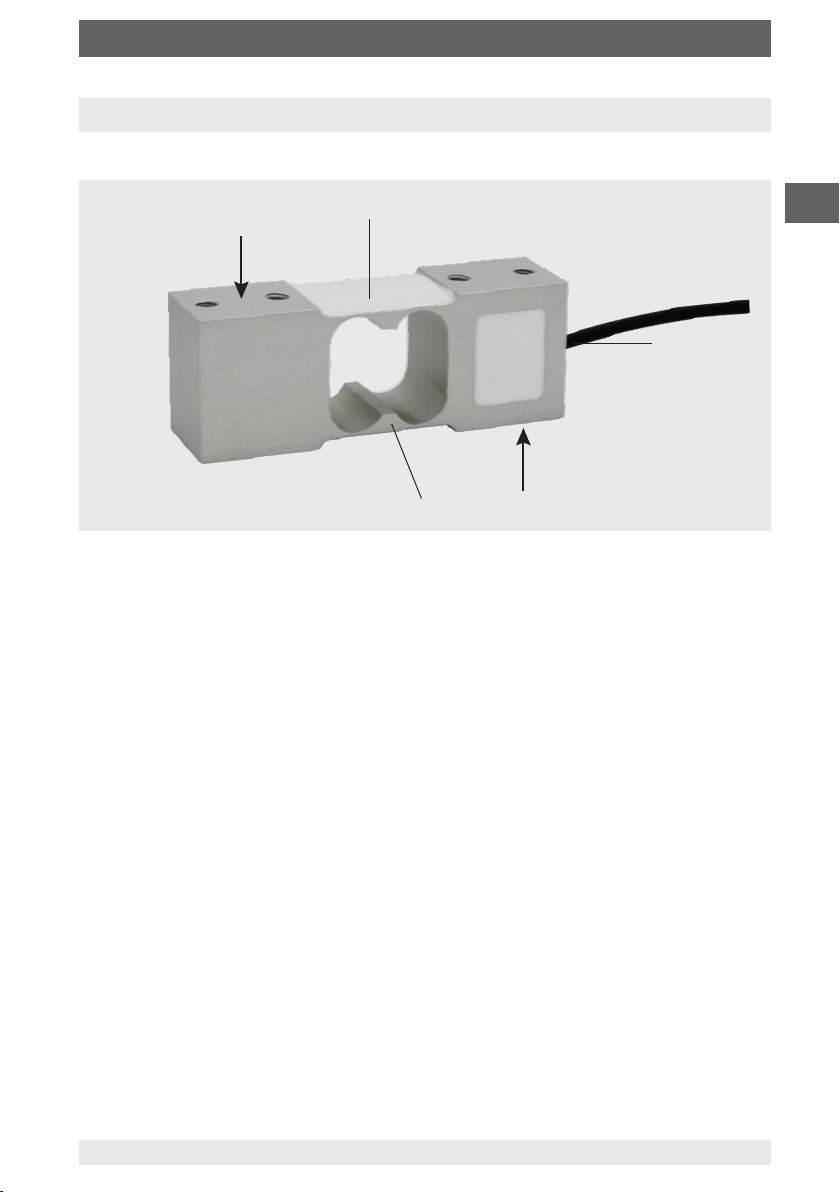

5.3 Mounting the single point load cell . . . . . . . . . . . . . . 12

5.4 Electrical connection. . . . . . . . . . . . . . . . . . . 13

6. Faults 13

7. Maintenance and cleaning 14

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . 14

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . 14

8. Dismounting, return and disposal 15

8.1 Dismounting . . . . . . . . . . . . . . . . . . . . . 15

8.2 Return. . . . . . . . . . . . . . . . . . . . . . . . 15

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . 15

9. Specifications 16

9.1 Approvals . . . . . . . . . . . . . . . . . . . . . . 31

10. Accessories 32

10.1 Cable amplifier, model B1940. . . . . . . . . . . . . . . . 32

10.2 Multi-function display analogue signals, model E1931 . . . . . . . 32

10.3 Strain gauge weighing electronics, model

E1932 . . . . . . . . . . 32

10.4 Junction box, model B6578 . . . . . . . . . . . . . . . . 33

Annex: EU declaration of conformity 34

Annex: UK declaration of conformity 35