Stepp SRM User manual

1

OPERATIONS/MAINTENANCE/PARTS

MANUAL

Diesel Burner Systems

12325 River Road North Branch MN 55056 ~ Phone: 651-674-4491 ~ Fax: 651-674-4221

www.steppmfg.com

Rev. 12/2014

2

Warranty

Stepp Manufacturing Company Inc. hereby warrants to the original purchaser that products

manufactured by Stepp Mfg. will be free from defects in material and workmanship for a

period of one (1) year from the date of purchase.

Stepp Mfg., at its discretion, will provide for the repair or replacement of any part found

upon examination by Stepp Mfg. to be defective, except as noted below. Such repair or re-

placement will be free of charge to the original purchaser for a period of one (1) year from

the date of purchase, except as noted below.

No warranty is extended to cover:

•Product pump wear or damage caused by foreign objects.

•Routine maintenance, cleaning, and adjustments.

•Parts/components that have been altered, misused, or improperly adjusted or maintained.

•Transportation to and from the place of warranty repair.

•Removal of material from equipment.

The following items are covered solely by their manufactures warranty:

•Engines

•Hydraulic components

•Burners

•Pumps

•Tires

•Other component parts

The following items are covered by a pro-rata warranty:

•Hoses that carry heated materials.

•Heating elements for hoses and wands.

Disclaimer of further warranty:

Stepp Mfg. makes no warranty, expressed or implied, other than this warranty. The implied

warranties of merchantability and fitness for particular purpose are hereby disclaimed. Re-

pair or replacement of products or parts proving to be defective in material or workmanship

shall be the exclusive remedy for breach of this warranty.

Stepp Mfg shall not be liable for incidental or consequential damages including but not

limited to: damages for inconvenience, rental or purchase of replacement equipment, for

loss of profits, loss of material, or other loss resulting from breach of this warranty.

Stepp Mfg reserves the right to incorporate any changes in design into its products without

obligation to make such changes on products previously manufactured.

Please see Warranty section for more details.

Stepp Manufacturing Co., Inc.

12325 River Road

North Branch, MN 55056

P: 651-674-4491 F: 651-674-4221

www.steppmfg.com

3

INTRODUCTION

SRM Recycler

Thank you for selecting Stepp highway maintenance equipment. We are confi-

dent you will be satisfied with the Stepp Recycler Mixer. Stepp Manufacturing is

backed by over 70 years of experience in the design and manufacture of high-

way maintenance equipment. This experience, along with our innovative design

and unique features, make the Stepp Recycler Mixer an indispensable piece of

equipment for your road repairs.

In order to assure safe operation of this equipment, the operator must read and

understand all operating procedures and safety notices contained in this manu-

al. In addition, the operator must receive instruction on how to safely operate the

Stepp Recycler Mixer. Contact the manufacturer if any questions arise or if you

desire training for additional staff members.

Operating instructions, adjustments, and periodic maintenance procedures are

given so you, the operator, can keep your unit working like new and expect

many years of dependable service from it. Remember, any machine, regardless

of design or type, will perform only in relation to the way it is operated and the

maintenance it receives.

Read this manual carefully and observe all warnings and cautions. If you have

any recommendations or comments regarding this manual, please send them

to: Stepp Manufacturing Co. Inc., 12325 River Road, North Branch MN 55056-

6225 or call 651-674-4491. All comments we receive are reviewed and may be

incorporated into future manuals.

When ordering parts or making any inquiry about the Stepp Recycler Mixer, be

sure to include the model and serial number found on the data plate attached to

the frame.

WARNING Do not use the equipment unless the operator has read and understood the oper-

ating and safety instructions and has received proper training. Do not operate equipment un-

less all guards and safety devices are in place and functional.

WARNING Do not exceed safe operating temperature of asphalt or bituminous material.

Know the "Flash Point" temperature of the material being used and DO NOT exceed this tem-

perature. The recommended operating temperature information is available from the material

manufacturer. Exceeding the recommended temperature may cause equipment damage and

serious injury or death.

4

Dimensions (approx.)

Length.………………………………………………………………...……...……234 in.

Width…………………………………..………………...……………………..…...99 in.

Height……………………………………………………………..…….Operating 116 in.

Weight…………………………………………………..…………………...…..5,350 lbs.

General

Fuel Tank Capacity……………………..……………………………..……... 60 Gallons

Preheat Hopper

Capacity……………………………………………………………………….….10 cu.ft.

Opening Dimensions…………………………………………………………. …23"x 38"

Loading Conveyor

Belt………………………………………………………...…………... 16" Wide Cleated

Hydraulic Motor…………………….….4.0 cu.in. Hydraulic Motor w\ Forward-Reverse

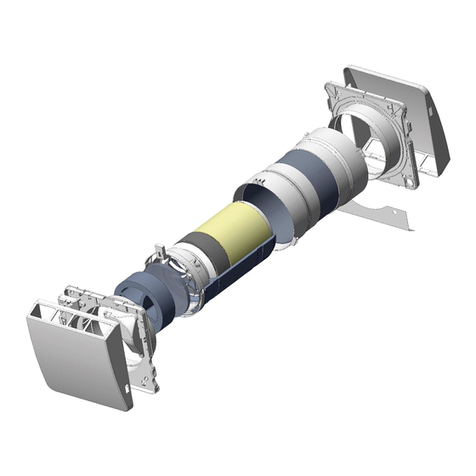

Mixing Chamber

Chamber Type………………………………...………………..Continuous Batch Mixing

Mixing Style…………………………………..……………………….. Rotating Pugmill

Liner Type……………………………………………………..….U-shaped, Replaceable

Combustion Chamber Liner Material……….....Replaceable ¼" Wear Resistant AR Steel

Insulation Type and Thickness…………………...….. 2" Fiberglass & Cerwool, 2" thick

Pugmill Drive, Hyd Motor……………..5.75:1 Gear Reduction Driven by 18/9 ci 2 speed

Pugmill:

Pugmill Dimensions…………………………………………..Length 57" x Diameter 27"

Shaft Size……………………………………………………………………...2½" Square

Paddle Size………………………………..………………….……... Replaceable 4" x 5"

Paddle Material………………….. Reversible, Replaceable, ¼" Wear Resistant AR Steel

Number of Paddles………..………………………………………………………........24

Mixing Chamber Heating System

Burner Type …………………………………..……………... Indirect Diesel, Forced Air

Number of Burners……………………………...………………………………...Two (2)

Fuel Type…………………………………………...……………………………… Diesel

Manufacturer………………………………………...…………………………..Beckett®

BTU Output……………………………...up to 420,000 BTU each - 840,000 BTU Total

CONTINUED ON NEXT PAGE

5

Kettle Pumping System

Pump Model……………………………………………………………….Viking HL32®

Relief Valve ………………………………………………………...…….…. WPC Valve

GPM Output Rating……………………………………………………………….20 gpm

Pump Mounting……………………….………………………………..……...Submerged

Pump Drive……………….…..Hydraulic, Reversible, Variable Speed with PLC Display

Engine

Manufacture………………………………..………………………………...…. Kubota®

Model…………………………………..……………………..……………….. V1505EB

Displacement…………………………..……………………...…………….81 cubic inch

Number of Cylinders…..…………………………………………………………...…..(4)

Horse Power…………………………..………………..…………………………35.1 HP

Fuel Type……………………………….……………..…………………………….Diesel

Cooling………………………………...……………….…………………………..Liquid

Hydraulic System

System Type………………………………………...…..Eaton 7000 Series Load Sensing

Pump Displacement…………………..…………………………...Variable 0 to 1.9 cu.in.

Control type ………………………………………....…..Forward/Reverse Flow Control,

Electric Over Manual Operated, Expandable Manifold Cartridge Valve

Hydraulically Powered Hopper Agitator, Hopper Loading Doors,

Sub. Pumping System, and Loading Conveyor

Reservoir Capacity……..………………………………………...…………….30 Gallons

Filtration………………………….………………………………...………….10 Microns

Chassis

Number of Axles………………………..………………………………..………..Two (2)

Axle Capacity…………………………..…………………………………..6000 lbs. each

Tire Size…………………………...………………………………………..….225/75R15

Brake Type…………………….……….…..…..Electric Std (Hyd Optional), all 4 wheels

Landing Gear Static Capacity………….…………………………………..8,000 lbs each

Screw jack Quantity……...……………...………………………………………...One (1)

Hitch Type……………....3" Pintle Ring or 2 5/16” Ball Type adjustable from 24" to 31"

Frame Material………………………..........................2"x 6"x 3/16” Rectangular Tubing

Lighting………………………...……………………...……Approved w/ Breakaway Kit

Recessed Grommeted Lights……………………………………………………Standard

6

TABLE OF CONTENTS

Introduction 3

Warnings, Cautions, Notes 7

Operations 9

Maintenance 27

Trouble Shooting 37

Replacement Parts 45

Warranty Guide 101

Schematics 107

Hydraulic Oil MSDS 111

Tire Information Insert

Engine Manual Insert

IMPORTANT NOTICE!

This manual contains cautions and warnings that alert you to potential safety issues.

WARNING is used to inform you of conditions or operations that could cause serious injury or death.

CAUTION is used to inform you of conditions or operations that could cause damage to the equipment.

NOTE is used to provide you with additional information that may be helpful or useful for a particular situation.

7

Before Starting or Operating this Machine

Understand and observe all the following Warnings, Cautions, and Notes.

WARNINGS

This equipment contains mechanical and heating components that may cause serious injury or death if not

handled or maintained properly. All personnel must be properly trained in the operation and maintenance of

this equipment.

Before refueling, shut off the burners and allow all flames in the burner and pilot light to extinguish. Shut off

the engine.

Check fuel lines, fuel line connections, and all other components for leaks. If any leaks are found, they must

be repaired before using the unit.

Know the temperature required for the material being used, and do not exceed this temperature. Avoid over

heating, as this may cause equipment damage, personal injury, and/or death.

Never load a tank with heated oil when moisture is present in the tank. Depending on the temperature of the

hot oil, the moisture may instantly boil causing hot oil to foam up and out of the tank causing severe burns.

Do not operate the tack tank burner when the amount of material in the tank is less than 4" above the flues.

Allow 10 minutes cool-down time after the burner has been shut off before exposing the flues. Exposed flues

will over-heat and cause an explosion and/or fire.

The tack tank cover must be unlatched when operating the tack tank burner. This is to provide for emergen-

cy venting, in the event of a flash, to prevent the tank from exploding.

CAUTIONS

Know the materials being used and know the proper handling, heating, application, clean-up, and storage

procedures. Not all materials are compatible with each other. Many materials have a very limited shelf life.

Most materials require special handling procedures to prevent personal injury and/or equipment damage.

Contact your material supplier and/or manufacturer for proper handling instructions. Equipment malfunction

or damage due to improper handling or use of the materials is not covered by warranty.

Do not exceed the maximum heating temperature or storage time as recommended by the material manu-

facturer. This may cause emulsion type materials to separate and become difficult or impossible to remove

from the machine. Consult with the material manufacturer for recommendations.

Over-agitation or circulation may cause emulsion type materials to separate and become difficult or impossi-

ble to remove from the machine. Consult with the material manufacturer for recommendations.

Do not mix Anionic and Cationic materials together, as the materials attach to each other and will become

difficult or impossible to remove from the machine. If you are not sure consult your material supplier.

NOTES

Become familiar with the Material Safety Data Sheet (MSDS) for the material being used in the machine and

take appropriate safety precautions. Wear the proper clothing and protective gear as recommended by the

MSDS and your safety director.

DO NOT use the equipment unless it is in good condition.

In case of skin contact with hot materials, dip into cool, clean water immediately. Do not wipe the product,

as this will spread the burn.

Consult the MSDS and contact your safety director for proper extinguishing of petroleum based fires.

Carry a fire extinguisher(s) as recommended by your safety director.

Notify your supervisor or the manufacturer if any questions arise concerning the operation of this equipment.

8

9

OPERATIONS

10

OPERATIONS Basic Operation

WARNING: Before refueling, shut off the burners and the engine.

CAUTION: Be sure operators have been properly instructed in starting and op-

erating all equipment before beginning.

NOTE: See following pages for specific instructions on operating burners and

heating systems.

Pre-Trip Inspection

1. Check engine fluid levels & grease machine.

2. Check tire pressure.

3. Start conveyor check for wear & tracking.

4. Inspect unit for any physical damage.

5. Check pugmill for broken paddles and excessive wear.

6. Check that discharge door is operating properly.

7. Truck hook-up and lights .

Transporting

Trailer Hook-up

1. Connect trailer to towing vehicle

a. Assure hitch is engaged properly.

b. Attach safety chains to towing vehicle.

c. Connect battery charging circuit to tow vehicle if required. (see illustration below)

d. Connect electrical plug to towing vehicle.

e. Connect breakaway cable to towing vehicle.

f. Check operation of lights and brakes.

2. Secure trailer for transport

a. Shut OFF the engine and burners.

b. Shut OFF all fuel valves.

c. Be sure the product temperature is not above the recommended operating

temperature.

d. Securely latch the tank cover.

WARNING: Prior to transporting, the driver of the tow vehicle must assure the

safety of the operation. The driver must also know, and assure, that the product

temperature is within limits.

11

1. Start engine (refer to engine operations).

2. Turn on control box power switch.

3. Load bituminous/asphalt material into kettle using the safety loading chute. Make sure no

moisture is present in tank. Be sure to wear proper protective clothing. Flues must be

completely covered with 4” or more of material to prevent equipment damage or personal

injury. Turn burner-oil switch on. The red indicator light on the switch will turn green. Set

tack oil SP (set point) thermostat to desired temperature using the up and down buttons

on the controller. The tack oil thermostat will display the actual temperature (top reading)

and SP (set point), or desired, temperature. Depending on the asphalt materials being

used, set temperature to a lower setting to allow temperature to “creep” for initial heat up.

4. When material is hot enough to flow, set valves for circulation and engage product pump

in "Pump" position (refer to pumping operations chart located on the rear of the pugmill).

Start the loading conveyor.

5. Fill preheat hopper with recyclable asphalt material to a level even with the top edge. Piec-

es must be small enough to pass through the trap doors. The equipment will provide bet-

ter performance with smaller pieces. Start conveyor and load hopper with material. NOTE:

Check hopper doors. Doors must be closed prior to loading.

6. Start pugmill burners, front and rear. Switch will turn green when on. CAUTION: Do not

use recycler timer for initial pugmill warm up. This could cause residue in hopper to catch

fire. If hopper catches fire, dispense load of material into hopper to smother fire, turn the

burners off, and allow the machine to cool down before re-firing. Burners will shut off at

set point temperature (250

°

). Over heating may cause pugmill damage.

7. Start pugmill mix paddles (2). NOTE: Make sure pugmill paddles are moving freely in both

directions, forward and reverse positions.

8. Engage pugmill mix. Empty contents of the preheat hopper into the recycler mixing cham-

ber using the hydraulic operated trap doors using the door open switch.

9. Set the recycler burner timer for desired heating time by using the up and down buttons

next to the timer. The amount of mixing time and heat necessary will be determined

through experience. Moisture and material quality varies and will vary the timer setting.

10.Set batch time. NOTE: Set initial batch time for 10 minutes. Normal batch times may vary

from anywhere between 8-16 minutes, with the first batch of the day taking longer due to

heating the machine up. Press the “Cycle Start” button to start the batch timer and activate

the burners to the pugmill set point. If more time is needed, adjust time accordingly. Oper-

ator will need to dispense a small amount of material to test the temperature with a hand

held infrared scanner. Burners will fire to the high level set point until additional time has

elapsed. When burners are firing, watch the top stack for moisture dissipating. Batch will

be very close to temperature once the steam has stopped and you are getting a clean ex-

haust. If exhaust starts to smoke or turn blue, the material is overheated or very close to

being overheated. If blue smoke is present turn burner switches off and discharge materi-

al. CAUTION: Discharge material at 320-350°. If material is at temperature before time is

done, shut off the burner.

11.Adjust the damper on the exhaust stack according to heating needs. Closing the damper

will retain more heat in the recycler’s mixing chamber. Opening the damper will allow raw

aggregate to dry quicker.

OPERATIONS Basic Operation

12

12.If necessary, add heated bituminous binding material to the recycler

mixing chamber (refer to the plumbing operations chart). Here again,

experience is the best indicator of how much to add. Start with 1/2-11/2

gallons of oil. Know the material being added and the flash point. We

recommend that you use an AC type oil and add the oil in the first three

minutes of the batch timer. The pump has an oil counter so you can

meter the amount of material added. With the pump running in the

“forward” position, move valve #2 to the “Mixer” position. The pump will run until the pre-

set amount is reached. At that point, the pump will stop and the attention light will flash

until valve #3 is returned to “Recirculate” position.

13.Reload preheat hopper while you wait for the mixing action to be completed. This will al-

low for the next batch to be preheated, resulting in faster batch times.

14.Set the toggle switch to discharge in order to empty the mixed material onto the shovel

platform for easy shoveling. Swinging the shovel platform up out of the way will allow the

mixed material to empty directly on the ground. The switch has two settings: green for

slow discharge, yellow for higher speed discharge. To engage high speed, press dis-

charge twice.

15.Reload the next batch. Press “Cycle Start” button in order to start the next batch.

16.To shut down the machine shut off all burner switches. Empty the recycler mixing cham-

ber.

WARNING: All flames (burners and pilot lights) must be extinguished before flushing opera-

tions begin to reduce the chance of fire and/or personal injury.

17.Flush the pump, wand, and plumbing to prevent a plugged system (refer to the plumbing

operations chart). NOTE: Running a load of coarse rock through the unit will help remove

asphalt deposits.

18.Shut off the engine.

NOTES:

Operator must have infrared heat gun to operate machine.

Check “Set Points” on control panel.

Never have burners on without material in pugmill, unless you are doing start up.

Check material temperature at 8 minutes. Material temperatures will climb quickly once

moisture is out of material. Check every minute or two after that.

Normal batch times vary from 6-18 minutes depending on moisture and material quality.

Initial batch could take 2x’s longer, due to initial heat up of machine.

1/2-1 1/2 gallons of oil additive is average for material.

Allow cooling at end of the day. (Open hopper doors and run pugmill for 10 minutes in dis-

charge.)

OPERATIONS Basic Operation

13

OPERATIONS Material Tips

Helpful Tips to Making Quality Recycled Materials

1. Have your millings tested for asphalt content. This will help you decide how much ad-

ditive you need. The average ton of asphalt top mix has 5-7% oil by weight. This trans-

lates into 100-125 pounds of asphalt added to virgin aggregate to make top mix. PG grade

asphalts are approximately 7.5 pounds per gallon. So if you convert that to gallons there is

approx. 13.3 gallons of asphalt in 100 pounds to make 1 ton of mix. 100/7.5= 13.3333.

Most millings need 1/2-1% of new oil to give you a quality patch material. The SRM makes

approximately a 1000 pound batch, so on average you need to add 1/2 gallon to 1 1/2 gal-

lon or 3.75 pounds to 11.25 pounds of asphalt additive to make a quality mix.

2. Recycled materials have huge variables. Different asphalt contents, different moisture

contents, different aggregates, base material containments, and different size aggregates

will all vary the batch times and material quality. Making your first batches in your SRM

will take some experimenting. You will need to find the right recipe. Start with shorter

batch times and check your material often on the first batch or two. Start with a little oil

and add more as you need it. Once you come up with your recipe for the materials that

you are using you should see consistent results. The next batches will be very similar and

you should only have to make minor adjustments.

3. Keep materials dry. Moisture content is the number one cause for slow batch times. If

you can, keep your millings inside or covered. It takes more BTU to dissipate a gallon of

water than it does to melt a gallon of asphalt. Moisture acts as a refractory in the material

and can not be dispersed until turned to a gas (steam). High moisture content can double

or triple batch times, so having dry millings is key to higher production.

4. Quality of materials. Using quality materials also aids in faster batch times. Materials

with large aggregates take longer to drive the heat into the stone. Contaminated materials

with base also take longer to heat because of lack of oil in the materials. Materials with

higher asphalt contents also heat up faster. The SRM does not care, it just may affect the

heat up times.

5. The SRM is capable of making materials from virgin aggregates. You can make virgin

materials with the SRM, you just need more oil. Using the reference above, in #1, you can

make your own custom mixes. Sand mixes, fine mixes, and mixes from virgin materials.

Again, you will need to do some experimenting to get the right mix design. If making virgin

mix, use the 5-7% to get you started (5-7gallons). Always start with a smaller amount of

oil; you can always add more oil, but you can’t take it away. Different oils will also give you

different results in materials.

6. Pre-made cold mix materials. You can use your SRM to warm your cold mix materials.

Use extreme caution when doing so. Most cold patch materials have a high content of cut-

ter (solvent) in the oil. This makes the material soft and pliable, but also makes them very

easy to catch on fire. If you are using the SRM to heat cold patch material, only fire the

burner in 1-2 minute cycles and check the temperature very often to prevent the material

from flashing.

14

WARNING: The burners must be shut off when the product reaches a level approximately 4"

above the flues. Exposed flues will overheat causing an explosion in the tank. This will cause

equipment damage and possible injury or death to personnel.

Before Igniting the Burner:

1. Know the materials being used. DO NOT exceed flash point or operating range tempera-

tures.

2. Ensure the kettle is level and the heating flues are completely immersed in product to pre-

vent damage to equipment or personal injury.

3. The kettle cover must be unlatched to provide emergency venting in event of a flash.

4. Vent the kettle by opening the cover for five minutes prior to firing.

5. Load bituminous/asphalt material into kettle using the safety loading chute. CAUTION:

Make sure that no moisture is present in tank and make sure to wear proper protective

clothing. Turn “burner-oil” switch on. When material is hot enough to flow, set valves for

circulation and engage product pump in "Pump" position (refer to pumping operations

chart located on the rear of the pugmill).

WARNING: Failure to observe these instructions may cause damage to the equipment, per-

sonnel injury, or death.

Igniting the Burner:

1. Verify heating flues are completely covered with a minimum 4" of product.

2. Verify proper heating temperature, and set the SP (set point) thermostat to that tempera-

ture.

3. Turn oil burner power switch ON and burner will ignite; a small flame indicator will appear.

The red indicator light on the switch will turn green. Set “tack oil SP” (set point) thermostat

to desired temperature using the up and down buttons on the controller. Tack oil thermo-

stat will display actual temperature (top reading) and SP (set point), or desired, tempera-

ture. Depending on asphalt materials used, set temperature to a lower setting to allow

temperature to “creep” for initial heat up.

4. Monitor product level in kettle and shut burner OFF when oil level is 4" above heating

flues.

NOTE: If the "Lockout" message appears on the screen, it indicates a malfunction of the

burner. Verify fuel supply to the burner (proper fuel and no air bubbles in system) then reset

the burner by setting power switch OFF then ON. If problem persists, consult a service techni-

cian. DO NOT reset burner more than two times, as excess fuel may accumulate in combus-

tion chamber creating a fire hazard.

Shutting off the Burner:

1. Set thermostat to the lowest setting and allow a one minute cooling period.

2. Turn OFF burner oil switch on the control box.

3. Close and latch kettle cover.

4. Turn main power switch OFF.

OPERATIONS Kettle Heating System

15

OPERATIONS Mixing Chamber Heating System

WARNING: It is the operators responsibility to set the proper temperature on the thermostats

as required for the operation.

Before Igniting the Burner:

1. Know the materials being used. DO NOT exceed flash point or operating range tempera-

tures.

Igniting the Burner:

1. The SRM recycler chamber has two set point temperatures. One “higher firing” set point

for heating up the mix, and one “stand-by” temperature setting that keeps the liner and

materials at a given temperature. Pressing the “Cycle Start” button changes the max set

point to the “higher firing” set point. These set points are set at 750°F for the “higher firing”

set point, and 250°F for the “stand-by” set point. Both of these are adjustable from the set-

up screen, which is accessed by pressing the ADJUST MILL SET POINT button located

on the upper right hand of the display. The temperatures displayed on the screen are the

temperature readings of the pugmil liner, not the material temperature.

2. Turn ON front, rear, or both recycler burner power switch(s) as desired and burner(s) will

ignite and a flame indicator will appear next to the front or rear on the recycler chamber

display. The burner will fire until the standby temperature is reached. The switch will turn

green when on. CAUTION: Do not use recycler timer for initial pugmill warm up. This

could cause residue in hopper to catch fire. If hopper catches fire, dispense load of

material into hopper to smother fire, turn the burners off, and allow the machine to

cool down before re-firing. Burner’s will shut off at set point temperature (250

°

). Over-

heating may cause pugmill damage.

3. Set batch time. NOTE: Set initial batch time for 10 minutes. Normal batch times may vary

from anywhere between 8-16 minutes, with the first batch of the day taking longer due to

heating the machine up. Press the “Cycle Start” button to start the batch timer and activate

the burners to the pugmill set point. If more time is needed, adjust time accordingly. Oper-

ator will need to dispense a small amount of material to test the temperature with a hand

held infrared scanner. Burners will fire to the high level set point until additional time has

elapsed. When burners are firing, watch the top stack for moisture dissipating. Batch will

be very close to temperature once the steam has stopped and you are getting a clean ex-

haust. If exhaust starts to smoke or turn blue, the material is overheated or very close to

being overheated. If blue smoke is present turn burner switches off and discharge materi-

al. CAUTION: Discharge material at 320-350°. If material is at temperature before time is

done, shut off the burner.

NOTE: If the "Lockout" message appears on the screen, it indicates a malfunction of the

burner. Verify fuel supply to the burner (proper fuel and no air bubbles in system) then reset

the burner by setting power switch OFF then ON. If problem persists consult a service techni-

cian. Do not reset burner more than 2 times as excess fuel may accumulate in combustion

chamber creating a fire hazard.

Shutting off the Burner:

1. Turn OFF power switch(s) on the control box.

16

OPERATIONS PLC Controller

Valve Position: Refers to #3 recirc/mixer valve located

above control box.

Tack Oil: Shows SP (set point) and actual

temperature of oil kettle.

Recycler Chamber: Shows temperature of

the recycler/mixing chamber. Does not

show indicated material temperature.

Oil Pumped: Displays actual gallons

pumped and SP (set point), or desired,

gallons pumped. 1/10 gallon increments.

Burner Timer: Top display batch time will

not restart without pressing the cycle start

button

Tack Oil SP

(set point)

Temperature

Adjustment

Oil Pumped

SP (set point)

Gallon Adjust-

ment

Meter Reset:

Resets the oil

pumped to ze-

ro

Cycle Start:

Resets the

batch timer.

Burner Tim-

er Adjust-

ment: Top

display

batch time

will not re-

start with-

out press-

ing the cy-

cle start

button.

All PLC Switching are latching switches. Press once to turn on and press second time

to turn off. When switch is activated it will turn from red to green.

Pugmill Mix:

Press once for

activating mixer.

Indicator will turn

green when on.

Pugmill Dis-

charge: Press

once for dis-

charge and twice

for high speed

discharge.

Oil Pump Reverse Compactor Plate Carrier

up/down

Optional Equipment

Oil Pump Forward

Conveyor Forward/

Reverse

Top Door Open/Close:

Opens trap door

Burner Con-

trols: Turns

on oil burn-

er, front and

rear pugmill

burners.

17

OPERATIONS Engine Starting

WARNING: Be sure all pre-start checks are complete prior to starting engine.

The SRM is equipped with a digital engine management system. This system will shut the en-

gine down in case of an engine overheat or low oil pressure. It is also equipped with an hour

meter, cold weather glow plug button, and a starting button.

1. Fill fuel tank.

2. Turn “Key Switch” clockwise to the “Start” position.

3. Press and hold Yellow glow plug button for 30-90 seconds.

4. Press Green button to start.

5. If engine does not start on first try, you must turn the “Key Switch” OFF and restart the

starting sequence.

6. To shut engine down turn “Key Switch” counterclockwise.

NOTE: If engine will not turn over, check the emergency shutdown button located on the op-

erators control box.

18

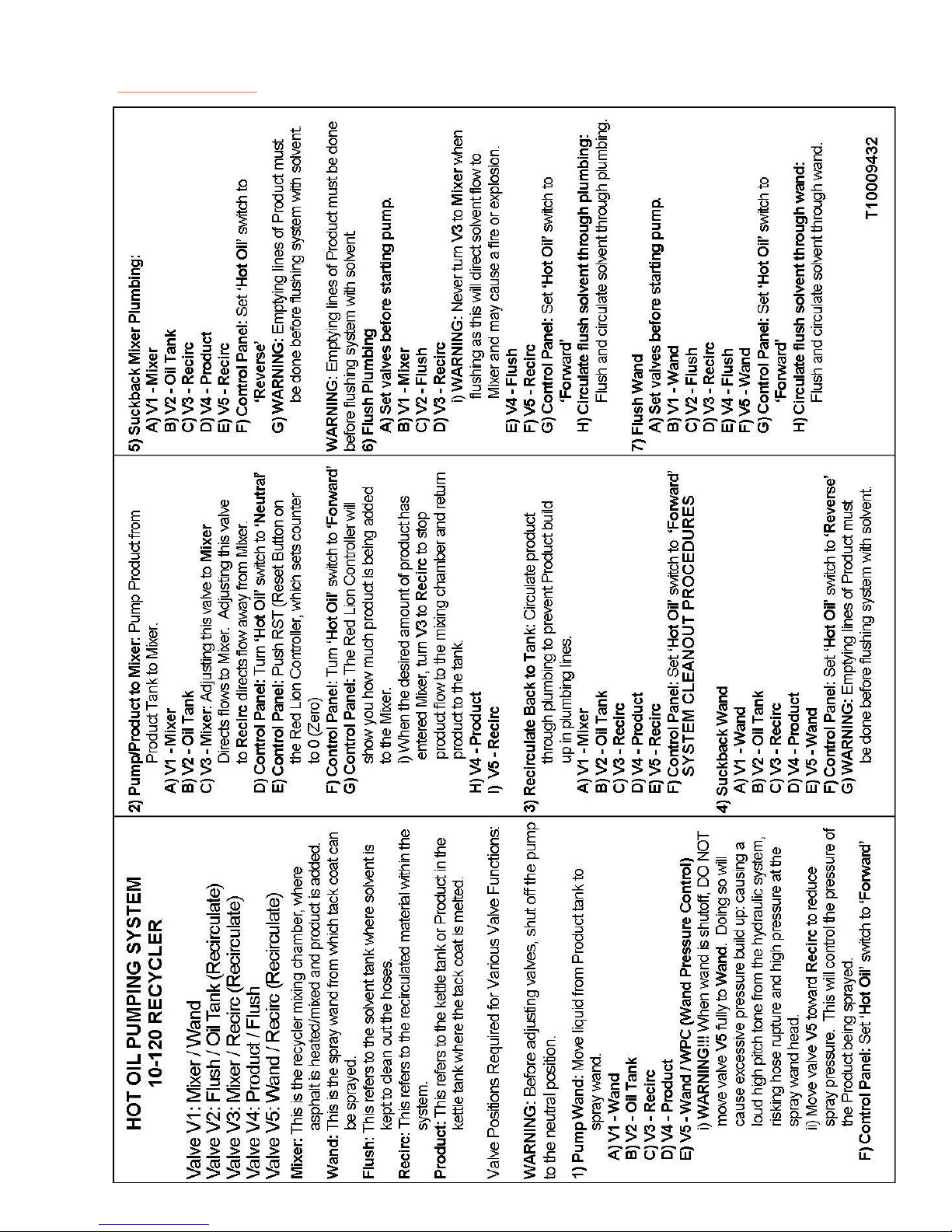

OPERATIONS Pumping System

WARNING:

DO NOT allow flushing solvent to enter hot oil tank or mixer.

DO NOT allow the hot oil tank burner to operate with the product level less than 2

inches above the flues. Severe damage to equipment and possible serious injury will

result!

DO NOT flush through a heated wand.

19

OPERATIONS Pumping System

20

Hand Wand

Wand Pressure Control Valve

(WPC Valve)

Operators must understand the proper operation of the WPC valve located on the top rear of

the unit. The purpose of this valve is to direct the flow of product either back to the tank

(during start-up to assist melting) or to the wand (during crack filling or pothole spraying oper-

ations).

Because of the properties of asphalt, no automatic relief valve is installed in the system.

Therefore, the operator must adjust the WPC valve to a position midway between the valve

stops. This will allow product to flow to the wand and also back to the tank at the same time,

preventing excessive pressure from building up in the hose and wand.

Positioning of the WPC valve towards "Recirculate" will cause less flow and less pressure to

the wand. Positioning of the WPC valve towards "Wand" will cause more flow and more pres-

sure to the wand.

The WPC valve should never be positioned fully to the “Wand” position, unless the wand con-

trol valve located on the wand is fully open, or for flushing operations to ensure that flush sol-

vent will not enter the tank. Excess flow and pressure to the wand may cause damage to the

hose and system, and possibly result in personal injury.

Observing unusual flexing in the wand hose should alert the operator that excess pressure is

being applied to the wand hose. Considering factors such as temperature of product, desired

amount of flow and varied operating conditions will assist the operator in selecting the proper

position of the WPC valve. The WPC valve must be left in the “Recirculate” position when the

unit is shut down.

CAUTION: The WPC valve should never be positioned fully to the “Wand” position, unless the

wand control valve located on the wand is fully open, or for flushing operations to ensure that

flush solvent will not enter the tank. Excess flow and pressure to the wand may cause dam-

age to the hose and system, and possibly result in personal injury.

OPERATIONS WPC Valve

Table of contents

Other Stepp Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics 1220-12ADB Installation and operating manual

Siemens

Siemens TNKM Series installation instructions

Wintriss

Wintriss wpc 2000 user manual

Festo

Festo CPV10-EX-VI Translation of the original instructions

schmersal

schmersal SLC 425I operating instructions

SCHUNK

SCHUNK PGN-plus Series Assembly and operating manual

Marley

Marley Air 4.0 Operating & assembly instructions

Panini

Panini BioCred user guide

Siemens

Siemens SIMOGEAR 2730 Mounting and operating instructions

Innovative Technology

Innovative Technology PureLab HE Glovebox user manual

New Leader

New Leader NL4560 Operator's manual

Beghelli

Beghelli Central Logica Compact SD LGFM quick start guide