EMUGE Speedsynchro Mini User manual

Speedsynchro®Mini

Speedsynchro®Mini

Operating instruction

Speedsynchro®Mini

2 Operating instruction edition: 13.09.2022

Contents:

1Application range, safety instructions and technical data............................. 4

1.1 Application range, determined use............................................................................................. 4

1.2 Specifications ............................................................................................................................. 5

1.3 Safety instructions and hints ...................................................................................................... 6

1.4 Proprietary rights ........................................................................................................................ 6

1.5 Dimensions and technical data .................................................................................................. 7

2Putting the Speedsynchro®Mini into operation.............................................. 8

2.1 Unpacking................................................................................................................................... 8

2.2 First putting into operation / preparation..................................................................................... 8

Locking block already mounted on the machine ............................................................. 9

Mounting of the machine-side locking block on the spindle block................................. 10

2.3 Programming notes.................................................................................................................. 12

2.4 Re-putting into operation.......................................................................................................... 13

2.5 Sealing disk / cooling disk ........................................................................................................ 14

Application ..................................................................................................................... 14

Assembly of the sealing disk or cooling disk................................................................. 14

2.6 Collets....................................................................................................................................... 15

Application ..................................................................................................................... 15

Assembly of the collet.................................................................................................... 15

2.7 Assembly of the tap/cold-forming tap....................................................................................... 16

............................................................................................................................................................... 16

2.8 Remove the tap/cold-forming tap, the clamping nut and the sealing disk................................ 17

3Readout operating data via NFC interface..................................................... 18

3.1 Speedsynchro- Electronics................................................................................................... 18

3.2 Readout operating data............................................................................................................ 18

3.3 Display in the app..................................................................................................................... 19

4Maintenance / Servicing .................................................................................. 21

4.1 Maintenance schedule.............................................................................................................. 21

4.2 External cleaning...................................................................................................................... 21

4.3 Maintenance............................................................................................................................. 21

5Storage when not in use.................................................................................. 22

6Disposal instructions....................................................................................... 22

7EU-Declaration of Conformity......................................................................... 23

8UK Conformity Assessed................................................................................ 24

9FCC-Rules......................................................................................................... 25

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 3

Warnings, symbols

In this operating instruction the following symbols are used:

Attention

Marks special instructions, rules and prohibitions, which are important in order to avoid

any damage.

Please observe these instructions!

Note

Marks application instructions and other useful information.

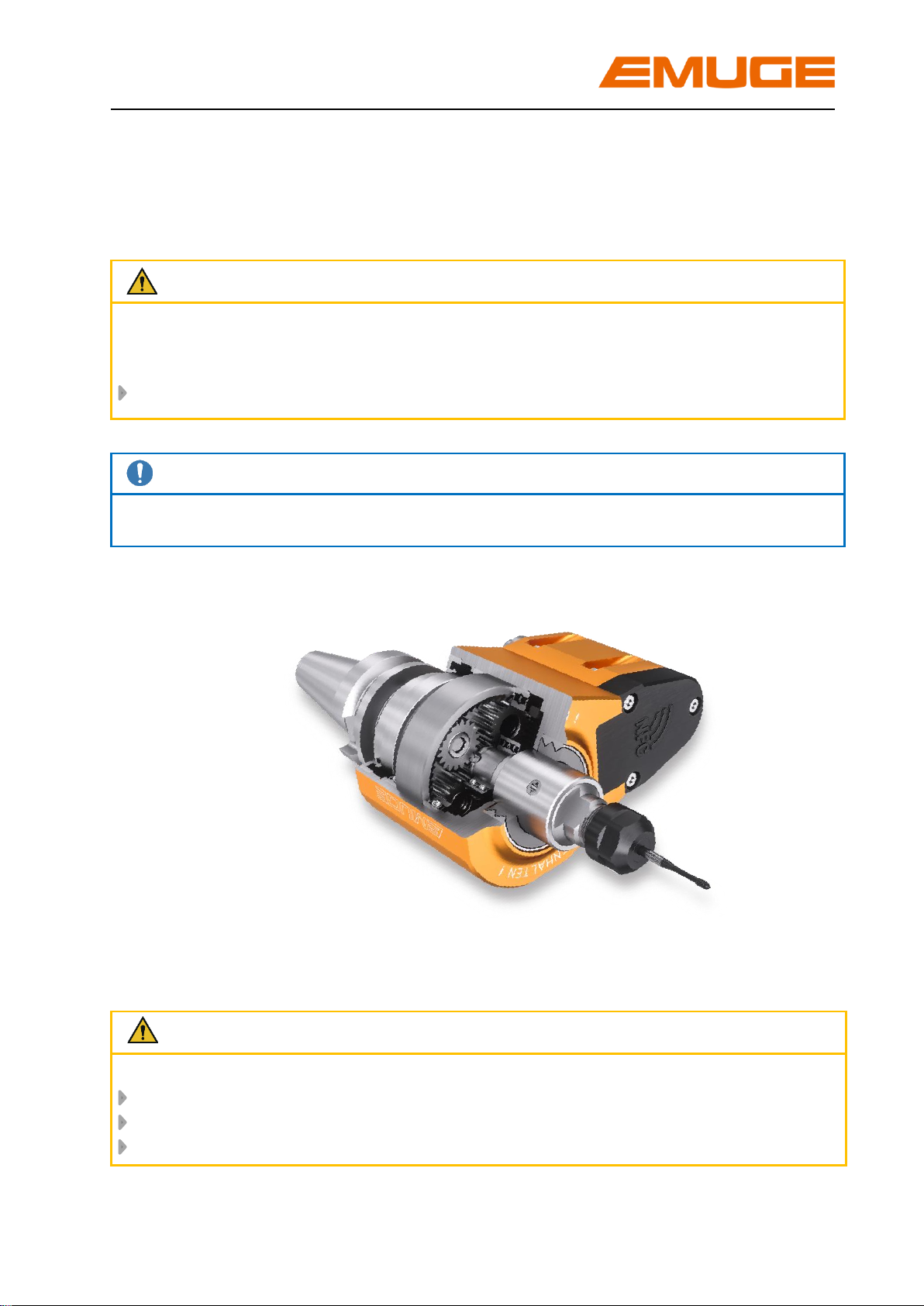

Sectional view:

Speedsynchro® Mini

Attention

Battery:

Not rechargeable

Do not incinerate

Dispose of as prescribed. Please refer to chapter 6, page 22.

Speedsynchro®Mini

4 Operating instruction edition: 13.09.2022

1 Application range, safety instructions and technical data

1.1 Application range, determined use

The collet holders type Speedsynchro®Mini are used on CNC-machining centers with

synchronous control. They are intended for clamping of taps/cold-forming taps for

thread production.

Normally the Speedsynchro®Mini are equipped with the following shank:

BT 30 (DIN) ISO 7388-2 JD

Applicable for cutting range M1 –M6, please refer to Table 1, page 7.

The tap/cold-forming tap is locked via the collets according to DIN ISO 15488.

The collets must be chosen depending on the used type and used tap/cold-forming

tap, for more information please refer to chapter 2.6, page 15.

The collet holders type Speedsynchro®Mini are designed for coolant-lubricant

pressure up to 70 bar.

For correct use, the Speedsynchro® Mini must be secured against twisting in the

machine spindle. This requires a stop fixture adapted to the machine-side locking

block. For further details, please refer to chapter 2.2 page 8.

The non-determined use exempts the manufacturer from any liability.

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 5

1.2 Specifications

Further characteristics of the Speedsynchro®Mini:

The Speedsynchro®Mini uses an integrated gear ratio of 1:4,412. (This enables the

machine spindle to be operated in a lower speed range, thus saving energy.)

The integrated minimal length compensation on tension and compression

compensates arising minimal pitch differences between synchronous spindle and

tap/cold forming tap possibly leading to high thread flank friction forces. A possible

increase of axial force during the thread producing cycle is reduced to a minimum.

The resulting advantages are:

- no mis-cutting of the threads

- optimized tool life of tap/cold-forming tap

The Speedsynchro®Mini has an NFC-Modul (NFC = Near Field Communication)

with integrated electronics. This takes and stores the operating data. An NFC-

enabled smartphone is required to read out the data (not included in the delivery).

For further details please refer to chapter 3, page 18.

Simple programming as synchronous cycle with feed programme adapted to the

transmission ratio.

The reversal of the tap/cold-forming tap is done by the machine spindle:

- no switching components in the Speedsynchro®Mini

- low wear and longer maintenance intervals

High changing speeds are possible due to the low weight (< 2 kg) and the compact

design.

Speedsynchro®Mini

6 Operating instruction edition: 13.09.2022

1.3 Safety instructions and hints

For all works, i.e. putting into operation, production or maintenance, please observe

the details given in the operating instruction.

All relevant safety regulations as well as local instructions are to be observed when

working.

Below please find some basic rules:

Attention

Please wear gloves during tool change to avoid injury.

Basically change the tool yourself to avoid the sudden start of the spindle

caused by mis-operating.

Hold the tool when loosening the tool clamping to avoid it falling down and

damaging the tool and the work piece.

Keep the tool adaptation clean.

There are maximum values for cutting speeds and feeds for every kind of

machining. Please observe such data.

Please observe the maximum tool dimensions.

Furthermore, the instructions of the tool manufacturers are valid!

1.4 Proprietary rights

The entire contents of these operating instructions are subject to German proprietary

rights legislation.

Any form of multiplication, processing, broadcasting, passing on to third parties - also

in the form of extracts - and any kind of use outside the boundaries of proprietary rights

requires the written consent of EMUGE GmbH&Co.KG.

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 7

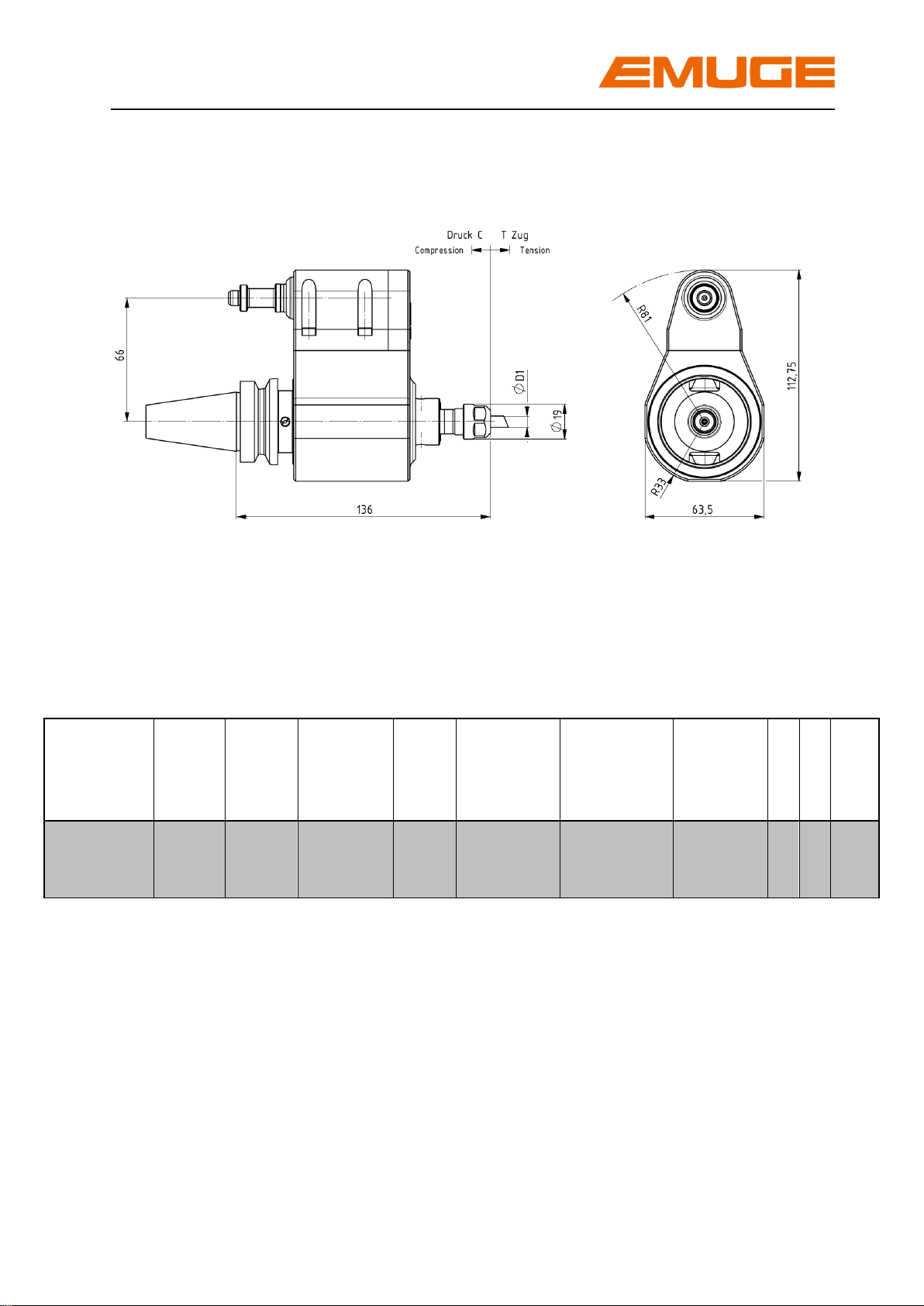

1.5 Dimensions and technical data

Picture 1: Dimensions of Speedsynchro®Mini

Table 1: Technical data of Speedsynchro®Mini

Type

Article

number

Cutting

range

Clamping

range

Ø D1 [mm]

Collet

size

max.

spindle

speed

[min –1/rpm]

Transmission

ratio

Shank

connection

C

T

P

max.

[bar]

Speedsynchro

® Mini

F3720I90

M1 –M6

2,5 –6

ER 11

(GB)

2700

1:4,412

BT30

ISO 73882

JD

0,5

0,5

70

Speedsynchro®Mini

8 Operating instruction edition: 13.09.2022

If necessary, turn the

shank until the stop fixture

engages

Alignment of the two

grooves

Picture 2

2 Putting the Speedsynchro®Mini into operation

2.1 Unpacking

Take the Speedsynchro®Mini from the packing

Clean the Speedsynchro®Mini with a duster to remove any conservation oil

Note

Do not use any aggressive solvents.

Do not use fibrous materials i.e. steel wool

2.2 First putting into operation / preparation

Note

The angel position of the Speedsynchro® Mini stop fixture is not adjustable.

The position of the machine-side locking block at the spindle is adjusted to the stop

fixture of the Speedsynchro® Mini during initial assembly.

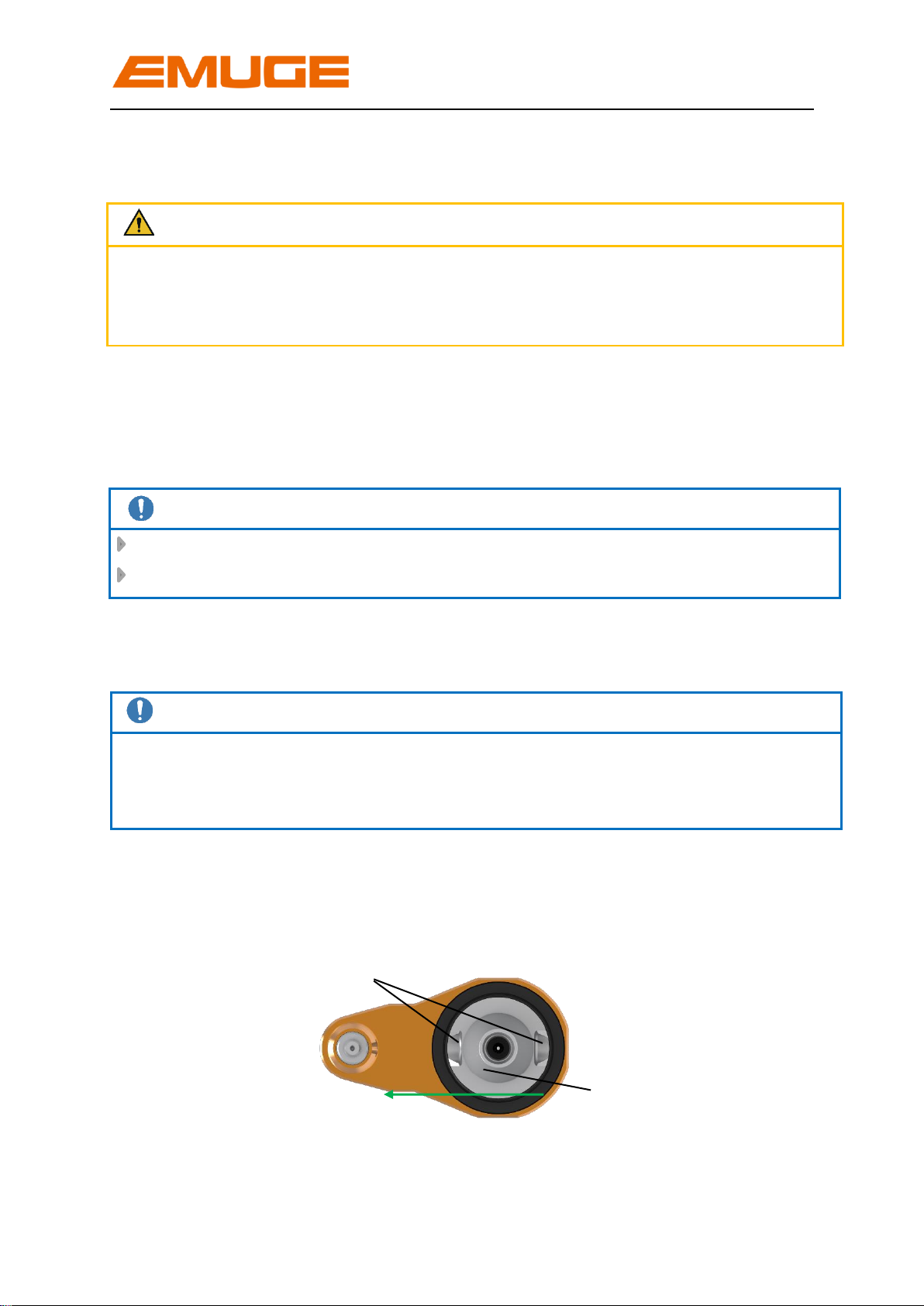

Hook the Speedsynchro® Mini manually into the designated magazine tool

slot. Make sure that the stop fixture is engaged in the angular position, please

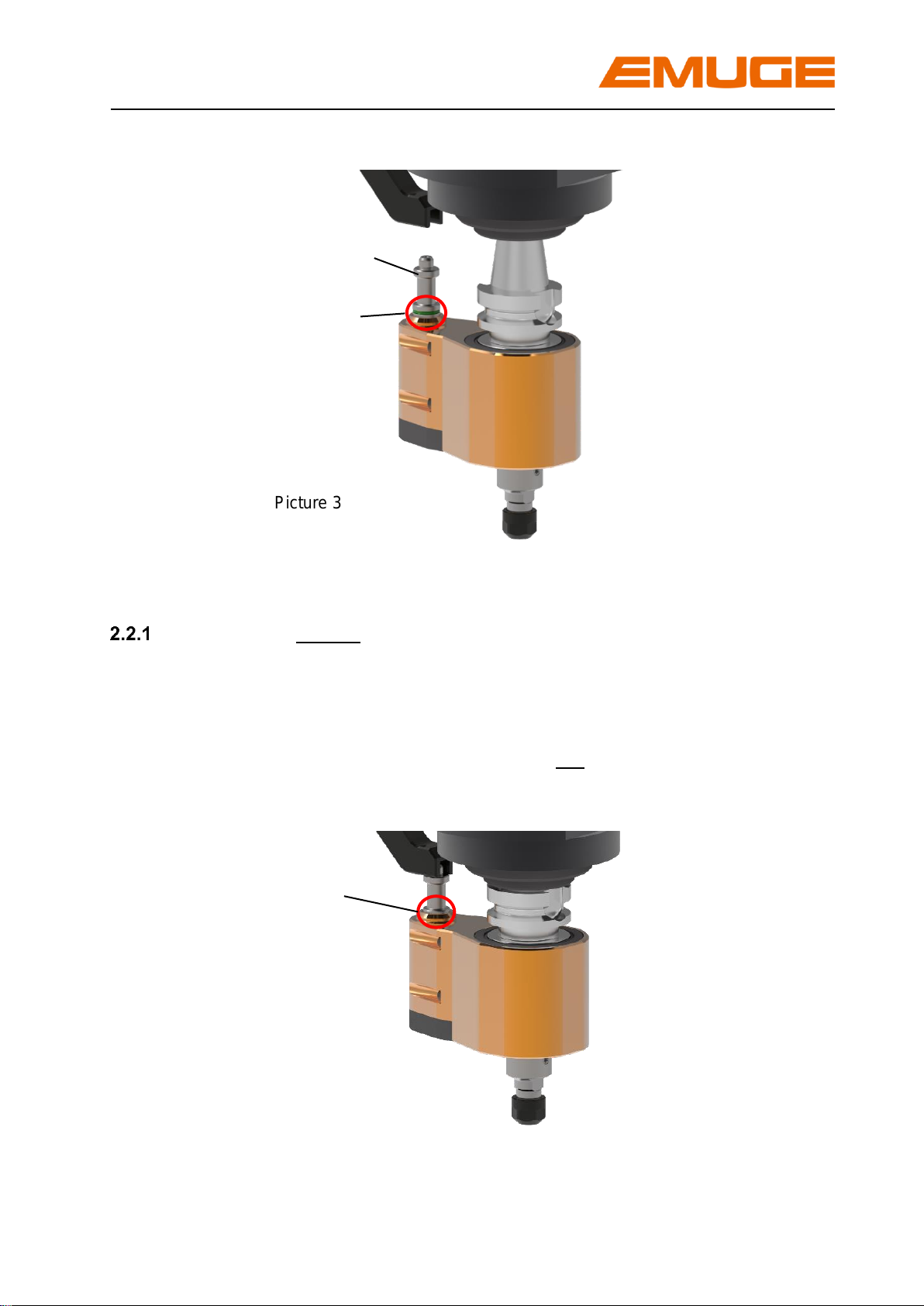

see Picture 2. Green marking ring is visible, please see Picture 3,page 9.

Attention

The housing of the Speedsynchro®Mini must be secured against twisting via stop fixture.

For the use of the Speedsynchro® Mini the machine-side locking block must be mounted.

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 9

Picture 3

Locking block already mounted on the machine

Insert the Speedsynchro® Mini into the spindle at the slowest speed of the

tool changer.

Check the correct position of the machine-side locking block.

Fixing bolt is engaged green marking ring is not visible, please see

Picture 4.

Picture 4

Green marking ring

Fixing bolt

Fixing bolt is engaged –green

marking ring not visible.

Spindle can be rotated.

Speedsynchro®Mini

10 Operating instruction edition: 13.09.2022

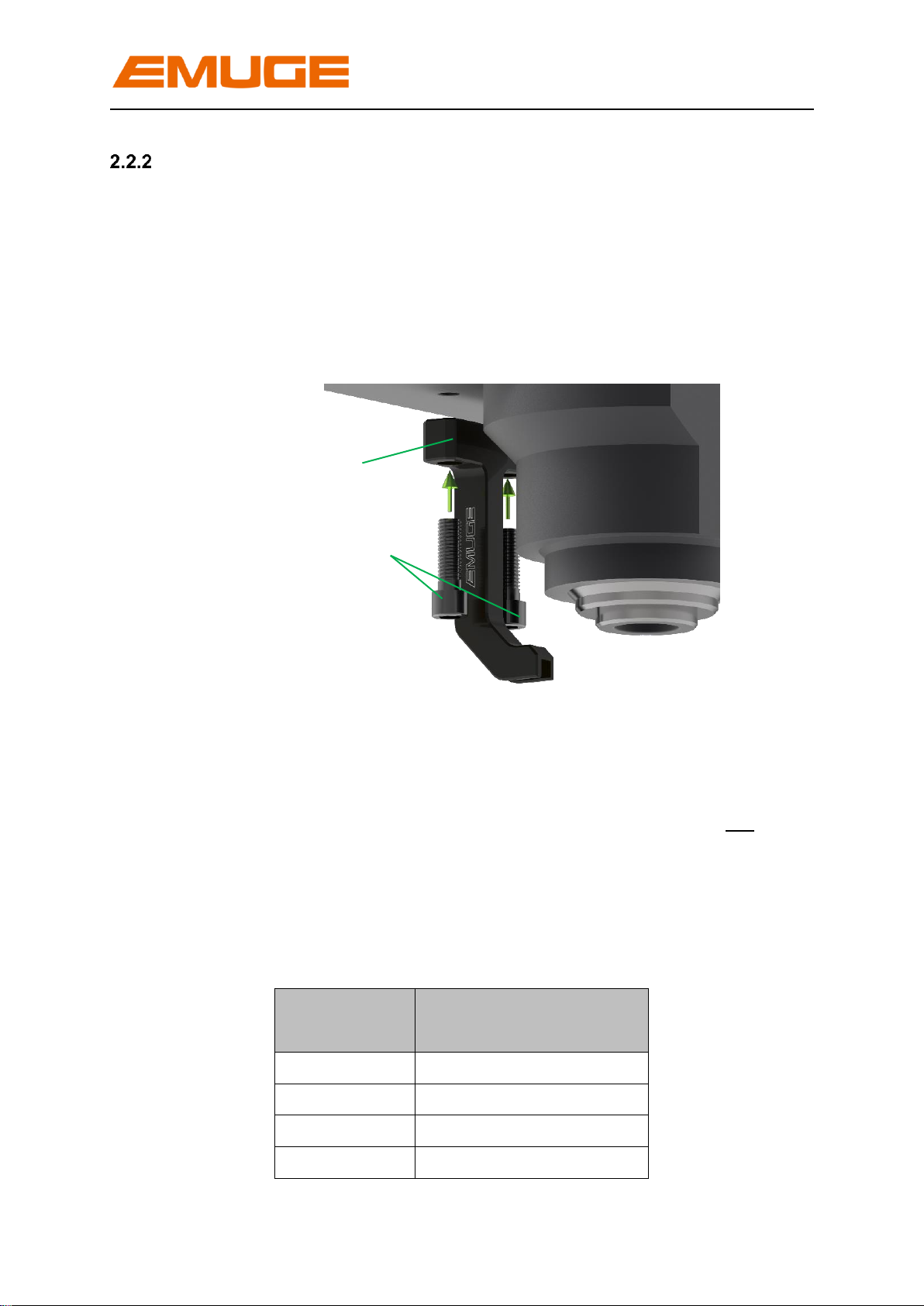

Mounting of the machine-side locking block on the spindle block

Mount the machine-side locking block hand-tight with two hexagon socket

screws.

The mounting threads on the spindle head are located on the side facing away

from the machine door, M6, M8, M10, or M12, depending on the machine.

Reducing sleeves are available as accessories for M6 and M8, please order

these separately.

Picture 5

Insert the Speedsynchro® Mini into the spindle at the lowest speed of the tool

changer.

Check the correct position of the fixing bolt green marking ring is not

visible, please see Picture 4, page 9.

Tighten the mounting screws on the machine-side locking block.

Table 2: Tightening torques of the mounting screws

Dimension

Recommended tightening

torque

M 6

10,5 Nm

M 8

25 Nm

M10

47 Nm

M12

78 Nm

Hexagon socket screws

Machine-side locking block

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 11

Replace the Speedsynchro® Mini via tool changer.

Insert the Speedsynchro® Mini again via the tool changer at slowest speed

and check the correct position of the stop fixture.

Note

For series use, please observe the programming instructions, chapter 2.3, page 12.

Speedsynchro®Mini

12 Operating instruction edition: 13.09.2022

2.3 Programming notes

The transmission ratio of the Speedsynchro®Mini is 1:4,412.

This results in the following programming guidelines.

Feed f

Rotational speed n of the machine spindle for the desired tool speed

Attention

The maximum speed at the machine spindle is: nMSP = 2.700 rpm

The maximum speed at the tool is: nTOOL = 11.912 rpm

Example: thread M2 / pitch P = 0,4 mm:

Desired rotational speed of threading tool:

nTOOL = 11.000 rpm

Required rotational speed of machine spindle:

nMSP = 11.000 rpm / 4,412 = 2.490 rpm

Required feed f, per revolution of the machine spindle:

f = 0,4 x 4,412 mm/rev. = 1,765mm/rev.

Der Speedsynchro®Mini is ready for use.

Attention

When working with internal coolant supply:

The maximum coolant-lubricant pressure is 70 bar.

The internal coolant is supplied centrally through the spindle.

√

nMSP = nTOOL / 4,412

f = P x 4,412

f = Feed [mm/rev.]

P = Pitch of threading tool [mm]

nMSP = Rotational speed of machine spindle [rpm]

nTOOL = Rotational speed of threading tool [rpm]

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 13

2.4 Re-putting into operation

If the Speedsynchro®Mini is put back into operation as described in chapter 5, page

22, please go through the following steps:

- Clean the Speedsynchro®Mini with a duster to remove any conservation oil

Note

Do not use any aggressive solvents.

Do not use fibrous materials i.e. steel wool.

- Test the stop fixture:

Press the fixing bolt down The fixation must be released, green marking

ring is not visible, please refer to Picture 4,

page 9.

Release the fixing bolt The stop fixture is engaged in the angular position,

green marking ring is visible, please refer to

Picture 3; page 9.

Speedsynchro®Mini

14 Operating instruction edition: 13.09.2022

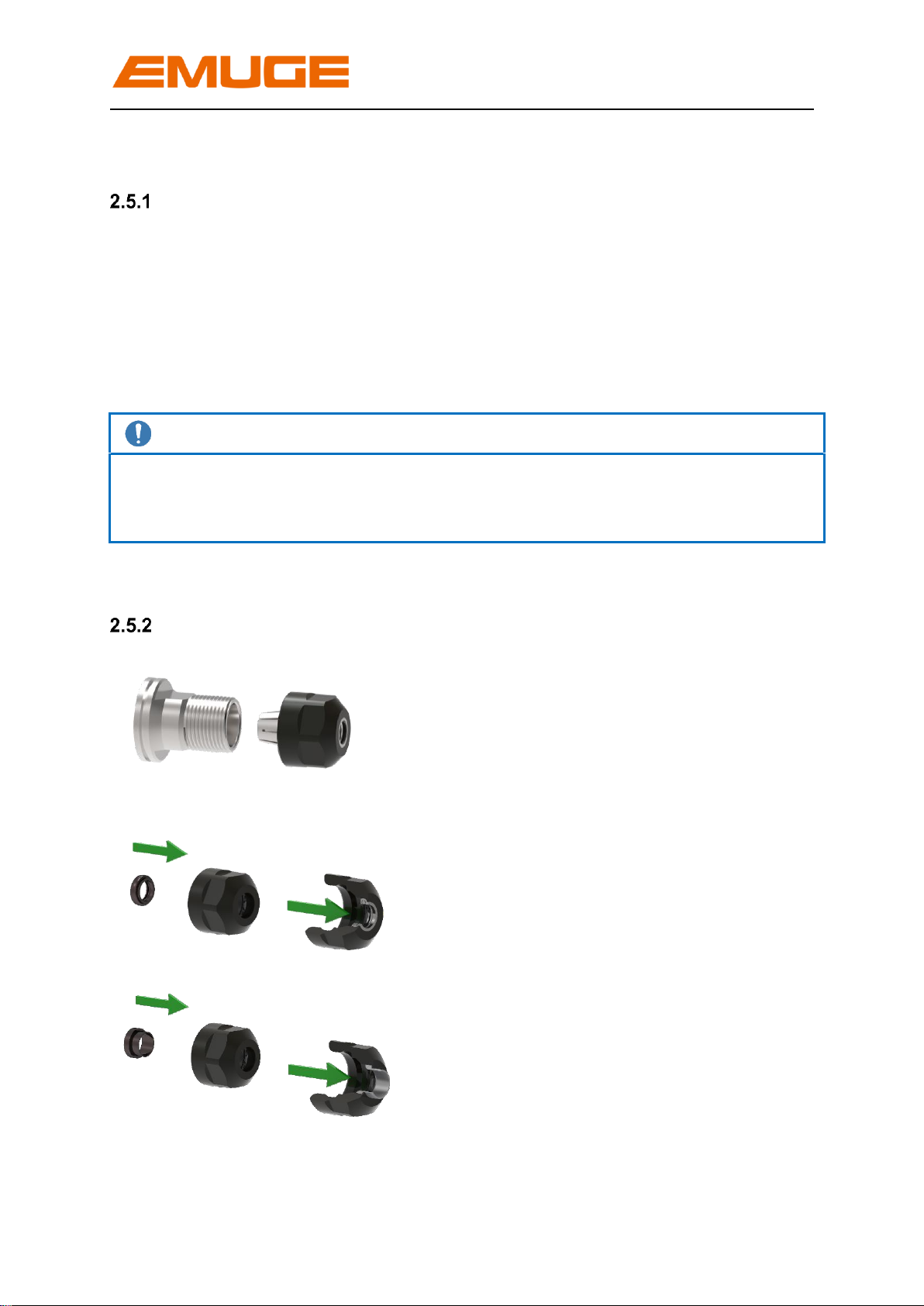

2.5 Sealing disk / cooling disk

Application

The sealing disks or cooling disks are inserted into the clamping nuts for producing

threads with internal coolant supply. The sealing disks respectively the cooling disks

additionally avoid the penetration of dirt and chips into the collet slots. We do

recommend the use of sealing disks or cooling disks.

In contrast to the sealing disks, the cooling disks guide the coolant directly along the

tool.

Note

Normally a clamping nut for sealing disks/cooling disks is part of the delivery.

The sealing disk or cooling disk hasto be ordered separately, suitable for clamping

nut and clamping diameter!

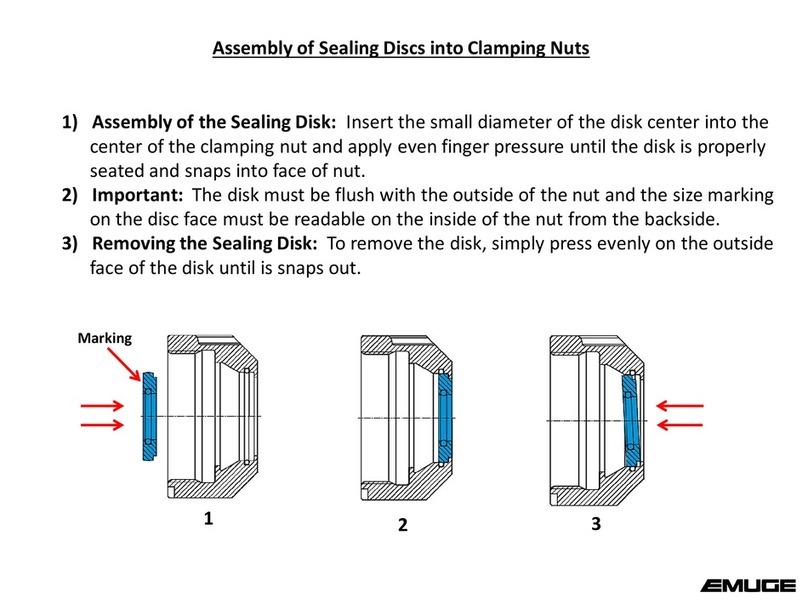

Assembly of the sealing disk or cooling disk

1. Screw off the clamping nut

2. Insert sealing disk/cooling disk

into clamping nut as shown on

picture.

Push sealing disk/cooling disk

forward into clamping nut until

you clearly hear the

engagement.

The sealing disk must be flush

at the front with the clamping

nut.

Click !

Sealing disk

Click!

Cooling disk

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 15

Click!

2.6 Collets

Application

The adaptation of the tap/cold-forming tap is done via collets type ER and/or ER/GB.

With collets type ER the tap/cold forming tap is centered and clamped via the shank

diameter. With collets type ER/GB the torque - arising during the thread producing

operation - is additionally transferred via the square integrated in the collet.

Note

Due to the better torque transmission we recommend the use of collets type ER/GB.

The collet sizes for the according SpeedsynchroMini may be taken from Table 1,

page 7. The clamping diameter is specified by the tap/cold-forming tap used.

Assembly of the collet

1. Insert collet into clamping nut,

tilt collet.

The groove of the collet must

engage in the eccentric ring of the

clamping nut at the marked

position. Tilt collet in opposite

direction until it clearly engages.

→Collet is flush with clamping nut

and/or sealing disk.

1. Screw clamping nut with engaged

collet onto the thread of the collet

holder.

Groove of the collet

Eccentric ring

Marking

√

Speedsynchro®Mini

16 Operating instruction edition: 13.09.2022

2.7 Assembly of the tap/cold-forming tap

1. Insert tap/cold-forming tap

If collet and tool are provided with a

square, the tool must be turned into

position in order to be inserted into

the square of the collet!

2. Tighten clamping nut with

appropriate wrench.

Attention

In order to avoid damaging of

Speedsynchro®Mini parts, it is

necessary during the tightening

of the clamping nut via wrench

to support with open-ended

spanner .

As an alternative to the open-

ended spanner the assembly

deviceF3720900 can be used.

Note

Wrenches are part of the delivery.

To adjust the correct torque (please see table 3), we recommend to use a torque

wrench.

Table 3: Tightening torques for clamping nuts

Type

Recommended tightening

torque [Nm]

Hi-Q/ERC 11

14

Clamping nut

Data valid for the use of ER-GB collets.

The maximum tightening torque must not be

more than

25% above the recommended values.

Higher torque

may result in the damage of the collet

holder.

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 17

2.8 Remove the tap/cold-forming tap, the clamping nut and the sealing disk

1. Loosen the clamping nut with

wrench

Attention

In order to avoid damaging of

Speedsynchro®Mini parts, it is

necessary during the loosening of

the clamping nut via wrench to

support with open-ended spanner

.

As an alternative to the open-

ended spanner the assembly

deviceF3720900 can be used.

2. Pull out tap/cold-forming tap

3. Screw off the clamping nut

4. Tilt collet up to the marking until it is

removed from the eccentric ring

Remove collet

5. Press the sealing disk or cooling

disk out of the clamping nut from

the front and remove it

Speedsynchro®Mini

18 Operating instruction edition: 13.09.2022

Picture 6

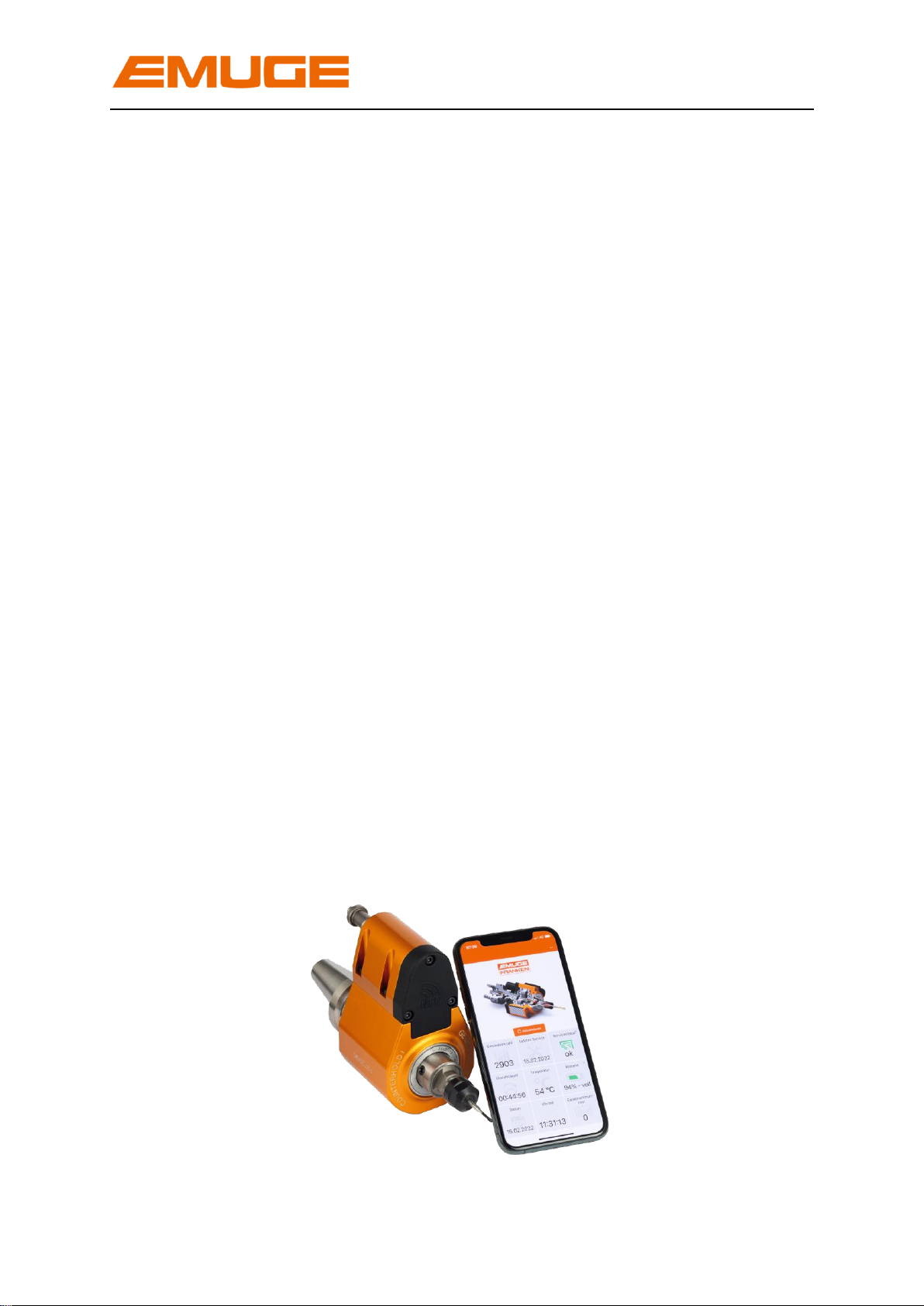

3 Readout operating data via NFC interface

The operating data is recorded and stored by the electronics integrated in the

SpeedsynchroMini. The readout of data is done via an NFC-enabled smartphone.

The required app can be downloaded free of charge for iOS from Apple store or for

Android operating systems from Google Play Store.

3.1 Speedsynchro- Electronics

The electronics of the Speedsynchrosystem are embedded and protected under the

cover, the NFC readout antenna is integrated inside. Depending on the operating

condition the electronics are in active or in energy saving mode.

Power is supplied by a battery integrated in the SpeedsynchroMini, the battery

charge state can be read via NFC. The battery has a service life of several years and

is replaceable. The operating data is not lost when the battery is changed.

3.2 Readout operating data

The operating data is read out via wireless coupling of smartphone and

SpeedsynchroMini antenna. The antenna is located under the cover. The position of

the antenna in the smartphone depends on manufacturer and model.

For coupling and reading the operating data, it is sufficient to move the back of the

smartphone in direct contact or within a few millimeters over the cover.

Depending on the smartphone model, the EMUGE app opens automatically and the

operating data can be read. If the app does not open automatically, it must be opened

manually before coupling the devices.

Speedsynchro®Mini

Operating instruction edition: 13.09.2022 19

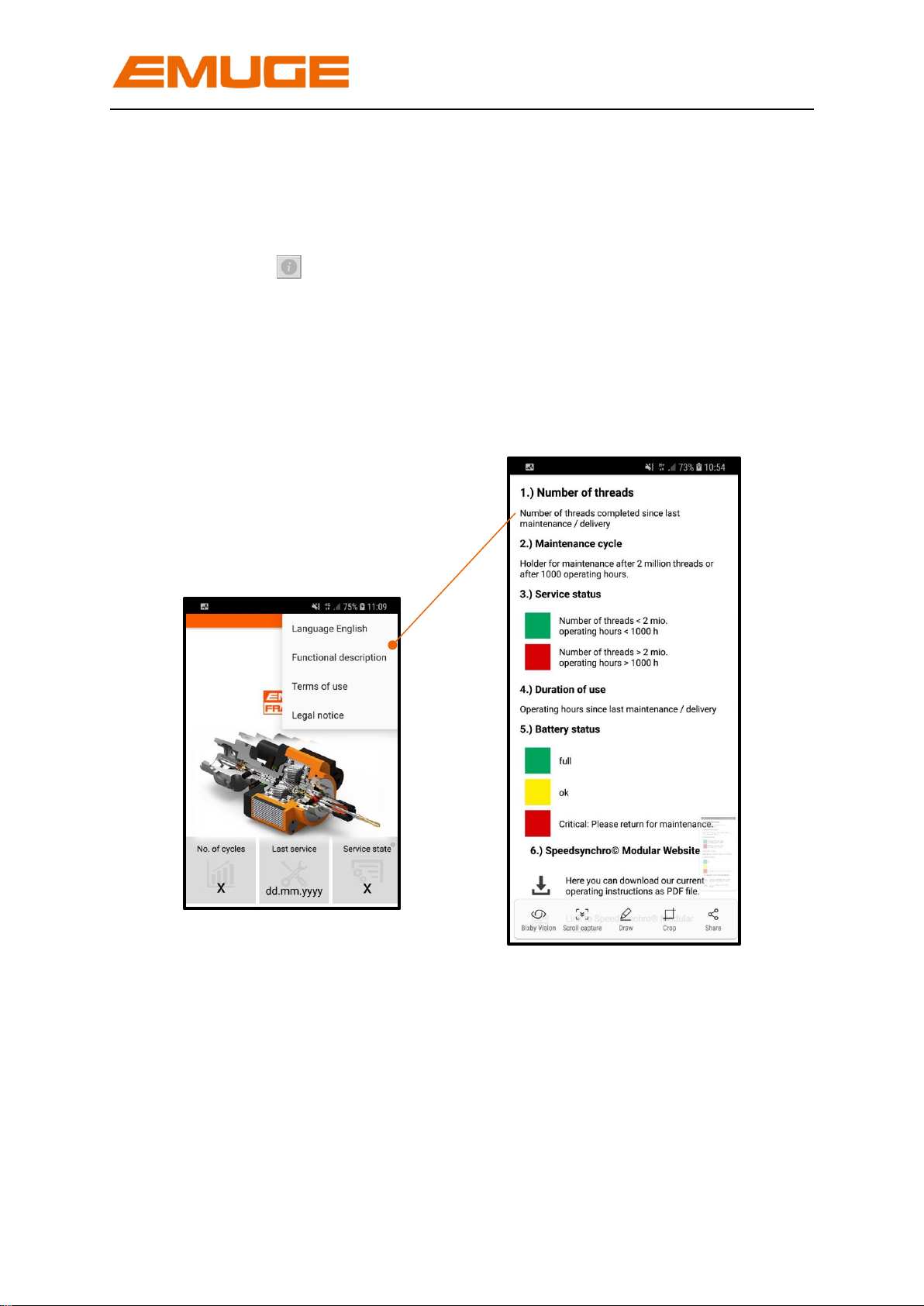

3.3 Display in the app

7 + 8 Date / Time

Shows the current date and time of time

zone Europe / Berlin.

Shows the number of threads produced since the

last maintenance or for new devices from date of

delivery. The display/number is reset to „0“during

maintenance at EMUGE.

4 Duration of use

Shows the operating hours since the last

maintenance or for new devices from date of

delivery. Is reset to „0“during maintenance at

EMUGE.

2 Last service

Shows the date of last maintenance or for new

devices the date of delivery.

3 Service status

Maintenance is recommended after production of

2 million threads or 1000 hours of operation.

If maintenance is due, the traffic indicator jumps

from green to red, which means in detail:

Number of threads < 2 Mio.

Operation hours < 1000

Number of threads > 2 Mio.

Operation hours > 1000

1

2

4

5

7

8

9

3

6

6 Battery status

The traffic light colours indicate the

status of the battery.

Specific meaning of the colours:

Fully charged

OK

Critical: Please return for

maintenance

5 Temperature

Shows the maximum temperature the

SpeedsynchroMini reached since last

maintenance/ / new delivery.

9 Device number

Shows the unique device number in addition to

the article number, is assigned by EMUGE

upon delivery.

1 Number of threads

Picture 7

Speedsynchro®Mini

20 Operating instruction edition: 13.09.2022

A short summary of the display functions is shown in the menu selection at the top

right under the item “Function description”

Tapping the button in fields 3 + 6 (picture 7, page 19) also takes you to this

page.

There are also the terms of use and the imprint.

Picture 8

Table of contents

Other EMUGE Industrial Equipment manuals