1

CONTENTS

FEATURES .................................................................................................................................................. 2

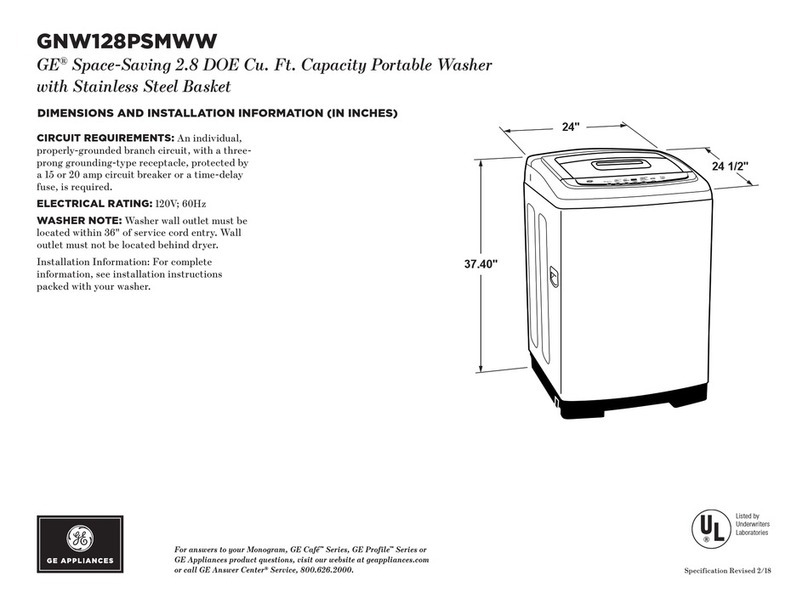

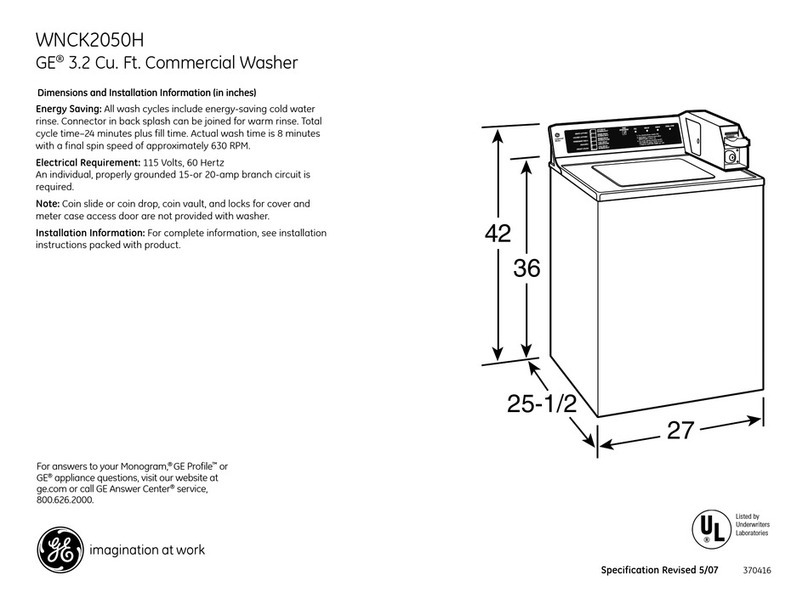

TECHNICAL SPECIFICATIONS .................................................................................................................. 3

TORQUE REQUIREMENT TABLE .............................................................................................................. 4

RESISTANCE TABLE ................................................................................................................................. 5

SCHEMATIC DIAGRAM .............................................................................................................................. 6

TIMER CYCLE CHART................................................................................................................................ 7

ELECTRONIC SPEED CONTROLLER ....................................................................................................... 8

WIRING DIAGRAM ...................................................................................................................................... 9

TROUBLESHOOTING DIAGRAMS............................................................................................................. 10

CONSTRUCTION AND OPERATION.......................................................................................................... 16

FUNCTIONAL COMPONENTS AND PARTS .............................................................................................. 21

Top Panel ..................................................................................................................................................... 21

Service Panel ............................................................................................................................................... 21

Loading Door ................................................................................................................................................ 21

Door Strike ................................................................................................................................................... 21

Door Hinge ................................................................................................................................................... 22

Door Safety Switch Assembly (Door Lock) ................................................................................................... 22

Timer ............................................................................................................................................................ 22

Timer Diagnostic Aid .................................................................................................................................... 24

Water Level Control ...................................................................................................................................... 26

Water Temperature Selector Control ............................................................................................................ 26

End of Cycle Signal ...................................................................................................................................... 27

Extra Rinse Switch ....................................................................................................................................... 27

Water Inlet Valve .......................................................................................................................................... 27

Automatic Dispenser .................................................................................................................................... 29

Drive Motor ................................................................................................................................................... 31

Drive Belt ...................................................................................................................................................... 32

Electronic Speed Control .............................................................................................................................. 33

Drain Pump and Motor Assembly ................................................................................................................. 34

Air Bell and Pressure Connecting Tube ........................................................................................................ 34

Tub Counterweights ..................................................................................................................................... 35

Air Shock Absorber....................................................................................................................................... 36

Door Bellows ................................................................................................................................................ 36

Outer Tub ..................................................................................................................................................... 36

Inner Tub and Bearings ................................................................................................................................ 37

Tub Vanes .................................................................................................................................................... 38

Exploded Views ............................................................................................................................................ 39

Timer Diagnostic Aid .................................................................................................................................... 42

Thisservicemanualis intended for use by persons having electrical and mechnical training and a level

of knowledge of these subjects generally considered acceptable in the appliance repair trade. The

manufacturer cannot be responsible, nor assume any liability, for injury or damage of any kind arising

from the use of this manual.

WARNING