Sterling SHR150 User manual

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

Owner’s Manual

●INSTALLATION GUIDE

●OPERATION

●MAINTENANCE

●REPLACEMENT PARTS

●WARRANTY

GAS-FIRED INFRA-RED

HEATER

MODELS:

SHR150/200

Caution: Read all instructions before use.

Retain them for future reference. All appli-

ances should be installed by a professional

gas heating equipment service person.

WARNING

Improper installation, adjustment, altera-

tion, service or maintenance can cause

property damage, injury or death. Read

the instructions thoroughly before install-

ing or servicing this equipment.

FOR YOUR SAFETY

DO NOT store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other heating equipment.

WHAT TO DO IF YOU SMELL GAS:

●DO NOT try to light any gas appliance.

●DO NOT touch any electrical switch: DO

NOT use any phone in your building.

●Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

●If you cannot reach your gas supplier, call

the fire department.

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

TABLE OF CONTENTS

Warnings 1

Ratings 2

Unpacking 2

Heater Installation 3

Choosing Heater Location 4

Minimum Clearance 4

General Mounting Instruction 6

Angle Mounting 7

Ventilation Requirements 7

Piping 7

Testing for Leaks 8

Manifold Pressure Checking 8

Spark Ignition System 9

Service Person’s Trouble Shooting Guide 10

Replacement Parts

Diagram 11

List 12

Main Burner Orifice 13

Procedure for Service warranty Claim 14

Customer’s record 14

Warranty Back Cover

WARNING

DO NOT Install or service this heater yourself. Call a

Professional gas heater equipment service person.

●DO NOT place flammable material on or

near the heater.

●When used with a thermostat, heater may

start at any time.

●Use only in well ventilated areas. DO NOT

install in an area where the heater could be

isolated.

●DO NOT obstruct the flow of combustion

and ventilation air.

●The installation must conform with local

codes or, in the absence of local codes, with

the National Fuel Gas Code, ANSI Z221.1*

in U.S.A. or in Canada CAN 1.2.16M81.

●DO NOT hang the heater with chains in

applications where repetitive swinging

motion of the heater may fatique the gas

connections to the heater or damage the

heater. Failure to do so could cause

property damage, bodily injury or death.

Rigid mounting should be used in the above

application.

●DO NOT hang heater on gas lines, water

lines conduit, etc. Hang only on structural

member (s) which could sufficiently support

the heater without impairing or endangering

other functions of the structural member (s).

●If heater is installed at altitudes 2,000 feet

or more above sea level the orifice must be

changed according to the chart on page 13.

●DO NOT use this heater if any part has

been under water. Immediately call a

professional gas heating equipment service

person to inspect the heater and to replace

any part which has been under water.

●Any changes to this heater or its controls

can be dangerous. Any additions, changes

or conversions required in order for this

heater to satisfactory meet the application

needs must be made by a profesiional gas

heating equipment service person using

factory specified and approved parts.

●Any safety screen, guard or part removed

for installation or service must be replaced

prior to operating the heater to avoid

property damage, bodily injury or death.

*ANSI Z223.1 (latest edition) is available from American Gas

Association, 8501 East Pleasant Valley Rd., Cleveland OH

44131 (216-524-4990), and all NFPA codes are available

from National Fire Prevention Association, Batterymarch Park

Quincy, MA 02269 (617-770-3000) or check your local library.

1

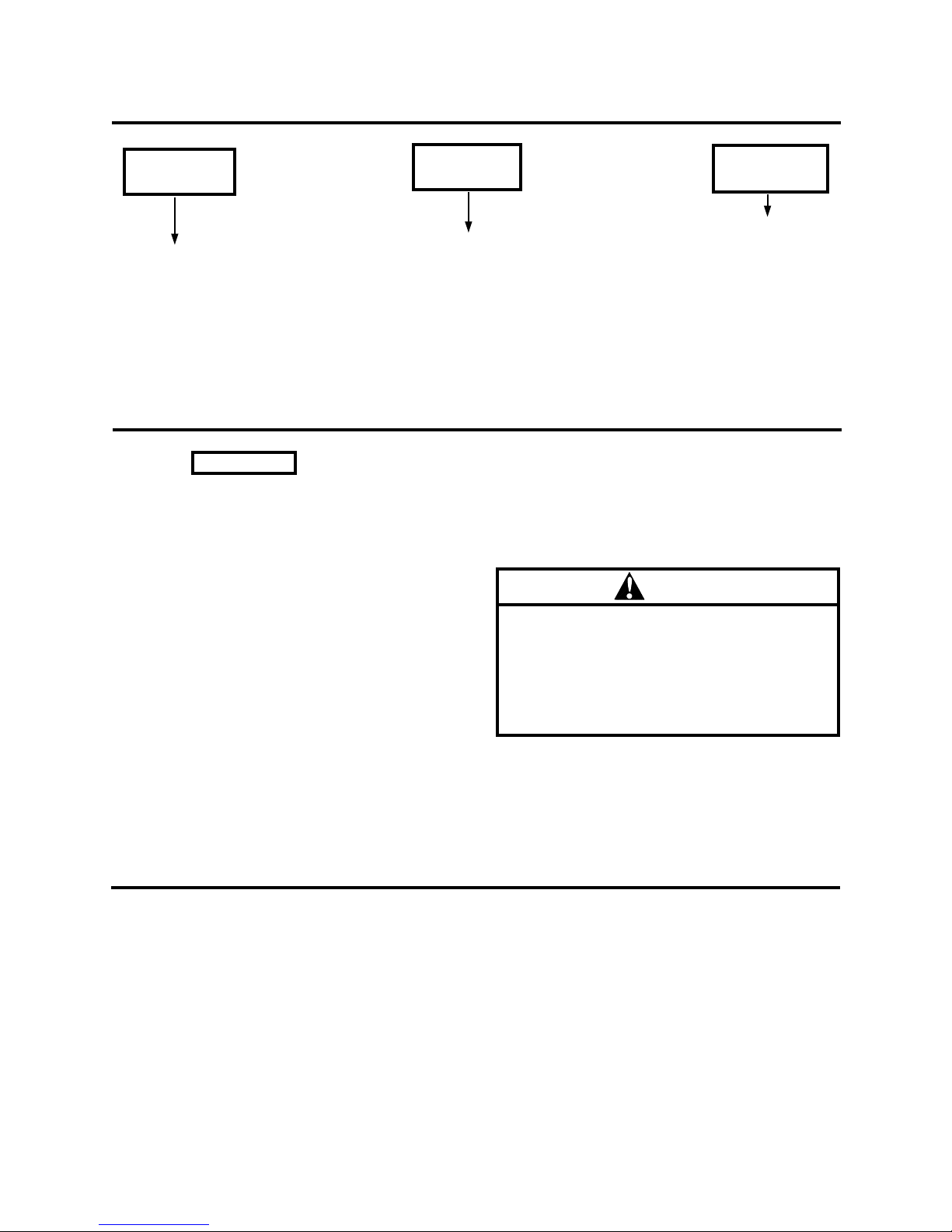

Model Type

Designation

Rate

Designation

Gas

Designation

SHR 150,000 – BTUH

200,000 – BTUH

N – Natural

L – Liquid

Petroleum/

Propane

ALTITUDE ORIFICE CHANGES

When the heater is installed at altitudes exceed-

ing 2,000 feel above sea level, the input must be

reduced by 4 percent for each 1,000 feet above

sea level.

Example: SHR150 installed at 4,000 feet

altitude;

Normal Input Rate 150,000 BTUH

Less 16% for 4,000 feet

above sea level 24,000 BTUH

Reduced input for 4,000

feet altitude 126,000 BTUH

For correct size orifice, refer to altitude orifice

conversion chart on page 13. Please call your

local heating parts supplier and/or gas company

for orifices in your area.

IMPORTANT

WARNING

Do Not alter the installed orifice in any manner.

Improper alteration could result in Carbon

Monoxide poisoning and possible death. If the

orifice must be changed or cleaned contact a

professional gas heating equipment service

person.

CHECKING FOR DAMAGE OR SHORTAGES

1. Unpack the heater from its carton and

examine the contents for damage or missing

parts.

2. If any parts are damaged at the time of deliv-

ery, notification should be made on the Bill of

Lading from the transportation

company.

3. Concealed damage must be filed within

fifteen (15) days with the carrier.

4. Claims for shortage must be filed with the

distributor within five (5) days.

2

RATINGS

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

VALVE ASSEMBLY

FIGURE 1

1. Remove valve and heater from carton.

Remove the three screws from each venturi

collector bell located on one end of the

heater.

2. Slide valve onto collector bells and insert

two vertical screws. Then install remaining

four screws.

3. To avoid possible damage to wiring connec-

tion, it may be advantageous to hang heater

before connecting wires. Connect two gray

wires to the flame sensors located by the

electrodes. Connect the two spark-plug

type high tension leads to the Electronic

Ignition Control. If a thermostat is used,

separate the two red wires that are twisted

together and connect the thermostat

between them. If a thermostat is not used,

connect the red wires to the positive side

of the power source and the single blue

wire to the negative via a switch.

HEATER INSTALLATION

Installation of Sterling Gas Fired Infra-Red

Heaters should conform to all Sterling Heating

Installation Design Procedures including ventila-

tion. All local and national codes requirements,

or in the absence of local codes, the National

Electrical Code (NFPA No. 70) and the National

Fuel Gas Code (ANSI A223.1 – latest edition)

in the U.S.A. or in Canada CSA B149.1-00 shall

be followed. ANSI Z223.1, is available from

the International Gas Association 8501 East

Pleasant Valley Road, Cleveland OH 44131,

and all NFPA codes are available from National

Fire Prevention Association, Batterymarch Park,

Quincy, NA 02269.

3

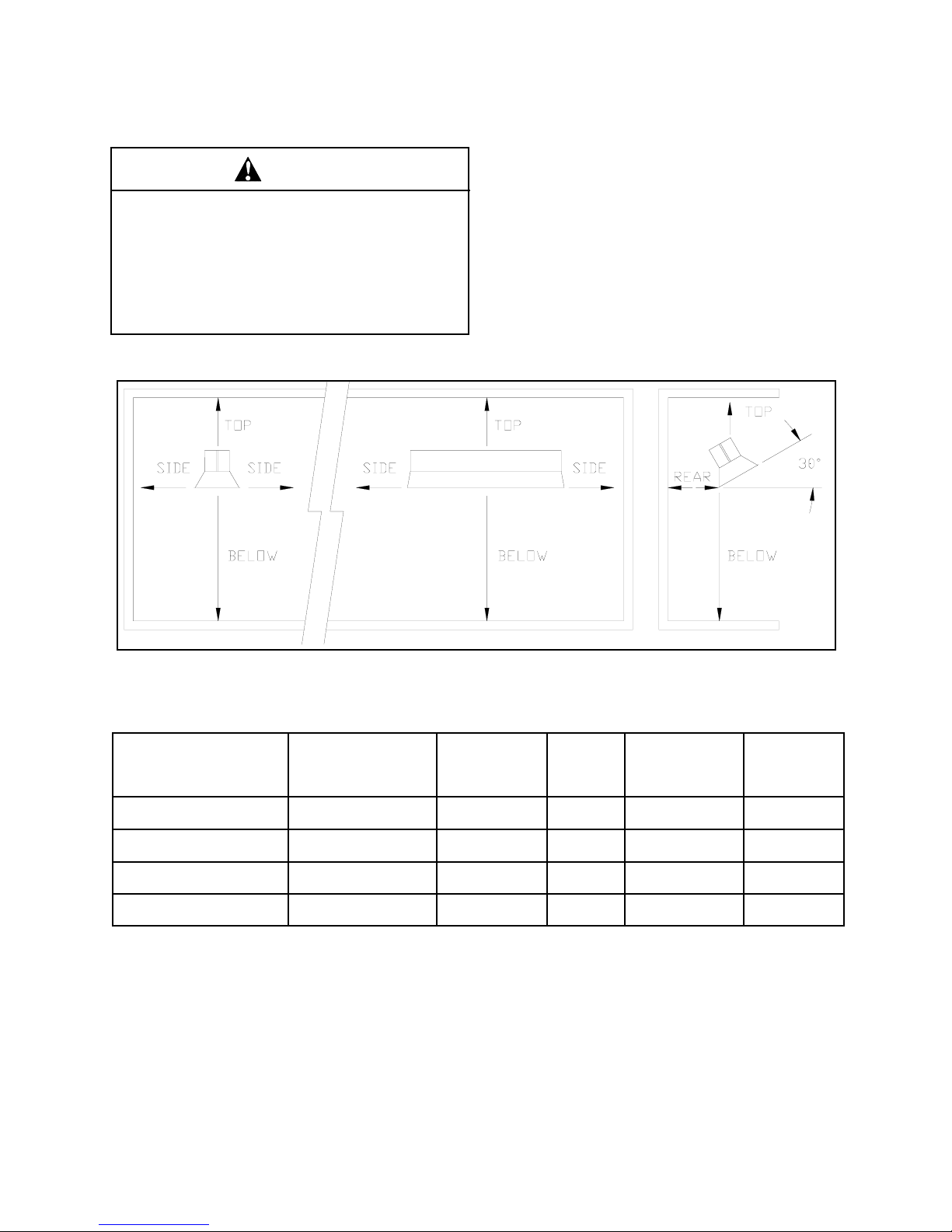

CHOOSING HEATER LOCATION

This model heater must be mounted with mini-

mum clearances between the heater and sur-

rounding combustible surfaces a shown in Table

A, below.

It should also be located with respect to building

construction and equipment in a manner which

provides sufficient clearance and accessibility for

servicing and cleaning of the burner and controls.

WARNING

Be aware of good safety practices by wearing

personal protective equipment such as gloves

and safety glasses to avoid being injured by

sharp metal edges in or around the heater and

while cutting or drilling holes. Failure to follow

these warnings could cause bodily injury or

death.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIAL

FIGURE 2

CLEARANCE TO COMBUSTIBLES CHART

MODEL NO. MOUNTING

ANGLE

FRONT SIDE

(Shade

to wall)

REAR

(Shade

to wall)

TOP

(Bottom of shade

to ceiling)

BELOW

(Tile to Floor)

SHR150L/N Horizontal ° Angle 55 55 52 121

SHR150L/N 30° Angle 80 36 52 121

SHR200L/N Horizontal ° Angle 55 55 52 121

SHR200L/N 30° Angle 80 36 52 121

4

TABLE A

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

5

IMPORTANT: In certain installations, clearances

in Table A & Figure 1 may not be adequate to

keep temperatures below 160°F. In these instal-

lations, it is the installer’s responsibility to insure

that single or multi-heater placement be such that

continuous operation of the heater or heaters will

not cause combustible materials or materials in

storage to attain a temperature of excess of 160°

F.

NOTE: When heaters are installed in proximity to

temperature-sensitive material (for example, vinyl

faced insulation), it is the installer’s responsibility

to insure that the surface temperature does not

exceed the allowable temperature of that mate-

rial. In these installations, minimum clearances

noted in Table A on page 4 are to be increased

by the necessary amount.

Under no circumstances should this heater be

installed in a combustible atmosphere or in a

location where the heater controls can be subject

to ambient temperatures in excess of 150°F.

INSTALLATION IN AIRCRAFT HANGARS

This heater is suitable for use in aircraft hangars

when installed in accordance with the following

standard: NFPA No. 409 (latest edition).

1. A clearance of 10 feet must be maintained

from the bottom of the heater to the highest

surface of the largest aircraft to be housed

in the hangar.

2. A minimum clearance of 8 feet must be

maintained from the bottom of the heater in

other sections of the aircraft hangars, such

as offices and shops.

3. The heater must be located so that it will be

protected from damage by aircraft and other

objects, such as cranes and movable scaf

folding.

4. The heater must be installed where it will be

accessible for serving and adjustment.

INSTALLATION IN COMMERCIAL GARAGES

This heater is suitable for use in commercial

garages when installed in accordance with ANSI/

NFPA No. 88B 1985 (latest edition), which states

clearances to combustible construction or

material in storage, from heater and vent, must

conform to standard NFPA No. 54 (ANSI Z223.1

latest edition), in U.S.A. and in Canada CSA

B149.1-00.

American National Standard Institute (ANSI)

Z223.1 (latest edition) states “overhead heaters

shall be installed at least (8) feet above the floor.”

In addition, they shall be located high enough to

maintain the minimum distance to combustibles,

as shown on the heater rating plate, between the

heater and any vehicles parked below the heater.

INSTALLATION OTHER THAN SPACE HEATING

Use for processing applications voids the

warranty and C.S.A. certification. Any additional

changes, or conversions required in order for the

heater to satisfactorily meet the heater needs

must be made by a Sterling distributor, or other

qualified agency, using factory specified and ap-

proved parts.

HEATER INSTALLATION CON’T

6

GENERAL MOUNTING INSTRUCTIONS

The following instructions are a guide to general

installation only. The procedure for installing the

infra-red system is based on structural members

of the building and how they can be used to

support the heating system. Before proceeding

with the installation of the system, we suggest

that you consult your Sterling Distributor for the

proper procedure for your particular job.

Since most installations will differ in many

details, these instructions are general. Sound

judgment must be exercised and careful supervi-

sion is essential to assure the installation will be

made in the best manner possible for trouble-free

operation and at minimal cost.

All systems must be done in accordance with

acceptable practices, local codes, and applicable

standards.

This heater is suitable for reflector mounting

angles up to 30 degrees along the short axis.

Improper angle mounting can result in overheat-

ing of controls and combustible materials.

The hangers support the infra-red heater and the

reflectors.

Chain, with a working load of at least 200 lbs., is

recommended for hanging the heater by connect-

ing the hanger(s) to a beam or other support.

If rigid means such as rods are used in place of

chains, swing joints or other means of sufficient

length must be provided to compensate for

expansion.

IMPORTANT: For either horizontal or angle

mounting, the long axis of the heater must be

level. Use only non-combustible mounting

hardware.

NOTE: It is the responsibility of the installer to

insure that the chosen suspension system will

support at least 200 lbs.

MODEL

AVERAGE MOUNT-

ING HEIGHT (IN

FEET)

DISTANCE FROM WALL

TO REAR OF HEATER

(LONG AXIS

PARALLEL TO WALL)

DISTANCE

BETWEEN

HEATERS

(SHORT

AXIS ) FT.

30°

ANGLE

HORI-

ZONTAL

30°

ANGLE

HORI-

ZONTAL

SHR150L 26 32

SERVICE

CLEAR-

ANCE

32 22-40 130

SHR150N 26 32 32 22-40 130

SHR200L 28 34 34 22-40 130

SHR200N 28 34 34 22-40 130

MAX. DISTANCE

BETWEEN ROWS

OR MAX. BUILD-

ING WIDTH (FT.)

FIGURE 2

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

ANGLE MOUNTING

This heater is suitable for mounting angles with the short

axis rotated in either direction as shown in Figure 3.

Improper angle mounting can result in damage to the

heater or unsafe operation.

IMPORTANT: For either horizontal or angle mounting,

the long axis of the heater must be level. Use only non-

combustible mounting hardware. In general, mounting

angles above 25° are only used for special application of

spot and area heating.

7

VENTILATION REQUIREMENTS

Natural or mechanical means shall be provided to

exhaust at least 4 CFM per 1,000 BTU per hour

input on installed heaters on Natural gas, 4.5

CFM per 1,000 BTU per hour input on installed

heaters on LP gas. Exhaust openings for remov

ing flue products shall be above the level of the

heaters.

When buildings are so tight that normal

infiltration does not provide the necessary air for

combustion, outside air must be introduced.

IMPORTANT: PIPING PRACTICES

1. Installation of ground pipe joint union is

required at the gas inlet connection to the

control valve on the heater. All components

upstream of the control valve are field sup

plied by the installer. See Figure 4.

2. If permitted by code, an approved 18” or 24”

flexible connection between the heater and

piping is recommended.

3. Installation of a 6” gas line trap “Drip-Leg” is

required at the inlet connection to the

heater. Failure to provide a drip leg could

result in condensation and foreign matter in

the valve which could cause damage.

4. On propane-fired heaters, a main line filter

is recommended.

5. Installation of a manual shut off valve is

required. Provide a 1/8 inch N.P.T. plugged

tap, accessible for test gauge connection,

immediately upstream of the gas supply

connection to the heater. It may be part of

the shut off valve as shown in Figure 4.

6. Piping joint compounds must be resistant to

the action of liquefied petroleum gases.

7. All piping must be installed according to

local codes.

8. To insure proper performance and full input

capacity, the gas supply line leading to the

heater from the main supply should be of an

adequate size. Check your local plumbing

codes for correct sizing for your installation.

FIGURE 3

FIGURE 4

TESTING FOR LEAKS

WARNING

All gas piping and connections must be tested for

leaks after the installation is completed.

DO NOT use a match or open flame of any kind to

test for leaks. Never operate the heater with leaky

connections.

Failure to follow these warnings could result in prop-

erty damage, bodily injury or death.

1. Disconnect the heater and the manual shut off

valve from the gas supply piping system during

any pressure testing .

2. Isolate the heater from the gas supply piping

system by closing the manual shut off valve

during any pressures equal to or less than 1.2

psig.

3. For Steps 4 and 5, apply a soap solution

to all connections and joints. If bubbles

appear, leaks have been detected and

should be corrected.

4. The supply system should be checked

first with the heater gas valve turned

OFF.

5. After the supply is checked, turn the

heater gas valve ON and check the

heater piping and controls while unit is in

operation.

6. The opening between the pipe and the

wall, or floor, through which the gas

piping is inserted should be sealed by

caulking.

MANIFOLD PRESSURE CHECKING

Be sure to check the manifold pressure with a

water manometer to verify proper operation of the

heater.

A pressure regulator is an integral part of the

automatic valve on all models for both Natural

and LP Gas. This pressure regulator will com-

pensate for minor fluctuations in input pressure,

but is NOT a suitable substitute for the line pres-

sure regulator on a Natural or LP gas line.

1. The manifold pressure can be meas-

ured at the 1/8 inch pipe tap on the

control valve. Pressure measurements

should be taken with a water mano-

meter. (Gauges which measure in

ounces per square inch or pounds per

square inch are not accurate enough to

properly measure or set the pressure).

MANIFOLD PRESSURE

(Inches Water Column)

Natural 5.0

Propane/LP 10.0

2. The line pressure can be measured at

the 1/8 inch pipe tap in the main gas

line. Pressure measurements should

be taken with a water manometer.

LINE PRESSURE

(Inches Water Column)

Min. Max.

Natural 6.0 14.0

Propane/LP 11.0 14.0

Input rate should never exceed that shown on the

rating plate. Orifice changes must be made by a

professional gas heating equipment service per-

son.

Natural Gas models are orificed for 1000 BTU/

CU FT gas. Propane/LP Gas models are orificed

for 2500 BTU/CU FT gas. When the actual heat-

ing value differs, an orifice change may be re-

quired.

IMPORTANT

IMPORTANT

CAUTION

CAUTION

8

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

9

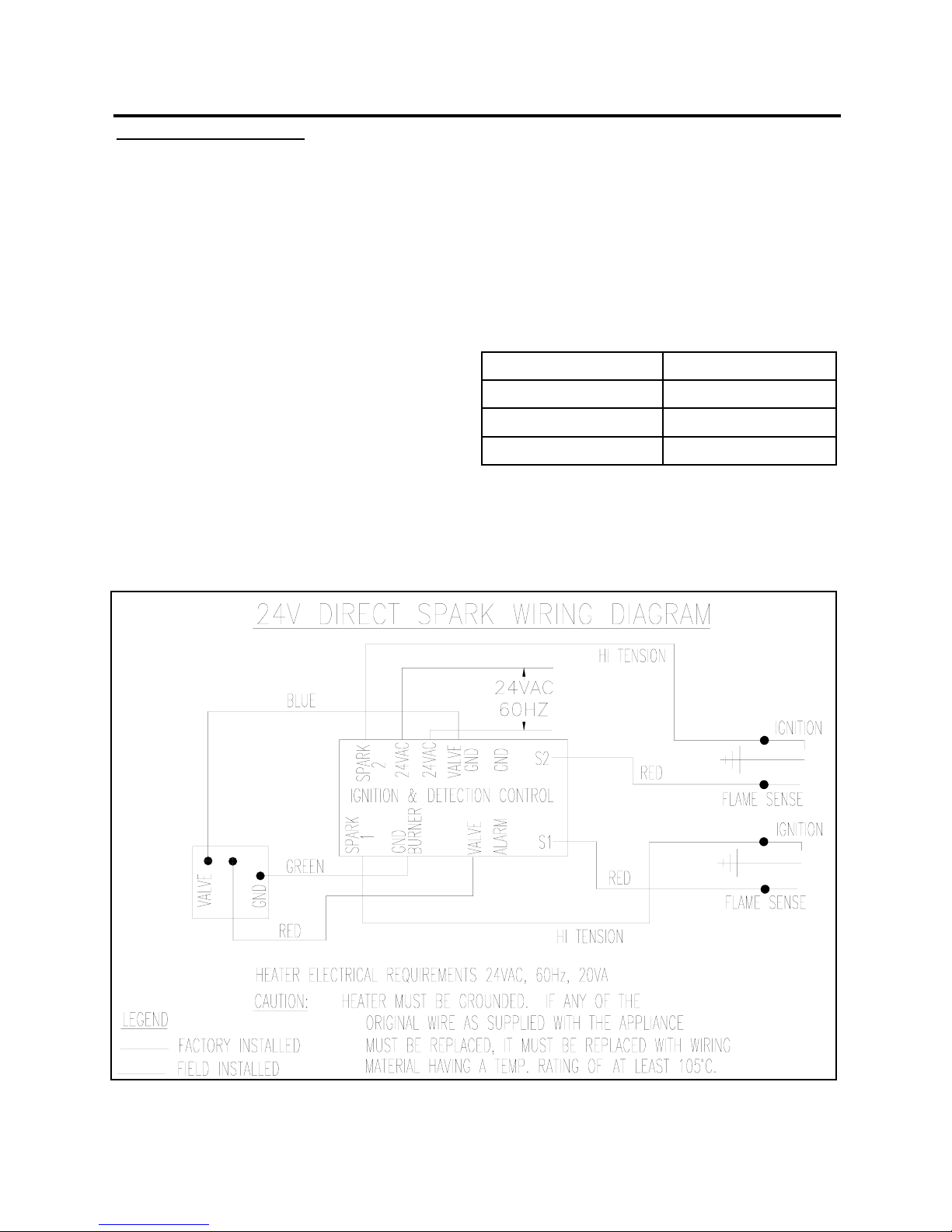

SPARK IGNITION SYSTEM INFORMATION

Sequence of Operation:

1. Supplies power to the electronic pulse-

generator circuit for the spark igniter.

2. Allows up to 21.6 seconds (maximum) for ig-

nition and 1 try before system safety lockout

occurs.

3. Senses burners flame for safe lighting.

4. Shuts off spark after burners are lit.

The control is powered by a 24 VAC transformer

and activated when the temperature control

requests for heat.

When the control is activated by the temperature

control’s request for heat, control performs a

safe-start check that determines proper operation

of the control before beginning the normal se-

quence of operation. Once the Safe Start Check

operation passes, the control turns on the spark

circuit and at the same time, the control opens

the gas control’s main valves, which allows gas to

flow to the main burners.

LED STATUS

OFF IDLE

BLINKING NORMAL

STEADY ON LOCKOUT

WIRING DIAGRAM

10

TROUBLE SHOOTING GUIDE

SERVICE HINTS AND MAINTENANCE CAUSE AND CORRECTIONS

TURN THERMOSTAT TO CALL FOR HEAT

24 VOLTS AT CONTROL TRANSFORMER

24 VOLT AT CONTROL

24 VOLTS OUT CONTROL

24 VOLTS AT GAS CONTROL

SPARK ACROSS IGNITER

OR IGNITER/SENSOR GAP

MAKE SURE THE MANUAL

LEVER ON THE VALVES

ARE OPEN AND THAT

THERE IS GAS GOING TO

THE VALVES.

MAIN BURNERS LIGHT

SPARKS STOPS

WHEN BURNERS

ARE LIT.

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS

CHECK FOR LINE VOLTAGE POWER SUPPLY

CHECK 24V WIRING FROM IGNITION CON-

TROL TO GAS VALVE

PULL IGNITION LEAD AND CHECK SPARK AT

IGNITION STUD.

CAUTION: HIGH VOLTAGE

SPARK OKAY??

CHECK 24V WIRING FROM TRANSFORMER

TO IGNITION CONTROL

REPLACE CONTROL

REPLACE TRANSFORMER

CHECK IGNITION CABLE, GROUND WIRE, CERAMIC INSULA-

TOR AND CAP, AND CORRECT. CHECK BOOT OF THE IGNI-

TION CABLE FOR SIGNS OF MELTING OR BUCKLING. TAKE

PROTECTIVE ACTION TO SHIELD CABLE & BOOT FROM EX-

CESSIVE TEMPERATURES.

CHECK FOR 24 VAC ACROSS VALVES AND VALVES TERMI-

NALS ON CONTROL IF NO VOLTAGE, REPLACE CONTROL.

SPARK IGNITERS MAY BE OUT OF POSITION. CHECK ELEC-

TRICAL CONNECTIONS BETWEEN CONTROL & GAS VALVES IF

OKAY, REPLACE GAS VALVES OPERATOR.

YES NO

YES

NO

YES

YES

YES

YES

NO

YES

NO

NO

NO

NO

NOTE: IF CONTROL GOES INTO LOCKOUT, RESET SYSTEM BY

INTERRUPTING POWER SOURCE.

CHECK CONTINUITY OR SENSOR CABLE AND GROUND WIRE.

CHECK THAT BURNER FLAME COVERS ALL ELECTRODES.

CHECK GROUND CONTINUITY. IF CHECKS ARE OKAY, RE-

PLACE CONTROL MODULE.

NOTE: IF CONTROL GOES INTO LOCKOUT, RESET SYSTEM BY

INTERRUPTING POWER SOURCE.

CHECK CONTINUITY OR SENSOR CABLE AND GROUND WIRE.

NOTE: IF GROUND IS POOR OR ERRATIC, SHUTDOWN MAY

OCCUR OCCASIONALLY EVEN THOUGH OPERATIONS IS NOR-

MAL AT THE TIME OF CHECKOUT.

IF CHECKS ARE OKAY, REPLACE CONTROL MODULE.

YES

YES

NO

YES

NO

CHECK FOR PROPER TEMPERATURE CONTROLLER OPERA-

TION. REMOVE VALVE LEAD AT CONTROL IF VALVE CLOSES,

RECHECK TEMPERATURE CONTROLLER AND WIRING; IF NOT,

REPLACE GAS VALVE OPERATOR.

CALL FOR HEAT ENDS;

SYSTEM SHUTS OFF

YES

TROUBLE SHOOTING ENDS

YES

NO

REPEAT PROCEDURE UNTIL TROUBLE FREE OPERATIONS IS OBTAINED.

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

11

MAINTENANCE

The efficiency of the heater can be impaired if it

gets dirty. If the heaters are installed in areas

where considerable dust is present in the air,

periodic burner cleaning may be necessary. Dust

may be entrained in the primary air supply and

deposited on the back side of the ceramic. This

can be very easily removed by dusting the

ceramic face and the air inlet with a blast of low

pressure air, a maximum of 20 psi. Occasionally

pilots or the burners refuse to function properly

after a summer shutdown. The burner passage-

ways can be cleaned out by using a flexible brush

(bottle brush) It is common for spider webs or

cocoons to be found present in these areas.)

Preventative maintenance is the best policy.

Heaters should be cleaned once a heating

season

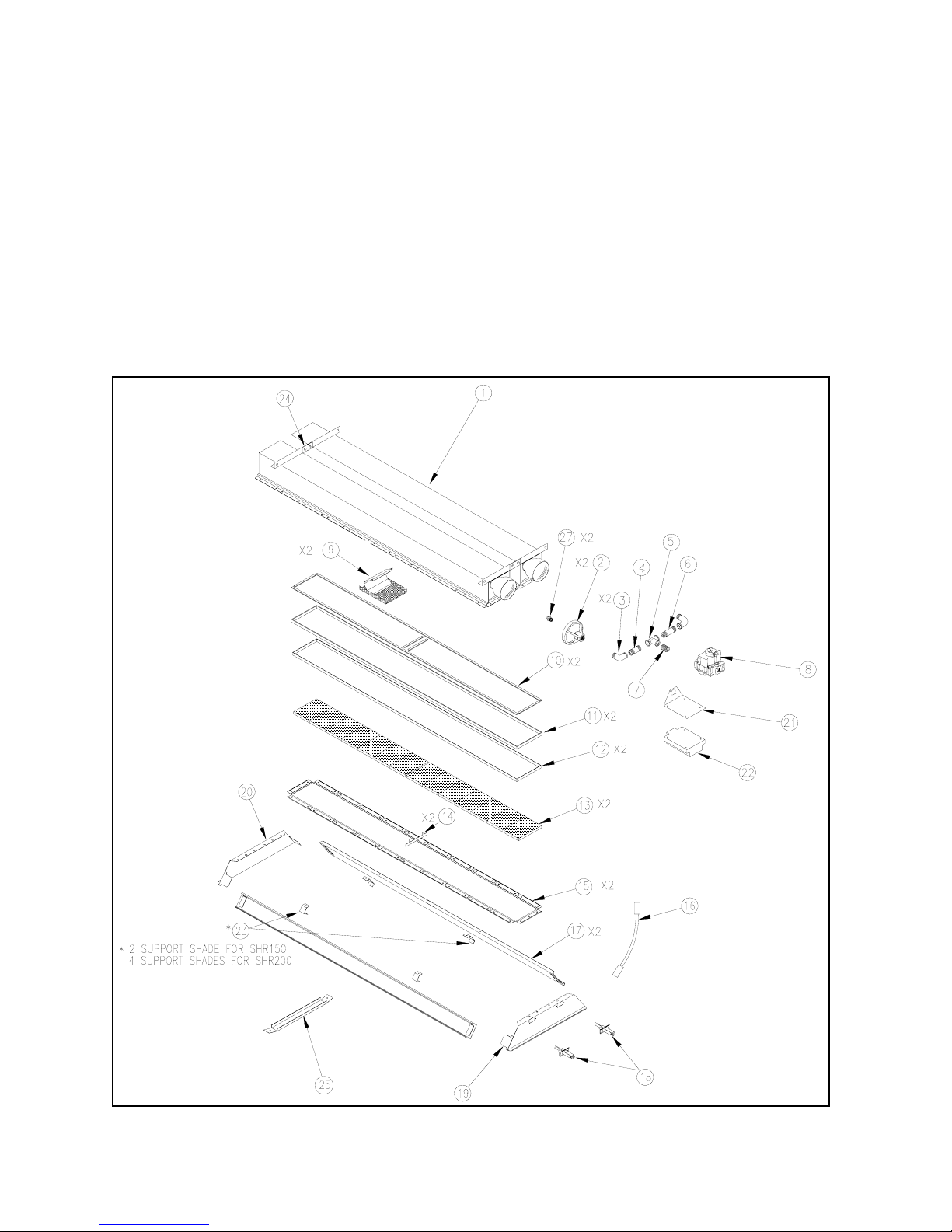

REPLACEMENT PARTS DIAGRAM– Reference next page

REPLACEMENT PARTS LIST Series Reference Page 11

ITEM

NO.

PART NAME

SHR150L

SHR150N

SHR200L

SHR200N

1 Burner Assy. 53573-1 53573-1 53576-1 53576-1

2 Orifice Support 49950-2 49950-2 49950-2 49950-2

3 Street Elbow 13503-G2 13503-G2 13503-G2 13503-G2

4 Nipple 2” 13504-G3 13504-G3 13504-G3 13504-G3

5 Tee 52629-1 52629-1 52629-1 52619-1

6 Nipple 3” 13504-63 13504-63 13504-63 13504-63

7 Nipple 1 1/2” 13504-G2 13504-G2 13504-G2 13504-G2

8 Valve 52387-2 52387-2 52387-2 52387-2

9 Baffle Assy. 49975-G1-1 49975-G1-1 49982-G1-1 49982-G1-1

10 Gasket (Fiberfraux) 51178-G1 51178-G1 51178-G1 51178-G1

11 Gasket (Fiberfraux) 49448-G1 49448-G1 49448-G1 49448-G1

12 Gasket (Fiberfraux) 49929-G1 49929-G1 49229-G1 49229-G1

13 Ceramic Tile 52138-G2 52138-G2 52138-G2 52138-G2

14 Central Tile Divider 51878-G1 51878-G1 51878-G1 51878-G1

15 Tile Retainer 51295-G2 51295-G2 51295-G2 51295-G2

16 High Tension Lead 51045-6 51045-6 51045-6 51045-6

17 Side Shade 51931-G1 51931-G1 51932-G1 51932-G1

18 Electrode 51487-G1 51487-G1 51487-G1 51487-G1

19 End Shade (Electrode) 51879-3 51879-3 51879-3 51879-3

20 End Shade 51927-2 51927-2 51927-2 51927-2

21 Valve & Control Bracket 53266-1 53266-1 53266-1 53266-1

22 Ignition Control 52960-1 52960-1 52960-1 52960-1

23 Support Shade 50576-G2 50576-G2 50576-G2 50576-G2

24 Connector Bracket 53295-1 53295-1 53295-1 53295-1

25 Shade Brace - - 52625-1 52625-1

26 Cap & Spring Convert 51270-G4 - 51270-G4 -

27 Main Burner Orifice See page 13 for replacement part numbers.

12

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

13

ACCESSORY GUIDE

MODEL NO DESCRIPTION ECOSCHWANK36 ECOSCHWANK52

JA276 Transformer X X

ORIFICE REPLACEMENT

MODEL NO NATURAL (N) PROPANE/LIQUID PETROLEUM (LP)

SHR150 46655-G18 (2) (DMS #27) 49955-G5 (2) (DMS #38)

SHR200 49955-40 (2) (DMS #18) 49955-G6 (2) (DMS #32

ALTITUDE ORFICE CONVERSION CHART

MODEL

NO

STAN-

DARD

ORIFICE

(DMS)

FOR USE AT ALTITUDES ABOVE (FEET)

2000 3000 4000 5000 6000 7000 8000

SHR150L #27 #28 #28 #29 #29 #29 #30 #30

PART NO 49955-G18 49955-42 49955-42 49955-G11 49955-G11 49955-G11 49955-G1 49955-G1

SHR150N #38 #39 #40 #41 #41 #42 #42 #43

PART NO 49955-G5 49955-43 49955-44 49955-45 49955-45 49955-G17 49955-G17 49955-G4

SHR200L #18 #19 #19 #20 #21 #22 #23 #24

PART NO 49955-40 49955-G12 49955-G12 49955-G25 49955-46 49955-47 49955-G2 49955-48

SHR200N #32 #33 #34 #35 #35 #36 #36 #37

PART NO 49955-G6 49955-G21 49955-38 49955-49 49955-49 49955-G8 49955-G8 49955-41

14

PROCEDURE FOR SERVICE OR WARRANTY CLAIM

1. Contact the distributor from whom you

purchased the product or a professional gas

heating equipment service person to deter

mine the problem.

2. The Distributor or professional gas heating

equipment service person may replace or

repair the defective part or require that the

part be removed and shipped to the

manufacturer for repair or replacement.

3. All service charges and shipping costs are

the responsibility of the owner.

4. Note to distributors and professional gas

heating equipment service personnel: all

returned parts must be accompanied by a

completed Return Material Tag which is

provided to all distributor.

5. All service and warranty claims must have

the product model and serial number on

the Returned Material Tag.

Under no circumstances should anyone ex-

cept a professional gas heating equipment

service person attempt to remove, repair, or

replace

CUSTOMER’S RECORD

Keep for your records. Record the information concerning your New Sterling Gas-Fired Infra-Red

Heater. The Model Number and Serial Number will be found on the rating plate.

Date of Purchase_______________ Sterling Model No. _________________Serial No.___________

Distributors Name____________________________________________________________________

Address___________________________________________State____________Zip______________

Comments__________________________________________________________________________

__________________________________________________________________________________

ZP-MEC3-BX-01A

SHR 150/200 Manual

RD: MAY, 2004

RL:1

KH

WHAT IS COVERED

Sterling warrants that this product is free from

defects in material or workmanship under normal

use and service subject to the terms of this docu-

ment.

ONE YEAR WARRANTY

Sterling’s sole obligation under this warranty shall

be limited to furnishing replacement parts, for 12

months from date of initial installation of the

heater, but not to exceed 18 months from the

date of shipment by Sterling of the heater, for any

parts which Sterling’s examination shall disclose

to its satisfaction to be defective. Defective parts

are to be returned to Sterling, with transportation

charges prepaid.

ADDITIONAL LIMITED WARRANTY

In addition to the above mentioned First-year

Warranty, Sterling warrants to the original pur-

chaser of a C.S.A. Certified Infra-Red Heater the

following. That at any time during the nine (9)

year period following the expiration of the first-

year Warranty, at the discretion of Sterling will

repair or replace to original or equivalent design,

the Effect-Tile Burner exclusive of control, which

proves to be inoperable due to defects in material

or factory workmanship to the satisfaction of

Sterling. Sterling’s sole obligation under this Ad-

ditional Limited Warranty shall be limited to fur-

nishing Effect Tile Burners only.

WHAT IS NOT COVERED

Sterling will not be responsible for labor charges

for analysis or a defective condition in the heater

or for installation of replacement part. The War-

ranties provided herein will not apply if the input

of the heater exceeds the rated input, as indi-

cated on the name plate, by more than 5%, or if

the heater in the judgment of Sterling has been

subjected to misuse, negligence, accident, con-

taminated and/or corrosive atmospheres, condi

tions which create a contaminated and/or corro

sive atmosphere in the presence of high tem-

perature or open flame, excessive thermal shock,

physical damage, impact, or abrasion, alterna-

tions by unauthorized service, operation contrary

to Sterling’s instructions or if the serial number

has been altered, defaced, or removed. Sterling

shall not be liable for any default or delay in per-

formance by it of these warranties caused by any

contingency beyond its control, including war,

government restrictions or restraints, strikes, fire,

flood, or short or reduced supply of raw material,

or parts. Written permission is required for the

return of any parts of equipment and such return

must be made on the basis of transportation

charges prepaid. Shipments may be refused

unless prior permission is obtained, and returned

prepaid. This Warranty applies only within the 50

United States of America.

LIMITATIONS AND EXCLUSIONS

This document contains all warranties made by

Sterling and may not be varied, altered or ex-

tended by any person. There are no promises,

or agreements extending from Sterling other than

the statements contained herein. THIS WAR-

RANTY IS IN LIEU OF ALL WARRANTIES EX-

PRESS OR IMPLIED, TO THE EXTENT AU-

THORIZED BY THE LAWS OF THE STATE OF

SALE, INCLUDING SPECIFICALLY THE WAR-

RANTIES OF MERCHANTIBILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

It is understood and agreed that Sterling’s

obligation hereunder is limited to repairing or re-

placing parts determined to be defective as

stated above.

In no event shall Sterling be responsible for

any alleged personal injuries or other special inci-

dental or consequential damages.

GAS-FIRED INFRA-RED HEATER LIMITED WARRANTY

Some states do not allow certain warranty exclu-

sions or limitations on how long a warranty lasts

or the exclusions or limitations of incidental or

consequential damages. In such states, the

above limitations or exclusions may not apply to

you and are not intended to do so where prohib-

ited by law. This warranty gives you specific legal

rights. You may also have other rights which vary

from state to state.

STERLING HVAC EQUIPMENT

260 NORTH ELM STREET

WESTFIELD, MA 01085

This manual suits for next models

1

Table of contents

Other Sterling Heater manuals

Popular Heater manuals by other brands

ORIGO

ORIGO FH9401 instruction manual

Caloritech

Caloritech CX Series Installation, operation & maintenance instructions

Modine Manufacturing

Modine Manufacturing HEX5 Series Installation, Parts, Service, and Maintenance Manual

Space-Ray

Space-Ray SSJ30-N2B Installation and operation instructions

Econo Heat

Econo Heat OMNI OWH-500 Installation, operation and service instructions

Zibro

Zibro Kamin R 102 C Operation manual